A 1/8 inch carbide end mill, particularly with a 1/2 inch shank and long reach, offers a robust solution for machining Inconel 718, providing precise cuts and durability against this challenging material. Proper selection and machining parameters are key for success.

Carbide End Mill 1/8 Inch: Your Proven Solution for Machining Inconel 718

Hey there, fellow makers and machinists! Daniel Bates here from Lathe Hub. If you’ve ever tangled with Inconel 718, you know it’s a beast. This superalloy is fantastic for high-temperature applications, but boy, does it make machining difficult. One question I get a lot is about the right tools, especially when you need to get into tight spots or make detailed cuts. That’s where a precisely chosen carbide end mill comes into play, and today, we’re diving deep into the 1/8 inch carbide end mill – specifically, how it becomes your go-to hero for Inconel 718.

Many beginners get intimidated by advanced materials like Inconel. You might be wondering if your milling setup can even handle it, or if you’ll just end up with dull tools and frustration. Don’t sweat it! With the right knowledge and the right tool, you can achieve amazing results. We’ll break down exactly why the 1/8 inch carbide end mill is so effective and guide you through using it like a pro.

We’ll cover everything from selecting the perfect end mill to setting up your machine and handling the actual cutting process. Get ready to turn those machining challenges into triumphs!

Understanding Inconel 718: Why It’s a Machining Challenge

Before we talk about the tool, let’s quickly chat about why Inconel 718 is such a tough nut to crack. Developed for jet engines and aerospace, this nickel-chromium superalloy boasts incredible strength, resistance to high temperatures, and excellent corrosion resistance. These are fantastic properties for its intended use, but they translate to significant machining hurdles.

Here’s what makes Inconel 718 so difficult to machine:

- High Hardness: Even in its annealed state, Inconel 718 is considerably harder than common steels. This means it requires more force to cut.

- Work Hardening: As you machine it, the material you haven’t cut yet at the surface gets harder. This rapid work hardening means tools can dull quickly if not used correctly, and it can lead to tool breakage.

- Low Thermal Conductivity: Inconel doesn’t dissipate heat well. This means heat concentrates at the cutting edge, which can lead to tool wear, melting, and poor surface finish.

- Gummy Texture: It tends to “gum up” on the cutting tool, similar to machining aluminum but with much harder material. This requires specific cutting strategies to manage chip formation and evacuation.

- High Cutting Forces: Due to its strength and work hardening, Inconel 718 generates significant cutting forces. This demands rigid machine setups and sturdy tooling to prevent chatter and inaccuracies.

Facing these challenges might sound daunting, but with the right tool and technique, it’s absolutely manageable. That’s where our star player, the 1/8 inch carbide end mill, steps in.

Why a 1/8 Inch Carbide End Mill is Your Inconel 718 Ace

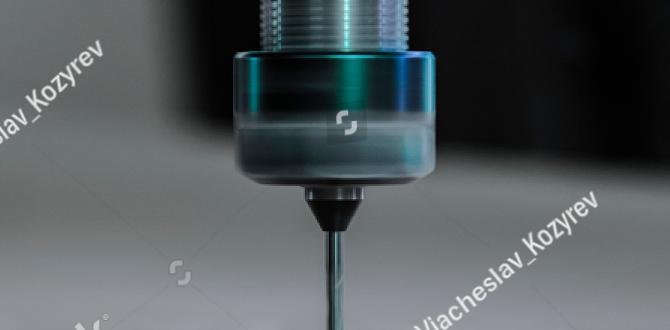

Now, let’s talk about why this specific tool is so well-suited for Inconel 718. When we talk about a “1/8 inch carbide end mill,” we’re referring to its cutting diameter. A small diameter like 1/8 inch has several advantages when dealing with tough materials, especially when combined with the properties of carbide and specific design features like a long reach and a 1/2 inch shank.

The Power of Carbide

Carbide (Tungsten Carbide) is a material incredibly hard and stiff, second only to diamond for hardness. This makes it ideal for cutting hard materials like Inconel 718 because:

- Heat Resistance: Carbide can withstand much higher temperatures than High-Speed Steel (HSS) tools. This is crucial because, as we know, Inconel generates a lot of heat.

- Edge Retention: Its hardness means it holds a sharp edge for longer, even when cutting abrasive and tough materials. This is vital for consistent performance.

- Rigidity: Carbide is very stiff, which helps resist deflection and allows for more precise cuts.

The Advantage of a 1/8 Inch Diameter

Why 1/8 inch specifically? It might seem small, but this size offers:

- Lower Cutting Forces: A smaller diameter tool means less material is being cut at any given moment. This results in lower cutting forces, reducing stress on the tool, the workpiece, and your machine.

- Easier Chip Evacuation: Smaller flutes can sometimes make it easier to manage chips in tough materials, especially when combined with proper speeds and feeds.

- Access to Tight Spaces: For intricate designs, small features, or detailed work within a part, a 1/8 inch end mill is often the only size that will fit.

- Reduced Risk of Breakage: While any small tool can be delicate, a well-supported 1/8 inch end mill is less prone to catastrophic failure than larger, thinner tools if subjected to excessive force.

The Role of a 1/2 Inch Shank and Long Reach

When machining challenging materials like Inconel 718 with small diameter mills, the support and reach are critical. A 1/2 inch shank provides significantly more rigidity and stability compared to smaller shank diameters (like 1/4 inch or 6mm). This increased rigidity is essential for:

- Reducing Chatter: A stiffer tool assembly vibrates less, leading to smoother cuts, better surface finish, and extended tool life.

- Withstanding Cutting Forces: The larger shank can handle higher radial and axial forces without deflecting as much.

- Improved Balance: A larger shank often means better tool balance, especially important at higher spindle speeds.

The “long reach” aspect of the end mill means the cutting flutes extend further down a slender shaft. While this grants access to those deep pockets, it introduces a cantilever effect. Therefore, the rigidity provided by the 1/2 inch shank becomes even more crucial to counteract any potential flexing or vibration associated with the long reach when cutting Inconel. It’s this combination – the hardness of carbide, the precision of a 1/8 inch diameter, the stability of a 1/2 inch shank, and the accessibility of a long reach – that makes this tool a specialized solution for Inconel 718.

Key Features to Look for in Your 1/8 Inch Carbide End Mill for Inconel 718

Not all 1/8 inch carbide end mills are created equal, especially when it comes to tackling a material like Inconel 718. Here are the critical features to prioritize:

1. Number of Flutes

For Inconel 718, you’ll typically want an end mill with fewer flutes. While more flutes can offer a better surface finish in softer materials, they tend to pack chips more readily in gummy materials.

- 2 Flutes: Often the best choice for Inconel. The larger chip gullets (the space between the flutes) allow for better chip evacuation, which is vital for preventing heat build-up and tool clogging. They are also less prone to chatter in materials that demand lower feed rates.

- 3 Flutes: Can be used, but might require more attention to chip evacuation and potentially lower feed rates to avoid chip welding. They can offer a slightly better surface finish than 2-flute tools in some applications.

- 4+ Flutes: Generally not recommended for roughing or heavy milling of Inconel 718, as chip packing becomes a significant issue. They might be suitable for very light finishing passes on specific geometries.

2. Helix Angle

The helix angle affects how the cutting edge engages the material. For tough, gummy materials like Inconel:

- High Helix Angle (30-45 degrees): These tools have a steeper spiral. They provide a shearing cutting action, which can reduce cutting forces and improve chip flow. This is often preferred for Inconel.

- Standard Helix Angle (30 degrees): A good balance.

- Low Helix Angle (e.g., 15 degrees – “Form tools” or “square end mills”): These are generally less suitable for Inconel as they offer a more rubbing action which can exacerbate heat build-up and work hardening.

3. Corner Radius or Chamfer

The very tip of the end mill is critical for strength and chatter resistance.

- Square End: A true square end offers maximum cutting area but is also most susceptible to chipping and cratering in Inconel.

- Corner Radius: A small radius (e.g., 0.010″ to 0.030″ for a 1/8″ end mill) significantly strengthens the corner, reducing the likelihood of chipping and improving tool life. This is highly recommended.

- Corner Chamfer: A light chamfer can also help with strength, but a radius is typically preferred for Inconel.

4. Coating

Coatings add a protective layer to the carbide, enhancing performance, especially in high-temperature environments.

- AlTiN (Aluminum Titanium Nitride) or TiAlN (Titanium Aluminum Nitride): These are excellent choices for Inconel 718. They form a tough, heat-resistant oxide layer at high temperatures, reducing friction and preventing catastrophic tool failure. They are ideal for dry or minimal coolant machining of superalloys.

- ZrAlN (Zirconium Aluminum Nitride): Another very good option, often performing well at higher temperatures than AlTiN.

- Uncoated: Can be used with copious amounts of coolant, but coated tools generally offer superior performance and longevity in Inconel.

5. Material Grade

The specific grade of carbide itself matters. For Inconel, a finer grain size carbide, often referred to as “micro-grain” or “sub-micron grain” carbide, is generally preferred. This provides a better balance of toughness and hardness.

6. “Designed for High Temp Alloys” or “Superalloy” Designation

Many reputable tooling manufacturers offer end mills specifically designed for machining high-temperature alloys, aerospace materials, or Inconel. These tools often incorporate a combination of the features mentioned above and are implicitly engineered for these demanding applications.

Essential Setup: Getting Your Machine Ready

Using the right tool is only half the battle. Proper machine setup is crucial for success when machining Inconel 718 with a 1/8 inch end mill.

1. Machine Rigidity is King

As mentioned, Inconel generates high cutting forces. A wobbly machine or loose components will lead to chatter, poor surface finish, and broken tools. Ensure your machine’s ways are tight, the spindle bearings are good, and any backlash in the axes is minimized or compensated for.

2. Secure Workholding

Your Inconel part needs to be held extremely securely. Use a robust vise, collet chuck, or fixtures. Avoid fixturing methods that can flex or shift under load. Ensure the part is seated firmly and doesn’t move during the cut. For small parts, consider using parallels to raise them slightly for better chip clearance underneath.

3. High-Quality Tool Holder Collets

For a 1/8 inch end mill, you’ll likely be using a 1/2 inch shank. Use a precision collet chuck or a high-quality ER collet system. A worn or runout-prone collet chuck will kill your tool and your finish.

- Runout: Ensure your tool holder and collet combination has minimal runout (ideally less than 0.0005″ or 0.012mm). Even a small amount of runout on a small end mill can cause uneven cutting, leading to breakage.

- Cleanliness: Keep collets and tool holders spotlessly clean. Contamination can lead to poor grip and runout.

4. Coolant/Lubrication – Essential!

Even with coated carbide, effective cooling and lubrication are paramount to managing heat and reducing friction with Inconel 718. If your machine has a flood coolant system, use it. If not:

- MQL (Minimum Quantity Lubrication): This is an excellent option for superalloy machining, delivering a fine mist of lubricant directly to the cutting zone.

- High-Pressure Coolant: If available, high-pressure coolant can help flush chips away from the cutting edge and cool the tool effectively.

- Lubricant Sticks/Pastes: For manual milling or very delicate operations where a full coolant system isn’t feasible, consider specialized milling pastes or sticks designed for high-temperature alloys. These provide localized lubrication.

5. Chip Evacuation Planning

Think about where chips will go. In deep pockets, chips getting re-cut are a major problem. Ensure your tool paths allow for chips to exit the cutting zone. You might need to use peck drilling cycles (ramping or plunging in small increments) to clear chips more effectively. For Inconel, it’s often better to take shallower axial depths of cut and wider radial passes (if possible with the tool size) rather than deep, problematic cuts.

Speeds and Feeds: The Heart of Machining Inconel 718

Getting speeds and feeds right for Inconel 718 and a 1/8 inch end mill is critical. This is where many beginners struggle, often because they use general-purpose recommendations. Inconel requires a more conservative approach.

General Guidelines (Always Adjust based on your specific setup and tool):

For a 1/8 inch (0.125″) 2-flute, AlTiN coated, high-helix carbide end mill on Inconel 718:

- Surface Speed (SFM): Start conservatively. For Inconel 718, this is often in the range of 30-70 SFM (Surface Feet per Minute). Lower end for roughing, higher for finishing with good coolant.

- Spindle Speed (RPM): Calculate from SFM. The formula is: RPM = (SFM 12) / (π Diameter).

- Let’s take the lower end for safety: RPM = (30 SFM 12) / (3.14159 0.125″) ≈ 917 RPM.

- Let’s take a mid-range: RPM = (60 SFM 12) / (3.14159 0.125″) ≈ 1833 RPM.

So, aim for something in the 1000-1800 RPM range as a starting point for roughing.

- Feed per Tooth (IPT): This is the amount of material each flute cuts. For a 1/8″ end mill, this is typically very small. Start around 0.0005″ to 0.001″ IPT.

- Max chip load for this size tool can be up to 0.002″ IPT but it’s very aggressive for Inconel.

- Chip Load (CL) in Inches per Minute (IPM): Calculate: IPM = RPM Flutes IPT.

- Using 1200 RPM, 2 flutes, and 0.0007″ IPT: IPM = 1200 2 0.0007 = 1.68 IPM.

- Using 1500 RPM, 2 flutes, and 0.001″ IPT: IPM = 1500 2 0.001 = 3.0 IPM.

This gives you a very slow, deliberate feed rate. This is normal for Inconel! Don’t expect rapid machining.

- Axial Depth of Cut (DOC): How deep you cut vertically. For Inconel, use shallow depths.

- Roughing: Start with 0.020″ to 0.050″ (0.5mm to 1.27mm). You might be able to push this a bit on very rigid setups, but start conservatively.

- Finishing: 0.005″ to 0.010″ (0.127mm to 0.254mm) for a good surface finish.

- Radial Depth of Cut (Stepover): How much you step over sideways.

- Roughing: For full slotting (creating a slot the

- Roughing: For full slotting (creating a slot the