For extended carbide end mill life in HDPE, choose the right geometry, manage chip load and spindle speed carefully, and ensure proper coolant delivery. This guide shows beginners how to make their bits last much longer when cutting High-Density Polyethylene.

Working with High-Density Polyethylene (HDPE) can be a dream for makers, but it also presents some unique challenges for your tools. One common frustration is seeing your carbide end mills wear out way too quickly. It feels like you just bought a brand-new bit, and already it’s struggling to make a clean cut. This isn’t just annoying; it costs you money and time. But don’t worry, getting a long tool life from your carbide end mills when cutting HDPE is totally achievable. We’ll walk through exactly how to do it, step-by-step, so you can get back to making great projects without constantly replacing your bits.

Understanding HDPE and Why It’s Tricky

High-Density Polyethylene (HDPE) is a fantastic material for many DIY projects. It’s strong, lightweight, resistant to chemicals, and easy to form. You’ll find it used in everything from cutting boards and industrial containers to pipes and even 3D printer filament. However, when it comes to machining, HDPE has a few properties that can really test your cutting tools.

The main issue is its low melting point and tendency to “gum up.” When a cutting tool interacts with plastic like HDPE, friction generates heat. Unlike metal, plastics don’t dissipate heat as effectively. This heat can soften the plastic, causing it to stick to the cutting edges of your end mill. This “chip welding” or “recutting” action doesn’t just make for a messy cut surface; it rapidly dulls the cutting edges and can even cause the material to melt and fuse onto the bit itself. This significantly shortens the usable life of your carbide end mill.

Furthermore, HDPE can be somewhat flexible, which means if your cutting parameters aren’t dialed in, the material can deflect instead of being cleanly cut. This leads to poor tolerances and uneven surfaces, but also puts extra stress on the end mill, potentially chipping or breaking it.

Choosing the Right Carbide End Mill for HDPE

Not all carbide end mills are created equal, especially when tackling plastics. For cutting HDPE, you need to select a tool that’s designed to handle the material’s characteristics. This is where specific geometries and coatings come into play.

End Mill Geometry for Plastics

When cutting HDPE, you want to minimize heat buildup and prevent material from sticking to the cutting edges. There are a few key geometric features to look for:

- High Rake Angle: Tools with a positive or high rake angle are designed to shear the material cleanly rather than scrape it. This creates smaller chips and reduces friction, leading to less heat.

- Polished Flutes: End mills with highly polished flutes are crucial. This smooth surface helps chips slide away from the cutting edge more easily, preventing them from welding onto the tool. Look for end mills specifically advertised as “plastic cutters” or “bright finish.”

- Few Flutes: For plastics like HDPE, fewer flutes are generally better. A 1-flute or 2-flute end mill provides more chip evacuation space. More flute space means chips can get out quickly, which is vital for preventing clogging and heat buildup. While 4-flute tools are common in metals, they can fill up too quickly with plastic chips.

- Sharp Cutting Edges: Naturally, sharp edges are paramount for any cutting operation. For HDPE, extremely sharp, almost razor-like edges are ideal to minimize deformation and heat.

The term “long reach” in your search for a “carbide end mill 1/8 inch 1/2 shank long reach for hdpe long tool life” refers to the length of the cutting flute and the overall length of the end mill. While a long reach can be useful for certain deep cuts, for general HDPE machining, it’s often more important to prioritize the flute geometry and coatings for tool life over extreme reach. If you need to make deep cuts, consider using multiple passes with a shorter, more rigid end mill.

Materials and Coatings

Carbide itself is a great choice for cutting plastics due to its hardness and heat resistance. However, some specific types of carbide can perform even better. Uncoated carbide is often preferred for plastics because coatings can sometimes add friction or heat points if not perfectly suited for the material.

When an uncoated end mill is not an option, look for specific coatings designed to reduce friction. While TiN (Titanium Nitride) coatings are common, they can sometimes increase friction in softer plastics. Coatings like ZrN (Zirconium Nitride) or AlTiN (Aluminum Titanium Nitride) can sometimes offer lower friction and better performance in plastics, though for HDPE, a well-polished, uncoated end mill is often the gold standard.

Optimizing Cutting Parameters for HDPE

Even with the perfect end mill, incorrect cutting parameters are the quickest way to ruin your tool and your workpiece. Finding the sweet spot for spindle speed (RPM) and feed rate is key to long tool life and clean cuts in HDPE.

Spindle Speed (RPM)

This is the speed at which your end mill rotates. For HDPE, a common mistake is running the spindle too fast. While faster RPMs can sometimes help with chip evacuation in metals, in plastics, they generate excessive heat. You want to run the spindle at a lower RPM than you might for metals.

A good starting range for a 1/8 inch carbide end mill in HDPE is typically between 10,000 and 20,000 RPM. However, this can vary significantly based on your specific machine’s capabilities and the actual type of HDPE you’re cutting. It’s always best to start at the lower end of the recommended range and gradually increase it while observing the cut.

Feed Rate

The feed rate is how fast the cutting tool moves through the material. For HDPE, you don’t want to feed too slowly, as this dwell time can lead to excessive heat buildup and melting. Conversely, feeding too fast can cause the tool to “push” the material, leading to deflection, poor finish, and potential tool breakage.

A general rule for plastics is to use a relatively high feed rate to ensure that each pass removes material cleanly and quickly. This helps carry heat away with the chips. Aim for a feed rate that allows for a shallow chip. A good starting point could be anywhere from 15 to 40 inches per minute (IPM) for a 1/8 inch end mill, depending on the depth of cut and spindle speed. Again, observation is key. Listen to the machine and look at the chips being produced.

Chip Load

Chip load is the thickness of the material that each cutting edge of the end mill removes with each revolution. It’s a critical factor directly related to feed rate and spindle speed. The formula for chip load is:

Chip Load = (Feed Rate) / (Spindle Speed Number of Flutes)

For HDPE, you want to aim for a chip load that is substantial enough to clear heat and material efficiently but not so large that it overloads the tool or causes melting. A common target for plastics is a chip load that results in a visible, discrete chip being formed. If the chips are too fine or dusty, you might be feeding too slowly or running too fast. If the chips are large, stringy, or look melted, you might be feeding too fast for the spindle speed, or the spindle speed is too low.

A good target chip load for a 1/8 inch 2-flute end mill in HDPE might be in the range of 0.003 to 0.006 inches per flute. This means that for a 2-flute end mill, your feed rate per tooth would be in that range.

Example Calculation:

Let’s say you’re using a 1/8 inch, 2-flute end mill at 15,000 RPM and you want a chip load of 0.004 inches per flute.

- Feed Rate = Chip Load Spindle Speed Number of Flutes

- Feed Rate = 0.004 inches/flute 15,000 RPM 2 flutes

- Feed Rate = 120 inches per minute (IPM)

This is just a starting point. You’ll likely need to adjust based on how the machine is cutting and the quality of the finish.

Depth of Cut

For plastics like HDPE, shallow depths of cut are generally recommended, especially when starting. This reduces the cutting load on the tool and minimizes the heat generated. Instead of taking a heavy, single pass, it’s far better to take multiple shallow passes.

A good rule of thumb for HDPE is to keep the radial depth of cut (how deep the mill cuts across its diameter) relatively small, and the axial depth of cut (how deep it cuts into the material from the surface) no more than 1-2 times the diameter of the end mill. For a 1/8 inch end mill, this means axial depths of cut of 1/8 to 1/4 inch and radial depths of cut of perhaps 1/16 inch or less for aggressive profiling. For cleaner finishes and longer tool life, even shallower passes are often preferred.

Coolant and Chip Evacuation Strategies

While metals often benefit from flood coolant to cool the tool and flush chips, plastics like HDPE behave differently. Flood coolant can sometimes cause issues with plastics:

- Swelling: Some plastics can absorb water-based coolants, leading to swelling and dimensional changes.

- Chip Clogging: If the coolant doesn’t properly flush the chips, it can mix with softened plastic to create a sticky sludge that gums up the flutes.

For HDPE, the best “coolant” strategy often involves effective chip evacuation and sometimes air blast:

- Air Blast: A directed stream of compressed air can be highly effective at blowing chips away from the cutting zone. This prevents recutting and clears the flutes, significantly reducing heat. Ensure the air blast is aimed correctly to blow chips out of the cut, not back into it.

- Vacuum/Dust Collection: While not a direct coolant, a powerful dust collection system can help remove chips and plastic particles from the work area, reducing the chances of them being re-cut.

- Specialized Plastic Cutting Fluids: Some manufacturers offer cutting fluids specifically designed for plastics. These are often mist coolants or dry lubes that can reduce friction without introducing significant moisture. A light mist of a suitable plastic cutting fluid can help prevent chip welding.

- Peck Drilling (for holes): When drilling holes, using a peck drilling cycle (where the drill retracts periodically) helps clear chips from the hole.

Remember, the primary goal with HDPE is to keep the tool from getting hot and to get the melted plastic (chips) away from the cutting edge as fast as possible. Air blast is often the most practical and effective method for most hobbyist setups.

Machining Techniques for Extended Tool Life

Beyond choosing the right tool and settings, how you approach the machining process itself can make a big difference. Implementing smart machining techniques will go a long way in preserving your carbide end mills.

Climb Milling vs. Conventional Milling

For plastics, climb milling is generally the preferred method. In climb milling, the cutter rotates in the same direction as it moves forward into the material.

- Climb Milling:

- The tool bites into the material with a thinning chip.

- This generates less heat and friction compared to conventional milling.

- It results in a smoother finish and less stress on the cutting edges.

- It is crucial for plastics like HDPE to avoid the cutting edge “dragging” through the material, which causes melting.

- Conventional Milling:

- The tool cuts against the direction of its forward motion.

- This creates a thickening chip and can lead to more heat and friction.

- It’s generally not recommended for soft plastics like HDPE as it can cause increased chip welding and tool wear.

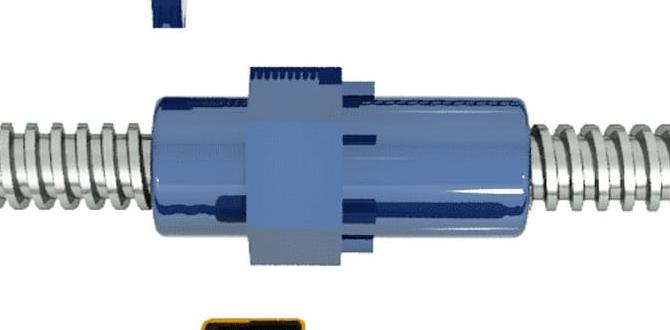

Ensure your CNC machine has minimal backlash (play in the screws and gears) if using climb milling, as excessive backlash can lead to chatter and poor finishes.

Prioritize Shallow Passes

As mentioned earlier, taking multiple shallow passes is far better than one deep pass. For profiling or contouring operations, engage the material radially shallowly (e.g., 1/16″ for a 1/8″ end mill) and the axial depth of the cut can be larger—but still, multiple passes are recommended. For example, if you need to cut 1/2 inch deep:

- Take 2-3 passes with an axial depth of 0.125″ (1/8″).

- Then, take a final finishing pass with a very shallow depth of cut (e.g., 0.010″-0.020″) to get a super clean surface finish.

This strategy reduces the load on the end mill for each pass, lowers heat generation, and significantly improves tool life.

Workholding and Rigidity

A rigid setup is essential for good machining results and tool longevity. Any flexing in the workpiece or the machine will translate to increased stress on the end mill.

- Secure Workholding: Ensure your HDPE is firmly clamped to your machine bed. Avoid relying on makeshift setups. Use clamps, vises, or custom fixtures that provide firm, even pressure.

- Minimize Overhang: Keep the length of the end mill that extends beyond the collet or holder to the absolute minimum necessary. Longer overhangs lead to deflection and vibration, which are detrimental to tool life. A “long reach” end mill should only be used when absolutely necessary for deep pocketing. For general cutting, a shorter, more rigid tool is always better.

- Machine Condition: Ensure your milling machine is in good repair. Worn spindle bearings, loose gibs, or sloppy lead screws can all contribute to chatter and premature tool wear.

Troubleshooting Common Issues

Even with the best practices, you might encounter some common problems. Here’s how to address them:

Melting/Chip Welding onto Bit

This is the most tell-tale sign of excessive heat and poor chip evacuation.

- Action:

- Reduce spindle speed (RPM).

- Increase feed rate (feed faster).

- Use compressed air blast more effectively to clear chips.

- Reduce depth of cut.

- Ensure flutes are polished; try a different brand or type of end mill.

- Consider a mist coolant designed for plastics.

Poor Surface Finish/Fuzzies

This can happen if the cutting edge is dull, the feed rate is too slow, or the material is deforming instead of being cut.

- Action:

- Ensure your end mill is sharp. If not, replace it.

- Increase feed rate.

- Reduce spindle speed.

- Take a finishing pass with a very shallow depth of cut.

- Use a helix angle or spiral type end mill designed for plastics.

Tool Chattering or Vibration

This indicates a lack of rigidity, incorrect cutting parameters causing chip recutting, or a dull tool.

- Action:

- Tighten workholding.

- Reduce depth of cut (both radial and axial).

- Ensure there’s no backlash in your machine’s axis.

- Reduce spindle speed.

- Ensure end mill is sharp and free of built-up edge.

- For deeper cuts, try a more specialized tool like a compression bit or a variable helix end mill if available.

Maintenance and Inspection for Longevity

Treating your end mills well outside of the machining process is just as important as your cutting strategy.

- Rigorous Cleaning: After every machining session, thoroughly clean your end mills. Use an appropriate solvent or cleaner to remove any plastic residue. A brass brush can sometimes help dislodge stubborn bits of plastic.

- Deburring: Occasionally, plastic chips can leave small burrs on the cutting edge. A very careful light deburr with a fine stone or diamond file might* help, but often it’s better to retire the tool if it’s showing signs of damage.

- Proper Storage: Store your end mills in a clean, dry place, ideally in a dedicated bit holder or case. This prevents them from getting damaged or dirty.

- Regular Inspection: Before and after each use, inspect your end mill for signs of wear, chipping, or excessive buildup. Knowing the condition of your tool helps you anticipate issues and makes informed decisions about replacing it before it causes problems.

When to Replace Your End Mill

Knowing when to retire an end mill is crucial for consistent results and to prevent damage to your project or machine. Don’t push a worn-out tool too far.

- Visible Wear: Look closely at the cutting