A 1/8″ carbide end mill is a super versatile tool, especially for wood. It’s perfect for detailed carving, engraving, and creating small, precise cuts on your CNC router or milling machine. Its small size lets you achieve fine details that larger bits can’t, making it a must-have for intricate woodworking projects.

Working with wood can be tricky, especially when you need those super-fine details. Many woodworkers find themselves frustrated by bits that are too large, splintery, or just don’t offer the precision needed for intricate designs. You might be looking at your CNC machine and wondering, “What’s the best tool for these delicate tasks?” A common problem is not having the right bit for tiny engravings or detailed carving. This can lead to wasted time, ruined materials, and a project that just doesn’t look the way you imagined. But don’t worry! The secret to unlocking these fine details lies in a surprisingly small but incredibly powerful tool: the 1/8″ carbide end mill. In this guide, we’ll explore why this little bit is a woodworking genius, how to use it safely and effectively, and the exciting projects you can tackle with it. Get ready to add incredible detail to your creations!

Carbide End Mill: Why Your Wood Projects Need This 1/8″ Wonder

When you’re working with wood, especially on a CNC machine or even a small milling setup, the right tool makes all the difference. For beginners, the world of cutting tools can seem overwhelming. You’ve got your standard router bits, but then there’s the specialized realm of end mills. And within that, the 1/8″ carbide end mill stands out as a true gem for woodworkers. Its small diameter, typically paired with a sturdy shank (though we’ll focus on the 1/8″ cutting edge for now), opens up a world of precision that larger bits simply can’t reach.

Carbide is a key player here. Unlike HSS (High-Speed Steel) bits, carbide is much harder and more heat-resistant. This means it stays sharp longer, cuts cleaner, and can handle denser materials and faster speeds without degrading as quickly. For wood, this translates to crisper lines, less tear-out, and a smoother finish, especially on delicate work.

The Magic of the 1/8″ Diameter

So, why is 1/8″ (which is about 3.175mm) such a sweet spot for wood cutting on smaller machines? It’s all about the detail. Imagine engraving a tiny signature, creating intricate scrollwork, or milling out the fine details on a miniature model. A 1/4″ bit would be far too chunky. That 1/8″ diameter allows for:

- Intricate Engraving: Perfect for text, patterns, and fine artistic details.

- Detailed Carving: Ideal for creating shallow reliefs or complex shapes in smaller projects.

- Small Slotting: Useful for precise slots in puzzles, models, or joinery.

- Sign Making: Essential for creating small, legible lettering.

- Prototyping: Great for detailed mock-ups and small functional parts.

You’ll often see these bits described with a specific shank diameter, like a 1/8″ shank, which is common for handheld routers or very small CNC machines. However, for CNC routers and milling machines, you’re more likely to encounter a 1/8″ cutting diameter on a standard 1/4″ (6.35mm) or even 1/2″ (12.7mm) shank. The “shank” is the part that goes into the collet or holder. For wood, bits with a 1/8″ cutting diameter are incredibly popular, regardless of shank size, because of the precision they offer. You might even find “extra-long” versions designed to reach deeper into material or profiles, though for most beginner woodworking tasks, standard lengths are perfectly adequate.

Let’s talk about something you might see in the product descriptions: the “High MRR” mention. MRR stands for Material Removal Rate. A high MRR means the tool can cut efficiently, removing material quickly and cleanly. For a small bit like a 1/8″ end mill used in wood, this usually refers to bits designed for efficient chip evacuation and a geometry that allows for reasonable feed rates without bogging down. High MRR doesn’t mean you’ll be hogging out huge chunks of wood like with a roughing bit; it means this small bit is optimized to do its detailed job as efficiently as possible.

Choosing Your 1/8″ Carbide End Mill for Wood

Not all 1/8″ end mills are created equal, especially when it comes to wood. Here’s what to look for:

Types of End Mills and What They Mean for Wood

The most common types you’ll encounter for wood CNC routing and milling are:

- Single Flute: These are often the best choice for wood. With only one cutting edge (flute), they excel at clearing chips efficiently, which is crucial in softer materials like wood to prevent clogging and burning. They generally allow for higher feed rates and produce a cleaner cut.

- Two Flute: While more common in metal, two-flute bits can also be used for wood. They offer a slightly better finish than single flute in some cases but can be more prone to chip packing. They are generally slower cutting than single flute in wood.

- Compression Bits: These combine an upcut and a downcut spiral. The downcut portion at the tip compresses the material surface, leading to a clean finish on the top. They are excellent for finishing passes and situations where you absolutely need no chip-out on the top surface. For a 1/8″ bit, they are fantastic for detailed engraving on plywood or veneers.

- O-Flute (Single Flute): This is essentially a specialized single-flute bit, often designed for plastics and wood. They are engineered for excellent chip evacuation and smooth cutting.

Material and Coatings

As mentioned, Solid Carbide is the go-to material for 1/8″ end mills used in woodworking, especially for CNC. It offers superior hardness, rigidity, and heat resistance compared to High-Speed Steel (HSS). Coatings are less common on 1/8″ bits for wood compared to metal machining, as the primary benefits of coatings (like extreme heat resistance or reduced friction in tough materials) aren’t as critical for wood. However, some bits might have basic coatings that can slightly improve chip evacuation or longevity.

Number of Flutes (Cutting Edges)

For wood, especially on a CNC:

- 1 Flute: The most recommended for general woodworking. Excellent chip clearing, good speed, and less prone to burning.

- 2 Flutes: Can offer a slightly smoother finish but requires more careful control of speeds and feeds to avoid chip packing.

- 3+ Flutes: Generally not recommended for most softwoods and hardwoods on standard CNC setups. They are designed for metal and create too much heat and chip packing in wood.

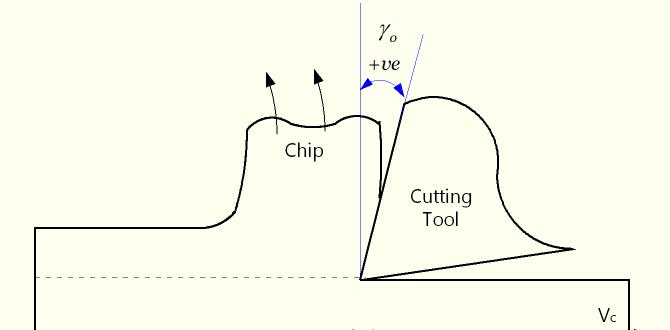

Helix Angle

The helix angle refers to the spiral of the flute. For wood, a steeper helix angle (often 30-45 degrees) is generally preferred. This steep angle helps with chip evacuation and gives a smoother cut. Some bits designed specifically for wood might have particularly aggressive helix angles.

Length and Shank

While the cutting diameter is 1/8″, the shank diameter is important for compatibility with your machine’s collet. Common shank sizes are 1/8″, 1/4″, and 1/2″. If you’re using a small desktop CNC or a handheld router, a 1/8″ shank is common. For larger machines, a 1/4″ or 1/2″ shank provides more rigidity. “Extra-long” bits offer increased reach, which can be helpful for 3D carving or reaching into deep recesses, but they can also be less rigid and more prone to vibration if not supported properly.

Key Specifications to Look For (Example):

When searching for this type of bit, you might see something like:

- Diameter: 1/8″ (3.175mm)

- Shank Diameter: 1/4″ (6.35mm)

- Flutes: 1

- Material: Solid Carbide

- Helix Angle: 30-45°

- Type: Upcut Spiral (or Compression, O-Flute)

- Coating: Uncoated (most common for wood)

Safety First: Handling Your 1/8″ Carbide End Mill

Even though it’s small, an end mill is a precision cutting tool, and safety is paramount. Here’s how to handle yours:

- Wear Safety Glasses: Always. Wood chips, even small ones, can fly unexpectedly.

- Secure Your Workpiece: Ensure your wood is firmly clamped to your worktable or CNC bed. Any movement during cutting can ruin the project and be dangerous.

- Proper Collet Use: Make sure the end mill is seated correctly and fully in the collet. A small bit doesn’t have much to grip onto, so a secure fit is crucial. Don’t overhang the bit more than necessary.

- Machine Stability: If using a handheld router, use a stable base and guide. For CNC, ensure the machine is stable and well-maintained.

- Dust Collection: Wood dust is a hazard. Always use a dust collection system to minimize airborne particles. This also helps keep your cutting area clean for better results.

- Feed and Speed Awareness: Using incorrect speeds and feeds is a major cause of tool breakage and poor finish. We’ll cover this more below.

Getting Started: Setting Up Your 1/8″ Carbide End Mill

Once you have your 1/8″ carbide end mill, the next step is setting it up correctly on your machine. This is a critical stage that influences the quality of your cuts and the longevity of your tool.

Choosing the Right Machine

A 1/8″ carbide end mill is incredibly versatile and can be used on:

- CNC Routers: This is where it truly shines for detailed work, from desktop hobby machines to larger industrial units.

- Milling Machines (Manual or CNC): For more controlled, heavier-duty operations, though a 1/8″ bit is quite delicate for true milling on tough materials. It’s excellent for engraving on a milling machine table.

- Handheld Routers: With appropriate jigs and templates, a 1/8″ bit can be used in a handheld router for detailed freehand work or guided cuts. You’ll need a router with a small collet size (often 1/4″ or 1/8″).

- Drill Presses: With a router motor attachment or a milling attachment.

Installing the End Mill

The process varies slightly depending on your machine, but the core principle is the same:

- Power Off: Always ensure the machine is powered off before changing tools.

- Remove Old Bit: If applicable, use the appropriate wrenches to loosen the collet nut and remove the previous tool.

- Clean the Collet: Lightly clean the collet and the machine’s spindle taper to ensure a good fit and prevent debris from causing runout (wobble).

- Insert the End Mill: Carefully insert the 1/8″ end mill into the collet. Ensure it’s seated properly and not angled. On most machines, you’ll tighten the collet nut with the end mill inserted, giving it a snug fit.

- Tighten Securely: Use the correct wrenches to tighten the collet nut firmly. Avoid over-tightening, which can damage the collet or spindle, but ensure it’s secure enough to prevent slipping. Be mindful of the tool length – you generally want the cutting edge to be as close to the collet as possible for maximum rigidity, and only extend it as far as needed for your cut depth.

Understanding Your Material’s Properties

What type of wood are you cutting? This significantly impacts your settings.

- Softwoods (Pine, Fir): Lighter, easier to cut, but prone to tear-out. Chip clearing is crucial.

- Hardwoods (Oak, Maple, Walnut): Denser, require slightly slower speeds or more power, produce cleaner cuts generally, but can dull bits faster.

- Plywood/MDF: Consistent, but can be abrasive. MDF, in particular, is very abrasive and will dull carbide much faster than natural wood.

- Exotic Woods: Some can be very dense or contain silica, which is extremely abrasive.

The Heart of the Matter: Setting Speeds and Feeds

This is where many beginners struggle. Getting the speed (how fast the spindle spins) and feed rate (how fast the tool moves through the material) right is crucial for a good finish, tool longevity, and avoiding tool breakage. For a 1/8″ carbide end mill in wood, precision is key.

Defining the Terms

- Spindle Speed (RPM): Revolutions Per Minute. Higher RPM generally allows for faster cutting but can generate more heat.

- Feed Rate (IPM/mm/min): Inches Per Minute or Millimeters Per Minute. How fast the tool moves into and through the material.

- Plunge Rate: How fast the tool descends into the material when starting a cut. Should typically be slower than the feed rate.

- Depth of Cut (DOC): How deep each pass removes material.

- Stepover: How much the tool moves sideways between passes when milling an area (e.g., for pocketing or surfacing).

General Guidelines for 1/8″ Carbide in Wood

These are starting points. Always test on scrap material first!

Spindle Speed: Higher speeds generally work well for small bits in wood. A common range is 18,000 – 24,000 RPM.

Feed Rate: This is heavily dependent on the wood type and the bit’s flute count. For a 1-flute bit in hardwood, you might start around 30-50 inches per minute (IPM) or 760-1270 mm/min. For softwood, you might push closer to 50-80 IPM (1270-2032 mm/min). For a 2-flute bit, you’d typically reduce these numbers by about half.

Plunge Rate: Keep this significantly slower than your feed rate to avoid excessive heat build-up and excessive chip load. A good starting point is often 1/3 to 1/2 of your feed rate. So, if your feed rate is 40 IPM, try a plunge rate of 15-20 IPM.

Depth of Cut (DOC): For a 1/8″ bit, you generally want to avoid taking full-depth cuts in a single pass, especially in harder woods. A good rule of thumb is to take shallow passes. For 1/8″ diameter, a DOC of anywhere from 1/16″ (1.5mm) to 1/8″ (3mm) is often suitable for a finished pass. For roughing out material, you might go a bit deeper, but it’s often better to do multiple shallower passes.

Chip Load: Chip load is the thickness of material removed by each cutting edge per revolution. For a 1/8″ 1-flute bit, a chip load of 0.003″ to 0.005″ (0.07mm to 0.13mm) is a good target. You can calculate your feed rate using: Feed Rate = Spindle Speed (RPM) × Number of Flutes × Chip Load. For example: 18,000 RPM × 1 flute × 0.004″ chip load = 72 IPM.

Using a Feeds and Speeds Calculator

Many online calculators can help you determine optimal settings. These are invaluable tools, especially for beginners. Look for calculators that allow you to input:

- Your machine’s capabilities (e.g., max spindle speed)

- The material you are cutting

- The type of end mill (carbide, number of flutes, diameter)

A great resource for general machining data, which can be adapted for wood, is provided by the Niagara Cutter Feeds and Speeds resources. While geared towards metal, understanding the principles and looking for commonalities in their material guides can be a starting point for fine-tuning.

Test Cuts are Essential

Here’s the most important advice: Always test on scrap material!

- Listen to the Cut: A good cut sounds like a smooth, consistent tearing or slicing sound. A high-pitched whine or a ch