Tialn ball nose end mills provide smooth, efficient facing for G10 materials, offering superior surface finish and extended tool life compared to standard end mills. It’s a smart choice for clean G10 machining.

Working with G10 can be a bit tricky, especially when you need a perfectly flat, smooth surface. Many beginners find that standard end mills can chip, leave a rough finish, or wear out quickly. This can be frustrating, leading to wasted material and time. But what if there was a tool designed specifically to handle G10 brilliantly? That’s where the Tialn ball nose end mill shines. We’re going to break down exactly why this tool is a game-changer for facing G10 and how you can use it for fantastic results.

Why G10 is a Unique Machining Challenge

G10 is a popular material in the maker community, known for its strength, electrical insulation, and light weight. It’s essentially a composite made from layers of fiberglass cloth impregnated with epoxy resin. This combination makes it tough and durable, but also abrasive and prone to delamination or chipping when machined incorrectly.

The fiberglass strands act like tiny sandpaper, quickly dulling standard cutting tools. The epoxy resin can also get sticky, causing heat buildup and leading to a poor surface finish. For facing operations, where you’re removing material to create a perfectly flat surface, these issues can become magnified. You often end up with a fuzzy, uneven, or chipped edge.

Enter the Tialn Ball Nose End Mill

So, what makes a Tialn ball nose end mill so special for G10? Let’s break down its key features:

Tialn Coating: This is a Titanium Aluminum Nitride coating. It’s incredibly hard and offers excellent resistance to heat and abrasion. This means the tool stays sharper for longer, even when cutting through tough, abrasive materials like G10. It also helps reduce friction, leading to a cleaner cut and less material buildup on the tool.

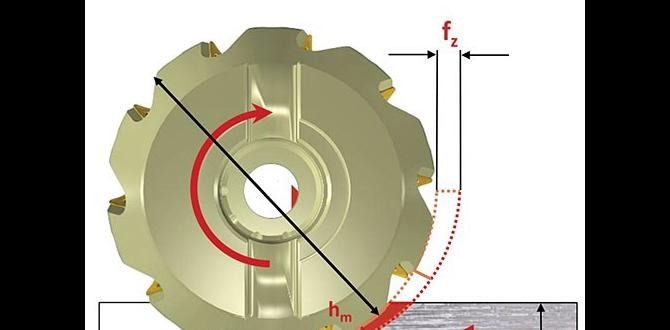

Ball Nose Geometry: Unlike a standard flat-bottomed end mill, a ball nose end mill has a rounded tip. This geometry is fantastic for G10 facing because it distributes the cutting forces more evenly. Instead of a sharp corner digging in and potentially causing chips, the rounded profile allows for a smoother engagement with the material. This leads to a much finer surface finish and significantly reduces the risk of chipping.

Specific Angle (e.g., 40-degree): While there are various ball nose end mills, specific angles like a 40-degree relief angle (often paired with the ball nose) can be highly beneficial for G10. This angle helps clear chips effectively without weakening the cutting edge, again contributing to a cleaner cut and preventing heat buildup.

This combination means your G10 parts will come off the machine with a beautifully smooth, flat finish, and you won’t be constantly replacing dull or broken tools.

Benefits of Using a Tialn Ball Nose End Mill for G10 Facing

Let’s look at the advantages in more detail:

Superior Surface Finish: The gentle, rolling cut of the ball nose, combined with the hardness of the Tialn coating, results in a dramatically smoother surface finish compared to conventional end mills. This is crucial for aesthetic parts or components where flatness and finish are important.

Reduced Chipping and Delamination: The rounded profile of the ball nose end mill minimizes stress concentration at the cutting edge. This directly combats the tendency of G10 to chip or delaminate during machining.

Extended Tool Life: The Tialn coating is incredibly durable and heat-resistant. This means the cutting edge remains sharp for many more parts, saving you money and downtime.

Faster Machining (Potentially): While you still need to respect G10’s properties, the efficiency of this tool can sometimes allow for slightly faster feed rates without sacrificing finish, thanks to its optimized geometry and coating.

Versatility: While fantastic for facing, ball nose end mills are also great for profiling edges, creating rounded slots, and even some 3D contouring.

Key Considerations for G10 Machining

Before we dive into the “how-to,” let’s cover a few essential points to keep your G10 projects running smoothly and safely.

Tooling and Machinery

End Mill Quality: Always opt for high-quality end mills from reputable manufacturers. A good end mill is an investment that pays off in precision and longevity.

Machine Rigidity: A rigid milling machine is vital for any machining task, but especially for composites. A wobbly machine arm or loose spindle can lead to chatter and poor results.

Tool Holder: Use a clean, well-balanced tool holder. A runout in the tool holder can cause uneven cutting and premature tool wear.

Machining Environment

Dust Extraction: G10 dust is abrasive and can be irritating. Always use a robust dust extraction system when machining G10. This protects your lungs and keeps your workshop cleaner. For more information on safety when machining materials, you can consult resources like OSHA’s guidelines for machining operations.

Coolant/Lubrication: While not always mandatory for G10, a light mist of coolant or even compressed air can help manage heat and clear chips, leading to an even better finish and extended tool life. Some machinists find a light flood coolant works well.

Material Handling

Proper Clamping: G10 can be brittle. Ensure your workpiece is securely clamped, but avoid over-tightening, which can cause cracks. Using soft jaws or a good clamping strategy is essential. Ensure your clamps are positioned to avoid interference with the cutting tool during the operation.

How to Face G10 Using a Tialn Ball Nose End Mill: A Step-by-Step Guide

Let’s get down to the practical steps. This guide assumes you have a CNC mill or a manual mill with the ability to control feed and speed accurately.

Step 1: Secure Your G10 Workpiece

Accuracy starts with a stable setup.

1. Clean the Work Surface: Ensure the surface of your milling machine bed or vise jibs are clean and free of debris.

2. Position the G10: Place your G10 material on the milling machine bed or in a vise. Ensure it’s flat and stable.

3. Clamp Securely: Use clamps, T-nuts, or a milling vise to hold the G10 firmly in place. Distribute clamping pressure to avoid deforming or cracking the material. Pay attention to where your clamps are located to ensure they don’t collide with the end mill during the facing operation. For thin G10 sheets, consider using a vacuum hold-down system or backing plates to prevent warping.

Step 2: Set Up Your Tialn Ball Nose End Mill

This is crucial for accuracy and long tool life.

1. Insert the End Mill: Carefully insert the Tialn ball nose end mill into the tool holder and then into the spindle of your milling machine. Ensure it’s seated correctly.

2. Tool Length Measurement: Use a tool setter or a dial indicator to accurately measure the tool length sticking out of the spindle. This is vital for setting your Z-depth correctly. You want the tool to project enough to clear your workpiece but not so much that it becomes unstable. The exact projection will depend on your machine and setup, but generally, for facing, you aim for minimal overhang to maximize rigidity.

Step 3: Define Your Zero and Depth

Precision is key for a perfect facing job.

1. Set X and Y Zero: Touch off your workpiece to establish your X and Y zero point on the milling machine. This is the reference point for your programmed cuts.

2. Set Z Zero (Initial): You’ll typically set your initial Z zero with the tip of the ball nose end mill just touching the highest point of the G10 surface you intend to face. This is important because the ball nose geometry means the effective cutting diameter changes depending on the depth of cut.

3. Determine Facing Depth: Decide how much material you need to remove to achieve a flat surface. This will be your target Z-depth. It’s often best to take multiple shallow passes rather than one deep pass, especially with composites. A depth of cut (DOC) between 0.010″ and 0.050″ (0.25mm to 1.25mm) is a good starting point for G10, depending on the mill’s rigidity and the end mill’s diameter.

Step 4: Milling Parameters (Speeds and Feeds)

Getting these right is critical for a good finish and tool life.

Spindle Speed (RPM): For G10 with a Tialn coated ball nose end mill, a good starting point for spindle speed is typically between 8,000 and 15,000 RPM. The exact speed depends on the diameter of your end mill and your machine’s capabilities. Higher speeds generally help with chip formation and surface finish in composites.

Feed Rate (IPM or mm/min): Feed rate is how fast the tool moves through the material. A starting point for a 1/4″ (6mm) diameter end mill might be around 15-30 IPM (380-760 mm/min). Always aim for a feed rate that allows the end mill to cut cleanly without rubbing or chattering.

Chip Load: Chip load is the thickness of the material being removed by each cutting edge. For G10, you want a relatively small chip load to avoid chipping. A chip load of 0.002″ – 0.005″ (0.05mm – 0.12mm) per tooth is a good range to aim for.

Example Machining Parameters Table

Here’s a table with suggested starting parameters for common ball nose end mill sizes. Always perform test cuts on scrap material!

| End Mill Diameter | Coating | Material | Spindle Speed (RPM) | Feed Rate (IPM) | Depth of Cut (DOC) | Chip Load per Tooth (Est.) | Notes |

|---|---|---|---|---|---|---|---|

| 0.125″ (3mm) | Tialn | G10 | 10,000 – 18,000 | 10 – 20 | 0.010″ – 0.030″ (0.25mm – 0.75mm) | 0.001″ – 0.003″ | Use conservative values first. |

| 0.250″ (6mm) | Tialn | G10 | 8,000 – 15,000 | 15 – 30 | 0.015″ – 0.050″ (0.38mm – 1.25mm) | 0.002″ – 0.005″ | Good general-purpose size. |

| 0.500″ (12mm) | Tialn | G10 | 5,000 – 10,000 | 25 – 50 | 0.020″ – 0.080″ (0.5mm – 2mm) | 0.003″ – 0.007″ | Requires a more rigid machine. |

Note: IPM = Inches Per Minute. For metric, consult a reliable machining calculator.

Important: These are starting points. The best parameters depend on your specific end mill, machine rigidity, coolant, and desired finish. Always do test cuts!

Step 5: Program Your Facing Operation

For CNC users, you’ll program this as a facing operation. Many CAM software packages have specific “Face Milling” toolpaths.

1. Toolpath Strategy: A common strategy is a zig-zag or spiral pattern. For facing, a zig-zag pattern where the tool moves back and forth across the surface, with a slight overlap between passes, is very effective. Ensure the stepover (the distance the tool moves in the Y-axis between passes) is small enough to achieve the desired surface finish. A stepover typically between 40-75% of the tool’s diameter is common for facing.

2. Z-Depth Management: Input your facing depth. You will likely want to program multiple passes. For example, if you need to remove 0.100″, you might program four passes of 0.025″ each, or even shallower if you notice any issues.

3. Ramping/Plunge Moves: When entering the material, consider using a ramp move or a shallow plunge instead of a direct vertical plunge, especially with larger diameter tools. For facing operations, the tool profile often allows for a gentle rise or fall to engage the material.

Step 6: Execute the Facing Cut

Safety first, always!

1. Dry Run: Before cutting into your actual workpiece, perform a “dry run” with the spindle off. Watch the toolpath carefully to ensure there are no collisions with clamps or your fixture. If you have a full CNC, use the “single block” or “step” mode to advance through the program line by line, confirming movement.

2. Initiate Spindle: Turn on your spindle to the programmed RPM.

3. Start the Feed: Begin the feed rate to engage the G10. Listen to the machine. A clean cut will sound consistent. If you hear chattering, grinding, or excessive noise, stop the machine immediately and re-evaluate your speeds, feeds, or depth of cut.

4. Monitor the Cut: Stay attentive throughout the entire operation. Watch for excessive heat, smoke, or chips packing up. If you’re using coolant or air blast, ensure it’s directed effectively at the cutting zone.

5. Multiple Passes: Allow the machine to complete each programmed pass. For a final finishing pass, consider reducing the depth of cut for an even smoother surface.

Step 7: Inspect and Refine

Check your work and learn from it.

1. Clean the Surface: Once the operation is complete, carefully remove the finished part. Clean off any dust.

2. Check for Flatness and Finish: Use a high-quality straight edge or a surface plate to check the flatness of the machined surface. Inspect it visually for any signs of chipping, fuzziness, or unevenness.

3. Adjust if Necessary: If the surface isn’t perfectly flat or has minor imperfections, you may need to take another shallow finishing pass. Based on your inspection, you might adjust the depth of cut, feed rate, or spindle speed for the next attempt.

Alternative Tools and Why They Fall Short for G10 Facing

While you can face G10 with other tools, they often don’t perform as well:

Standard Flat-Bottom End Mills: These can work, but they are prone to chipping the G10, especially at the edges of the cut. They also tend to wear out faster due to the abrasive nature of the material. The sharp corners of a flat end mill concentrate force, leading to delamination.

Carbide End Mills (Non-Coated): Standard carbide is hard but doesn’t have the same heat and abrasion resistance as a Tialn coating. Without the coating, they will still experience faster wear and potentially a poorer finish on G10 compared to a Tialn variant.

Hogging/Roughing End Mills: These are designed for aggressive material removal. While they can quickly remove G10, they will leave a very rough surface finish that would then require significant secondary finishing.

The Tialn ball nose end mill is specifically chosen for G10 facing because it balances hardness, heat resistance, efficient chip evacuation, and a cutting geometry that minimizes the material’s tendency to chip.

Maintaining Your Tialn Ball Nose End Mill

To ensure your tool performs optimally and lasts as long as possible:

Keep it Clean: After each use, clean the end mill thoroughly. Use an ultrasonic cleaner or a specialized tool cleaner to remove any resin buildup or G10 debris.

Inspect for Wear: Regularly inspect the cutting edges under magnification. Look for any signs of chipping, dulling, or excessive wear.

Proper Storage: Store your end mills in a protective case to prevent damage to the cutting edges.

Avoid Overheating: While Tialn is heat-resistant, prolonged overheating can still degrade the coating and dull the edge. Ensure your speeds, feeds, and cooling are appropriate.

Frequently Asked Questions about Tialn Ball Nose End Mills for G10

Here are some common questions beginners have about using these tools.

Frequently Asked Questions

Q1: Is a Tialn ball nose end mill the only tool I can use for G10?

No, but it’s highly recommended for facing operations. Standard end mills can be used, but you’ll likely experience more chipping, a rougher surface finish, and significantly shorter tool life due to G10’s abrasive nature. A Tialn ball nose is designed to overcome these specific challenges.

Q2: What’s the main difference between a ball nose and a flat end mill for G10?

A flat end mill has a sharp corner that can easily dig into G10, causing chips and delamination. A ball nose end mill has a rounded tip that engages the material more gently and gradually, distributing cutting forces. This results in a smoother cut, a better surface finish, and less risk of damaging the G10.