Imagine walking into a workshop filled with the hum of machines. Among them, the 2025 metal lathe stands out. This powerful tool can shape metal with precision. Have you ever wondered how small parts for robots are made?

The 2025 metal lathe does just that. It takes big blocks of metal and transforms them into amazing shapes. These shapes help build everything from toys to high-tech gadgets. Isn’t it cool to think about?

In the world of metalworking, the right tools make all the difference. The 2025 metal lathe is designed for both beginners and experts. It offers new features that help everyone create more—faster and easier. Imagine mastering this incredible machine!

In this article, we’ll explore why the 2025 metal lathe is a favorite among makers. You might just find your next weekend project waiting for you!

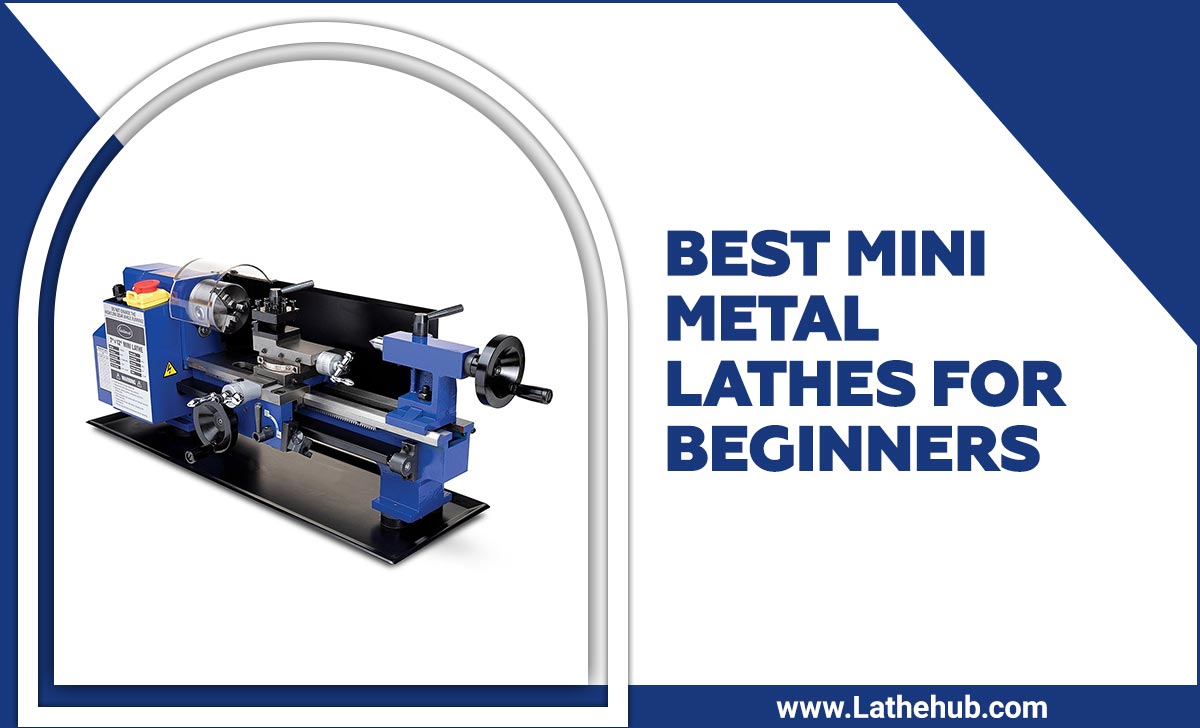

Discover The Best 2025 Metal Lathe For Your Workshop

The 2025 metal lathe stands out for its precision and durability. This tool is perfect for both beginners and experienced machinists. Did you know that lathes can create complex shapes from simple materials? With advancements in technology, the 2025 model is faster and more efficient. Many users report smoother operations and less noise. Whether you’re shaping metal or wood, this lathe can handle it. It’s a great addition to any workshop, enhancing creativity and productivity!

What is a Metal Lathe?

Definition and basic principles of operation. Importance in metalworking and manufacturing.

A machine that spins metal? That’s a metal lathe for you! It shapes materials by cutting away parts. Think of it as a giant pencil sharpener but for metal. These machines are essential in metalworking, helping create everything from simple screws to complex engine parts. About 75% of metal manufacturers use lathes in their work, making them super important. A metal lathe ensures precision and quality, turning raw metal into finished products faster than you can say “turn it up!”

| Function | Importance |

|---|---|

| Shaping metal | High precision in manufacturing |

| Producing parts | Speeding up production |

| Custom projects | Enabling creativity and innovation |

Key Features to Look for in a 2025 Metal Lathe

Size and capacity considerations. Precision and accuracy metrics. Motor power and speed options. Choosing a metal lathe for 2025 can feel overwhelming, like picking the right ice cream flavor—too many choices!

First, think about the size and capacity. Will it fit in your workshop? Next, consider precision and accuracy. You want your projects to turn out just right, not like a lopsided snowman! Finally, look at motor power and speed options. A powerful motor can save time, but be careful not to let it spin too fast unless you enjoy the thrill of making things fly.

| Feature | Considerations |

|---|---|

| Size | Make sure it fits your workspace! |

| Precision | Look for tight tolerances to avoid mistakes. |

| Motor Power | More power means smoother cuts! |

Applications of Metal Lathes in Various Industries

Use in automotive and aerospace industries. Applications in toolmaking and fabrication.

Metal lathes are truly the superheroes of many industries! In the automotive and aerospace sectors, they help shape parts that make cars zoom and planes fly. Imagine a robot working tirelessly to spin and cut metal into precise shapes. That’s a lathe for you! They are also key players in toolmaking and fabrication, allowing craftsmen to create tools with incredible detail. You can think of lathes as the “Mr. Fix-It” of the workshop—always ready to help out!

| Industry | Application |

|---|---|

| Automotive | Shaping engine parts and wheels |

| Aerospace | Creating components for aircraft |

| Toolmaking | Fabricating precision tools |

Innovations and Technology Trends for Metal Lathes in 2025

Advances in CNC technology. Integration of automation and smart features. In 2025, metal lathes will see exciting new changes. Advances in CNC technology will make machines smarter and faster. They’ll be easier to control and use, helping workers do their jobs better. Automation will also play a big role. Many lathes will have smart features that keep them working smoothly on their own. This means less time fixing and more time creating! Here are some upcoming changes:

- Enhanced precision for better projects.

- Improved user interfaces for easy operation.

- Smart sensors that monitor performance.

- Automatic tool changes to save time.

What is CNC technology?

CNC stands for Computer Numerical Control. It helps machines run with high accuracy and speed. This makes metal lathes more efficient and easier to use.

Cost Considerations When Buying a Metal Lathe

Breakdown of pricing factors. Comparison of budget vs. highend options.

Buying a metal lathe can feel like picking out an ice cream flavor—so many options! Prices vary based on size, features, and brand. Generally, you can find budget models starting around $500, while high-end ones can soar to $5,000 or more. It’s like comparing a toy car to a real race car. For a quick comparison, check out the table below:

| Type | Price Range | Features |

|---|---|---|

| Budget | $500 – $1,200 | Basic functions, smaller size |

| Mid-range | $1,200 – $3,000 | More features, larger size |

| High-end | $3,000+ | Advanced features, heavy duty |

Choosing wisely will avoid future headaches. Remember, spending a little more now might save a ton of trouble later. Who likes a metal lathe that breaks on the first day, right?

Maintenance Tips for Longevity of Metal Lathes

Routine maintenance practices. Common issues and troubleshooting. To keep a metal lathe running smooth, follow some easy maintenance tips. First, check the oil levels often. Regularly clean the machine to remove dust and metal shavings. Don’t forget to tighten loose bolts. It helps prevent bigger problems down the road. If you notice strange noises or vibrations, it’s time to troubleshoot. Here’s what you can do:

- Check belts for wear.

- Inspect the motor for issues.

- Clean the feed and cross slides.

A little care goes a long way. It can even make your 2025 metal lathe last years longer!

What are common issues with metal lathes?

Users often face issues like vibrations, poor cuts, and overheating. Regular checks can help spot problems early!

Community Resources and Support for Metal Lathe Users

Online forums and groups. Workshops and training opportunities.

Finding help and info about metal lathes can feel like searching for a needle in a haystack. Luckily, online forums and groups are filled with friendly experts who love to share their tips. Websites like Reddit and Facebook are great places to ask questions or share your metal lathe victories. You might even find workshop invites nearby! Did you know? Many local community colleges offer hands-on training that can turn you into a metal lathe wizard. Here’s a quick table of resources:

| Resource Type | Name | Link |

|---|---|---|

| Online Forum | Reddit – r/metalworking | Visit |

| Training Opportunity | Local Community College | Find Your College |

So, grab your tools and dive into these resources. Learning with others is way more fun, and who knows? You might end up making some great lathe-loving friends!

Conclusion

In 2025, metal lathes will be vital for many projects. They help you shape and create metal parts with precision. As technology improves, these machines become easier to use and more efficient. We encourage you to explore different models and consider your needs. Learn more about metal lathes to enhance your skills and take on exciting new projects!

FAQs

What Advancements In Technology Can We Expect To See In Metal Lathes By 2025?

By 2025, we can expect metal lathes to be smarter. They might use artificial intelligence (AI) to help make better cuts. You could see machines that work faster and use less energy. Some lathes may be able to talk to each other to share information. This means we could make parts more easily and with fewer mistakes!

How Will The Integration Of Automation And Smart Technology In 20Metal Lathes Impact Machining Efficiency?

Using automation and smart technology in metal lathes makes machining faster and easier. These machines can do tasks on their own, which reduces mistakes. We can also watch the machines from a distance and fix problems quickly. This means you can make more parts in less time. Overall, it helps everyone work better and saves money!

What Are The Key Features And Specifications That Buyers Should Look For In A 20Metal Lathe?

When choosing a 20-inch metal lathe, look for a strong motor for good power. Check if it has a digital display to help you see measurements clearly. You should also see if it has easy-to-use controls. It’s important to have enough space on the bed for bigger projects. Finally, make sure it has safety features to keep you safe while working.

How Do Advancements In Materials And Tooling Influence The Capabilities Of Metal Lathes In 2025?

In 2025, stronger and lighter materials help metal lathes work better. We can make parts faster and with more detail. New tools cut metal more easily and stay sharp longer. This means you can create more things in less time. Overall, we can do more cool projects!

What Role Will Sustainability And Energy Efficiency Play In The Design And Operation Of Metal Lathes In 2025?

In 2025, we will focus more on using less energy when making metal lathes. This means they will run smoother and waste less power. Metal lathes will be made with better materials that last longer and are friendly to our planet. By being energy-efficient, they help save money and keep the environment clean. We all benefit when machines work better and use less energy!

Resource:

-

Understanding V-Belts and Flat Belts

URL: https://www.engineersedge.com/motors/v-belts.htm

Use it in your “Types of Belts” section. -

Anchor Text: How to Measure and Replace Power Transmission Belts

URL: https://www.motionindustries.com/blog/how-to-measure-v-belt

Fits well in the “Installation & Replacement” section. -

Anchor Text: Proper Belt Maintenance Tips

URL: https://www.industr.com/en/keeping-drive-belts-in-check-2473910

Add to the “Maintenance Tips” section. -

Anchor Text: Choosing Between Budget and Premium Tools

URL: https://www.makeuseof.com/tag/budget-vs-premium-tools/

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A 20Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a machine that helps us shape metal. It spins metal pieces while tools cut and smooth them. You can use it to make many things like parts for cars or tools. We can adjust the speed and position to get the right shapes. It’s a fun and useful tool for making cool projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer, and I’ll respond in a way that’s easy to understand.”}},{“@type”: “Question”,”name”: “What Advancements In Technology Can We Expect To See In Metal Lathes By 2025?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “By 2025, we can expect metal lathes to be smarter. They might use artificial intelligence (AI) to help make better cuts. You could see machines that work faster and use less energy. Some lathes may be able to talk to each other to share information. This means we could make parts more easily and with fewer mistakes!”}},{“@type”: “Question”,”name”: “How Will The Integration Of Automation And Smart Technology In 20Metal Lathes Impact Machining Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using automation and smart technology in metal lathes makes machining faster and easier. These machines can do tasks on their own, which reduces mistakes. We can also watch the machines from a distance and fix problems quickly. This means you can make more parts in less time. Overall, it helps everyone work better and saves money!”}},{“@type”: “Question”,”name”: “What Are The Key Features And Specifications That Buyers Should Look For In A 20Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a 20-inch metal lathe, look for a strong motor for good power. Check if it has a digital display to help you see measurements clearly. You should also see if it has easy-to-use controls. It’s important to have enough space on the bed for bigger projects. Finally, make sure it has safety features to keep you safe while working.”}},{“@type”: “Question”,”name”: “How Do Advancements In Materials And Tooling Influence The Capabilities Of Metal Lathes In 2025?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In 2025, stronger and lighter materials help metal lathes work better. We can make parts faster and with more detail. New tools cut metal more easily and stay sharp longer. This means you can create more things in less time. Overall, we can do more cool projects!”}},{“@type”: “Question”,”name”: “What Role Will Sustainability And Energy Efficiency Play In The Design And Operation Of Metal Lathes In 2025?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In 2025, we will focus more on using less energy when making metal lathes. This means they will run smoother and waste less power. Metal lathes will be made with better materials that last longer and are friendly to our planet. By being energy-efficient, they help save money and keep the environment clean. We all benefit when machines work better and use less energy!”}}]}