Have you ever wondered how machines shape metal into amazing parts? The 2025 metal lathe drive system is a key tool in this process. It’s like the heart of the machine, helping it work smoothly and precisely. Imagine creating a shiny metal piece from a block. Isn’t that cool?

This drive system does much more than just spin. It controls speed and power, making it easier for craftsmen to create detailed designs. In 2025, this technology has become even better. It’s faster, quieter, and more efficient. With these advancements, anyone can become a talented metalworker.

Did you know that many inventions, from bicycles to airplanes, started with metal lathes? Every year, new changes make them even more important for builders and artists. So, what makes the 2025 metal lathe drive system different? Let’s explore together!

2025 Metal Lathe Drive System: Innovations And Features

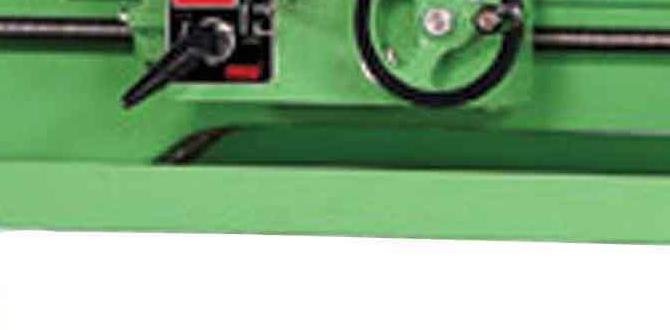

2025 Metal Lathe Drive System

The 2025 metal lathe drive system offers powerful advancements. Imagine turning metals with ease! This modern system uses smarter technology, making it easier for everyone from hobbyists to professionals. The drive system is quieter and more efficient. Have you ever wished for more control while working on a project? This system provides just that! It’s a game changer in metalworking, enhancing precision and reducing errors. Explore how this innovative design can elevate your crafting experience!Understanding Metal Lathe Drive Systems

Definition and components of a metal lathe drive system. Importance of drive systems in precision machining.A metal lathe drive system helps machines work smoothly. This system includes key parts like motors, belts, and pulleys. Together, they control the speed and turning of the metal piece. Precision is vital in machining. It ensures that the shapes produced are exact, which is important for quality products. Without a strong drive system, errors can happen. This can lead to waste and extra costs, which is why understanding these systems is crucial.

What is a metal lathe drive system?

A metal lathe drive system is a set of parts that makes the lathe rotate and cut metal accurately. It uses different elements to achieve smooth movements.

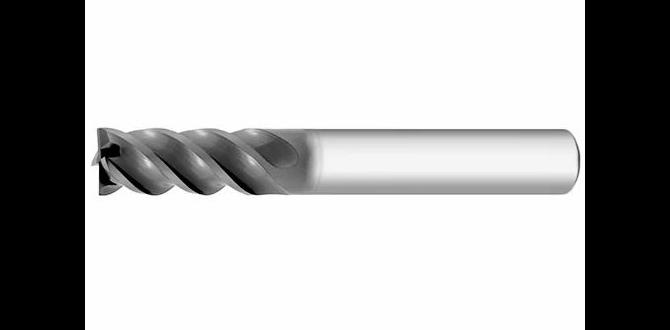

Key components include:

- Motor

- Belt

- Pulleys

- Gears

Why are drive systems important?

Drive systems are essential for precision machining. They ensure that lathes operate correctly. This helps create high-quality parts that fit together perfectly. Without them, machining can be imprecise.

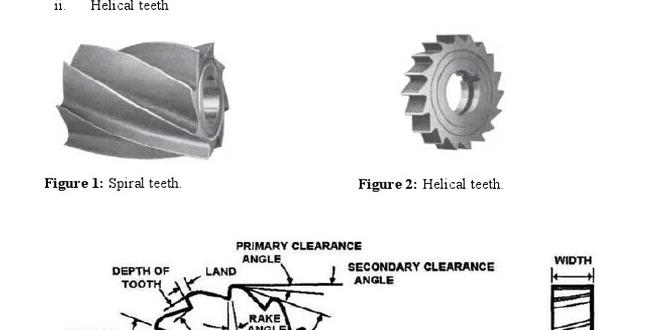

Types of Drive Systems in Metal Lathes

Belt drive systems: advantages and disadvantages. Direct drive systems: efficiency and performance.Metal lathes use different drive systems to spin their magic! One type is the belt drive system. It’s like a car engine, using belts to transfer power. The advantages are smooth operation and easy repairs. However, belts can wear out and need replacements. Then there’s the direct drive system. This is more like a superhero—quick and powerful! It enhances efficiency and overall performance, but it can be pricier to set up. Let’s look at their differences in the table below:

| Drive System | Advantages | Disadvantages |

|---|---|---|

| Belt Drive | Smooth operation, easy to repair | Belts may wear out |

| Direct Drive | High efficiency and performance | Higher setup costs |

Benefits of Upgrading to a 2025 Metal Lathe Drive System

Improved accuracy and reliability. Enhanced operational speed and efficiency.Upgrading to the latest drive system can bring many rewards. First, you gain improved accuracy. This means your projects turn out just right every time. You will also enjoy enhanced operational speed. This makes tasks quicker and helps you finish jobs faster. With a better system, you can trust that your work is done right and done well.

What are the main benefits of a newer drive system?

Two main benefits stand out:

- Higher Precision: Projects will be more accurate, reducing mistakes.

- Faster Work: Work gets done more quickly, saving time.

Installation and Maintenance of 2025 Metal Lathe Drive Systems

Stepbystep guide to installation. Routine maintenance tips for longevity and performance.To install the 2025 metal lathe drive system, follow these simple steps. Begin by placing the lathe on a stable surface. Next, connect the motor to the drive system as shown in the manual. Secure all screws tightly. Finally, check the wiring to ensure everything is safe and secure.

For routine maintenance, remember these tips:

- Regularly clean the lathe to remove dust and debris.

- Check belts and gears for wear.

- Lubricate moving parts every few months.

This will help keep your machine running smoothly and lasting longer.

What are some common maintenance practices for a metal lathe?

To maintain a metal lathe, inspect parts regularly, clean the machine often, and keep it lubricated.

By following these steps, you can enjoy your 2025 metal lathe for years to come!

Cost Analysis of 2025 Metal Lathe Drive Systems

Initial investment vs. longterm savings. Factors influencing pricing.Buying a 2025 metal lathe drive system costs money upfront, but it can save you cash over time. Think about these points:

- Initial Investment: Prices can vary based on features.

- Long-term Savings: Better efficiency reduces energy bills.

- Quality of Parts: Cheaper materials might break sooner.

Smart buying means looking at costs now and savings later. Investing in quality can pay off. Wise choices help in the long run!

What affects the cost of a metal lathe drive system?

The cost of a metal lathe drive system depends on several key factors. Major influences include brand reputation, features, and quality of materials. Cheaper parts may save today but cost more later due to repairs. Always compare before you buy!

Real-world Applications of 2025 Metal Lathe Drive Systems

Industries benefiting from modern metal lathe technology. Case studies showcasing successful implementations.Many industries use modern metal lathe drive systems. They improve how products are made. Here are a few examples:

- Automotive: Car makers use lathes to create precise parts.

- Aerospace: Plane builders need strong, light components.

- Manufacturing: Factories rely on lathes for various tasks.

- Tool-making: Sharp tools come from highly accurate machines.

One case study shows a small factory increased product quality by 30% after upgrading its lathe system. This highlights how important modern technology is for success.

What are the benefits of using a metal lathe drive system?

Using a metal lathe drive system improves accuracy, efficiency, and reduces waste. This means businesses can save time and money while making better products.

Future Trends in Metal Lathe Drive Systems

Predictions for technological advancements post2025. The role of automation and AI in future drive systems.In the coming years, metal lathe drive systems will likely see significant changes. We can expect developments that will make them faster and smarter. Tools will use more automation and AI to enhance performance. This will help machines work better and safer. Imagine a lathe that adjusts itself for perfect cuts! Here are some trends to watch:

- More use of sensors for real-time monitoring.

- AI to predict maintenance needs.

- Greater energy efficiency for lower costs.

These advancements could make manufacturing more efficient and less labor-intensive.

What will drive systems look like after 2025?

Future drive systems will be more automated, integrating AI for smart adjustments and predictive maintenance.

Conclusion

In 2025, metal lathe drive systems will be key for better performance and precision. They will use advanced technology to be more efficient and user-friendly. You can explore different models and features to find the best fit for your needs. Learning about these systems will help you make smart choices in your projects. Keep researching to see what’s new!FAQs

Here Are Five Related Questions On The Topic Of A 20Metal Lathe Drive System:Sure! A 20 metal lathe drive system helps machines spin metal pieces. This lets us shape the metal into different forms. The drive system uses motors to make everything work smoothly. It’s important for making precise and cool metal parts. Using this system, you can create things like tools and toys!

Sure! Please give me the question you want me to answer, and I’ll do my best to help you.

What Advancements In Technology Are Expected To Be Incorporated Into The Drive Systems Of Metal Lathes In 2025?In 2025, metal lathes will use better motors that can spin faster and smoother. They will also have smart systems that can tell us when to fix something. You’ll see more buttons and screens that make it easy to use. Plus, some lathes will connect to the internet to help us control them from far away. These changes will make metal lathes work better and help us make things more easily.

How Will The Integration Of Smart Technologies And Iot Impact The Efficiency Of Metal Lathe Drive Systems By 2025?By 2025, smart technologies and the Internet of Things (IoT) will make metal lathe drive systems work better. These smart tools will help us watch and control machines from anywhere. This means we can fix problems faster and save energy. Overall, metal lathes will be quicker and more reliable, helping everyone do more work with less effort. We will make things easier and smarter!

What Materials And Design Innovations Are Anticipated To Enhance The Performance And Durability Of Drive Systems In Metal Lathes?We expect new materials like stronger metals and lighter plastics to help metal lathes last longer. Better designs will make parts fit together tighter, reducing wear and tear. Improved motors can work faster and use less energy. These changes will make lathes easier for you to use and keep running well for a long time.

How Will The Use Of Automation And Robotics Affect The Operation And Functionality Of Drive Systems In Metal Lathes In 2025?In 2025, automation and robotics will make metal lathes work faster and better. You will see machines that can do tasks on their own. This means fewer mistakes and more precise cuts. We might not need as many people to watch over them, so we can focus on other important jobs. Overall, it will help make metalworking easier and more efficient.

What Are The Expected Trends In Energy Efficiency And Sustainability For Metal Lathe Drive Systems By 2025?By 2025, we can expect metal lathe drive systems to use less energy. This means machines will run more efficiently. We will see more use of eco-friendly materials, making them better for the Earth. New technology will help reduce waste and energy use. Overall, metal lathes will become greener and save more power!