Imagine working on a project where every precise cut matters. Have you ever thought about how important the parts of a metal lathe are in achieving that perfect finish? The 2025 metal lathe lead screw plays a key role in this process.

The lead screw helps move the cutting tool smoothly. This can make your work easier and more accurate. Did you know that a well-functioning lead screw can save you time and reduce mistakes?

In this article, we will explore the features of the 2025 metal lathe lead screw. We will also discuss why it’s crucial for every metalworker. Whether you are a beginner or a pro, knowing more about this part can help you improve your skills.

Are you ready to dive into the world of metal lathes? Let’s get started and learn how the 2025 model can change your projects!

Exploring The 2025 Metal Lathe Lead Screw Innovations

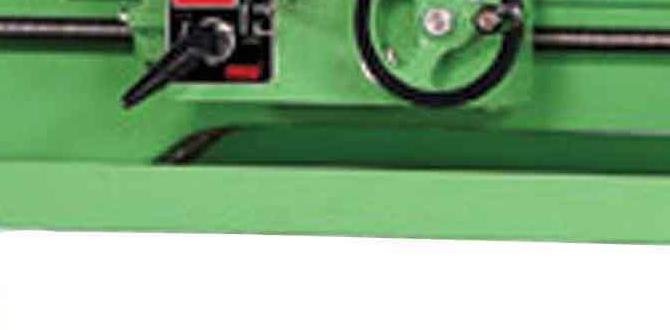

2025 Metal Lathe Lead Screw

The 2025 metal lathe lead screw is essential for precise machining. It helps move the lathe tool along the workpiece smoothly. Did you know that a well-maintained lead screw can improve your workflow significantly? Smooth operation means better quality cuts. Users can also find various materials for lead screws, which impacts durability. Whether you are a hobbyist or a pro, understanding lead screws is key. A small upgrade may lead to big results in your project!What is a Metal Lathe Lead Screw?

Definition and function of a lead screw in metal lathes. Importance of lead screws in precision machining.A lead screw is a crucial part of a metal lathe. It helps move the cutting tool smoothly along the metal as it spins. This movement ensures that cuts are precise and accurate. Without a lead screw, machining would be much harder.

Importance of lead screws:

- They enhance precision machining by allowing accurate tool movement.

- They improve the quality of the finished product.

- They reduce wear and tear on the machine.

In short, lead screws make metal lathes work better, leading to better projects!

What are the benefits of using a lead screw in metal lathes?

The benefits include increased accuracy and smoother motion. They also help in reducing machine wear and improve overall efficiency.

Benefits of Upgrading to a 2025 Lead Screw

Enhanced accuracy and efficiency in machining processes. Improved durability and lifespan compared to earlier models.Upgrading to a new lead screw brings many benefits to your machining work. Firstly, it helps with enhanced accuracy and better efficiency. This means your machines can cut and shape materials more precisely. Secondly, the 2025 lead screw is more durable and lasts longer compared to older models. With this upgrade, you can spend less time on repairs and more time on making great things. It’s a smart choice for anyone serious about their projects!

What makes the 2025 lead screw a better choice?

Upgrading to the 2025 lead screw leads to better results in your work. It offers improved accuracy and a longer lifespan. You will notice the difference right away!

Key Benefits:

- Increased accuracy in cutting

- Improved efficiency in machining

- Long-lasting durability over time

How to Choose the Right 2025 Metal Lathe Lead Screw

Factors to consider: size, material, and thread type. Compatibility with existing lathes and setups.Picking the perfect 2025 metal lathe lead screw is like choosing the right pizza topping—size, material, and thread type matter! First, check the size. Too big? It won’t fit. Too small? Well, that’s awkward. Next up, look at the material. Metal screws last longer than spaghetti during dinner! Lastly, consider the thread type. It should match your lathe for a smooth operation, like a dance. Don’t forget to ensure compatibility with your setup, or it’ll groove to a different beat!

| Factor | Considerations |

|---|---|

| Size | Must fit your lathe size correctly. |

| Material | Durable metals are preferred over softer materials. |

| Thread Type | Choose the same type as your existing screw. |

Installation Guide for the 2025 Lead Screw

Stepbystep instructions for installing the lead screw. Common pitfalls and how to avoid them during installation.Installing the lead screw can be simple if you follow some steps. Here’s how to do it:

- Gather your tools: screwdriver, wrench, and the lead screw.

- Make sure the lathe is powered off.

- Remove the old lead screw carefully.

- Align the new lead screw with the slots.

- Tighten the screws gently to secure it.

Be careful not to over-tighten. This can break the screws. Also, avoid bending the lead screw, which can cause problems later.

What are common mistakes during installation?

Some common mistakes are:

- Forgetting to power off the lathe.

- Not aligning the lead screw correctly.

- Using the wrong tools, which can cause damage.

Read the manual for your specific model for better results.

Maintenance Tips for Longevity of Your 2025 Lead Screw

Routine maintenance practices to ensure optimal performance. Signs of wear and when to consider replacement.Taking care of your lead screw can help it last longer and work better. Regular checks and some simple cleaning can go a long way. Look for signs like strange noises or unwanted play in the movement. If it feels loose or sticky, it might be time for a replacement. Here’s a quick table to help you:

| Maintenance Task | Frequency | Signs of Wear |

|---|---|---|

| Clean the lead screw | Every month | Dust and grease build-up |

| Lubricate moving parts | Every few months | Difficulty in movement |

| Inspect for wear | Every six months | Unusual noise or play |

By remembering these tips, you can keep your lead screw happy and healthy. After all, a well-maintained lead screw is like a good friend—always there for you!

Comparative Analysis: 2025 Lead Screw vs. Other Models

Key differences between the 2025 and other popular lead screw models. Performance benchmarks and user reviews for informed decisionmaking.Comparing the 2025 lead screw with other models reveals some key differences. The 2025 is known for its smooth operation and precise control. It has less backlash, making it a top choice for detailed projects. Other models may not perform as well in these areas. User reviews show that many prefer the 2025 for its reliability. When making a choice, consider performance and satisfaction from others.

What are the key differences between the 2025 lead screw and other models?

The 2025 lead screw has better accuracy and less backlash compared to many other models. This makes it ideal for fine machining tasks.

Performance Benchmarks:

- 2025 Lead Screw: Smooth performance with minimal vibrations.

- Other Models: More vibrations and less precise control.

- User Satisfaction: Higher ratings for the 2025 in reviews.

Real-World Applications of the 2025 Metal Lathe Lead Screw

Industries that benefit most from using the 2025 lead screw. Specific applications and projects showcasing the lead screw’s capabilities.The 2025 metal lathe lead screw is important in many industries. It helps machines make precise parts. Many companies use it for different projects. Here are a few areas where it is especially useful:

- Aerospace: This industry designs parts for airplanes.

- Automotive: Car makers create engines and features.

- Medical: It makes devices like surgical tools.

- Manufacturing: Factories use it to produce everyday items.

For example, the aerospace industry relies on the 2025 lead screw for accurate part creation. This leads to safer airplanes. It shows how this part is key in making high-quality products.

Where is the 2025 metal lathe lead screw commonly used?

The lead screw is commonly used in manufacturing, automotive, aircraft, and medical equipment industries. These areas benefit greatly from its precision and reliability.

Cost Considerations When Investing in a 2025 Lead Screw

Price range and factors affecting the cost of lead screws. Cost vs. performance: understanding the value proposition.Buying a lead screw is like choosing an ice cream flavor. It can be sweet, but sometimes it’s a bit pricey! The cost of a 2025 metal lathe lead screw usually sits between $50 and $300. This price depends on materials, brand, and quality. Remember, expensive isn’t always better. A cheaper screw can perform just as well. Think of it this way: is it really worth it to spend more on something that doesn’t do much extra? Performance matters, but so does your wallet!

| Cost Factors | Impact on Price |

|---|---|

| Material Quality | Higher durability and strength |

| Brand Reputation | Trustworthy brands charge more |

| Size and Specifications | More complex designs cost more |

In the end, do your homework! A good deal is not just about the lowest price; it’s about finding the best value for your needs.

Frequently Asked Questions about 2025 Metal Lathe Lead Screws

Common queries and clarifications for potential users. Expert answers to help users make informed purchasing decisions.Many people have questions about lead screws for metal lathes. Here are some common concerns:

What is a lead screw?

A lead screw is a key part of a metal lathe. It helps move the cutting tool smoothly. Choosing the right lead screw makes machining easier and more precise.

How long do lead screws last?

With proper care, a lead screw can last for many years. Regular cleaning and lubrication can help maintain its performance.

What sizes are available?

- Lead screws come in different lengths and diameters.

- The size depends on the lathe model you have.

How do I know if it fits my lathe?

Check the specifications of your lathe. Match the measurements of the lead screw to ensure it fits properly.

Conclusion

In summary, the 2025 metal lathe lead screw is essential for precision in machining. It helps you make accurate cuts and shapes in metal. Understanding its features can improve your projects. We recommend exploring more resources or watching tutorials to see it in action. Start experimenting and discover how this tool can elevate your crafts to the next level!FAQs

Sure! Here Are Five Related Questions On The Topic Of The 20Metal Lathe Lead Screw:Sure! A lead screw is an important part of a metal lathe. It helps move the cutting tool. When you turn the lead screw, it moves smoothly. This makes it easier to shape and cut metal. Knowing how it works is fun and helpful for making cool projects!

Sure! Please provide the question you would like me to answer.

What Are The Specifications And Features Of The Lead Screw Used In The 20Metal Lathe Model?The lead screw in the 20 metal lathe helps move the tools and metal pieces. It’s usually made of tough steel for strength. This screw is often about 1 inch thick and long enough to fit the machine. You can easily turn it to adjust the tool’s position. This makes it important for making precise cuts when we work with metal.

How Does The Lead Screw Mechanism Impact The Precision And Accuracy Of The Machining Process In The 20Metal Lathe?The lead screw is like a special screw that helps move parts of the lathe. It makes sure the cutting tool moves exactly where it needs to go. This helps us make very precise parts. If the lead screw works well, we get more accurate shapes and sizes in our projects. So, it is important for good machining!

What Are Common Maintenance Practices To Ensure The Longevity And Smooth Operation Of The Lead Screw In A 20Metal Lathe?To keep the lead screw on a 20-inch metal lathe working well, you should clean it often. Use a soft cloth to wipe off dirt and old grease. You also need to add fresh grease to keep it moving smoothly. Check for any signs of wear, like scratches or dents. If you see them, it might be time to fix or replace parts.

Are There Recommended Upgrades Or Modifications Available For The Lead Screw Of The 20Metal Lathe To Enhance Performance?Yes, there are upgrades for the lead screw of the 20 metal lathe. You can replace it with a better quality lead screw for smoother operation. Adding a lubricant can also help it move more easily. You might consider a stronger motor for faster speeds. These changes can make your lathe work better and last longer.

How Does The Lead Screw Design Of The 20Metal Lathe Compare To That Of Other Metal Lathes In Terms Of Durability And Ease Of Use?The lead screw on a 20 metal lathe is made to be strong and last a long time. It helps you move the tool smoothly while you work. Compared to other lathes, this design is easier to use, making it better for beginners. You won’t have to worry about it breaking easily, which is good for your projects!