2025 Metal Lathe Taper Turning: Techniques And Tips

2025 Metal Lathe Taper Turning

Metal lathes are essential tools for shaping metal pieces. In 2025, taper turning will become easier with advanced technology. Want to make precise angles? New features allow you to adjust settings quickly. Imagine crafting beautifully tapered parts with ease! This method enhances the quality of your projects. Did you know that taper turning can improve the fit of machine parts? It’s a game-changer for hobbyists and professionals alike. Enjoy exploring the exciting world of taper turning with your metal lathe!Understanding Taper Turning and Its Importance

Definition of taper turning. Applications in various industries.Taper turning means shaping a piece of metal to form a pointy end, like a pencil! It’s done with a metal lathe. This method pops up in many industries. For example, machinists use it to create parts for tools and machines.

| Industry | Application |

|---|---|

| Automotive | Making axles |

| Aerospace | Producing fittings |

| Construction | Creating supports |

So, taper turning not only looks cool, but it also keeps the world running smoothly!

Types of Tapers in Metalworking

Explanation of common taper types (external, internal, etc.). Comparison of different taper angles.When it comes to metalworking, tapers can be as different as pizza toppings! There are two main types: external tapers and internal tapers. External tapers are like ice cream cones, getting wider as they go up. Internal tapers, on the other hand, are like a secret passage, narrowing inside a hole. Taper angles also matter; a small angle is like a gentle slope, while a big one is a steep hill! Below is a fun summary of common tapers and their angles:

| Taper Type | Description | Angle |

|---|---|---|

| External Taper | Wider at the top | 5° to 10° |

| Internal Taper | Narrower at the top | 1° to 5° |

Understanding these differences can help every metalworker find the right cut—kind of like picking the best slice of pizza! So, next time you’re lathe turning, keep an eye on those tapers!

Step-by-Step Guide to Taper Turning on a Metal Lathe

Preparation of the workpiece and lathe. Detailed process of taper turning.Before starting taper turning, prepare your metal lathe and workpiece. First, make sure the lathe is clean and set up properly. Check the tool bits for sharpness. Then, secure your workpiece in the lathe chuck tightly. This step is key for safety and precision.

Next, follow these steps for taper turning:

- Adjust the tailstock to the desired angle.

- Set the spindle speed to a suitable level.

- Start the lathe and gently guide the tool along the workpiece.

- Check your progress and make adjustments as needed.

This careful process ensures a smooth taper cut. Remember to always wear safety gear when working!

What is taper turning on a metal lathe?

Taper turning is the process of creating a gradual change in the diameter of metal, forming a cone shape. This is useful for parts needing a good fit in machines.

Common Challenges in Taper Turning and Solutions

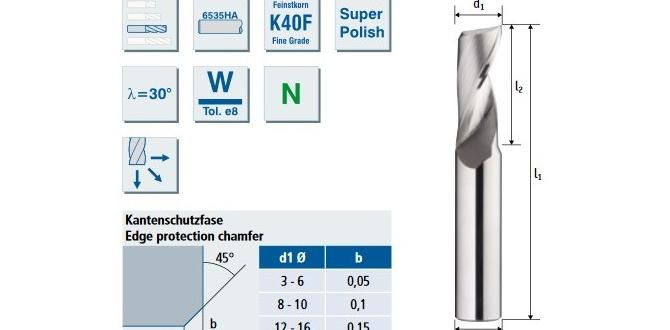

Identifying frequent issues encountered. Tips for troubleshooting and avoiding mistakes.Taper turning can be tricky. Common problems include uneven taper, wrong angles, and tool wear. Here are some simple tips to help you troubleshoot:

- Check your setup. Make sure everything is level and secure.

- Use the right tool for your material. Dull tools can ruin your finish.

- Monitor your speed and feed rates. Too fast can cause errors.

- Practice on scrap material first.

Learning from mistakes can make you better. Remember, every expert was once a beginner!

What are common mistakes in taper turning?

Common mistakes include misalignment, using the wrong tool, and incorrect feed rates. These issues can lead to a bad finish and wasted materials. Always double-check everything!

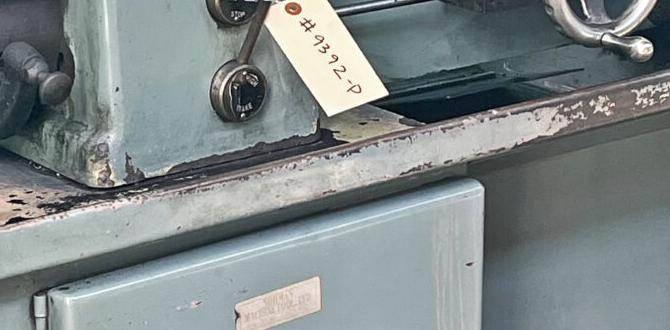

Maintenance Tips for Longevity of Your Metal Lathe

Importance of routine maintenance. Recommended maintenance practices for optimal performance.Routine maintenance is key to keeping your metal lathe in top shape. Regular checks help catch small issues before they become big problems. This can save you time and money. Here are some recommended practices:

- Clean the lathe after each use.

- Lubricate moving parts regularly.

- Check for any loose screws or parts.

- Inspect belts for wear and tear.

- Replace worn tools promptly.

Remember, a well-maintained lathe works better, lasts longer, and is safer to use!

What is the best way to maintain a metal lathe?

The best way to maintain a metal lathe is through regular cleaning, lubrication, and inspections. This keeps it performing well and ensures safety while working.

Conclusion

In 2025, metal lathe taper turning will be important for creating precise shapes. Understanding how to use lathes will boost your skills. We can explore different techniques to master taper turning together. Remember to practice and test your skills on real projects. For more insights, check out tutorials or guides on metalworking. Let’s keep learning and improving!FAQs

Sure! Here Are Five Questions Related To Taper Turning On A Metal Lathe In 2025:Taper turning on a metal lathe means making one end of a piece of metal smaller than the other. You can do this using special tools called taper attachments or by moving the tool at an angle. First, you set up your lathe and choose the right speed. Then, you measure how much smaller you want one end to be. Finally, you carefully cut the metal while watching the shape change!

Sure! Please share the question you’d like me to answer.

What Are The Advancements In Taper Turning Technology For Metal Lathes That Have Emerged In 2025?In 2025, new machines make taper turning easier and faster. They have better controls, like touch screens, so you can see what you’re doing. These machines also have special tools that help cut shapes more smoothly. Plus, they save energy, which is good for the planet. Overall, taper turning is now simpler and smarter!

How Can Cnc Lathes Improve The Accuracy And Efficiency Of Taper Turning Compared To Traditional Manual Lathes?CNC lathes, which stands for Computer Numerical Control lathes, can make taper turning much easier. They follow precise instructions from a computer. This helps us cut shapes exactly the way we want them. With CNC lathes, we can save time because they work fast and don’t need constant adjustments like manual lathes. This means we get better results and finish projects quicker!

What Are The Best Practices For Setting Up A Metal Lathe For Taper Turning To Ensure Consistent Results?To set up a metal lathe for taper turning, first, make sure your workpiece is tightly held. Check the angle of the tool to match the taper you want. Adjust the speed of the lathe to a good level for cutting. Finally, take your time and make small cuts to get the best and most even shape. This way, you will get consistent results every time!

What Safety Considerations Should Be Taken Into Account When Performing Taper Turning Operations On A Metal Lathe?When using a metal lathe to taper turn, safety is really important. Always wear safety goggles to protect your eyes from flying metal bits. Make sure your hair and clothes are tied back and away from the machine. Keep your hands away from the moving parts. Finally, make sure the area around the lathe is clean and free from clutter.

How Do Different Types Of Taper (E.G., Straight, Compound, Or Elliptical) Affect The Choice Of Tooling And Setup On A Metal Lathe?Different types of tapers change how we work with a metal lathe. For straight tapers, we can use simple tools and settings. With compound tapers, we need to adjust the angle more carefully, which can be tricky. Elliptical tapers are special and often require unique tools. Each taper type helps us make different shapes of metal pieces.