Imagine walking into a workshop filled with shining metal lathe tools. The year is 2025, and these advanced tools have changed everything. Have you ever wondered how metal lathes can create such precise designs?

In 2025, metal lathe tools are smarter and more efficient than ever. They help makers, engineers, and hobbyists turn raw metal into beautiful, functional items. These tools are not just machines; they are gateways to creativity.

Did you know that the first metal lathe was invented over 2,000 years ago? Fast forward to today, and you see technology has brought us incredible innovations. With new features, you can now work faster and safer than before. Whether you’re building models or repairing parts, the right tools make a huge difference.

In this article, we will dive into the world of 2025 metal lathe tools. We will explore what makes them special and how they can help you create amazing projects. Are you ready to discover the future of metalworking?

Discover The Best 2025 Metal Lathe Tools For Precision Work

2025 Metal Lathe Tools

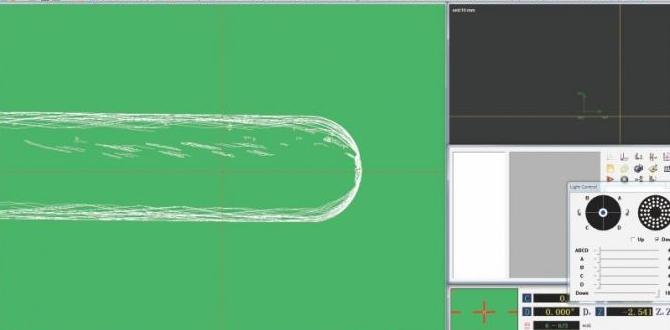

Metal lathe tools in 2025 promise exciting advancements. Imagine a world where precision is even easier! New technology enhances efficiency and reduces errors, making projects smoother. Modern designs focus on user-friendliness, ideal for beginners and experts alike. Did you know that some tools now feature smart technology? This helps users get real-time feedback while working. Investing in the right tools can transform your metalworking projects. Get ready to create like never before!Understanding Metal Lathe Tools

Definition and function of metal lathe tools. Importance in machining and manufacturing processes.Metal lathe tools are like magic wands for shaping metal. They spin around to carve, cut, and shape metal into many useful items. These tools are very important in making parts for machines and cars. Without them, we would all be stuck with square wheels! In 2025, expect even smarter metal lathe tools that make work easier and faster.

| Function | Importance |

|---|---|

| Shaping metal | Essential for manufacturing |

| Creating precise parts | Boosts efficiency |

Smartly designed lathes mean more time for the fun stuff, like dreaming about what to create next. So, let’s give a round of applause to these clever tools that keep our world spinning smoothly!

Essential Features to Consider When Choosing a Metal Lathe Tool

Key specifications (e.g., spindle speed, bed length). Material and build quality factors.Choosing the right metal lathe tool is crucial. Look at key specifications that matter. Spindle speed helps with cutting speed. A longer bed length allows for larger projects. Consider the material and build quality too. Strong metals last longer and handle tougher jobs.

- Spindle Speed: Affects cutting speed and flexibility.

- Bed Length: Important for larger materials and projects.

- Material: Durable materials ensure longer life.

- Build Quality: A solid frame keeps everything stable.

What is the importance of spindle speed?

The spindle speed determines how fast the lathe can cut materials. A higher speed means quicker work, but materials may vary in best speed. Always check what you are working on!

Why does bed length matter?

The bed length gives you space for larger pieces. If your projects are big, a longer bed is better!

Popular Brands and Models for 2025 Metal Lathe Tools

Comparison of leading brands in the market. Highlighting top models and their unique features.Many people love using metal lathes. In 2025, notable brands make machines that stand out. Grizzly offers the G0602, famous for its solid build and smooth operation. On the other hand, Jet has the JWL-1442, which comes with a futuristic digital readout. Want to get fancy? Check out the Mini-Lathe from Harbor Freight, perfect for small projects. Below is a quick look at these top brands and their special features.

| Brand | Model | Unique Features |

|---|---|---|

| Grizzly | G0602 | Sturdy design, easy to use |

| Jet | JWL-1442 | Digital readout, variable speed |

| Harbor Freight | Mini-Lathe | Compact, ideal for hobbyists |

Look for these brands when you shop. They deliver fun and precision, making your metal lathe experience enjoyable!

Advancements in Metal Lathe Technology

Innovations that enhance efficiency and precision. Impact of automation and smart technology.New tools for metal lathes are making work faster and more accurate. These machines now use smart technology and automation. This means they can control processes with little human help. Some innovations include:

- Advanced sensors: These help detect errors in real time.

- Smart software: It can learn from tasks to improve performance.

- Robotic arms: They handle heavy parts safely and quickly.

These changes make metalworking easier. As technology grows, so does efficiency and precision.

What are some benefits of smart technology in metal lathes?

Smart technology improves accuracy and saves time in metal lathing. It allows machines to work with little human input, making processes faster.

Maintenance Tips for Metal Lathe Tools

Routine maintenance practices to ensure longevity. Troubleshooting common issues with metal lathes.Taking care of your metal lathe tools can be easy and even a bit fun! Start with regular cleanings to keep those chips away. Think of it as giving your lathe a shower—no soap required! Check the oil levels too; it’s like giving your lathe a drink. If something’s not working, like the motor or the belt, don’t panic! You can usually solve it with a little troubleshooting. Just like checking your shoelaces before a race!

| Maintenance Practice | Frequency |

|---|---|

| Clean the lathe | After every use |

| Check oil levels | Weekly |

| Inspect the belt and motor | Monthly |

Remember, a well-maintained lathe can last longer and perform better! If you can’t find why things aren’t working, don’t hesitate to ask for help. Even the best need a hand sometimes!

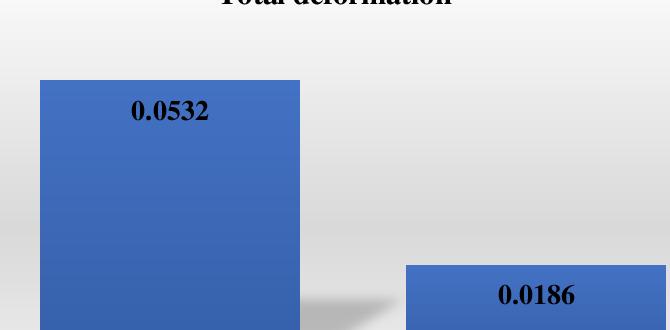

Cost Analysis: Budgeting for Metal Lathe Tools

Average costs of various types and models. Additional expenses (accessories, maintenance, etc.).Buying metal lathe tools can feel like diving into a treasure chest… if that treasure chest has a price tag! Different types of lathes can range from $500 to $5,000. Yes, that’s quite a jump! Don’t forget to budget for accessories like cutting tools and tool holders, which can add another $200 to $1,000. And let’s not skip maintenance; think of it as a car tune-up for your lathe. Regular upkeep can cost around $100 a year. Keeping all this in mind can help your wallet breathe easier!

| Type of Lathe | Average Cost | Accessories Cost | Maintenance Cost (Yearly) |

|---|---|---|---|

| Mini Lathe | $500 – $1,200 | $200 – $400 | $50 |

| Mid-size Lathe | $1,200 – $3,000 | $400 – $800 | $75 |

| Heavy-duty Lathe | $3,000 – $5,000 | $800 – $1,500 | $100 |

Best Practices for Safe Operations of Metal Lathes

Safety protocols and gear to use. Training and skill requirements for operators.Working with metal lathes can be fun, but safety is key. Wear protective gear like goggles and gloves. This helps protect your eyes and hands. Always keep your workspace clean. Training is also important. Operators should know how to use the tools safely. They should get enough hands-on practice. Understanding safety protocols can prevent accidents and injuries.

- Always wear your safety goggles.

- Use gloves to protect your hands.

- Keep the area tidy to avoid tripping.

- Learn from a skilled operator before starting.

What safety gear do metal lathe operators need?

Metal lathe operators need to wear proper gear. This includes safety goggles to protect their eyes and gloves to keep their hands safe. A mask may also be useful.

Key Safety Tips:

- Inspect the lathe before use.

- Follow all instructions carefully.

- Be aware of your surroundings.

Future Trends in Metal Lathe Technology (Post-2025)

Predictions on the evolution of metal lathe tools. Impact of emerging technologies (AI, IoT) on lathe machining.The world of metal lathe tools is about to get a major upgrade! By 2025, we can expect amazing changes. Artificial intelligence will help machines think on their own. Imagine a lathe that knows how to fix itself after a mishap—handy, right? Plus, with the Internet of Things (IoT), these tools will be more connected than your favorite pair of socks! They will share data instantly, leading to better efficiency. That’s right, folks—lathe tools may soon be the smartest crowd at the manufacturing party!

| Emerging Technologies | Impact on Metal Lathes |

|---|---|

| Artificial Intelligence | Self-diagnosing and predictive maintenance |

| Internet of Things | Real-time data sharing for improved performance |

Conclusion

In 2025, metal lathe tools will be more advanced and user-friendly. You can find smarter designs that make work easier. Investing in quality tools boosts your projects’ quality and safety. If you’re interested, explore reviews and guides to choose the best tools for you. By learning more, you can enhance your skills and create amazing projects!FAQs

What Advancements In Technology Are Expected For Metal Lathe Tools By 202By 2024, metal lathe tools will become smarter. They might use robots to help us shape metal better. New sensors can check if everything is running right. You could also see more machines that can work on their own. These changes will make it easier and faster to create metal parts.

How Will The Materials Used In Manufacturing Metal Lathe Tools Evolve By 202By 2025, we might see new materials for making metal lathe tools. These materials could be lighter and stronger. This means the tools will last longer and work better. We will also use more recycled materials to help the Earth. So, our tools may become smarter and more eco-friendly!

What Are The Anticipated Trends In Automation And Smart Features For Metal Lathe Tools In 202In 2024, we can expect metal lathe tools to get smarter and more automated. These tools might use special computer systems to help you work faster and make fewer mistakes. You could see features like automatic adjustments, which would mean less manual work for you. Some tools might even connect to your phone, giving you alerts and tips while you work. Overall, these changes will help you create better projects more easily!

How Will The Demand For Environmentally Friendly Metal Lathe Tools Impact Production By 202The demand for environmentally friendly metal lathe tools will make companies change how they make tools. We will see safer tools that create less waste. This could mean a bit more work for factories, as they learn new ways to make these tools. But in the end, it helps our planet! More people will want to buy green tools, so production could actually go up.

What Is The Expected Price Range For High-Quality Metal Lathe Tools In 202And How Might This Affect Hobbyists Versus Professional Machinists?High-quality metal lathe tools can cost between $300 and $2,000 in 2023. If you are a hobbyist, this might feel too expensive. You may choose to buy simpler tools instead. Professional machinists rely on these tools for their work, so they might spend more. For them, the investment pays off because they earn money with their tools.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Advancements In Technology Are Expected For Metal Lathe Tools By 202 “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “By 2024, metal lathe tools will become smarter. They might use robots to help us shape metal better. New sensors can check if everything is running right. You could also see more machines that can work on their own. These changes will make it easier and faster to create metal parts.”}},{“@type”: “Question”,”name”: “How Will The Materials Used In Manufacturing Metal Lathe Tools Evolve By 202 “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “By 2025, we might see new materials for making metal lathe tools. These materials could be lighter and stronger. This means the tools will last longer and work better. We will also use more recycled materials to help the Earth. So, our tools may become smarter and more eco-friendly!”}},{“@type”: “Question”,”name”: “What Are The Anticipated Trends In Automation And Smart Features For Metal Lathe Tools In 202 “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In 2024, we can expect metal lathe tools to get smarter and more automated. These tools might use special computer systems to help you work faster and make fewer mistakes. You could see features like automatic adjustments, which would mean less manual work for you. Some tools might even connect to your phone, giving you alerts and tips while you work. Overall, these changes will help you create better projects more easily!”}},{“@type”: “Question”,”name”: “How Will The Demand For Environmentally Friendly Metal Lathe Tools Impact Production By 202 “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The demand for environmentally friendly metal lathe tools will make companies change how they make tools. We will see safer tools that create less waste. This could mean a bit more work for factories, as they learn new ways to make these tools. But in the end, it helps our planet! More people will want to buy green tools, so production could actually go up.”}},{“@type”: “Question”,”name”: “What Is The Expected Price Range For High-Quality Metal Lathe Tools In 202And How Might This Affect Hobbyists Versus Professional Machinists? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “High-quality metal lathe tools can cost between $300 and $2,000 in 2023. If you are a hobbyist, this might feel too expensive. You may choose to buy simpler tools instead. Professional machinists rely on these tools for their work, so they might spend more. For them, the investment pays off because they earn money with their tools.”}}]}