Have you ever wondered how to set up a metal lathe? If you’re getting ready for your 2025 metal lathe project, you’ll need to understand the wiring. Wiring may seem tricky, but it’s crucial for smooth operation. Once you grasp the basics, it can be quite exciting!

Imagine turning raw metal into amazing shapes with your own hands. The right wiring diagram helps make that dream a reality. A good metal lathe wiring diagram shows you how to connect the parts safely and effectively. It guides you step by step. You wouldn’t want to start cutting without knowing how to power your machine.

Here’s a fun fact: the first metal lathes were invented over 200 years ago! They have come a long way since then. Now, with the correct wiring diagram in hand, you can dive into your own projects. Let’s explore how to wire your lathe for success!

2025 Metal Lathe Wiring Diagram: A Comprehensive Guide

2025 Metal Lathe Wiring Diagram

Understanding the 2025 metal lathe wiring diagram is crucial for safe operation. By following the diagram, users can connect components correctly and efficiently. This prevents short circuits and other dangerous problems. Did you know that a small wiring mistake can lead to machine failure? Learning the proper wiring helps ensure the lathe runs smoothly, making your projects easier and safer. Don’t hesitate to explore diagrams to boost your metalworking skills!Essential Tools and Materials for Wiring

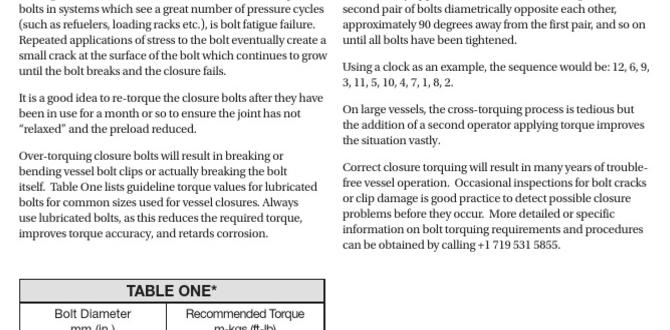

List of necessary tools for wiring a metal lathe. Recommended materials for creating a reliable wiring setup.Getting ready to wire your metal lathe? You’ll need some handy tools! Start with wire cutters and stripper tools. Don’t forget screwdrivers for putting everything together, and a trusty multimeter to test connections. If you enjoy surprises, this tool will let you know what’s working and what’s not!

Next up, choose reliable materials. High-quality wires are a must, and using the right connectors is crucial to avoid short circuits. Safety first! A good insulation tape will keep things safe and sound. In wiring, a little prep goes a long way!

| Tools | Recommended Materials |

|---|---|

| Wire Cutters | High-quality Wires |

| Wire Stripper | Reliable Connectors |

| Screwdrivers | Insulation Tape |

| Multimeter |

Step-by-Step Wiring Process

Detailed instructions on wiring the motor, switches, and control panel. Wiring color codes and conventions specific to metal lathes.Wiring your metal lathe might seem tricky, but it can be easy! Follow these steps to connect the motor, switches, and control panel correctly:

- Identify the motor leads. Typically, you’ll find three wires: red for power, black for ground, and green for neutral.

- Attach the red wire to the power switch. This helps turn the lathe on.

- Connect the black wire to the control panel. This allows you to control speed and direction.

- Finally, link the green wire to the ground point. This ensures safety during operation.

Make sure to double-check the connections. For safety, always refer to the wiring diagram specific to your lathe model.

What are common color codes in metal lathe wiring?

Typical color codes are: Red for power, black for ground, and green for neutral. Remember these colors to avoid mistakes!

Common Wiring Configurations for Different Models

Wiring diagram variations based on different metal lathe models. Explanation of adaptability and modifications as per machine requirements.Different metal lathe models have various wiring configurations. Each model comes with its unique wiring diagram. Understanding these differences is essential. Adapting the wiring can improve performance. Your lathe may need slight modifications based on its specific requirements. Here are some common configurations:

- Single-phase wiring for simple tasks.

- Three-phase wiring for heavy-duty work.

- Variable speed controls for flexibility.

Always refer to the manual for your model. This ensures safe and correct wiring practices.

What are the typical wiring types for metal lathes?

The typical wiring types for metal lathes include single-phase and three-phase connections. Single-phase is great for home use, while three-phase suits commercial settings.

What modifications may be needed for wiring?

- Upgrade to variable speed.

- Change power sources based on your needs.

Troubleshooting Common Wiring Issues

Identifying and solving common wiring problems. Safety tips during the troubleshooting process.Wiring problems can be tricky. First, check connections. Make sure wires are tight and not damaged. Look for loose or broken parts. If a machine won’t start, inspect the power source. Did you check the plug? Always prioritize safety. Unplug the machine before touching wires. Use gloves to avoid shocks.

What are common wiring issues?

Common issues include broken wires, loose connections, and damaged plugs.

Safety Tips During Troubleshooting

- Unplug before fixing anything.

- Wear rubber gloves for insulation.

- Work in a dry area to avoid electrical hazards.

Maintenance Tips for Longevity of Wiring Systems

Best practices for maintaining wiring and electrical components. Signs of wear and tear to watch for in the wiring system.Keeping wiring systems in good shape helps them last longer. Make sure to check wiring regularly for any signs of damage. Here are some best practices:

- Keep wiring clean and dry.

- Avoid tight bends in wires.

- Use proper insulation to prevent fraying.

Look for signs of wear, like:

- Exposed wires.

- Strange smells or buzzing sounds.

- Flickering lights.

Following these tips can keep your wiring safe and efficient.

What are common signs of wiring problems?

Keep an eye out for buzzing sounds, flickering lights, or heat around wires. These may mean the wiring needs to be checked.

Resources and References for Further Learning

Recommended books, websites, and forums for advanced wiring techniques. Links to downloadable wiring diagrams and schematics for specific models.To learn more about wiring techniques, check out these resources:

- Books: “Metal Lathe Wiring for Dummies” and “Advanced Lathe Techniques.”

- Websites: Explore Wiring Diagrams Online and Machinery’s Handbook.

- Forums: Join discussions on Home Shop Machinist and The Lathe Forum.

For specific wiring diagrams, many websites offer downloadable files. Check model-specific areas to find what you need!

What are some good resources for learning wiring techniques?

Look for helpful books, websites, and forums. They guide you and offer downloadable diagrams for better understanding.

Conclusion

In conclusion, a 2025 metal lathe wiring diagram helps you understand how to connect wires properly. This knowledge ensures your lathe runs safely and efficiently. You can explore different diagrams online to find the one that fits your needs. Remember to practice safe wiring and consult professionals if needed. Keep learning for the best results with your projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of A 20Metal Lathe Wiring Diagram:A 20-inch metal lathe is a tool that shapes metal. To understand its wiring diagram, you will see lines and symbols. These show how to connect the wires. They help the lathe work properly. Always be careful when dealing with electricity!

Sure! Please ask your question, and I’ll be happy to help answer it.

What Are The Essential Components Typically Included In A Wiring Diagram For A 20Metal Lathe?A wiring diagram for a 20-inch metal lathe usually has a few key parts. First, it shows the power source, like the electricity supply. You’ll see switches that turn the lathe on and off. It also includes wires that connect everything together. Finally, it shows the motor that makes the lathe move, helping us cut metal.

How Do You Interpret The Symbols Used In A Metal Lathe Wiring Diagram?To understand a metal lathe wiring diagram, look for symbols. Each symbol stands for something specific, like a switch or a wire. You can find a key or legend on the diagram that explains what each symbol means. By following these symbols, you can see how everything connects. This helps you understand how to use the metal lathe safely.

What Safety Precautions Should Be Taken When Wiring A 20Metal Lathe?When wiring a 20 metal lathe, we need to be careful. First, always turn off the power before touching any wires. Use insulated tools to avoid electric shocks. Make sure your hands are dry and the floor is clean. Finally, double-check your work to ensure everything is safe before turning the machine on.

Are There Any Specific Electrical Requirements For Powering A 20Metal Lathe Based On Its Wiring Diagram?Yes, a 20-inch metal lathe needs specific electricity to work. You usually need to check the voltage, which is how strong the electricity is. Most lathes work on 120 or 240 volts. You also need to make sure it has enough power, measured in amps. Always follow the wiring diagram carefully to connect everything right!

Where Can I Find A Detailed Wiring Diagram For A Specific Model Of The 20Metal Lathe?You can find a detailed wiring diagram for your 20 metal lathe in a few places. First, check the manual that came with the lathe. If you don’t have it, visit the manufacturer’s website; they often have diagrams available. You can also look on forums or websites where people share advice about lathes. Remember to search with your specific model number to get the right information!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A 20Metal Lathe Wiring Diagram:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A 20-inch metal lathe is a tool that shapes metal. To understand its wiring diagram, you will see lines and symbols. These show how to connect the wires. They help the lathe work properly. Always be careful when dealing with electricity!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help answer it.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Typically Included In A Wiring Diagram For A 20Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A wiring diagram for a 20-inch metal lathe usually has a few key parts. First, it shows the power source, like the electricity supply. You’ll see switches that turn the lathe on and off. It also includes wires that connect everything together. Finally, it shows the motor that makes the lathe move, helping us cut metal.”}},{“@type”: “Question”,”name”: “How Do You Interpret The Symbols Used In A Metal Lathe Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To understand a metal lathe wiring diagram, look for symbols. Each symbol stands for something specific, like a switch or a wire. You can find a key or legend on the diagram that explains what each symbol means. By following these symbols, you can see how everything connects. This helps you understand how to use the metal lathe safely.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring A 20Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a 20 metal lathe, we need to be careful. First, always turn off the power before touching any wires. Use insulated tools to avoid electric shocks. Make sure your hands are dry and the floor is clean. Finally, double-check your work to ensure everything is safe before turning the machine on.”}},{“@type”: “Question”,”name”: “Are There Any Specific Electrical Requirements For Powering A 20Metal Lathe Based On Its Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, a 20-inch metal lathe needs specific electricity to work. You usually need to check the voltage, which is how strong the electricity is. Most lathes work on 120 or 240 volts. You also need to make sure it has enough power, measured in amps. Always follow the wiring diagram carefully to connect everything right!”}},{“@type”: “Question”,”name”: “Where Can I Find A Detailed Wiring Diagram For A Specific Model Of The 20Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find a detailed wiring diagram for your 20 metal lathe in a few places. First, check the manual that came with the lathe. If you don’t have it, visit the manufacturer’s website; they often have diagrams available. You can also look on forums or websites where people share advice about lathes. Remember to search with your specific model number to get the right information!”}}]}