Quick Summary: For a 3/8 inch face mill in Delrin, aim for a spindle speed between 1,500-3,000 RPM and a feed rate of 0.003-0.006 inches per tooth. Always start conservatively and adjust based on chip formation and surface finish for optimal results.

Hey there, workshop friends! Daniel Bates here from Lathe Hub. Ever stared at a block of Delrin, excited to machine it, but then frozen up wondering about the right settings for your face mill? Getting the cuts just right can feel like a big puzzle. Don’t worry, it’s a common head-scratcher for many of us diving into plastics. We want clean cuts, no melting, and a perfect finish. Fortunately, with a little guidance, getting those 3/8 inch face mill feeds and speeds dialed in for Delrin is totally achievable. We’ll walk through it step-by-step, making sure you feel confident and ready to tackle your project. Stick around, and let’s get your Delrin projects looking sharp!

Understanding Delrin (Acetal) for Machining

Before we dive into specific numbers, let’s talk a bit about Delrin. This stuff, also known as Acetal, is a fantastic engineering thermoplastic. It’s super strong, stiff, has low friction, and is really stable dimensionally. Because of these great properties, it’s a favorite for making gears, bushings, bearings, and all sorts of functional parts. However, like many plastics, Delrin can be a bit… temperamental when you start cutting it. It’s prone to melting if you push your tools too fast or don’t manage chip buildup. That’s where understanding the right feeds and speeds becomes crucial.

Think of it this way: metal machining is often about brute force with good lubrication. Plastic machining is more about finesse. We need to remove material quickly enough to prevent heat buildup but gently enough to avoid that gooey, melted mess. For Delrin, this balance is key. Our goal is to create nice, fluffy chips that easily clear the cutting area, keeping the material cool and ensuring a smooth, accurate cut.

Why Feeds and Speeds Matter for Delrin

You might be asking, “Why all the fuss about feeds and speeds?” Well, imagine trying to shave with a dull razor very quickly. You’d probably get nicks and an uneven shave, right? Machining Delrin is similar. If your spindle speed (how fast the tool spins) is too high and your feed rate (how fast the tool moves through the material) is too low, the cutting edge rubs rather than cuts. This friction generates heat, and Delrin, notoriously, loves to melt. We end up with sticky chips welded to the cutter, a gummy mess on your part, and a frustratingly poor surface finish – if you get any finish at all!

On the other hand, if your feed rate is too high and your speed is too low, you can overload the cutting edges, leading to tool breakage or chatter. Chatter is that annoying vibration that leaves a wavy, rippled surface on your part. It’s also inefficient and hard on your tooling.

The sweet spot for feeds and speeds ensures that:

- Heat is Minimized: Each cutting edge engages for a brief period, removing material efficiently without excessive friction.

- Chips are Managed: The material is ejected cleanly, preventing buildup and re-cutting.

- Surface Finish is Optimized: A smooth, accurate surface is achieved with minimal effort.

- Tool Life is Extended: Your expensive cutting tools last longer.

- Machine Performance is Enhanced: Your milling machine runs smoothly and efficiently.

So, getting these settings right isn’t just about making a pretty part; it’s about making the machining process smooth, efficient, and enjoyable. Let’s zero in on the 3/8 inch face mill and Delrin.

Your 3/8 Inch Face Mill: The Tool of Choice

A 3/8 inch face mill is a common and versatile tool for milling flat surfaces. These tools have multiple cutting inserts, making them efficient for removing material quickly across a wider area. When working with Delrin, the type of inserts you use matters. For plastics, you generally want sharp, polished inserts with a high rake angle. This helps the material flow off the cutting edge easily. Carbide inserts are typically a good choice. They are hard and can handle the cutting forces, but always ensure they are the right geometry for plastics.

The diameter of the face mill (3/8 inch) tells us how much surface area it will cover in one pass. A smaller face mill like this is great for smaller parts or when you need good control. The rigidity of your setup is also important. Ensure the workpiece is securely clamped and the milling machine’s spindle is in good condition to avoid vibration.

Decoding Feeds and Speeds for Delrin

Now for the core of it: what numbers should you use? The terms “feeds and speeds” refer to two primary settings on your milling machine:

- Spindle Speed (RPM): This is how fast the cutting tool rotates, measured in revolutions per minute (RPM).

- Feed Rate (IPM or ITP): This is how fast the cutting tool moves through the material. It’s often expressed in inches per minute (IPM) for the machine’s movement, or inches per tooth (IPT) for the amount of material each cutting edge removes. For plastics, thinking in IPT is often more intuitive.

When machining Delrin with a 3/8 inch face mill, we need to find a balance that prevents melting and achieves a good finish. Here’s a general guideline, which we’ll break down further:

Recommended Ranges for 3/8 Inch Face Mill on Delrin

These are starting points. Always listen to your machine and watch the chips!

| Parameter | Recommended Range | Notes |

|---|---|---|

| Spindle Speed (RPM) | 1,500 – 3,000 RPM | Higher speeds can work with good chip evacuation but risk melting if not managed. Start lower. |

| Feed Rate (IPM) | 10 – 30 IPM | Adjust within this range based on spindle speed and chip load. |

| Chip Load (IPT – Inches Per Tooth) | 0.003 – 0.006 inches per tooth (IPT) | This is crucial. Too high, and you’ll chip or melt; too low, and you generate heat. |

| Depth of Cut (DOC) | 0.050 – 0.125 inches | For facing, shallower cuts are often better to manage heat and vibrations. |

| Cooling/Lubrication | Compressed Air or Plastic-Specific Coolant | Essential for preventing melting and clearing chips. |

Calculating Feed Rate from Chip Load

If your machine uses Chip Load (IPT) as the primary setting, you can calculate the desired IPM using this formula:

Feed Rate (IPM) = Spindle Speed (RPM) × Number of Teeth × Chip Load (IPT)

Let’s do an example:

- You have a 4-tooth 3/8 inch face mill.

- You choose a spindle speed of 2,000 RPM.

- You aim for a chip load of 0.004 IPT.

Calculation:

Feed Rate (IPM) = 2000 RPM × 4 teeth × 0.004 IPT = 32 IPM

This formula helps when your machine control requires IPM. When setting up, think about each cutting tooth taking a small, efficient bite. That’s the essence of a good chip load.

Factors Influencing Your Settings

The numbers above are a great starting point, but several critical factors can sway your decision. It’s like cooking; you need to taste and adjust!

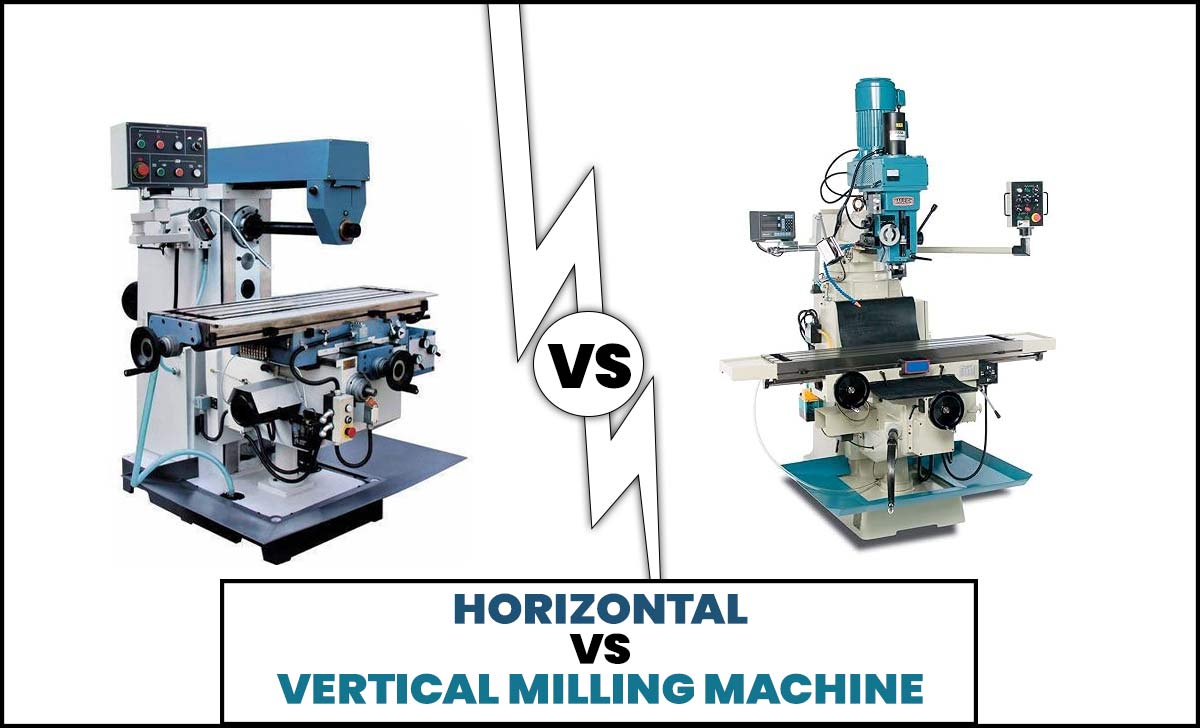

1. The Milling Machine

- Rigidity: A sturdy, well-maintained machine can handle more aggressive cuts than a light-duty hobby machine. Chatter is the enemy here. If your machine vibrates, slow down your feed rate.

- Spindle Taper and Bearings: A worn spindle can introduce runout (wobble), which negatively impacts your surface finish and can lead to uneven cutting.

- Power: Ensure your machine has enough power to maintain speed under load with a face mill.

2. The Cutting Tool

- Insert Geometry: As mentioned, sharp, polished inserts with high rake angles are best for Delrin. Negative rake inserts designed for steel won’t perform well. Look for inserts specifically made for plastics or soft materials.

- Number of Teeth: More teeth can mean higher metal removal rates but also require higher feed rates to maintain chip load. Fewer teeth might allow for slower, more controlled cutting.

- Insert Condition: Dull or chipped inserts will generate more heat and lead to poor results.

3. The Delrin Material Itself

- Grade: While most common Delrin grades behave similarly, specific additives or formulations might slightly alter their machining characteristics.

- Temperature During Machining: If the ambient temperature is high, or if previous operations have heated the part, Delrin can become softer and more prone to melting.

- Thickness: Very thin Delrin workpieces can act as heat sinks, drawing heat away, or they can be prone to flexing and vibration.

4. The Operation

- Depth of Cut (DOC): Shallower depths of cut are generally preferred for Dalrin. Removing too much material at once increases the cutting load and heat. For facing operations, taking multiple shallow passes is often better than one deep pass.

- Wet vs. Dry Machining: While plastics are often machined dry, a blast of compressed air is highly recommended to clear chips and cool the cutting zone. A specialized plastic cutting fluid can also help, but avoid flood coolants that can make Delrin brittle or cause swelling. You can learn more about best practices for machining plastics from resources like engineering societies or material suppliers. For example, the Oak Ridge National Laboratory provides valuable material property data.

Step-by-Step Guide to Machining Delrin with a 3/8 Inch Face Mill

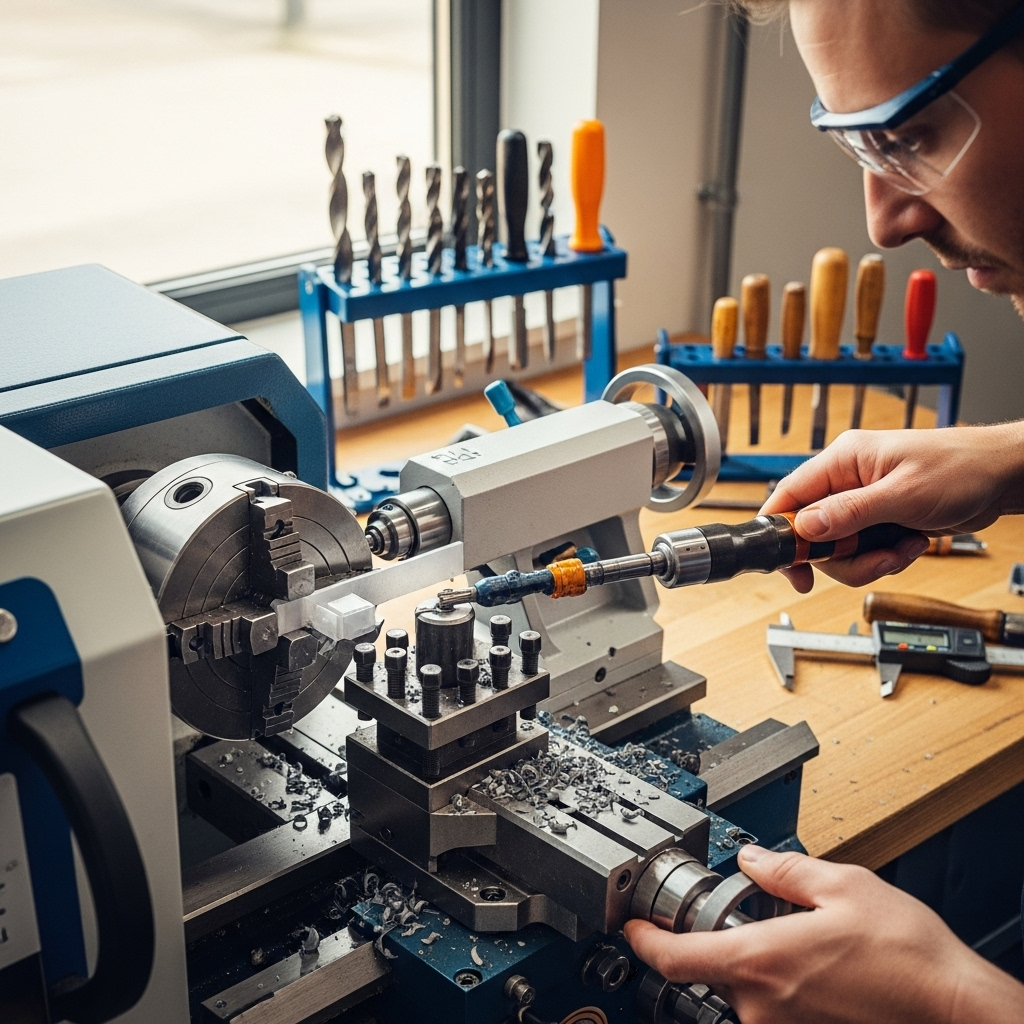

Let’s walk through setting up and running your face mill on Delrin. Remember, safety first! Always wear safety glasses, and understand your machine’s emergency stop procedures.

Step 1: Prepare Your Workpiece

- Ensure the Delrin is securely clamped in your milling machine vise or fixture. Use soft jaws if necessary to avoid damaging or deforming the material.

- Make sure the surface of the Delrin you intend to face is relatively flat and clean.

- Position the workpiece so that the face mill will start cutting into the material, not just brush the edge.

Step 2: Mount the Face Mill

- Carefully insert the 3/8 inch face mill into your milling machine’s spindle. Ensure it’s seated correctly and locked in place according to your machine’s procedure.

- Double-check that the inserts are secure and free from any debris.

Step 3: Set Your Initial Feeds and Speeds

- Based on our table and calculations, let’s start with conservative settings.

- Set your spindle speed to around 1,800 RPM.

- Calculate your feed rate. If you have a 4-tooth face mill, and aiming for 0.004 IPT, that’s 1800 4 0.004 = 28.8 IPM. Let’s round it to 30 IPM for simplicity.

- Set your Depth of Cut (DOC) to a shallow 0.060 inches for the first pass.

Step 4: Engage the Spindle and Feed

- Turn on your milling machine’s coolant system, if you’re using one, or ensure your compressed air blast is ready.

- Start the spindle rotating at your set RPM.

- Slowly begin feeding the face mill into the Delrin at your set feed rate and depth of cut.

- Crucially: Observe!

Step 5: Observe and Adjust

This is the most important part of machining plastics. Watch and listen:

- Chip Formation: What kind of chips are you getting?

- Ideal: Small, light, stringy chips that fly away from the cutter.

- Too Hot/Melting: Gummy, sticky chips that are melting and gumming up the inserts. This usually means your feed rate is too low, or your spindle speed is too high. Increase feed rate or decrease RPM slightly.

- Too Aggressive/Chiseling: Large, chunky chips that sound like the tool is digging in hard. This might mean your feed rate is too high for the current RPM, or your depth of cut is too much. Decrease feed rate or DOC.

- Surface Finish: Does the surface look smooth and clean, or is it wavy, melted, or rough?

- A rough, wavy surface often indicates chatter due to incorrect feed/speed or a lack of rigidity. Try adjusting feed rate or DOC.

- A melted, gummy surface confirms heat buildup. Address as above (increase feed, decrease speed).

- Sound: Listen for smooth cutting sounds. Any screeching, grinding, or loud banging indicates a problem.

- Temperature: While not always easy to judge, if you can touch the removed chips (carefully!), they should not be hot enough to burn you. The part itself shouldn’t feel excessively warm.

Adjustment Strategy:

- If you’re getting melting or poor chip formation, try increasing the feed rate first (e.g., from 30 IPM to 35 or 40 IPM) while keeping RPM the same. If that doesn’t help enough, try reducing the RPM slightly (e.g., from 1800 to 1500 RPM) and recalculating your feed rate for the new RPM.

- If you’re experiencing chatter or aggressive cutting, try reducing the feed rate or the depth of cut.

- Make one adjustment at a time so you know what caused the change.

Step 6: Take Multiple Passes if Necessary

For a perfectly flat finish, especially on larger parts, you might need to take several shallow passes rather than attempting to take off the full amount in one go. This is also a good strategy if you’re new to machining Delrin, as it allows for easier correction if you encounter issues.

Step 7: Final Inspection

Once you’ve achieved the desired result, carefully remove the finished part from the machine. Inspect it for surface finish, dimensional accuracy, and any signs of thermal damage or stress.

Troubleshooting Common Delrin Machining Issues

Even with the best intentions, sometimes things don’t go perfectly. Here are some common problems and how to fix them:

Problem: Melting or Gummy Chips

- Cause: Too much heat generated. Typically due to low feed rate, high spindle speed, or insufficient chip clearance.

- Solution:

- Increase feed rate.

- Decrease spindle speed.

- Ensure compressed air or coolant is effectively clearing chips AND cooling the cut.

- Reduce depth of cut.

- Verify you’re using sharp inserts with a good geometry for plastics.

Problem: Chatter or Rough Surface Finish

- Cause: Vibration. Can be due to machine rigidity, loose tooling, inconsistent feed, or incorrect chip load (often too high).

- Solution:

- Decrease feed rate.

- Consider a slightly higher spindle speed (as this reduces chip load for a given IPM).

- Reduce depth of cut.

- Ensure workpiece and tool are rigidly held. Check spindle runout.

- Use inserts with a broader nose radius or less aggressive geometry if possible.

Problem: Tool Breakage

- Cause: Excessive cutting forces, dull tools, or encountering unexpected hard spots.

- Solution:

- Reduce feed rate and depth of cut.

- Ensure inserts are sharp and properly seated.

- Check for any obstructions or inconsistencies in the Delrin.

- Verify that your spindle speed isn’t too low, leading to excessive force per tooth