For cast iron, a 5/8 inch carbide end mill typically runs well between 200-400 SFM (Surface Feet per Minute) and chip loads of 0.001″ – 0.005″ per tooth. These proven speeds are a great starting point for achieving smooth cuts and extending tool life.

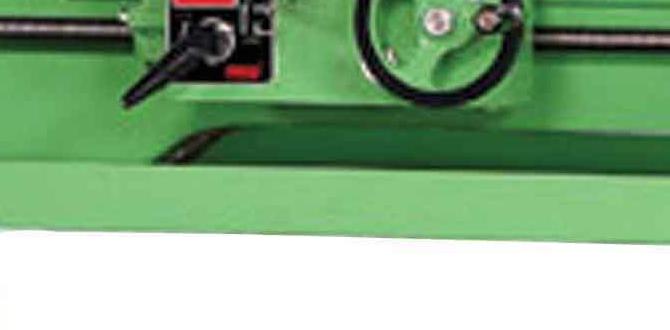

Milling cast iron can feel a bit tricky at first, especially when you’re not sure about the right speeds and feeds. Getting this wrong often leads to dull tools, rough surfaces, or even broken cutters. It’s a common worry for anyone starting out with CNC or manual milling machines, and frankly, it can be frustrating to spend time and money on tooling only to have it struggle. But don’t you worry, I’m Daniel Bates from Lathe Hub, and I’ve spent countless hours at the mill. We’re going to break down exactly how to find those sweet spot speeds and feeds for your 5/8 inch carbide end mill in cast iron, making it simple, safe, and successful. Stick around, and you’ll be milling cast iron with confidence in no time!

Understanding Your 5/8 Inch Carbide End Mill and Cast Iron

Before we dive into numbers, let’s get a feel for the tools and the material. Your 5/8 inch carbide end mill is a workhorse, but it has its limits and preferences. Carbide is tough and holds an edge incredibly well at higher speeds, which is what we want for efficient machining. Cast iron, on the other hand, is brittle and abrasive. It comes in various forms, like gray cast iron and ductile iron, each with slightly different machining characteristics. The abrasiveness means it can wear down tools faster if not handled correctly, and its brittleness means we need to avoid chatter or excessive force that could cause chipping.

The key is finding a balance. We want to spin the tool fast enough to leverage the carbide’s strength and heat resistance, but not so fast that it overheats or vibrates. Likewise, the feed rate needs to be just right to allow the cutting edges to shear the material effectively, creating small, manageable chips without overloading the tool or the machine. Think of it like a well-tuned engine – everything working together smoothly for optimal performance.

Why Speeds and Feeds Matter So Much

Getting your speeds and feeds (often shortened to “S&F”) correct is arguably the most critical step in milling any material, especially something like cast iron. Here’s why it’s a big deal:

- Tool Life: Too fast, and you’ll burn up your end mill in minutes. Too slow, and you might rub the material away, leading to premature dulling. Finding the sweet spot dramatically extends how long your carbide tool will last, saving you money.

- Surface Finish: The right S&F ensures clean cuts. Incorrect settings can lead to rough surfaces, tool marks, and an unacceptable finish for your project. Precise control means a beautiful, smooth finish right off the mill.

- Machine Health: Aggressive or incorrect settings can put undue stress on your milling machine’s spindle, bearings, and structure. Smooth, consistent machining protects your investment.

- Chip Evacuation: This is HUGE, especially in cast iron. The correct feed rate helps create chips that are small enough to be easily thrown clear of the cutting area. Clogged flutes with packed-in chips can lead to tool breakage and poor finishes.

- Accuracy: Consistent and correct speeds and feeds contribute to predictable material removal, which is essential for achieving tight tolerances and accurate part dimensions.

The Magic Numbers: Proven Speeds and Feeds for 5/8″ Carbide End Mills in Cast Iron

Now, let’s get to the good stuff – the numbers you can start with. These are proven starting points, and it’s always good practice to listen to your machine and adjust as needed. Surface Feet per Minute (SFM) is how fast the cutting edge is moving along the surface of the workpiece, measured in feet per minute. Inches per tooth (IPT) is how much material each cutting edge of the end mill removes with each rotation.

For a 5/8 inch (0.625″) 2-flute carbide end mill cutting common cast iron materials:

Recommended Spindle Speeds (RPM)

We need to convert SFM to RPM. The formula is: RPM = (SFM × 12) / (π × Diameter). For a 5/8″ (0.625″) end mill:

- Lower End (for rigidity, less chatter, or softer cast iron): Around 300 SFM.

- Calculated RPM: (300 SFM × 12) / (3.14159 × 0.625″) ≈ 573 RPM. Let’s round this to 500-600 RPM as a safe starting point.

- Higher End (for faster material removal, harder cast iron, or if your machine is very rigid): Around 400 SFM.

- Calculated RPM: (400 SFM × 12) / (3.14159 × 0.625″) ≈ 764 RPM. We can aim for 700-800 RPM.

So, a good general range for spindle speed is 500-800 RPM. Start on the lower end and increase if your setup is stable and the cut is clean.

Recommended Feed Rates (IPM – Inches Per Minute)

Feed rate is calculated by: IPM = RPM × Number of Flutes × Chip Load (IPT).

For a 5/8″ 2-flute carbide end mill in cast iron, a common chip load range is 0.001″ to 0.005″ per tooth. The specific chip load depends heavily on the depth of cut and width of cut.

- Light Finishing Cuts: Use a lower chip load, around 0.001″ – 0.002″ IPT.

- Heavier Roughing Cuts: Use a higher chip load, around 0.003″ – 0.005″ IPT.

Let’s calculate some IPM values:

- At 500 RPM, 2 flutes, and 0.002″ IPT: 500 RPM × 2 flutes × 0.002″ IPT = 2.0 IPM

- At 500 RPM, 2 flutes, and 0.004″ IPT: 500 RPM × 2 flutes × 0.004″ IPT = 4.0 IPM

- At 800 RPM, 2 flutes, and 0.002″ IPT: 800 RPM × 2 flutes × 0.002″ IPT = 3.2 IPM

- At 800 RPM, 2 flutes, and 0.004″ IPT: 800 RPM × 2 flutes × 0.004″ IPT = 6.4 IPM

This gives us a broad range of 2.0 to 6.4 IPM. You’ll typically want to be in the lower half for finishing and the upper half for roughing, while always observing the cut.

The Role of Depth and Width of Cut

These numbers aren’t set in stone. The depth of cut (DOC) and width of cut (WOC) you’re taking have a massive impact. Smaller DOC and WOC require lighter chip loads to avoid overloading the tool, while larger cuts can often handle slightly higher chip loads for aggressive material removal.

A common rule of thumb is that for a full width of cut (slotting), you should reduce your chip load. For partial width of cut (profiling), you can often use a higher chip load. Always refer to your end mill manufacturer’s recommendations if available, as they often provide specific guidance for different materials and cutting strategies.

A Table of Recommended Starting Points (5/8″ 2-Flute Carbide End Mill in Cast Iron)

Here’s a table to summarize some practical starting points. Remember, these are for a standard 5/8″ 2-flute end mill. The actual hardness and composition of your cast iron can influence these settings. Always start with conservative values and adjust upwards.

| Operation Type | SFM Range | RPM Range (Approx.) | Chip Load (IPT) | Feed Rate Range (IPM) | Notes |

|---|---|---|---|---|---|

| Roughing (Partial Width of Cut) | 300 – 400 | 500 – 800 | 0.003 – 0.005 | 4.0 – 12.8 IPM (for 800 RPM) | Focus on removing material quickly. Deep DOC possible if machine is rigid. |

| Finishing (Partial Width of Cut) | 300 – 400 | 500 – 800 | 0.001 – 0.002 | 1.0 – 3.2 IPM (for 800 RPM) | Aim for a smooth surface finish. Lighter DOC. |

| Slotting (Full Width of Cut) | 200 – 300 | 400 – 600 | 0.001 – 0.002 | 0.8 – 2.4 IPM (for 600 RPM) | Slotting is demanding. Reduce SFM and IPT for lower stress. |

Note: These are starting points. Adjust based on your machine’s rigidity, coolant use, and observed cutting performance. Higher SFM and IPT values are generally for more aggressive cuts but require a robust setup. Lower values are safer and good for delicate operations or less rigid machines.

Factors Influencing Optimal Speeds and Feeds

The numbers above are excellent starting points, but the real “art” of machining comes from understanding how various factors can push those numbers up or down. Don’t be afraid to experiment within safe limits!

1. The Type of Cast Iron

Not all cast iron is created equal. Your chosen end mill will behave differently depending on the specific alloy:

- Gray Cast Iron: This is the most common type. It’s relatively easy to machine but can be quite abrasive due to free graphite flakes. Your standard speeds and feeds are usually a good match here.

- Ductile Iron (Nodular Iron): This is stronger and tougher due to graphite in a nodular form. It can be more challenging to machine and might require slightly lower speeds or feeds to prevent tool wear.

- Malleable Iron: Similar to ductile iron, it has improved strength and ductility over gray iron and may require adjustments.

If you’re unsure about the exact type of cast iron, it’s always best to err on the side of caution with lower speeds and feeds until you can assess its machinability.

2. Machinery Rigidity and Condition

This is perhaps the most significant factor after the material and tooling.

- Rigid Machines (e.g., production CNC mills, heavy-duty manual mills): These machines can handle higher speeds and more aggressive feeds without excessive vibration (chatter). You can push your tooling harder.

- Less Rigid Machines (e.g., lighter hobby CNCs, older manual mills with wear): You’ll need to be more conservative. Chatter is your enemy; it sounds like a high-pitched squeal or grinding noise. If you hear it, back off on your feed rate or spindle speed, or reduce your depth/width of cut.

A sign of a rigid setup is a quiet, smooth cutting sound. When the machine is well-maintained and solid, you can leverage the full capabilities of your carbide tools.

3. Coolant and Lubrication

Machining cast iron is a dry operation for many. However, if you are using a coolant or a mist system:

- Benefits: Coolant helps to flush chips away, reduce friction, and keep the cutting edge cooler. This can allow for slightly higher cutting speeds and significantly improve tool life.

- Considerations: When using coolant, the risk of thermal shock to the tool is reduced. Ensure your coolant is specifically designed for machining metals and is compatible with cast iron.

According to standards from organizations like the National Institute of Standards and Technology (NIST), proper thermal management is key to optimizing machining processes. While NIST focuses on research, their principles highlight how temperature control impacts material processing and tool wear.

4. Tool Coating and Geometry

Your 5/8 inch carbide end mill might have specific coatings or flute geometries. While we are focusing on standard 2-flute end mills for cast iron:

- Uncoated Carbide: This is common and works well.

- TiN, TiCN, or AlTiN Coatings: These coatings add hardness and reduce friction. An AlTiN coating, for example, is excellent for high-temperature machining and can allow for higher speeds, though some machinists prefer to run uncoated for cast iron as it’s less about extreme heat and more about abrasive wear.

- Number of Flutes: We’ve focused on 2-flute end mills, which are great for cast iron as they offer good chip clearance. 4-flute mills can sometimes chatter more in softer materials or slotting applications, but can be superior for profiling due to their ability to take a higher chip load per flute when not slotting.

Always check the manufacturer’s recommendations for their specific tool model. Some specialized end mills are designed for higher performance in specific materials.

5. Chip Evacuation – The Critical Step

Cast iron produces small, abrasive chips. If these aren’t cleared properly, they can:

- Recut into the workpiece, causing a poor surface finish.

- Pack into the flutes of your end mill, leading to increased cutting forces, overheating, and potential tool breakage.

Strategies for good chip evacuation:

- Use Compressed Air: A blast of air from a nozzle can effectively blow chips out of the way.

- Pecking Cycles (in CNC): For deeper holes or slots, a drilling peck cycle (where the tool retracts periodically) can help clear chips.

- Wider Flutes: Ensure your end mill has generous flute space.

- Appropriate Feed Rate: As discussed, a good chip load ensures the chips are formed and ejected correctly.

A clean flute means a happy tool and a good cut. For inspiration on chip management, look at resources from manufacturing technology experts, such as those found on university engineering department sites, which often detail material removal strategies.

Step-by-Step Process for Setting Up Your Cut

Let’s walk through how to apply this information to your actual milling job.

Step 1: Identify Your Material and End Mill

Confirm you are working with cast iron and that your end mill is indeed 5/8 inch and carbide. Determine if it’s 2 or 4 flutes. For this guide, we’re assuming a 2-flute carbide end mill.

Step 2: Choose Your Operation

Are you roughing out a shape, creating a precise pocket, or cutting a slot? This will guide whether you aim for higher or lower chip loads.

Step 3: Select Initial Speeds and Feeds

Based on the table and the factors above, pick a conservative starting point. For instance, if you’re roughing, you might start with:

- SFM: 300

- RPM: 573 (round to 575 or 600 RPM on most machines)

- Chip Load: 0.004 IPT

- Number of Flutes: 2

- Feed Rate (IPM): 575 RPM × 2 Flutes × 0.004 IPT = 4.6 IPM

Step 4: Set Depth of Cut (DOC) and Width of Cut (WOC)

For this initial test, especially if unsure about your machine’s rigidity, start with a shallow DOC (e.g., 0.100″ to 0.250″) and a partial WOC (e.g., 0.500″ or less of the 0.625″ diameter). Never attempt a full-width slotting cut with aggressive parameters on your first try.

Step 5: Program