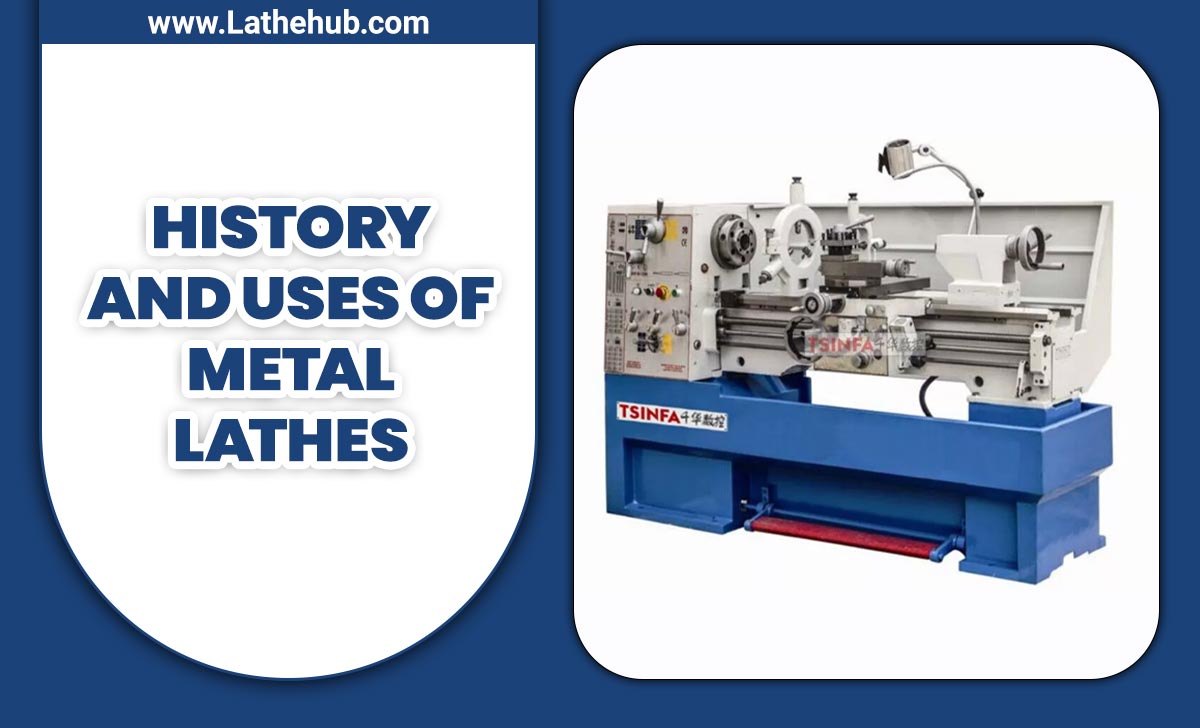

Metal lathes have played a crucial role in shaping the history of modern manufacturing. These tools, also known as engine lathes, were first invented in ancient Egypt and later refined during the Industrial Revolution.

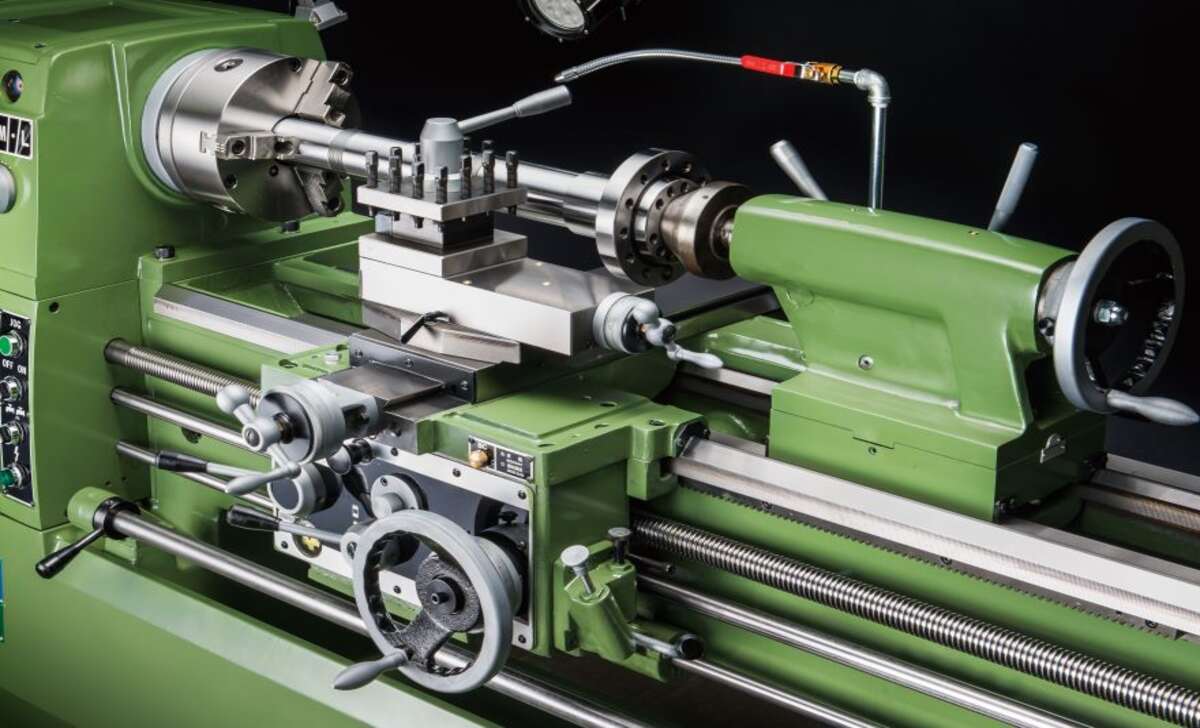

Today, metal lathes are integral to various industries, including automotive, aerospace, and construction. These versatile machines can precisely cut, drill, sand, and shape metal pieces, making them a valuable asset for any metalworking project.

Here, we will delve into the history and evolution of metal lathes and explore their uses in different industries. From their humble beginnings to their current advanced capabilities, metal lathes have been an essential tool for shaping our world. Join us as we deeply dive into metal lathes’ fascinating history and uses.

The History Of Metal Lathes From Ancient Civilizations To The Industrial Revolution

The history of metal lathes is a fascinating journey that spans centuries and civilizations. From the ancient Egyptians and Greeks, who were among the first to develop rudimentary forms of lathes, to the industrial revolution that revolutionized the manufacturing process, these machines have played a pivotal role in shaping human civilization.

In ancient times, artisans used simple bow lathes to shape metal objects. However, during the medieval period, the development of the pedal lathe brought about significant advancements. With the advent of the Industrial Revolution,

lathes became mechanized, enabling mass production and leading to the modern lathe machines that we see today. The evolution of metal lathes reflects the ingenuity and innovation of mankind as we continually strive to improve and refine our tools and techniques.

Historical Overview Of History And Uses Of Metal Lathes

Metal lathes have a rich history that dates back to ancient times. The first evidence of a lathe can be traced back to ancient Egypt, where early craftsmen used a primitive form of a lathe to shape wood into various objects. Over time, the lathe evolved, and during the Industrial Revolution, it became an essential tool in manufacturing. Metal lathes were introduced in the 19th century, allowing for the precision turning of metal materials.

Since then, metal lathes have been handy in various industries, including automotive, aerospace, and machining. They are crucial in creating intricate metal parts, such as screws, bolts, and gears, with high precision and accuracy. The evolution of metal lathes has revolutionized the manufacturing industry and continues to play a significant role in modern-day production processes. Here are some details on the history and uses of metal lathes.

Origins Of Metal Lathes And Their Early Uses

Metal lathes have a long and rich history that dates back centuries. People can trace the origins of metal lathes back to ancient Egypt, where they found them handy for woodworking. Over time, the design and capabilities of metal lathes evolved, and they became essential tools in various industries. During the Industrial Revolution, metal lathes played a crucial role in manufacturing processes, allowing for the mass production of precision parts.

Today, metal lathes are handy in various industries, including automotive, aerospace, and construction. They are handy for tasks such as shaping and cutting metal components with high accuracy and precision. The development and advancements in metal lathe technology have revolutionized the manufacturing industry and continue to play a vital role in modern production processes.

Evolution And Advancements In Metal Lathe Technology

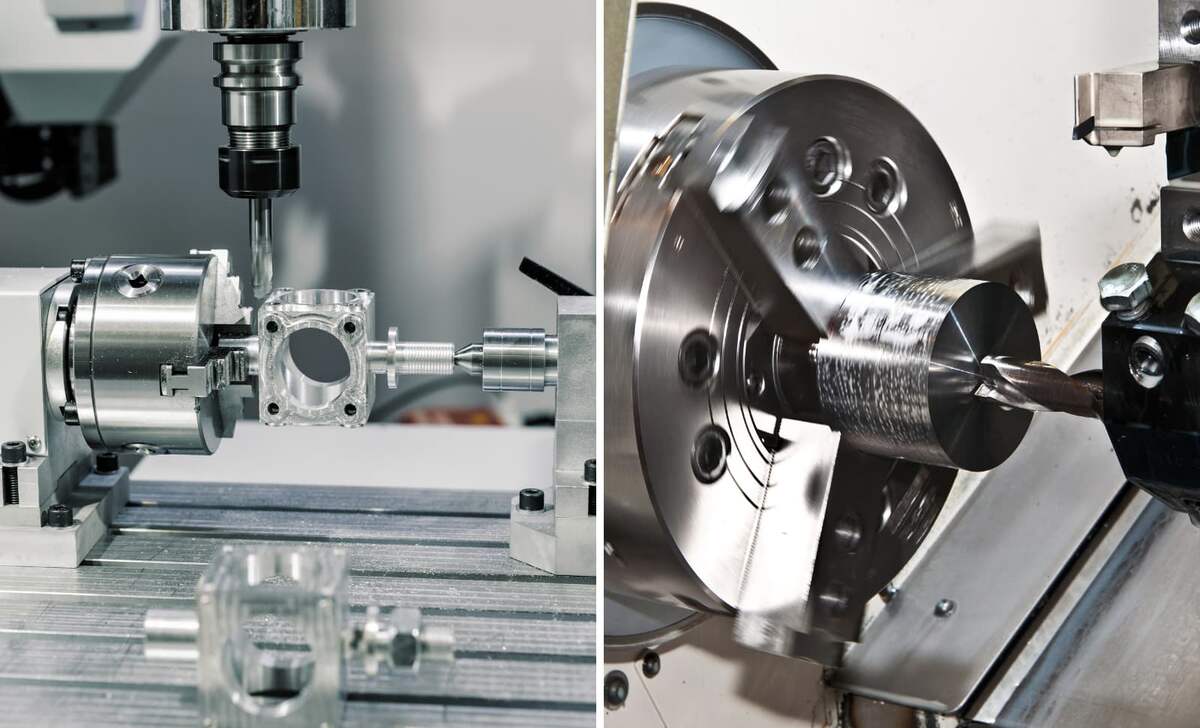

The history of metal lathes dates back centuries, with early versions powered by hand or foot pedals. However, it was during the Industrial Revolution that significant advancements in metal lathe technology came along. They introduced steam power and later electric motors to drive the lathe, increasing its efficiency and productivity. Over time, CNC (Computer Numerical Control) technology was integrated into metal lathes, allowing for precise and automated machining processes.

These advancements have revolutionized manufacturing, aerospace, and automotive industries, where metal lathes are handy for turning, facing, drilling, and threading tasks. Modern metal lathes continue to evolve with the integration of AI (Artificial Intelligence) and IoT (Internet of Things) technologies, enabling even greater precision and efficiency in metalworking processes.

Notable Milestones Or Breakthroughs In The History Of Metal Lathes

Notable milestones and breakthroughs have revolutionized the manufacturing industry in the history of metal lathes. One significant milestone was the invention of the screw-cutting lathe by Henry Maudslay in the early 19th century. This innovation allowed for precise and efficient threading, making it easier to create standardized parts.

Another breakthrough came with the development of automatic lathes in the late 19th century, which reduced the need for manual labor and increased productivity. In the 20th century, computer numerical control (CNC) technology transformed metal lathes, allowing for even greater precision and automation. These advancements in metal lathe technology have played a crucial role in shaping modern manufacturing processes and have paved the way for countless innovations in various industries.

Present-Day Applications Of Metal Lathes

Metal lathes continue to be widely handy in various industries today. These versatile machines are handy for various applications, including metalworking, manufacturing, and machining. Metal lathes are commonly used to shape and finish pieces of metal by rotating them against a cutting tool.

They are crucial for creating precision components, such as automobile parts, aircraft components, and industrial machinery. Metal lathes are also handy in woodworking to turn wooden pieces into intricate shapes and patterns.

Furthermore, metal lathes produce musical instruments, jewelry, and even scientific research. With technological advancements, modern metal lathes offer automated features and computer numerical control (CNC) capabilities, allowing for more efficient and precise machining operations. Overall, metal lathes play a significant role in various industries today, providing the means to create precise and intricate metal parts and components.

Industries And Sectors That Heavily Rely On Metal Lathes

Metal lathes have various present-day applications across various industries and sectors. Manufacturing industries rely heavily on them for precision metal shaping and machining processes. Additionally, metal lathes are commonly handy in automotive production for creating engine components and other metal parts.

They are also indispensable in the aerospace industry for manufacturing aircraft parts with high accuracy. Furthermore, metal lathes are crucial in fabricating tools and equipment in the construction and woodworking sectors. Overall, metal lathes are essential in numerous industries where precise metal shaping and machining are required.

Examples Of Specific Uses And Projects Where Metal Lathes Are Essential

In the present day, metal lathes find many applications across various industries. They are essential in manufacturing precision components for the aerospace and automotive industries. Metal lathes are also handy to create intricate jewelry designs and craft musical instruments. Additionally, they play a vital role in producing screws, bolts, and other fasteners. Metal lathes are indispensable in modern manufacturing processes, from creating custom parts to mass production.

Benefits And Advantages Of Using Metal Lathes In Modern Applications

Metal lathes have become indispensable tools in modern applications across various industries. Their benefits and advantages are numerous. With precise cutting and shaping capabilities, metal lathes allow for the creation of complex and intricate parts. They are essential in the automotive, aerospace, and manufacturing industries, where precision and efficiency are paramount.

Metal lathes enable the production of high-quality components, contributing to improved product performance and durability. Additionally, they offer versatility, allowing for machining different materials like steel, aluminum, and brass. In summary, metal lathes are crucial in present-day applications, revolutionizing manufacturing and driving innovation.

Prospects And Advancements In Metal Lathe Technology

The prospects for metal lathe technology are undoubtedly exciting. With continuous advancements in design and capabilities, there is immense potential for developing more efficient and versatile metal lathes. One area of focus is the integration of automation and artificial intelligence, which could revolutionize the way metal lathes operate.

Imagine a machine that can self-adjust, detect errors, and optimize cutting processes, all while minimizing human intervention. Additionally, emerging trends such as nanotechnology and additive manufacturing could influence the future of metal lathes by enabling the production of intricate and precise components.

As industries evolve and demand for complex parts increases, metal lathes are expected to play a crucial role in the aerospace, automotive, and healthcare sectors. It is fascinating to speculate about how these advancements will shape the future of metal lathe technology and the industries it serves.

Tips For Choosing The Right Metal Lathe For Your Needs

Choosing the right metal lathe for your needs is crucial to ensure efficient and accurate machining. Considering these factors, you can find a metal lathe that meets your specific needs and helps you achieve high-quality machining results. Here are some tips to help you make the best decision:

- Consider The Size And Capacity: Determine the maximum diameter and length of the workpieces you will be working with, and choose a lathe that can accommodate those dimensions.

2. Think About Spindle Speed: Different materials require different spindle speeds for optimal cutting. Look for a lathe with variable speed control or multiple speed options to handle a variety of materials.

3. Evaluate Horsepower And Torque: Higher horsepower and torque ratings will allow you to machine tougher materials and quickly remove material.

4. Check For Accuracy And Precision: Look for lathes with features like digital readouts, quick-change tooling systems, and adjustable gibs that ensure precise cuts and consistent results.

5. Consider Your Budget: Set a budget and look for a lathe that offers the best features within your price range. Consider additional expenses such as tooling, accessories, and maintenance costs.

Safety Precautions And Best Practices When Using A Metal Lathe

When using a metal lathe, it is vital to prioritize safety and follow best practices to prevent accidents and injuries. Following these safety precautions and adhering to best practices can ensure a safer and more productive experience when using a metal lathe. Here are some key safety precautions to keep in mind:

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and ear protection to protect yourself from potential hazards.

- Familiarize yourself with the machine’s operating instructions and ensure you properly understand how to use and adjust its various components.

- Keep your work area clean and organized, removing any clutter or debris that could interfere with the lathe’s operation.

- Securely fasten your workpiece in the lathe using appropriate clamps or fixtures to prevent it from becoming loose or spinning out of control during operation.

- Always use the correct cutting tools for the specific material you are working with, ensuring they are sharp and properly secured in the lathe’s toolpost.

- Take regular breaks to rest and avoid fatigue, as tiredness can increase the risk of accidents.

Maintenance And Care Of Metal Lathes To Ensure Longevity And Optimal Performance

Proper maintenance and care of metal lathes are essential to ensure their longevity and optimal performance. By following these maintenance tips, you can prolong the lifespan of your metal lathe and ensure that it continues to deliver precise and efficient results for years to come. Here are some key tips to keep in mind:

- Regularly Clean The Lathe: Dust, metal shavings, and other debris can accumulate on the lathe, affecting its performance. Clean the lathe regularly using compressed air or a soft brush to remove any build-up.

- Lubricate Moving Parts: Metal lathes have various moving parts that require lubrication to reduce friction and prevent wear. Apply lubricating oil or grease to these parts according to the manufacturer’s recommendations.

- Check And Replace worn-out parts: Certain lathe parts may become worn or damaged. Regularly inspect the lathe for any signs of wear, such as excessive noise or vibration, and promptly replace any worn-out parts.

- Calibrate The Lathe: To ensure accurate results, it is important to calibrate the lathe periodically. Use precision measuring tools to check for any dimension deviations and make necessary adjustments.

- Store The Lathe Properly: When not in use, store the lathe in a clean and dry environment, away from moisture and extreme temperatures. Cover it with a protective cover to prevent dust accumulation and potential damage.

Conclusion

Metal lathes have played a significant role throughout history, shaping our world today. From their inception in ancient times to their modern-day applications, these machines have produced various metal objects and components. The versatility and precision of metal lathes make them essential tools in manufacturing, automotive, and aerospace industries.

By understanding the history and uses of metal lathes, we can appreciate the advancements in machining technology and how it has transformed our society. To delve deeper into the fascinating world of metal lathes, explore our blog on the history and uses of these remarkable machines.

FAQs

1.What metal is used in lathe machines?

Ans: Lathe machines commonly come from cast iron, a durable and strong metal well-suited for the rigors of machining operations. Cast iron offers excellent stability and vibration-dampening properties, which are crucial for achieving precise and accurate cuts in metalworking.

2.What is the use of lathe in civil engineering?

Ans: A lathe is used in civil engineering for various purposes, such as machining and shaping materials like wood, metal, and plastic. It is commonly used for turning operations, where the material is rotated against a cutting tool to create cylindrical shapes, such as columns or pillars.

3.What bit do you use on a metal lathe?

Ans: A carbide insert tool is The most common bit on a metal lathe. Carbide bits are known for their durability and ability to withstand high speeds and temperatures. They can cut through various types of metal precisely and can be easily replaced when worn out.

4.Are lathes still used?

Ans: Yes, lathes are still widely used in various industries such as woodworking, metalworking, and manufacturing. They are essential machines for shaping and cutting materials, creating cylindrical shapes, and producing intricate designs.

5.Who discovered the lathe?

Ans: The ancient Egyptians are often credited with the discovery of the lathe, as evidence of lathe-like tools have been found in their archaeological remains. However, the ancient Greeks and Romans further developed the lathe as we know it today with a movable cutting tool.