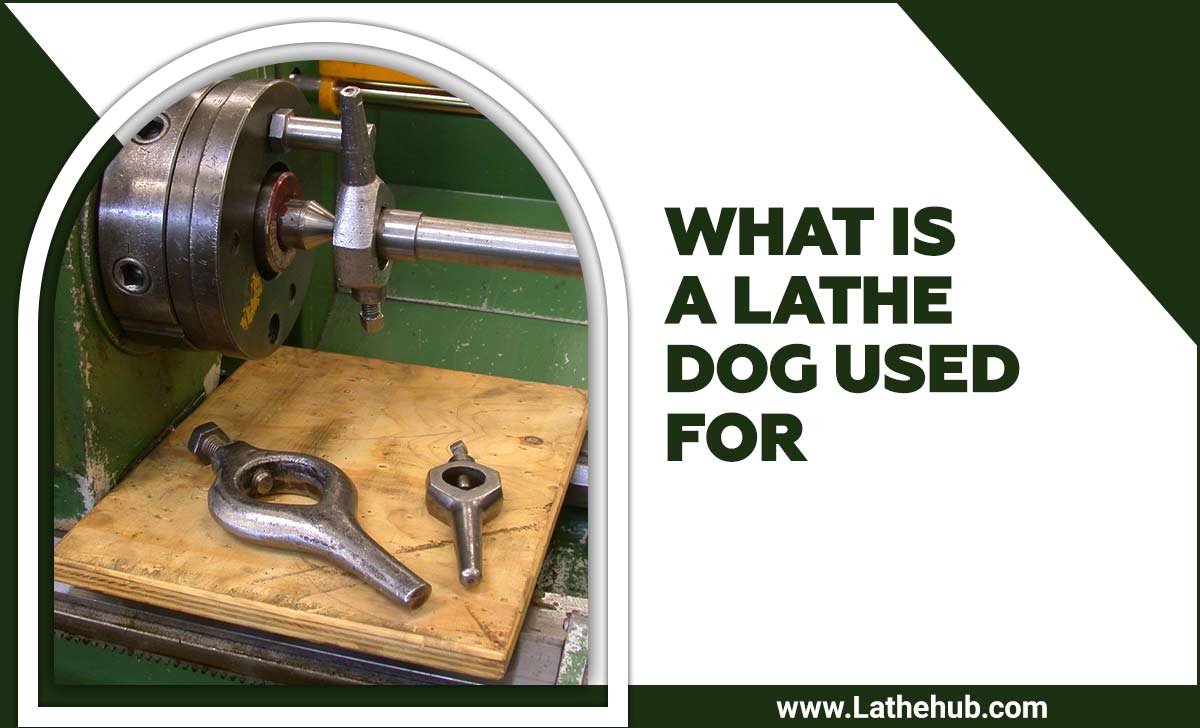

A lathe dog, also known as a lathe carrier or a dog driver, is vital for turning materials on a lathe machine. This mechanical device holds and rotates the workpiece securely while machining.

The lathe dog is an essential component in the metalworking industry, and its use has been traced back to ancient civilizations such as the Egyptians and the Greeks. Over the years, the design and functionality of lathe dogs have evolved, and they are now available in various sizes and shapes to accommodate different workpieces.

Here, we will delve deeper into what a lathe dog is handy for and explore its uses, types, and benefits in the metalworking industry. So, let us embark on a journey to uncover the intricacies of this versatile tool and its significance in the manufacturing world.

Types Of Lathe Dogs

A lathe dog, also known as a lathe carrier or a lathe driver, is a device handy in metalworking to hold and rotate a workpiece on a lathe machine. It is typically handy when the workpiece does not have a central hole or when using a chuck or other holding devices is impossible. There are several types of lathe dogs available, including:

- Bent tail lathe dogs: These have a curved tail that fits over the workpiece and secures it.

- Straight-tail lathe dogs: These have straight tails that fit into workpiece slots for better grip.

- Spring lathe dogs: These have a spring-loaded mechanism that allows for easy installation and removal of the workpiece.

- Faceplate dogs: These are designed to attach to the lathe’s faceplate and hold the workpiece securely.

Each type of lathe dog has advantages and is suited for different workpieces. Choosing the right type of lathe dog is important based on the size and shape of your workpiece to ensure safe and efficient machining.

History Of Lathe Dogs

Regarding using a lathe dog, proper maintenance and care are essential for optimal performance and longevity. By following these simple maintenance and care practices, you can extend the lifespan of your lathe dog and ensure its reliable performance whenever you need it. Here are some tips to keep your lathe dog in great shape:

- Lathe dogs have been handy in various forms of lathes for centuries.

- They originally came from wood and later transitioned to metal materials.

- The design and functionality of lathe dogs have evolved to meet the needs of different machining processes.

- Modern lathe dogs are available in various sizes and types to accommodate different workpieces and lathe setups.

Important Features Of Lathe Dogs

Lathe dogs are popular for their rigid construction and maximum strength, ensuring the secure clamping of workpieces during the rotary motion of the machine. The headstock end of a lathe dog typically features a clamp or jaw mechanism, allowing for the precise and stable attachment of the workpiece. Some lathe dogs have specific designs with a tapered shank, enabling them to be mounted directly into the lathe spindle.

Others may have a clamping arrangement, allowing them to be attached to a faceplate or chuck. Precision machining lathe dogs often feature hardened and ground clamping surfaces, enhancing durability and minimizing wear. Additionally, lathe dogs may incorporate unique features such as self-centring mechanisms or quick-release clamping, providing the machinist with increased efficiency and control.

What Is A Lathe Dog Used For: Everything You Need To Know

Machinists involved in turning and machining round workpieces require lathe dogs as essential accessories, with extensive applications in metalworking, woodworking, and other machining industries. Their primary function is to grip the workpiece, allowing the lathe to rotate for machining.

Understanding the proper selection and use of lathe dogs is crucial for efficient and safe machining operations, contributing significantly to the turning process’s precision, stability, and repeatability. The rotary motion of the machine, rigid construction, and maximum strength of lathe dogs ensure secure clamping. At the same time, accessories like faceplates and jaw chucks offer alternate options for clamping round jobs. Here are some details on what a lathe dog is handy for.

Choosing The Right Lathe Dog For Your Project

When selecting the appropriate lathe dog, several factors come into play. One must carefully consider the workpiece’s size, shape, and material to ensure a secure grip during machining. Matching the lathe dog’s clamping capacity with the workpiece diameter is crucial to maintaining stability and precision.

Factors such as machining forces required repeatability and specific machining operations influence the choice of the right lathe dog. Furthermore, the compatibility of the lathe dog with the lathe machine, tooling, and work-holding accessories is essential for successful and efficient machining processes.

How To Set Up A Lathe Dog

Clamp the workpiece between the lathe dog and the faceplate or chuck when setting up a lathe dog. It’s crucial to ensure proper clamping to enable smooth rotation without slippage. Positioning the lathe dog securely prevents jamming or alternate groove cutting while aligning the tailstock and headstock of the lathe, which is necessary for accurate machining.

Additionally, alignment with the workpiece taper or collet is essential for precise machining, ensuring the rotary motion of the machine is consistent and friction-free. The rigid construction of the lathe carrier ensures maximum strength and repeatability in machining, making it a valuable accessory for machinists working on round jobs.

Importance Of Lathe Dogs In Metalworking

Lathe dogs play a vital role in securing the workpiece to the spindle or faceplate, enabling the rotary motion of the machine for metalworking processes. They ensure that the workpiece rotates with the spindle, maintaining friction between the workpiece and the cutting tool, thus ensuring accurate turning and machining.

Additionally, the rigid construction of lathe dogs enhances safety by preventing the workpiece from coming loose during machining, which is crucial for precision and maximum strength in metalworking. Furthermore, lathe dogs are essential for threading, drilling, reaming, and other metalworking operations, contributing significantly to the efficiency and safety of the machining process.

Maintenance And Care For Lathe Dogs

Proper maintenance and care are essential for optimal performance and longevity when using a lathe dog. By following these simple maintenance and care practices, you can extend the lifespan of your lathe dog and ensure its reliable performance whenever you need it. Here are some tips to keep your lathe dog in great shape:

- Regular Cleaning: After each use, clean the lathe dog thoroughly to remove any debris or residue. Use a brush or cloth to wipe away any dirt or dust, and pay special attention to the teeth and gripping surfaces.

- Lubrication: Apply a small amount of lubricant, such as oil or grease, to the moving parts of the lathe dog. This will help reduce friction and ensure smooth operation.

- Storage: When not in use, store your lathe dog in a dry and clean environment to prevent rusting or corrosion. Consider using a protective cover or case to protect it from dust and other contaminants.

- Regular Inspections: Inspect your lathe dog for any wear or damage. Check the teeth for sharpness and make sure they are securely attached. If you notice any issues, address them promptly to avoid further damage or potential accidents.

Safety Measures When Using a Lathe Dog

When using a lathe dog, it is important to follow certain safety measures to ensure your safety and the proper functioning of the lathe. Following these safety measures can minimize the risk of accidents or injuries while using a lathe dog. Here are some key safety measures to keep in mind:

- Always wear appropriate personal protective equipment, such as safety glasses and gloves, to protect yourself from flying debris and sharp edges.

- Ensure you securely attach the lathe dog to the workpiece before starting the lathe.

- Clear your hands and other body parts of the rotating workpiece and lathe dog.

- Avoid loose-fitting clothing or jewellery caught in the lathe’s moving parts.

- Regularly inspect the lathe dog for any signs of wear or damage and replace it if necessary.

What Are the Alternatives to Lathe Dogs?

While lathe dogs are widely handy and highly effective, alternatives are available depending on the machining requirements. Some alternatives to lathe dogs include collets, faceplates, and centres. Collets provide a more secure and concentric clamping method, particularly for workpieces with a smaller diameter. They offer better precision and repeatability, making them ideal for machining operations that require high accuracy.

Faceplates, however, are handy to hold large or irregularly shaped workpieces. They provide a flat mounting surface for securing the workpiece, allowing for easy rotation and machining. Both live and dead centres are commonly handy to support long workpieces during turning operations. They provide stability and help to minimize workpiece deflection, resulting in better precision.

Conclusion

A lathe dog is an indispensable tool in metalworking. It is primarily used to hold and rotate the workpiece on a lathe machine, allowing for precision and efficiency in shaping and finishing. Whether a professional or a hobbyist, having the right lathe dog for your project is crucial. Consider material, size, and design factors when choosing the appropriate lathe dog.

Regular maintenance and proper care will also ensure its longevity and optimal performance. Remember to prioritize safety by following recommended guidelines and precautions when working with a lathe dog. While alternatives may be available, a lathe dog remains a reliable and essential tool in metalworking. We’ve discussed what a lathe dog is used for.

Frequently Asked Questions

1.What Is The Purpose Of Using A Lathe Dog?

Ans: A lathe dog serves the purpose of securely holding a workpiece in place during lathe turning. It features pointed screws that grip the workpiece, preventing any movement and ensuring accuracy and consistency in the final product. Different types of lathe dogs, including standard and bent tail versions, are available for various applications.

2.What Is A Lathe Dog Mainly Used With?

Ans: A lathe dog is handy with a lathe machine to rotate and secure long, thin workpieces. It clamps onto the workpiece and allows for controlled rotation at different speeds. Lathe dogs come in various sizes and shapes based on the workpiece type.

3.What Is A Dog Plate For On A Lathe?

Ans: A dog plate serves the purpose of mounting a workpiece onto a lathe. With multiple holes for securing the workpiece, it rotates along with the lathe spindle, enabling precise turning. Available in various sizes and shapes, it is an essential tool for lathe operators.

4.What Is Another Name For A Lathe Dog?

Ans: Another name for a lathe dog is a lathe carrier or a workpiece driver. It is an essential tool to hold and rotate the workpiece in a lathe machine. Lathe dogs come in various sizes and shapes to accommodate different workpieces, improving accuracy and productivity during turning operations.

5.What Is A Lathe Dog Good For?

Ans: Lathe dogs are essential tools handy on lathes to hold and rotate workpieces. They ensure precision and accuracy in turning operations, especially for irregular or uneven surfaces. Available in various sizes and shapes, lathe dogs accommodate different lathes and workpieces.