Precision and accuracy are essential aspects of any woodworking project, and the ability to cut a lathe taper is a skill every craftsman must possess. This technique allows for the gradual reduction of diameter in a cylindrical workpiece, creating a smooth and tapered shape.

While it may seem like a daunting task to achieve, with the right tools and techniques, anyone can master this technique. Here, we will guide you through the step-by-step process of cutting a taper on a lathe, providing you with the necessary knowledge and skills to create perfectly tapered pieces for your woodworking projects. Whether you are a beginner or an experienced woodworker, understanding how to cut a taper on a lathe will enhance your precision and elevate the quality of your work.

Selecting The Right Tools For Taper Turning

Taper turning and selecting the right tools is crucial for precise and accurate results. A taper attachment is a device attached to the lathe carriage and top slide, allowing the cutting tool to move at an angle to the lathe axis. The cutting tool, also known as the tool bit, is the primary tool for cutting the taper. Depending on the desired taper shape and machining material, it can be a form tool, boring tool, or custom-ground tool bit. Here are the essential tools you will need:

- Taper attachment

- Cutting tool

- Lathe machine

8 Steps On How To Cut A Taper On A Lathe

One essential skill that every machinist must master is the ability to cut a taper on a lathe. A taper is a gradual reduction in diameter from one end of a workpiece to the other. This technique is commonly handy in automotive, aerospace, and manufacturing industries to create conical shapes or ensure proper fit between components.

Cutting a taper on a lathe requires careful planning, precise measurements, and a steady hand. To begin the process, the machinist must thoroughly understand the taper specifications required. This includes the desired taper angle, length, and diameter at both ends. With this information, the machinist can set up the lathe accordingly, ensuring the workpiece is securely mounted and aligned properly.

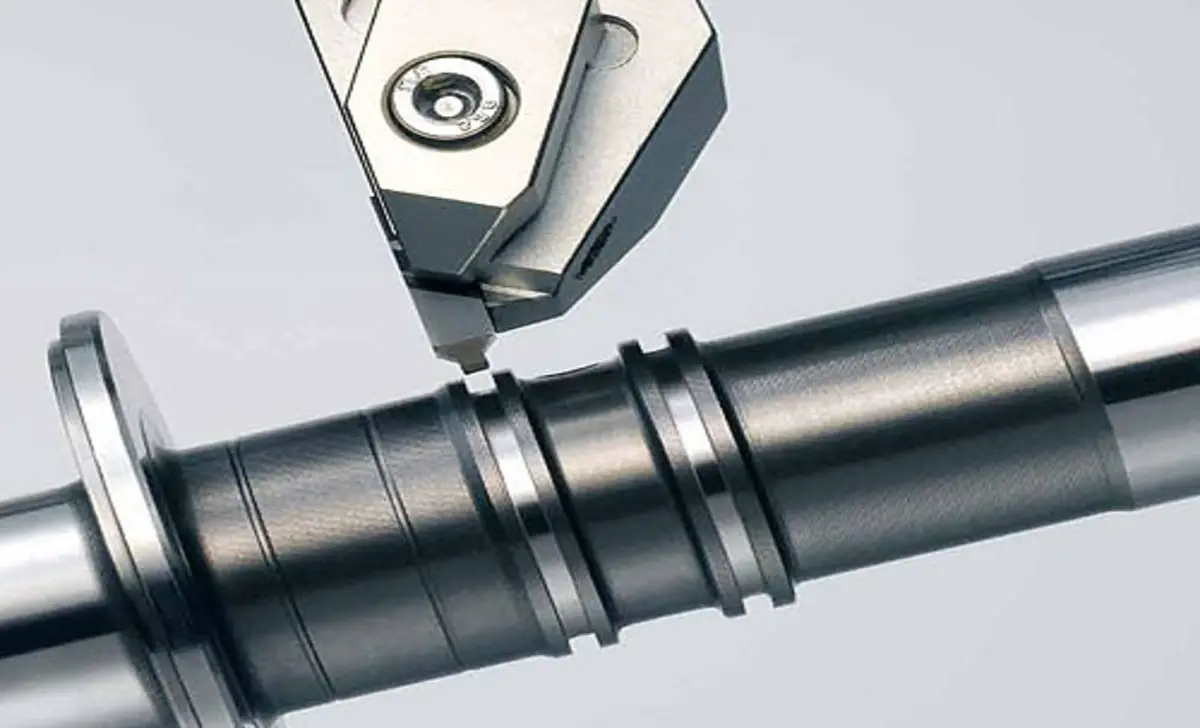

1.Set Up The Lathe

Setting up the lathe to cut a taper involves a few important steps. First, ensure that the lathe is properly aligned and leveled. Next, select the appropriate cutting tool and mount it securely on the tool post. Adjust the lathe’s speed and feed settings according to the material and desired taper dimensions.

Position the tailstock and set the desired taper angle using the compound rest. Finally, carefully engage the lathe and gradually feed the cutting tool into the workpiece, making necessary adjustments. Always prioritize safety and follow proper lathe operating procedures for accurate and smooth taper cuts.

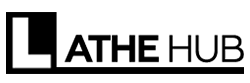

2.Select The Appropriate Cutting Tool

The cutting tool bit for taper turning has a specific angle, ensuring the right angles of the cutting edge. It should match the desired taper angle and be positioned at the starting point of the taper cut. Additionally, the depth of the cut is determined by the length of the taper. These factors significantly affect the precision and quality of the tapered workpiece.

3.Calculate The Taper Angle

Measuring the workpiece length is essential for taper angle calculation. The tangent of the desired angle is used to determine the taper angle. The guide bar is also crucial for providing the required taper angle when taper-turning. A dial indicator calculates the taper angle accurately to ensure precision. Moreover, the taper attachment method enables taper turning of various taper methods, ensuring versatility and efficiency in cylindrical workpiece shaping.

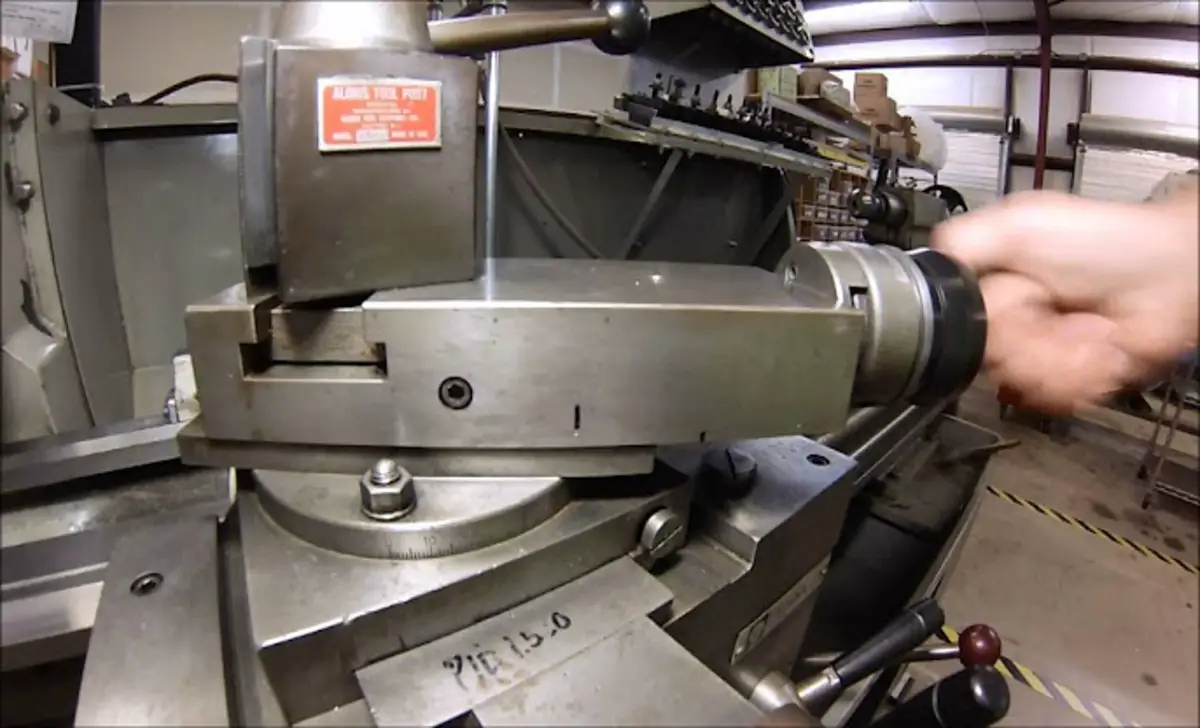

4.Set The Compound Rest

Adjusting the compound slide allows for taper turning on internal workpiece surfaces, making it suitable for any taper size. This method is particularly useful for turning tapered workpieces and cutting pipe threads with the lathe machine. Additionally, it facilitates the cutting of tapered threads on the lathe, offering a versatile approach to achieving the desired taper angle and enhancing the precision of the turning process.

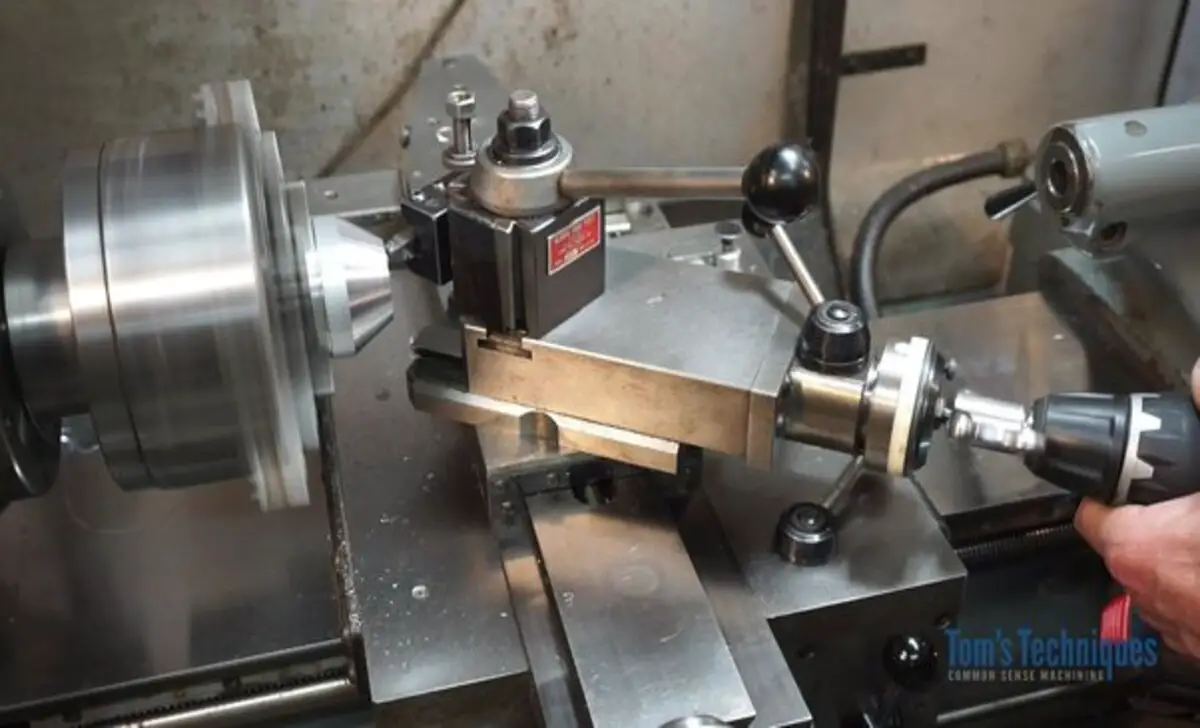

5.Position The Tool

Position the cutting tool bit at the lathe machine’s top slide. Set the tool bit at the far end of the workpiece for taper turning, aligning it with the axis of the workpiece. Ensure the tapered piece is positioned with the right end of the tool bit and at the required angle for taper turning. This step is crucial for achieving precision tapers without repeating any information already covered in the blog.

6.Begin The Cut

Engaging the lathe spindle initiates the taper-turning process while adjusting the lathe carriage kicks off the gradual reduction of the workpiece. Moving the compound slide starts the taper-turning cut, ensuring precision through the taper-turning attachment method. Commence the taper turning cut at the right end of the workpiece for optimal results.

7.Monitor The Cut

Check the taper angle to ensure precision in taper turning. Monitor the feed rate and depth of cut throughout the process. Adjust the lathe’s change gears to control the feed rate. Verify that the lathe axis aligns with the center axis of the taper turning cut. The dead center is crucial for maintaining the correct taper-turning process.

8.Troubleshooting And Common Mistakes

One of the most common issues is improper tool alignment. If you do not position the tool correctly, it can result in an uneven taper or even cause the tool to dig into the material. Another mistake is using the wrong cutting speed or feed rate. This can lead to poor surface finish or even tool breakage.

Insufficient coolant or improper chip evacuation can cause heat buildup and affect the cutting performance. Regularly checking and maintaining the lathe is important, ensuring you properly tighten and adjust all components. By being mindful of these common mistakes and troubleshooting any issues, you can achieve accurate and smooth tapers on a lathe.

Troubleshooting And Common Mistakes To Avoid

one essential skill to master is the ability to cut a taper. A taper refers to a gradual decrease or increase in diameter along the length of a cylindrical object. This technique is commonly handy in various industries, such as manufacturing, engineering, and woodworking, to create precision components or decorative items. Here are Troubleshooting and Common Mistakes to Avoid:

- Check for loose connections or faulty wiring

- Please verify that you properly power on all equipment and devices

- Ensure that software and drivers are up to date

- Double-check settings and configurations for accuracy

- Avoid excessive multitasking or running too many programs simultaneously

- Regularly clean and maintain equipment to prevent overheating or damage

- Back up important data regularly to avoid data loss

- Be cautious when installing new software or updates, as they may conflict with existing programs

Advanced Taper Turning Techniques

Once all preparations are complete, the cutting process can begin. Maintaining a steady feed rate and consistent cutting depth throughout the operation is important. You can achieve this by carefully adjusting the lathe’s speed and the position of the cutting tool. Here are Advanced Taper Turning Techniques:

- Use a taper-turning attachment or a compound rest to achieve precise taper angles

- Set the desired taper angle on the taper turning attachment or adjust the compound rest accordingly

- Secure the workpiece firmly in the lathe and ensure proper alignment

- Start the lathe at a slow speed and gradually increase it while feeding the cutting tool towards the workpiece

- Use a sharp cutting tool and maintain a consistent cutting speed to achieve smooth and accurate taper turning

- Regularly check the taper angle using measuring tools to ensure it matches the desired specifications

Tips And Tricks For Achieving Precision Tapers

When cutting a lathe taper, it is important to understand the meticulous steps involved in achieving precise and accurate results. A taper gradually decreases in diameter, usually towards one end of a cylindrical workpiece. Companies in various industries, such as manufacturing, engineering, and woodworking, commonly find this technique handy for creating tapered components for specific applications. Here are Tips and Tricks for Achieving Precision Tapers:

- Use a sharp, high-quality razor or trimmer for precise tapers.

- Start by outlining the desired taper shape using a comb or brush.

- Gradually blend the hair from longer to shorter, ensuring a seamless transition.

- Pay attention to the angle and direction of your cuts to achieve the desired taper effect.

- Take your time and make small, controlled movements to avoid making mistakes.

- Use a mirror or ask for a second opinion to ensure evenness and symmetry.

- Regularly maintain and clean your tools to ensure they perform optimally.

Conclusion

Learning how to cut a taper on a lathe is a valuable skill for any woodworker or machinist. By following the step-by-step guide on how to cut a taper on a Lathe, you can achieve precise and accurate tapers for your projects. Remember to select the right tools, calculate the taper angle, and properly set up the lathe before beginning the cut.

Monitor the cut closely and adjust as needed to ensure a smooth and even taper. Additionally, avoid common mistakes and consider advanced taper-turning techniques for more complex projects. With practice and attention to detail, you can master the art of taper turning and create professional-quality workpieces.

Frequently Asked Questions

1.What Is Taper Turning?

Ans: Taper turning is the process of gradually decreasing the diameter of a workpiece on a lathe. You achieve this by using a specific angle tool and controlling its movement along the length of the workpiece. Taper turning can be done manually or with CNC machines, and it is commonly handy in manufacturing shafts, spindles, and pins.

2.How Are Tapers Cut On A Lathe?

Ans: You can cut taps on a lathe using a taper attachment or offsetting the tailstock. The angle of the taper is determined by the tool degree and the distance between centers. Positioning the tool correctly and gradually moving it along the workpiece helps achieve the desired taper.

3.What Cutting Tool Is Used For Taper Turning?

Ans: The lathe tool bit is the cutting tool used for taper turning. It can be ground to the desired angle of the taper. Adjust the cutting speed and feed rate based on the workpiece diameter and taper angle. Coolant or lubrication is essential to prevent overheating and damage to the cutting tool.

4.What Is The Process Of Taper Turning On A Lathe?

Ans: Taper turning on a lathe involves gradually reducing the diameter of a workpiece from one end to the other. It requires adjusting the cutting tool angle and moving it along the length of the workpiece. Precision measurements and adjustments are crucial for achieving an even taper and avoiding damage to the workpiece.

5.What Causes Taper On A Lathe?

Ans: Taper on a lathe can occur due to factors like misalignment of the tailstock or headstock, worn-out bearings, and improper tool selection. Regular maintenance and proper alignment can help minimize taper in lathe operations.