Metal lathes are powerful machine tools that shape cylindrical metal stock. They are an essential tool in any machine shop or metalworking facility, allowing users to perform a wide range of cutting, sanding, knurling, and drilling operations.

Metal lathes are versatile machines that can create precise and intricate metal components, making them invaluable to hobbyists and professionals. We will walk you through using a metal lathe, from understanding the basic components to performing advanced turning operations. Whether new to machining or looking to expand your skills, it will give you the knowledge and confidence to use a metal lathe effectively and safely.

What Is A Metal Lathe

A metal lathe, also known as a lathe machine or a machine tool, is a device used to shape cylindrical metal stock. It consists of a rotating workpiece, usually secured by a jaw chuck or between centers, and a cutting tool that trims and shapes the workpiece as it rotates.

Metal lathes come in various types, including engine lathes, turret lathes, and special-purpose lathes, each designed for specific applications. These machines play a crucial role in the manufacturing industry, enabling the production of precise and intricate metal components.

Safety Precautions And Equipment

Safety should always be the top priority when operating a metal lathe. Following proper safety precautions and using the appropriate protective equipment to prevent accidents and injuries is essential. Here are some key safety guidelines to keep in mind:

- Always wear protective gear (safety goggles, gloves, smock)

- Familiarize yourself with the emergency stop button on the lathe

- Regularly inspect for loose or damaged parts

- Use cutting oil or lubricants as needed and ensure proper ventilation

- Keep the work area clean and organized

How To Use A Metal Lathe In 5 Steps

Now that we understand the basic concept of metal lathes let’s look at how to use a metal lathe effectively. In the following sections, we will outline the key steps in setting up and operating a metal lathe, providing you with a solid foundation. Following these 5 steps, you can easily perform basic turning operations and create precise metal components.

Step 1:Setting Up The Metal Lathe

Setting up a metal lathe is an important first step in using this powerful tool. Before you begin, ensure you have a clear workspace free from clutter or hazards. Place the lathe on a sturdy workbench or stand, ensuring it is securely bolted to prevent movement during operation.

Next, attach the necessary accessories and tools to the lathe, such as the chuck and cutting tools. It is important to carefully follow the manufacturer’s instructions when setting up the lathe, as each model may have specific requirements. Once everything is properly set up, double-check all connections and ensure all safety measures are in place before turning on the machine.

Step 2:Selecting And Install The Cutting Tool

Selecting and installing the cutting tool is crucial in using a metal lathe. The cutting tool removes material from the workpiece, so choosing the right tool for the job is important. When selecting a cutting tool, consider the machined material type, the desired finish, and the cutting speed.

Once you have chosen the appropriate cutting tool, carefully install it into the lathe’s tool holder. Ensure that it is securely fastened and aligned properly with the workpiece. Selecting and installing the cutting tool properly will help ensure accurate and efficient machining operations on your metal lathe.

Step 3:Adjusting The Speed And Feed Rate

Adjusting the speed and feed rate is crucial in using a metal lathe effectively. The speed at which the lathe rotates can significantly impact the quality of your work. Generally, higher speeds are handy for smaller-diameter workpieces or smaller cutting tools, while lower speeds are suitable for larger-diameter workpieces or when using larger cutting tools.

It is important to consult the manufacturer’s recommendations for the specific lathe you are using to determine the appropriate speed range. Adjusting the feed rate also controls how quickly the cutting tool moves along the workpiece. A higher feed rate can result in faster material removal but may also increase the risk of chatter or tool wear. On the other hand, a lower feed rate allows for more control and precision but may take longer to complete a cut.

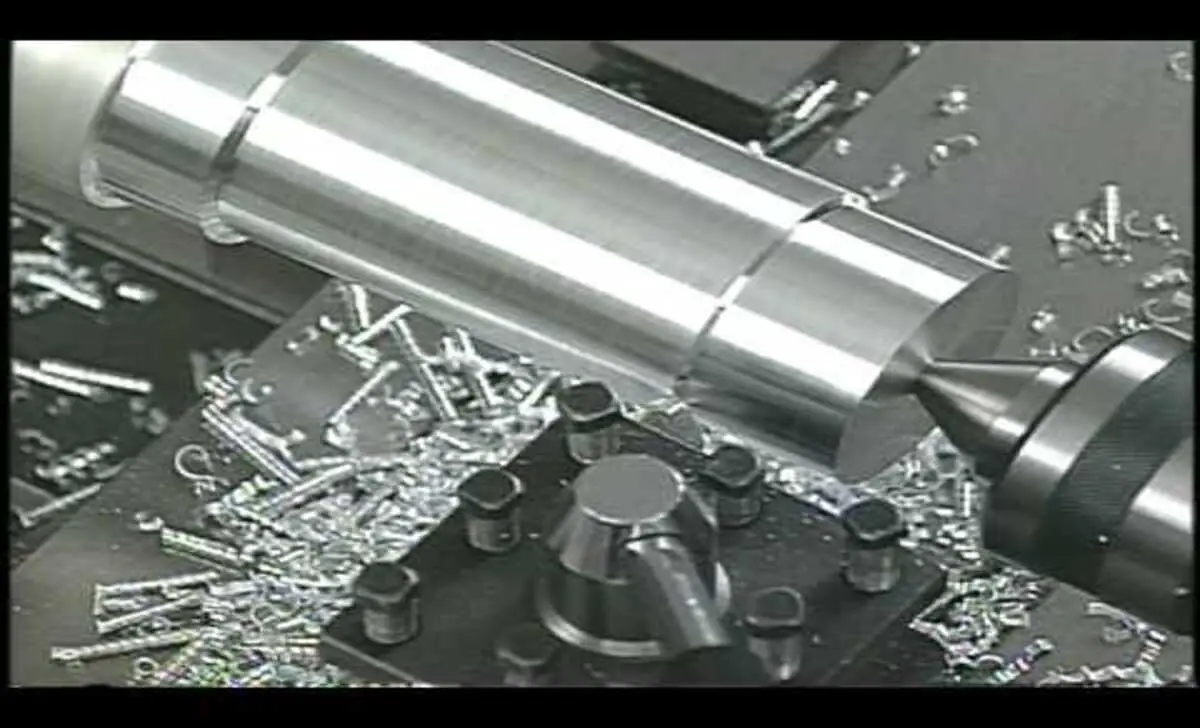

Step 4:Performing Basic Turning Operations

Performing basic turning operations is an essential skill when using a metal lathe. Turning removes material from a workpiece to create a desired shape or size. To perform turning operations on a metal lathe, follow these steps:

- Secure The Workpiece: Use a chuck or collet to hold the workpiece on the lathe spindle securely.

- Set The Cutting Tool: Choose an appropriate tool for the desired operation and secure it in the holder. Adjust the tool height and angle according to the specifications of your project.

- Set The Speed And Feed Rate: Determine the optimal speed and feed rate for your specific material and cutting tool. Consult the lathe’s operating manual or refer to machining guidelines for guidance.

- Position The Tool: Near the workpiece, ensuring it is properly aligned and ready to contact the material.

- Start The Lathe: Turn on the lathe motor and gradually increase the speed to your desired setting. Take caution when starting up, as excessive speed can cause instability or damage the machine and the workpiece.

- Engage The Cutting Tool: Slowly move it towards the workpiece, ensuring it contacts at a controlled pace. Apply consistent pressure as needed, allowing the tool to remove material gradually.

- Monitor Progress: Pay close attention to the machining process, checking for any signs of excessive heat, vibration, or irregularities in the surface finish. Make adjustments as necessary to maintain optimal cutting conditions.

- Complete Turning Operation: Continue moving the cutting tool along your desired path until you have achieved your desired dimensions or shape. Take note of any finishing passes needed for surface quality improvement.

Step 5:Finishing And Polishing The Workpiece

Finishing and polishing the workpiece is crucial in using a metal lathe. After the desired shape has been achieved, it is important to ensure that the surface of the workpiece is smooth and free from any imperfections. Various tools, such as sandpaper, emery cloth, or a polishing wheel, can be handy. You will choose the tool based on the material being worked on and the desired finish.

It is important to start with a coarse grit and gradually move to finer grits to achieve a smooth surface. Additionally, cutting fluids or lubricants can help improve the finish and prevent overheating of the workpiece. Taking the time to finish and polish the workpiece properly will result in a professional-looking final product.

Troubleshooting Common Issues

Using a metal lathe can be valuable for any hobbyist or professional machinist. However, like any tool, common issues can arise during use. Here are some tips for troubleshooting common issues with a metal lathe:

- Poor Surface Finish: If you are experiencing a poor surface finish on your workpiece, it could be due to improper cutting speed or feed rate. Adjusting these settings can help improve the finish. Additionally, using the correct cutting tool and ensuring it is sharp can make a difference.

- Chatter Or Vibration: Chatter or vibration during lathe operation can be caused by several factors, including improper tool alignment, excessive tool overhang, or worn-out bearings. Check these areas and make necessary adjustments or replacements to reduce chatter and vibration.

- Difficulty Holding Workpiece: If you are having trouble holding your workpiece securely in the lathe chuck or collet, ensure that you have properly tightened the jaws or collet to provide a secure grip.

- Excessive Tool Wear: Excessive wear on lathe-cutting tools can occur due to incorrect speeds and feeds, inadequate lubrication, or using dull tools. Use the correct cutting parameters for your material, and keep your tools sharp and properly lubricated to extend their lifespan.

Advanced Techniques And Tips For Using A Metal Lathe

If you’re looking to take your metal lathe skills to the next level, a few advanced techniques and tips can help you achieve greater precision and efficiency in your work. Here are some key points to consider:

- Tool Selection: One of the most important factors in achieving quality results on a metal lathe is using the right cutting tools. Invest in high-quality carbide or high-speed steel tools suitable for the specific material you’re working with. This will ensure clean cuts and minimize tool wear.

- Speed And Feed: Adjusting the speed and feed rates is crucial for achieving the desired finish and preventing tool breakage. Experiment with different settings to find the optimal balance between cutting speed and chip load. Remember to refer to the manufacturer’s guidelines for recommended speeds and feeds.

- Tool Geometry: Pay attention to the geometry of your cutting tools. Properly ground tools with the correct rake, clearance, and relief angles can significantly improve cutting performance and reduce chatter. Regularly inspect and sharpen your tools to maintain their effectiveness.

- Work Holding: Effective work holding is essential for precision machining. Use collets, chucks, or faceplates to hold your workpiece in place securely. Use soft jaws or custom fixtures to ensure stability and accuracy when working on delicate or irregularly shaped parts.

- Lubrication: Using the right lubricant can enhance tool life and surface finish. Apply cutting fluid or coolant to minimize heat buildup, lubricate the cutting edge, and flush away chips. Be mindful of the type of lubricant recommended for your machining material.

Conclusion

To master the art of using a metal lathe, you must approach it with patience, practice, and a commitment to safety. Always follow the recommended safety precautions and wear the necessary protective equipment. You can create precise and intricate metalwork with the right techniques and understanding of the machine’s functions.

Whether you’re a beginner or looking to refine your skills, this beginner’s guide will equip you with the knowledge to operate a metal lathe confidently. So, ready to unleash your creativity and explore this versatile tool’s endless possibilities.

Frequently Asked Questions

1.How Is A Metal Lathe Used?

Ans: A metal lathe is a machine tool used to shape and cut metal. It rotates a workpiece against a cutting tool, removing material to create the desired shape or size. The lathe can be used for various operations, such as turning, facing, drilling, and threading.

2.What Can I Do With A Metal Lathe?

Ans: With a metal lathe, you can shape and cut metal workpieces to create various products such as bolts, screws, bushings, and shafts. It allows you to perform turning, facing, tapering, threading, and drilling operations on metal materials.

3.What Are The Rules For Metal Lathes?

Ans: Some common rules for operating a metal lathe include wearing protective gear, such as safety glasses and gloves, securing the workpiece properly, using the correct cutting tools and speeds, and maintaining a clean and organized work area.

4.What Are The Disadvantages Of A Metal Lathe?

Ans: Some disadvantages of a metal lathe include the high initial cost, the need for regular maintenance and lubrication, and the noise and vibrations produced during operation. Additionally, metal lathes require skilled operators to ensure accurate and safe operation.

5.Why Do I Need A Metal Lathe?

Ans: A metal lathe is a versatile machine handy in metalworking applications. It allows you to shape and cut metal precisely, creating various components and parts. Whether hobbyist or professional, a metal lathe is essential for turning, threading, and facing metal workpieces.