Milling machines are versatile and essential in many industries, from manufacturing to construction. These powerful machines can produce precise and complex cuts on various materials such as metal, wood, and plastic. However, with this power and precision comes potential danger if proper safety measures are not followed.

As such, it is crucial for operators and anyone working in proximity to these machines to be aware of the potential hazards and safety precautions. We will discuss important milling machine safety tips that can help prevent accidents and injuries in the workplace. These tips are based on industry standards and best practices, and following them can ensure a safe and efficient work environment. So, let’s dive in and explore the key safety measures every milling machine operator should know.

The Importance Of Safety In Operating Milling Machines

When operating milling machines, safety should always be a top priority. It is crucial to be aware of the potential risks and take necessary precautions. Always wear appropriate personal protective equipment, such as safety goggles and gloves. Make sure to secure loose clothing to prevent accidents.

Familiarize yourself with the milling machine’s table and understand how to use milling cutters properly. Additionally, never forget to use the milling machine spindle brake to ensure a safe working environment. By following these safety guidelines, you can minimize the risks of milling machine operations and protect yourself from potential harm.

Personal Protective Equipment (Ppe)

When operating a milling machine, it is crucial to prioritize safety by implementing necessary precautions and following basic safety tips. Personal Protective Equipment (PPE) is essential in ensuring machine tool safety.

This includes wearing safety glasses or face shields to protect the eyes, using ear protection to prevent hearing damage, wearing gloves and protective clothing to minimize the risk of injuries, and ensuring proper footwear for stability and protection. Emphasizing these safety measures will help create a safer working environment for everyone involved.

Milling Machine Safety Tips: Safe Procedures

When operating a milling machine, it is essential to prioritize safety. Always wear appropriate protective gear, such as safety glasses and gloves, to prevent potential injuries. Ensure the machine is properly maintained and inspected regularly to avoid malfunctions. Familiarize yourself with the operating instructions and follow them precisely. Here, we discuss milling machine safety tips.

Familiarizing Yourself With The Machine’s Manual

When working with milling machines, it is essential to familiarize yourself with the machine’s manual to ensure safety. Understanding the operation of drill presses and manual milling machines is crucial. The manual provides important instructions and guidelines for a successful and secure milling operation. Following the safety tips outlined in the manual can minimize the risk of accidents and ensure a smooth and efficient milling process.

Understanding The Machine’s Controls And Functions

When operating a milling machine, it is crucial to prioritize safety measures. One important aspect is understanding the machine’s controls and functions to ensure smooth operation. Additionally, wearing appropriate protective gear, such as hearing protection, is essential to safeguard against excessive noise levels.

Moreover, wearing a dust mask is vital to prevent inhaling harmful particles. Following these precautions can significantly reduce the risk of accidents and health hazards, ensuring a safe working environment.

Starting Up And Shutting Down The Machine Correctly

Safety should be the top priority when operating a milling machine. Properly starting up and shutting down the machine is essential. Before starting, ensure all necessary safety equipment, such as safety glasses and protective clothing, is in place.

Familiarize yourself with the machine’s operating manual and follow all recommended procedures. When shutting down, turn off the power, wait for all moving parts to come to a complete stop, and clean up any debris or materials. By following these milling machine safety tips, you can minimize the risk of accidents and maintain a safe working environment.

Proper Handling And Securing Of Workpieces

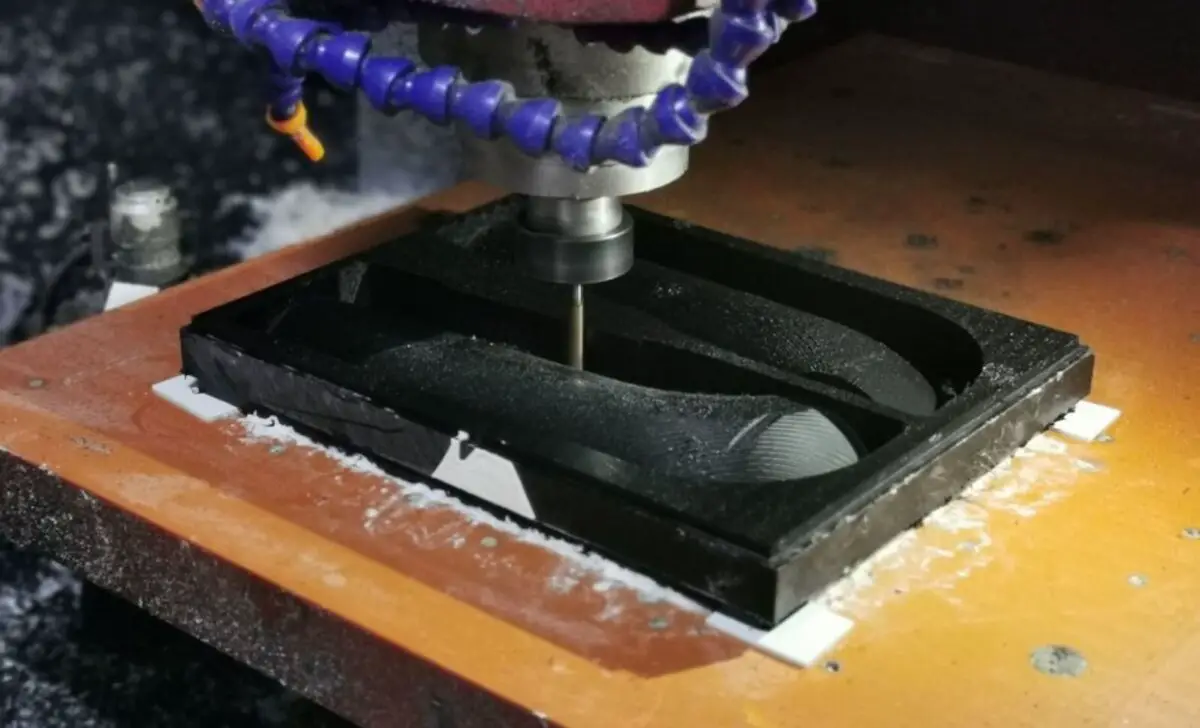

Proper handling and securing of workpieces are essential for ensuring milling machine safety. Before starting any milling operation, inspecting the workpiece for any damage or defects is crucial. Additionally, workpieces should be securely clamped or held in place to prevent movement during milling.

Operators should also wear appropriate personal protective equipment, such as safety glasses and gloves, to protect themselves from potential hazards. Regular maintenance and inspection of the milling machine are vital to ensure its safe and efficient operation. By following these essential safety tips, operators can minimize the risk of accidents and maintain a safe working environment.

Regularly Maintain And Inspect The Machine For Any Potential Hazards.

Regularly maintaining and inspecting the milling machine is crucial to ensure safety in the workplace. You can prevent accidents and injuries by checking for any potential hazards, such as loose parts or damaged equipment. Implementing milling machine safety tips, like wearing appropriate protective gear and following operating instructions, further enhances workplace safety. Prioritizing these measures protects the workers and promotes smooth and efficient machine operation.

Train And Educate All Operators On Milling Machine Safety Protocols

To ensure the safety of all operators, it is crucial to provide comprehensive training and education on milling machine safety protocols. This includes familiarizing operators with proper machine operation, maintenance procedures, and the use of personal protective equipment.

Additionally, emphasizing the importance of regular equipment inspections, safe material handling techniques, and the potential hazards of milling machines will help prevent accidents and promote a safe working environment. By implementing these milling machine safety tips, operators can confidently and effectively carry out their tasks while minimizing the risk of injuries or incidents.

Tooling And Workpiece Setup

When considering milling machine safety tips, it is important to consider factors such as tooling and workpiece setup. Firstly, it is crucial to carefully select the appropriate cutting tools for the job at hand. Secondly, properly installing and aligning the workpiece is essential to ensure accurate and safe milling operations.

Lastly, using clamps and fixtures to secure the workpiece provides stability and reduces the risk of accidents or errors. By following these guidelines, operators can enhance safety and optimize milling machine performance.

Using Machine Guards And Safety Devices

When operating a milling machine, it is crucial to prioritize safety by taking necessary precautions. This includes ensuring that all safety guards are properly in place to protect against potential hazards. Adjusting work stops and limit switches can help prevent accidents and promote a safe working environment.

Another important aspect is the implementation of interlocks and presence-sensing devices, which can further enhance machine safety by detecting potential dangers and taking immediate action. Adopting these measures can significantly reduce the risk of injuries and accidents, providing a secure and productive milling experience.

Conclusion:

Following proper safety protocols when operating a milling machine is crucial for preventing accidents and injuries. These powerful tools can shape and cut various materials, but they pose a significant risk if proper safety protocols are not followed.

By implementing these safety tips, such as wearing appropriate protective gear and ensuring the machine is properly maintained, we can ensure the safety of ourselves and those around us. Remember, safety should always be the top priority in any workplace, and we must be proactive in preventing accidents. So, let’s always prioritize safety when using a milling machine.

FAQ

1.Why Is Machine Safety Important?

Ans: Machine safety is important because it helps prevent workplace accidents and injuries. Implement proper safety measures, such as installing guards, providing safety training, and conducting regular maintenance.

2.What Is Mechanical Safety?

Ans: Mechanical safety refers to the measures and precautions taken to ensure the safe operation and use of mechanical equipment and machinery. This includes implementing safety features such as guards, emergency stop buttons, and safety interlocks to protect operators and prevent accidents.

3.What Is General Safety In The Workshop?

Ans: General safety in a workshop involves taking precautions to prevent accidents and injuries. This includes wearing appropriate personal protective equipment (PPE) such as safety goggles, gloves, and ear protection.

4.What Is Machine Risk?

Ans: Machine risk refers to the potential dangers and hazards of using machines or mechanical equipment. It includes the risk of accidents, injuries, or damage due to malfunctioning or improper use of machines.

5.What Is Level D Protection?

Ans: Level D protection refers to the lowest personal protective equipment (PPE) level required for workers in hazardous environments. It typically includes basic protective clothing like coveralls or work uniforms, safety glasses, and gloves.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.