Have you ever wondered how precise metal parts are made? A tool called an automatic metal lathe is key. This machine creates perfect shapes from metal by spinning it quickly. But what makes it even more intriguing is the compound rest.

The compound rest is a small part of the lathe that helps control the cutting angle. Imagine being able to slice through metal like butter! With the automatic metal lathe compound rest, you can easily change the direction of your cuts. This makes metalworking both fun and satisfying.

Did you know that these lathes can create things like gears and bases for machines? They play a big role in many industries. So, next time you see a shiny metal object, think about the amazing tools that helped create it. The automatic metal lathe compound rest truly makes magic happen in the world of metal crafting!

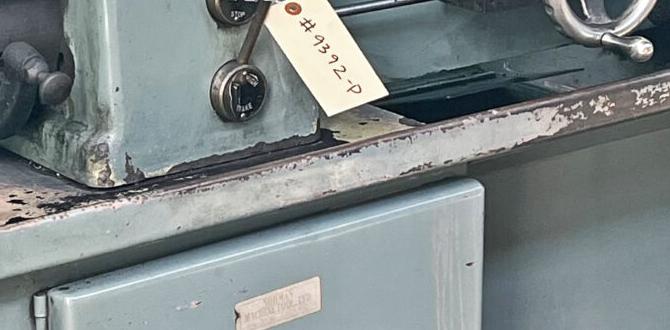

Automatic Metal Lathe Compound Rest: Precision Machining Tool

Understanding the Automatic Metal Lathe Compound Rest

The automatic metal lathe compound rest is a key part of a lathe. It helps move the cutting tool easily for precise shaping of metal pieces. Imagine crafting a smooth, shiny part for a robot! This tool makes it simpler and faster. It allows users to adjust angles and positions quickly for different projects. Knowing how to use it can boost your skills and creativity in metalwork. Isn’t it amazing how small changes can lead to great results?Key Components of an Automatic Metal Lathe Compound Rest

Description of the main parts: carriage, cross slide, and compound slide. Explanation of automation mechanisms (e.g., servo motors, CNC integration).The automatic metal lathe compound rest has several key parts that work together like a well-rehearsed dance team. The carriage moves back and forth to help position the tool. Then there’s the cross slide, which lets the tool move left and right. Finally, the compound slide tilts for more precise cuts. Automation? That’s where the magic happens! Servo motors and CNC integration do all the heavy lifting, making sure your lathe runs smoothly and accurately. Who knew machines could be this fancy?

| Component | Function |

|---|---|

| Carriage | Moves tool back and forth |

| Cross Slide | Moves tool left and right |

| Compound Slide | Tilts for precise cuts |

| Automation | Uses servo motors and CNC for smooth operation |

Advantages of Using an Automatic Metal Lathe Compound Rest

Improved precision and repeatability in machining processes. Increased efficiency and productivity compared to manual systems.Using an automatic metal lathe compound rest offers many benefits. First, it boosts precision and repeatability, making sure each part is just right. Imagine trying to bake cookies, but they all turn out different—disaster! With this tool, each cut is clean and consistent.

Next up is efficiency. This gadget works faster than a squirrel on caffeine! It helps you get more done in less time. You save energy and keep your projects moving like a well-oiled machine.

| Benefit | Description |

|---|---|

| Precision | Each cut is accurate and reliable. |

| Efficiency | Speeds up work and increases output. |

In conclusion, an automatic metal lathe compound rest makes life easier and work better. Why not give it a whirl? You might just love it!

Choosing the Right Automatic Metal Lathe Compound Rest

Factors to consider: size, compatibility, and automation level. Recommendations for different user needs (hobbyists vs. professionals).Choosing the right automatic metal lathe compound rest can improve your project. Size matters; make sure it fits your machine. Check compatibility to ensure smooth working. Finally, think about the automation level—more options help save time. Here are some tips:

- For hobbyists: A small, basic model is perfect.

- For professionals: Choose a larger model with advanced features.

Enjoy crafting with the right tools!

What should I look for in an automatic metal lathe compound rest?

Look for size, compatibility, and automation level. These factors help find the right fit for your needs.

Common Applications for Automatic Metal Lathe Compound Rests

Industry uses: automotive, aerospace, and custom fabrication. Examples of projects that benefit from precise machining.Many industries rely on automatic metal lathe compound rests for their projects. In the automotive sector, they shape parts like gears and axles. The aerospace industry uses them to create lightweight components, ensuring safety and efficiency. Custom fabrication shops benefit too; they craft unique items like custom tools or artistic sculptures. With precise machining, even the trickiest shapes become easy! Who knew metal could be so flexible—like a gymnast at the Olympics!

| Industry | Examples of Projects |

|---|---|

| Automotive | Gears, axles |

| Aerospace | Lightweight components |

| Custom Fabrication | Unique tools, sculptures |

Maintenance Tips for Automatic Metal Lathe Compound Rests

Routine maintenance tasks to ensure longevity and performance. Troubleshooting common issues related to the compound rest.To keep your automatic metal lathe compound rest running smoothly, regular maintenance is key. Here are some simple tasks:

- Clean the compound rest often to remove dust and debris.

- Check and tighten screws to prevent loose parts.

- Lubricate moving parts to reduce friction.

- Inspect for wear or damage regularly.

If you notice problems, like sticking movement or unusual noises, these steps can help:

- Ensure lubrication is applied evenly.

- Check for dirt or chips stuck in the mechanism.

- Adjust the setup if the parts are misaligned.

Taking care of your equipment helps it last longer and perform better.

What are common issues with automatic metal lathe compound rests?

Common issues include sticking movement, unusual noises, and loose screws. Checking lubrication and cleaning can often solve these problems. Keeping everything in good shape leads to fewer headaches!

Comparing Manual vs. Automatic Metal Lathe Compound Rests

Pros and cons of each type in different applications. Cost considerations and return on investment analysis.When it comes to lathes, knowing your options can help you make the best choice. Manual compound rests offer hands-on control, perfect for detailed work and quick adjustments. But, they can be a workout! Think lots of turning wheels and sweating. On the flip side, automatic compound rests simplify tasks and save time, ideal for repetitive jobs. However, they can be pricier upfront, and you might need to break out the piggy bank for repairs.

| Type | Pros | Cons | Cost Considerations |

|---|---|---|---|

| Manual | Control, Flexibility | Physically Demanding | Lower Initial Investment |

| Automatic | Efficiency, Consistency | Higher Costs, Maintenance | Long-Term Savings |

In conclusion, choose wisely! Matching the lathe to your tasks can bring big benefits, whether it’s a gym workout with manual versions or breezy efficiency with automatic ones.

Future Trends in Automatic Metal Lathe Technology

Innovations in automation and control systems. Predictions for market growth and technology advancements in metal lathes.The future looks bright for automatic metal lathe technology! Exciting innovations in automation and control systems are on the way. Think robots that can do more than just dance; they’ll help create precise parts too! Predictions show a growth rate of 8.3% in the market over the next five years. It’s a game-changer! Expect smarter machines that are easier to use, making production faster and more fun. Who wouldn’t want a metal lathe that finds your coffee while it works?

| Trend | Impact |

|---|---|

| Automation | Increase in efficiency |

| Advanced control systems | Better precision |

| AI integration | Smarter operations |

Conclusion

In conclusion, an automatic metal lathe’s compound rest helps you cut shapes accurately. It allows for smooth movements and precise adjustments. By understanding its functions, you improve your metalworking skills. You can practice using it to make parts more efficiently. Explore tutorials and guides to learn more and boost your confidence with this valuable tool. Happy machining!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Automatic Metal Lathe Compound Rests:Sure! A compound rest is a part of a metal lathe. It helps you move the cutting tool in different directions. This lets you make precise cuts and shapes on the metal. Using a compound rest makes your work easier and more accurate. It’s important for making great pieces!

Sure! Just let me know what question you want me to answer.

What Is The Primary Function Of The Compound Rest On An Automatic Metal Lathe, And How Does It Enhance Precision Machining?The compound rest on an automatic metal lathe helps you adjust the tool’s angle. This makes it easier to cut shapes and details on metal. By tilting the tool, we can make better, more precise cuts. This means our work is smoother and fits perfectly!

How Does The Design Of The Compound Rest Influence The Setup And Operation Of An Automatic Metal Lathe?The compound rest is an important part of a metal lathe. It helps you adjust the tool’s angle easily. This makes it simple to shape the metal correctly. When the compound rest is well-designed, you can set up your machine faster and work more smoothly. It helps you make precise cuts and create better parts.

What Are The Key Differences Between Manual And Automatic Adjustments Of The Compound Rest On A Metal Lathe?Manual adjustments on a metal lathe mean you turn knobs or levers by hand. This gives you full control, but it takes more time. Automatic adjustments use a motor to move the compound rest for you. This is faster and can be more accurate. However, you might not feel as involved when using the automatic system.

How Does The Use Of Cnc Technology Impact The Functionality And Accuracy Of The Compound Rest In Modern Automatic Metal Lathes?CNC stands for Computer Numerical Control. It helps machines, like lathes, work faster and more accurately. With CNC, the compound rest can move smoothly and perfectly. This means we can make better parts with cleaner shapes. Overall, CNC makes our tools easier to use and improves their performance.

What Common Maintenance Practices Should Be Followed To Ensure The Longevity And Performance Of The Compound Rest In An Automatic Metal Lathe?To keep the compound rest on a metal lathe working well, you should clean it regularly. Use a soft cloth to wipe off dirt and oil. Check the screws and tighten them if they are loose. Lubricate the moving parts with oil to help them move smoothly. Finally, always cover the lathe when you’re not using it to protect it from dust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Automatic Metal Lathe Compound Rests:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A compound rest is a part of a metal lathe. It helps you move the cutting tool in different directions. This lets you make precise cuts and shapes on the metal. Using a compound rest makes your work easier and more accurate. It’s important for making great pieces!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of The Compound Rest On An Automatic Metal Lathe, And How Does It Enhance Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest on an automatic metal lathe helps you adjust the tool’s angle. This makes it easier to cut shapes and details on metal. By tilting the tool, we can make better, more precise cuts. This means our work is smoother and fits perfectly!”}},{“@type”: “Question”,”name”: “How Does The Design Of The Compound Rest Influence The Setup And Operation Of An Automatic Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest is an important part of a metal lathe. It helps you adjust the tool’s angle easily. This makes it simple to shape the metal correctly. When the compound rest is well-designed, you can set up your machine faster and work more smoothly. It helps you make precise cuts and create better parts.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between Manual And Automatic Adjustments Of The Compound Rest On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manual adjustments on a metal lathe mean you turn knobs or levers by hand. This gives you full control, but it takes more time. Automatic adjustments use a motor to move the compound rest for you. This is faster and can be more accurate. However, you might not feel as involved when using the automatic system.”}},{“@type”: “Question”,”name”: “How Does The Use Of Cnc Technology Impact The Functionality And Accuracy Of The Compound Rest In Modern Automatic Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC stands for Computer Numerical Control. It helps machines, like lathes, work faster and more accurately. With CNC, the compound rest can move smoothly and perfectly. This means we can make better parts with cleaner shapes. Overall, CNC makes our tools easier to use and improves their performance.”}},{“@type”: “Question”,”name”: “What Common Maintenance Practices Should Be Followed To Ensure The Longevity And Performance Of The Compound Rest In An Automatic Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the compound rest on a metal lathe working well, you should clean it regularly. Use a soft cloth to wipe off dirt and oil. Check the screws and tighten them if they are loose. Lubricate the moving parts with oil to help them move smoothly. Finally, always cover the lathe when you’re not using it to protect it from dust.”}}]}