Have you ever wondered how some machines create metal parts so perfectly? One important tool in this process is the automatic metal lathe control panel. This special control panel helps operators guide the lathe, making sure everything runs smoothly.

Imagine a robot that spins and shapes metal just like clay. That might sound like science fiction, but it’s happening right now! The automatic metal lathe control panel makes this possible. With just a few buttons and knobs, you can turn raw pieces of metal into precise shapes.

But how does this control panel really work? It helps manage speed, direction, and even the cutting tools. This makes it easier for machines to create complex designs. Picture a skilled sculptor, but instead of a chisel, they use a powerful lathe controlled by a smart panel.

As you read on, you’ll discover the magic behind these control panels and how they are changing the way we make things. Keep reading to explore the amazing world of automatic metal lathes!

Automatic Metal Lathe Control Panel: Features And Benefits

Exploring Automatic Metal Lathe Control Panels

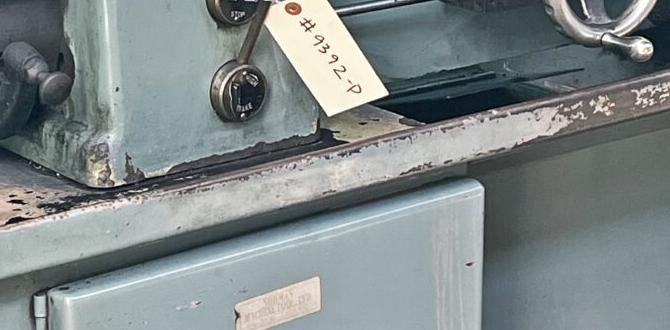

Automatic metal lathe control panels are fascinating machines that make metalworking easier. They allow users to program complex tasks with just a few button presses. Imagine creating precise metal parts without much effort! These panels often include digital displays and user-friendly interfaces. They help improve accuracy and cut down on production time. Did you know that modern control panels can even save designs for future projects? It’s a game-changer for hobbyists and professionals alike!What is an Automatic Metal Lathe Control Panel?

Definition and functionality. Importance in machining.An automatic metal lathe control panel is like the brain of a robot chef! It helps manage the machine that shapes metal pieces. You tell it what to do, and like a good assistant, it follows your orders. This control panel is important for precision in machining. Without it, making exact cuts would be as tricky as slicing a jelly donut without squishing it. A well-functioning control panel can make the difference between a masterpiece and a metal mess!

| Functionality | Importance |

|---|---|

| Controls machine operations | Ensures accuracy |

| Program speeds and feeds | Increases efficiency |

| Displays machine status | Enhances safety |

Components of an Automatic Metal Lathe Control Panel

Key hardware elements. Software integration.An automatic metal lathe control panel has important parts that work together. Key hardware includes motors, sensors, and displays. These pieces help the machine to move and show information. The software connects these tools. It allows users to program the lathe easily. This combination makes manufacturing precise and efficient.

Here are key elements:

- Motors: Power the lathe’s movement.

- Sensors: Monitor the lathe’s position and speed.

- Displays: Show important information to the user.

What software is used in an automatic metal lathe control panel?

The control panel usually uses advanced software for programming and operation. This software is user-friendly. It helps users set the lathe’s tasks easily. Modern software improves accuracy and reduces errors, making it a crucial part of the system.

Types of Control Panels for Metal Lathes

CNC vs. manual control panels. Differences in capabilities.Metal lathes come with different types of control panels, like CNC and manual. CNC panels are like having a robot friend that does the hard work. They let you type in complex designs and watch the machine do its magic. Manual panels, on the other hand, are more hands-on, like driving a car without power steering. Both have their perks! Here’s a quick comparison:

| Feature | CNC Control Panels | Manual Control Panels |

|---|---|---|

| Ease of Use | Very easy | More skill needed |

| Capabilities | Complex shapes | Simple tasks |

| Setup Time | Quick | Slower |

CNC lathes are fast and precise, making them great for tricky designs. Manual lathes require more attention but can be fun for hands-on lovers. Choose the one that fits your style!

Benefits of Using an Automatic Control Panel

Increased precision and efficiency. Timesaving advantages.An automatic control panel makes a big difference in metal lathe work. It helps machines run accurately and efficiently. This means less waste and better products. Time is saved too! Operating costs drop because tasks finish faster. Both workers and businesses benefit from improved productivity. Here’s a quick look at its advantages:

- Increased precision: Machines cut materials with exact measurements.

- Efficiency boost: Less time is spent on each job.

What are the benefits of an automatic control panel?

It improves accuracy and saves time! An automatic control panel can make your work smoother and quicker. This leads to more products finished in less time, which is great for business.

How to Choose the Right Control Panel for Your Lathe

Factors to consider (size, compatibility, features). Popular brands and models.Choosing the right control panel for your lathe is important. Consider these key factors:

- Size: Ensure the panel fits your workspace.

- Compatibility: Check if it works with your lathe model.

- Features: Look for options that suit your needs, like speed control.

Some popular brands include:

- Grizzly: Known for durability.

- Jet: Offers user-friendly features.

- Dewalt: Ideal for various projects.

Choosing wisely can make your projects easier and more fun!

What are common features in a control panel?

Common features include speed control, digital displays, and emergency stop buttons.

Installation Process of Automatic Metal Lathe Control Panels

Stepbystep installation guide. Common challenges and solutions.Installing an automatic metal lathe control panel can seem tricky, but it’s like assembling a giant puzzle! First, always read the manual—it’s your best friend. Next, gather your tools: a screwdriver, some wires, and maybe a snack for energy. Pay attention to the wiring; a wrong connection can turn your lathe into a mysterious machine. Don’t worry! If you hit a snag, double-check the instructions. Remember, challenges are just fun plot twists in your installation saga.

| Common Challenge | Solution |

|---|---|

| Wires aren’t connecting | Check for loose connections and re-strip the wire ends. |

| Panel not turning on | Inspect the power supply and ensure it’s plugged in. |

| Error messages on screen | Refer to the manual for error codes or reset the panel. |

With a bit of patience and laughter, your lathe panel will be purring like a kitten in no time!

Maintenance Tips for Longevity

Routine checks and maintenance practices. Troubleshooting common issues.Keeping your automatic metal lathe control panel running smoothly is easier than you think! Regular checks are like giving it a spa day. Make sure to clean the connections and check for loose wires. These small steps can prevent big headaches down the road.

If something goes wrong, don’t panic! Many issues are simple to fix. For instance, if the panel is unresponsive, try resetting it first. Always consult the manual for guidance.

| Issue | Solution |

|---|---|

| Panel won’t turn on | Check power source and cables. |

| Unusual noises | Lubricate moving parts. |

Remember, just like your favorite pet, a little attention goes a long way in keeping your machine happy!

Future Trends in Metal Lathe Control Technology

Innovations and advancements. Impact of automation on the industry.New technology keeps pushing the limits of how we use metal lathes. Innovations like smart sensors and easy-to-use control panels give machines superpowers! Automation is like giving your lathe a brain. It can work faster and with fewer mistakes. Researchers predict that, by 2025, we might see a boost in productivity by 30% in our industry. So, say goodbye to long hours and hello to more time for snack breaks!

| Innovation | Impact |

|---|---|

| Smart Sensors | Reduce errors |

| User-friendly Panels | Speed up training |

| AI Automation | Boost productivity |

Conclusion

In conclusion, an automatic metal lathe control panel is essential for smooth machining. It helps you easily adjust settings and monitor processes. Understanding how to use it can improve your projects significantly. Remember to explore user guides and tutorials for better skills. Try experimenting with different settings to see how your work improves. Happy machining!FAQs

What Are The Essential Features To Look For In An Automatic Metal Lathe Control Panel?When looking at an automatic metal lathe control panel, you want a few important features. First, there should be clear buttons and a simple screen. This helps you see what settings you are using. Second, it should let you change speeds easily for different tasks. Finally, having safety features is important to keep you safe while using the machine.

How Does The User Interface Of An Automatic Metal Lathe Control Panel Impact Machining Efficiency?The user interface of an automatic metal lathe control panel helps you work better and faster. When buttons are easy to find, you can change settings quickly. A clear display shows important information, so you don’t make mistakes. The better the interface, the more parts we can make in less time. This means we can get things done more efficiently!

What Types Of Software Are Commonly Integrated Into Automatic Metal Lathe Control Panels For Programming And Operation?Automatic metal lathes use different types of software to help us program and run them. One common type is Computer-Aided Design (CAD) software, which helps us create designs. Then, we use Computer-Aided Manufacturing (CAM) software to turn those designs into instructions for the lathe. There’s also software for monitoring and controlling the machine during operation. This way, we ensure everything runs smoothly.

How Do Safety Protocols Integrate With The Functionality Of An Automatic Metal Lathe Control Panel?Safety protocols help keep us safe when using a metal lathe, which is a machine that shapes metal. The control panel has buttons and screens to help us operate it. Safety features, like emergency stop buttons, let us quickly turn off the machine if something goes wrong. We also use covers and guards to protect our hands and eyes while we work. By following these safety rules, we can use the machine safely and effectively.

What Are The Advantages Of Using A Cnc (Computer Numerical Control) System In An Automatic Metal Lathe Control Panel Compared To Manual Operation?Using a CNC system in a metal lathe makes work easier and faster. You can create precise shapes, and the machine does most of the work for you. This means fewer mistakes and better quality in your projects. Also, you can repeat the same design many times without changing anything. Overall, it saves time and gives good results!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Features To Look For In An Automatic Metal Lathe Control Panel? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When looking at an automatic metal lathe control panel, you want a few important features. First, there should be clear buttons and a simple screen. This helps you see what settings you are using. Second, it should let you change speeds easily for different tasks. Finally, having safety features is important to keep you safe while using the machine.”}},{“@type”: “Question”,”name”: “How Does The User Interface Of An Automatic Metal Lathe Control Panel Impact Machining Efficiency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The user interface of an automatic metal lathe control panel helps you work better and faster. When buttons are easy to find, you can change settings quickly. A clear display shows important information, so you don’t make mistakes. The better the interface, the more parts we can make in less time. This means we can get things done more efficiently!”}},{“@type”: “Question”,”name”: “What Types Of Software Are Commonly Integrated Into Automatic Metal Lathe Control Panels For Programming And Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automatic metal lathes use different types of software to help us program and run them. One common type is Computer-Aided Design (CAD) software, which helps us create designs. Then, we use Computer-Aided Manufacturing (CAM) software to turn those designs into instructions for the lathe. There’s also software for monitoring and controlling the machine during operation. This way, we ensure everything runs smoothly.”}},{“@type”: “Question”,”name”: “How Do Safety Protocols Integrate With The Functionality Of An Automatic Metal Lathe Control Panel? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Safety protocols help keep us safe when using a metal lathe, which is a machine that shapes metal. The control panel has buttons and screens to help us operate it. Safety features, like emergency stop buttons, let us quickly turn off the machine if something goes wrong. We also use covers and guards to protect our hands and eyes while we work. By following these safety rules, we can use the machine safely and effectively.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Cnc (Computer Numerical Control) System In An Automatic Metal Lathe Control Panel Compared To Manual Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a CNC system in a metal lathe makes work easier and faster. You can create precise shapes, and the machine does most of the work for you. This means fewer mistakes and better quality in your projects. Also, you can repeat the same design many times without changing anything. Overall, it saves time and gives good results!”}}]}