Have you ever wondered how complex metal parts are made? In factories, machines work hard to create these pieces every day. One of the key machines is the automatic metal lathe. It shapes metal into various forms with precision and speed.

These machines use many special parts to work efficiently. Each part has a unique role to play. For example, the cutting tool slices through metal, while the spindle holds everything in place. If any of these parts fails, the entire process can stop.

Imagine a world without automatic metal lathe parts. Many products, from toys to tools, would not exist. It’s fascinating to think about how important these components are. They make things possible in our everyday lives.

In this article, we will dive deeper into the world of automatic metal lathe parts. You will learn how they function, why they matter, and the latest advancements in technology. Get ready to discover the hidden heroes of the manufacturing world!

Automatic Metal Lathe Parts: Understanding Their Importance

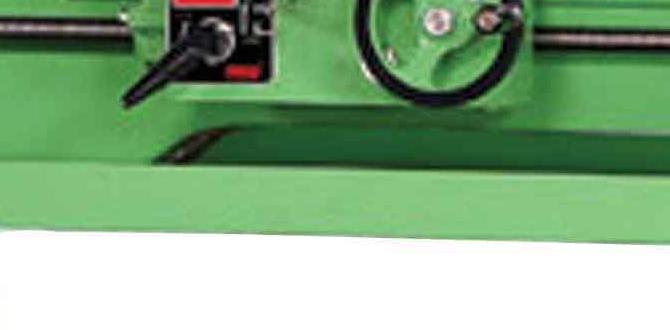

Automatic Metal Lathe Parts

Automatic metal lathe parts are crucial for making precision items. They help in shaping metal accurately for many industries. Did you know that these machines can work non-stop, creating parts much faster than a human? Common parts include spindles and tool holders, each playing a special role. Understanding these components opens up a world of engineering magic. Imagine how these tiny pieces work together like a well-tuned orchestra, producing perfect designs every time.Key Components of Automatic Metal Lathes

Description of essential parts (spindle, carriage, tailstock, etc.). Role of each component in the lathe operation.In an automatic metal lathe, several key components work together like a well-choreographed dance. First, there’s the spindle, which spins the workpiece with the grace of a ballerina. Next, the carriage moves the cutting tool back and forth, like a kid on a swing. The tailstock helps support longer pieces, keeping everything steady, much like a trusty friend. Each part plays a significant role in making precise cuts and shaping metal smoothly. Here’s a quick peek at these essential components:

| Component | Role |

|---|---|

| Spindle | Holds and spins the workpiece |

| Carriage | Moves the cutting tool |

| Tailstock | Supports long workpieces |

With these parts working together, the lathe can create amazing shapes and sizes, turning raw metal into masterpieces!

Types of Automatic Metal Lathes

Comparison of CNC lathes vs. traditional automatic lathes. Advantages and disadvantages of each type.Two main types of automatic metal lathes exist: CNC lathes and traditional automatic lathes. CNC lathes use computers for precision, while traditional lathes rely on manual settings. CNC lathes are like super-smart robots that can work overnight, but they can cost more. Traditional lathes are cheaper but take more time and skill to operate. Think of it like comparing a smart fridge to a regular one; the smart fridge might cost more, but it can help you remember your grocery list!

| Type | Advantages | Disadvantages |

|---|---|---|

| CNC Lathes | High precision, Programmable | High cost, Needs training |

| Traditional Lathes | Cost-effective, Simple design | Less precision, More labor-intensive |

Whether you choose CNC or traditional lathes depends on your needs. Remember, even if a robot can be faster, sometimes the good old ways have a charm of their own!

Material Considerations for Auto Lathe Parts

Common materials used for manufacturing lathe components. Impact of material selection on performance and durability.Choosing the right material for automatic metal lathe parts is crucial. Common materials include:

- Aluminum: Lightweight and easy to machine.

- Steel: Strong and durable, perfect for heavy tasks.

- Brass: Rust-resistant and good for precision parts.

Each material affects performance and durability. For example, steel parts can last longer under stress, while aluminum is great for speed. A smart choice means better parts and longer life for tools.

What are popular materials for lathe parts?

The top materials used for lathe parts include aluminum, steel, and brass. These materials each have unique benefits that help them perform well in different tasks.

Maintenance Tips for Automatic Metal Lathes

Routine maintenance procedures to ensure optimal performance. Common issues and troubleshooting techniques.Keeping your automatic metal lathe running smoothly is key. Regular maintenance makes a big difference. Always check and clean the parts like the bed and tool holder to prevent issues. Don’t forget to oil the moving parts – they deserve a spa day too! If you notice weird noises, it might be time for some troubleshooting. Common problems include loose belts or dull tools. Catch them early, and your lathe will thank you with smooth operation!

| Common Issues | Troubleshooting Tips |

|---|---|

| Loose belts | Check tension and tighten if needed. |

| Dull tools | Sharpen or replace them promptly. |

| Unusual noises | Inspect for misalignment or debris. |

Cost Factors of Automatic Metal Lathe Parts

Breakdown of costs associated with different components. Factors affecting pricing in the aftermarket parts market.Understanding costs is key for automatic metal lathe parts. Prices vary based on what you need. Each component—like motors, gears, and tools—has its own cost. Some parts are cheaper because they are made from basic materials, while others can make your wallet feel light, thanks to fancy tech.

Aftermarket parts can change costs too. Their quality and brand make a difference. If you see a part priced like a rare trophy, it might be worth it. Here’s a quick look at what drives costs:

| Component | Price Range |

|---|---|

| Motors | $100 – $300 |

| Gears | $50 – $200 |

| Tools | $25 – $150 |

Keep your eyes open for deals; a great part can turn your lathe into a superstar. Remember, good quality will save you money in the long run! And who doesn’t want a lathe that runs like a dream?

Future Trends in Automatic Metal Lathe Technology

Innovations in lathe technology and parts. Predictions for the future of automatic metal lathes in manufacturing.New advancements in automatic metal lathe technology are changing the way we make parts. Machines are becoming smarter, using sensors to improve efficiency. This helps factories produce more with less waste. Experts believe that by 2030, automatic metal lathes will be faster, quieter, and more precise than ever. These innovations will lead to:

- Higher production rates

- Less energy consumption

- Greater customization options

With these changes, the future of manufacturing looks bright! Expect to see machines that can think and adapt on their own.

What are the key trends for the future of automatic metal lathes?

Key trends include the rise of smart machines, eco-friendly designs, and better customization for various industries.

Conclusion

In summary, automatic metal lathe parts are vital for creating precise metal products. They help machines work efficiently and accurately. By learning about these parts, you can understand how objects are made. If you’re interested, explore more about lathe operations or even try using one yourself. This knowledge can spark your creativity and open up new possibilities!FAQs

What Are The Key Components Of An Automatic Metal Lathe And How Do They Contribute To Its Functionality?An automatic metal lathe has several important parts. The main part is the spindle, which spins the metal. Then, there’s the tool holder, which holds the cutting tools that shape the metal. The feed system moves the tool closer to the metal as it spins. Finally, the control panel lets you set how fast it works and what shape you want to create. These parts work together to make metal pieces quickly and accurately.

How Do Variations In Materials Affect The Performance And Durability Of Parts Produced By An Automatic Metal Lathe?Different materials can change how strong and long-lasting the parts from a metal lathe are. For example, softer metals may wear out faster, while harder metals last longer. This affects how well the parts work and how often they need to be replaced. If we choose the right material, the parts we make can perform better and last longer!

What Are The Common Maintenance Practices Required To Ensure The Optimal Operation Of Automatic Metal Lathe Parts?To keep an automatic metal lathe working well, we should follow some simple steps. First, clean the machine regularly to remove dust and metal shavings. Next, check and change the oil often so the parts move smoothly. We also need to tighten loose screws or bolts to prevent problems. Finally, inspect the parts for wear and replace them when necessary to keep everything running smoothly.

How Do Advancements In Technology, Such As Cnc (Computer Numerical Control), Impact The Design And Precision Of Automatic Metal Lathe Parts?Advancements like CNC, which stands for Computer Numerical Control, help machines work better. With CNC, we can make metal parts very accurately. This means the designs are cleaner and fit together perfectly. We can also change designs easily when needed. Overall, it helps us create high-quality metal parts faster and with less waste.

What Are The Most Common Uses For Parts Manufactured By Automatic Metal Lathes In Various Industries?Parts made by automatic metal lathes are used in many industries. You can find them in cars, where they make engine parts. We also see them in toys, helping to create strong and safe pieces. In machines, these parts help everything work smoothly. Overall, they are important for making things we use every day!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components Of An Automatic Metal Lathe And How Do They Contribute To Its Functionality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “An automatic metal lathe has several important parts. The main part is the spindle, which spins the metal. Then, there’s the tool holder, which holds the cutting tools that shape the metal. The feed system moves the tool closer to the metal as it spins. Finally, the control panel lets you set how fast it works and what shape you want to create. These parts work together to make metal pieces quickly and accurately.”}},{“@type”: “Question”,”name”: “How Do Variations In Materials Affect The Performance And Durability Of Parts Produced By An Automatic Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials can change how strong and long-lasting the parts from a metal lathe are. For example, softer metals may wear out faster, while harder metals last longer. This affects how well the parts work and how often they need to be replaced. If we choose the right material, the parts we make can perform better and last longer!”}},{“@type”: “Question”,”name”: “What Are The Common Maintenance Practices Required To Ensure The Optimal Operation Of Automatic Metal Lathe Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep an automatic metal lathe working well, we should follow some simple steps. First, clean the machine regularly to remove dust and metal shavings. Next, check and change the oil often so the parts move smoothly. We also need to tighten loose screws or bolts to prevent problems. Finally, inspect the parts for wear and replace them when necessary to keep everything running smoothly.”}},{“@type”: “Question”,”name”: “How Do Advancements In Technology, Such As Cnc (Computer Numerical Control), Impact The Design And Precision Of Automatic Metal Lathe Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Advancements like CNC, which stands for Computer Numerical Control, help machines work better. With CNC, we can make metal parts very accurately. This means the designs are cleaner and fit together perfectly. We can also change designs easily when needed. Overall, it helps us create high-quality metal parts faster and with less waste.”}},{“@type”: “Question”,”name”: “What Are The Most Common Uses For Parts Manufactured By Automatic Metal Lathes In Various Industries? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Parts made by automatic metal lathes are used in many industries. You can find them in cars, where they make engine parts. We also see them in toys, helping to create strong and safe pieces. In machines, these parts help everything work smoothly. Overall, they are important for making things we use every day!”}}]}