Have you ever wondered how metal parts get their perfect shapes? Imagine a machine that can spin metal and create the finest details while you do other things. That’s the magic of an automatic metal lathe!

One of its coolest features is taper turning. This process creates a pointed shape on the end of the metal piece, just like a pencil. It’s vital in many industries, from making tools to crafting decorative items. Did you know that a skilled lathe operator can produce these shapes much faster than by hand?

Using an automatic metal lathe makes this job even easier. It can do tasks again and again with precision. This means less time wasted and better results. So, whether you’re a curious beginner or an expert in metalwork, understanding taper turning can open new doors in your projects.

Let’s dive deeper into how this amazing process works and explore why it’s so important!

Automatic Metal Lathe Taper Turning: Precision And Efficiency

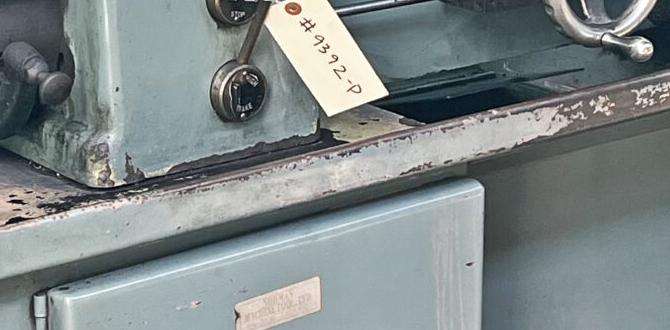

Automatic Metal Lathe Taper Turning

Imagine needing to create a perfect cone shape in metal. An automatic metal lathe is your best friend for taper turning. This machine shapes metal quickly and accurately. It reduces errors and saves time, making it great for mass production. Plus, with its advanced controls, even beginners can achieve great results. Learning about taper turning can open doors in metalworking. Did you know that a slight angle can change the entire design? It’s fascinating what machines can do!Understanding Automatic Metal Lathes

Definition and key features of automatic metal lathes. Comparison with manual lathes.Automatic metal lathes are smart machines that shape metal into different forms. They spin metal pieces while tools cut and shape them. Key features include precise controls, faster production, and repeatability. Unlike manual lathes, which need hands-on help, automatic lathes work mostly on their own. They can make multiple items in less time—perfect for those who want to create without breaking a sweat! Think of it as a robot helper in the metal shop.

| Feature | Automatic Lathes | Manual Lathes |

|---|---|---|

| Speed | High | Low |

| Precision | Very Accurate | Moderately Accurate |

| Ease of Use | Easy | Requires Skill |

The Importance of Taper Turning

Explanation of taper turning and its applications. Benefits of using taper turning in metalworking.Taper turning is like giving your metal a stylish haircut. It shapes the ends of metal pieces to be wider or narrower, making them fit perfectly in machines. Think of it as making a pencil pointy! This technique has many uses, like creating furniture legs and tool fittings. Using taper turning in metalworking can improve accuracy and save time. Why use a plain stick when you can have a fancy tapered one? It adds flair to any project!

| Benefit | Description |

|---|---|

| Increased Precision | Taper turning helps to achieve exact dimensions. |

| Time Efficiency | Speeds up the production process. |

| Versatile Applications | Used in various industries, from automotive to furniture. |

Setting Up an Automatic Metal Lathe for Taper Turning

Stepbystep setup process. Essential tools and equipment needed.To set up an automatic metal lathe for taper turning, follow these simple steps. First, gather the essential tools. You will need:

- A lathe machine

- Cutting tools

- Measuring tools

- Safety glasses

Next, securely attach the workpiece to the lathe. Adjust the tailstock and set the angle for taper turning. Lastly, plug in the machine and test it at a low speed before increasing it. Always prioritize safety!

What tools do I need for taper turning?

The main tools for taper turning on an automatic metal lathe include a lathe machine, cutting tools, measuring tools, and safety glasses.

Common Issues and Troubleshooting

Frequent problems encountered in taper turning. Solutions and preventive measures.While using an automatic metal lathe for taper turning, you may face common problems. These issues can slow down your work and affect the quality of your project. Here are some frequent problems and their solutions:

- Inaccurate Taper Angles: Check the lathe settings. Adjust the tool’s position if needed.

- Tool Wear: Use sharp tools. Replace dull tools to maintain quality.

- Vibration: Ensure the lathe is stable. Tighten loose parts to reduce shaking.

- Feed Issues: Clean the feed mechanism. Oil it regularly to ensure smooth operation.

Preventing these issues can help your taper turning run smoothly. Regular maintenance is key. Always inspect your equipment before starting. This way, you enjoy better results and less frustration!

How can I fix common taper turning problems?

To fix taper turning problems, make quick adjustments. Inspect parts regularly, replace worn tools, and keep the lathe clean. Small changes can lead to big improvements!

Maintenance Tips for Automatic Metal Lathes

Routine maintenance tasks for optimal performance. Signs of wear and how to address them.Keeping your automatic metal lathe in tip-top shape is easier than you think! Start with routine maintenance tasks like cleaning and lubricating parts regularly. This helps it run smoothly and prevents any nasty surprises. If you notice unusual noises or your machine starts acting like a cranky toddler, it might be time to check for wear and tear. A little TLC can go a long way!

| Maintenance Task | Frequency | Signs of Wear |

|---|---|---|

| Clean and lubricate | Weekly | Unusual noises |

| Check and tighten bolts | Monthly | Vibrations |

| Inspect belts and gears | Quarterly | Worn edges |

Remember, a well-maintained lathe is a happy lathe. Treat it right, and it will return the favor by producing great work and keeping tantrums at bay!

Future Trends in Automatic Metal Lathe Technology

Innovations in taper turning technology. Impact of automation and Industry 4.0 on metal lathes.Exciting changes are coming to the world of lathes! New taper turning tech is making them faster and better. Imagine a robot that can finish a metal part while you are still deciding what to have for lunch. That’s the magic of automation! With Industry 4.0, lathes can now talk to each other—like a gossiping group of friends sharing secrets. This means less waiting time and more awesome parts. Who knew metal could be so chatty?

| Innovations | Impact |

|---|---|

| Smart sensors for precision | Faster production with fewer errors |

| AI-driven controls | Better quality and consistency |

| Cloud-based monitoring | Remote management and updates |

Conclusion

In summary, automatic metal lathe taper turning helps create precise, smooth tapered shapes. You can save time and improve accuracy with this technique. Understanding how it works opens up new possibilities for your projects. If you’re interested, explore more about lathes and machines to dive deeper into this exciting field. Let’s keep learning and creating together!FAQs

What Are The Key Principles Of Taper Turning Using An Automatic Metal Lathe?Taper turning means making one end of a piece of metal wider than the other. With an automatic metal lathe, we set the machine to move the tool at an angle. This helps create the slope we want. You need to measure carefully, so it looks just right. Finally, always check your work to make sure it’s perfect!

How Do You Set Up An Automatic Metal Lathe For Accurate Taper Turning Operations?To set up an automatic metal lathe for taper turning, first, measure the part you want to make. Next, adjust the angle of the tailstock. This helps create the right slope on your piece. Then, check the speed and feed rates for smooth cuts. Finally, test the setup with a small piece before starting the real work.

What Are The Common Tools And Cutting Techniques Used For Taper Turning On An Automatic Lathe?To make a taper on a piece of metal using an automatic lathe, we use special tools like cutting bits. These bits are shaped to help create the slanted edge. We can move the tool in a certain way or change the speed to get the right angle. By doing this carefully, we can make nice, smooth tapers on our projects.

How Can You Calculate The Taper Angle And Dimensions Required For A Specific Workpiece On An Automatic Metal Lathe?To calculate the taper angle, you first measure the thickness of the workpiece at both ends. Next, find the difference in thickness. Then, you can use a simple formula: the angle equals the difference divided by the length of the part. For dimensions, use the measurements you took and adjust them based on the taper angle. Finally, write down your results so you can set up the lathe correctly.

What Safety Considerations Should Be Taken Into Account When Performing Taper Turning On An Automatic Metal Lathe?When using an automatic metal lathe for taper turning, always wear safety goggles to protect your eyes. Keep your hair tied back and your clothes snug to avoid getting caught in the machine. Make sure the lathe is turned off when you’re changing tools or measuring pieces. Lastly, keep your hands away from the moving parts to stay safe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Principles Of Taper Turning Using An Automatic Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Taper turning means making one end of a piece of metal wider than the other. With an automatic metal lathe, we set the machine to move the tool at an angle. This helps create the slope we want. You need to measure carefully, so it looks just right. Finally, always check your work to make sure it’s perfect!”}},{“@type”: “Question”,”name”: “How Do You Set Up An Automatic Metal Lathe For Accurate Taper Turning Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up an automatic metal lathe for taper turning, first, measure the part you want to make. Next, adjust the angle of the tailstock. This helps create the right slope on your piece. Then, check the speed and feed rates for smooth cuts. Finally, test the setup with a small piece before starting the real work.”}},{“@type”: “Question”,”name”: “What Are The Common Tools And Cutting Techniques Used For Taper Turning On An Automatic Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a taper on a piece of metal using an automatic lathe, we use special tools like cutting bits. These bits are shaped to help create the slanted edge. We can move the tool in a certain way or change the speed to get the right angle. By doing this carefully, we can make nice, smooth tapers on our projects.”}},{“@type”: “Question”,”name”: “How Can You Calculate The Taper Angle And Dimensions Required For A Specific Workpiece On An Automatic Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calculate the taper angle, you first measure the thickness of the workpiece at both ends. Next, find the difference in thickness. Then, you can use a simple formula: the angle equals the difference divided by the length of the part. For dimensions, use the measurements you took and adjust them based on the taper angle. Finally, write down your results so you can set up the lathe correctly.”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Taken Into Account When Performing Taper Turning On An Automatic Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using an automatic metal lathe for taper turning, always wear safety goggles to protect your eyes. Keep your hair tied back and your clothes snug to avoid getting caught in the machine. Make sure the lathe is turned off when you’re changing tools or measuring pieces. Lastly, keep your hands away from the moving parts to stay safe.”}}]}