Have you ever wondered how small changes can make a big impact on a machine? Upgrading your automatic metal lathe can do just that. Imagine turning a basic tool into a powerhouse of creativity. With the right upgrades, you can improve your projects and save time.

Many people don’t realize that even simple upgrades can enhance performance. For instance, a new chuck can increase accuracy. Better software can simplify programming. These small steps can lead to amazing results.

Think about it: what if your metal lathe could work faster and with less effort? Upgrading your equipment might be the key. It not only makes your work easier, but it also helps you create better pieces.

Join us as we explore the exciting world of automatic metal lathe upgrades. You might discover that some updates are just what you need to take your skills to the next level!

Exploring The Benefits Of An Automatic Metal Lathe Upgrade

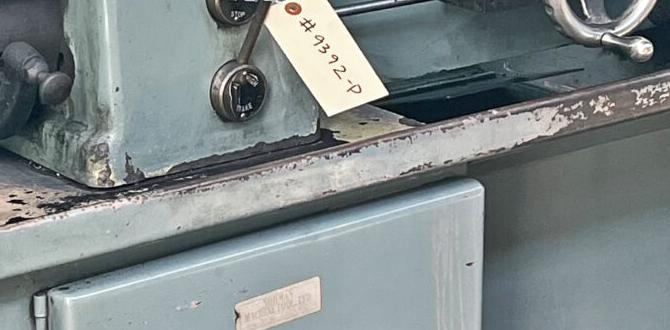

Automatic Metal Lathe Upgrade

Upgrading to an automatic metal lathe can change your workshop game. Imagine turning hours of work into minutes! With smarter technology, these tools increase precision and speed. They are also easier to use. Have you ever wished for more time to focus on creativity? This upgrade allows that by handling tedious tasks for you. A well-chosen metal lathe not only boosts productivity but also enhances the quality of your projects. Let’s explore how to make the most of this powerful tool!Understanding Automatic Metal Lathes

Definition and function of automatic metal lathes. Key components and their roles in machining processes.An automatic metal lathe is a machine that shapes metal. It spins the metal and uses cutting tools to create parts. Think of it like a spinning top that carves designs on the surface. Some key parts of this machine include:

- Spindle: This holds and spins the metal.

- Cutter: This cuts shapes into the metal.

- Control System: It guides the machine and decides how fast to work.

These parts work together to make precise metal pieces quickly and easily.

What does an automatic metal lathe do?

It shapes metal by spinning it while cutting tools carve out specific designs. This machine is key in factories that make parts for cars, tools, and more.

Benefits of Upgrading Your Automatic Metal Lathe

Increased precision and efficiency in production. Enhanced capabilities for complex projects.Upgrading your automatic metal lathe has many benefits. First, it can increase precision in production. A new lathe can cut parts more accurately. This leads to fewer mistakes and waste. Second, an upgrade boosts efficiency. It allows for faster production rates. Operators can complete tasks quicker than before. Lastly, modern machines handle complex projects easily. They can create intricate designs without trouble.

What Are the Benefits of Upgrading?

Upgrading improves accuracy and speeds up work. It also opens doors to more complex projects, making your work stand out.

- Better precision

- Faster production

- Ability to tackle complex designs

Identifying Outdated Features in Your Current Lathe

Common outdated technologies in automatic metal lathes. Signs that an upgrade is necessary.Many older automatic metal lathes use outdated technology. They may have slow speeds and limited control options. You might notice:

- Longer job times

- Frequent breakdowns

- Inconsistent quality

- Lack of programmable features

If you face these issues, it may be time for an automatic metal lathe upgrade. Upgrading can improve your efficiency and product quality.

How can I tell if my lathe needs an upgrade?

Look for signs like persistent problems and slower performance. If it no longer meets your needs, consider an upgrade. Upgrading can save time and money.

Essential Upgrades for Improved Performance

Upgrading the CNC control system. Enhancing the spindle speed and tooling options.Upgrading your CNC control system can feel like giving your lathe a brain boost. A smarter brain means better precision and efficiency, making your projects smoother. Pair that with enhanced spindle speed, and it’s like switching from a bicycle to a rocket ship! New tooling options can also open a world of creativity, allowing you to shape metal like a sculptor. Who knew metal could be this fun?

| Upgrade | Benefit |

|---|---|

| CNC Control System | Improves precision and efficiency |

| Spindle Speed | Faster work completion |

| Tooling Options | Increased creativity and versatility |

With these upgrades, your lathe transforms into a performance powerhouse. As the saying goes, “Upgrade today, impress tomorrow!”

Choosing the Right Upgrades for Your Needs

Evaluating your machining requirements. Budget considerations for different upgrade options.Upgrading your machine requires careful thought. Start by looking at what you need. Consider how the upgrade will improve your work. Think about your budget too. Some upgrades cost more than others. Ask yourself: can you afford it? Set clear goals and priorities. This helps you make smart choices in your upgrades. Here’s a quick guide:

- Analyze your production needs.

- Determine costs of each upgrade.

- Set a budget limit.

Balancing your needs and budget is key to a successful upgrade.

What are some common considerations for upgrading?

Consider production speed, accuracy, and machine compatibility. Each aspect affects how well your new upgrade will perform.

Installation and Integration of New Upgrades

Stepbystep process for upgrading components. Common challenges and solutions during installation.Upgrading components for your automatic metal lathe can be a breeze with the right steps! First, gather all tools and parts. Next, carefully remove the old components. Remember, they may try to cling on like a kid at a school fair. Then, install the new parts one by one, checking for a snug fit. If things get tricky, don’t panic! Common challenges include mismatched sizes and tight spots. Solutions? Use adapters or a good old wrench!

| Common Challenge | Solution |

|---|---|

| Mismatched Sizes | Use adapters |

| Tight Spaces | Get a longer wrench |

| Incorrect Install | Double-check the manual |

Humor can help lighten the mood during tough tasks! Just remember, every step brings you closer to an upgraded lathe ready to make shiny new parts. With a little patience, you’ll be spinning metal like a pro!

Maintenance Tips for Enhanced Longevity of Upgraded Lathes

Regular maintenance practices postupgrade. Importance of software updates and technical support.To keep your upgraded lathe running well, regular maintenance is key. Check for wear and tear often. Clean dust and debris to prevent damage. Lubricate moving parts to ensure smooth operation. Software updates are also important. They fix bugs and add features. Stay in touch with technical support. They can help if something goes wrong. Following these steps can help your lathe last longer.

Why is regular maintenance needed for upgraded lathes?

Regular maintenance helps prevent problems and keep machines running longer. It reduces breakdowns and keeps parts working smoothly.

Maintenance Checklist:

- Inspect parts regularly

- Clean the machine often

- Lubricate moving components

- Update software as needed

- Contact support for issues

Case Studies: Successful Upgrades from Industry Leaders

Examples of businesses that improved productivity through upgrades. Lessons learned and best practices from successful projects.Several companies have seen big wins by upgrading their machines. For example, a car parts maker updated to a modern metal lathe and boosted production by 30%. They learned to prioritize training. When workers know how to use upgrades, they can work faster. A candy factory upgraded its machinery and saw fewer mistakes. Their slogan? “Upgrade, don’t fudge it!” Below is a summary of key lessons learned:

| Company | Improvement | Key Lesson |

|---|---|---|

| Car Parts Co. | 30% more production | Training is crucial |

| Candy Factory | Fewer errors | Upgrade smartly |

Overall, upgrades can make a big difference in productivity! Remember, a happy machine is a busy machine!

Conclusion

Upgrading to an automatic metal lathe can boost your efficiency and precision. You’ll save time and reduce errors. Think about your specific needs to choose the right model. Consider reading reviews or visiting a showroom for hands-on experience. With the right upgrade, you can take your metalworking skills to the next level. Let’s explore this exciting opportunity together!FAQs

What Are The Key Features To Consider When Upgrading An Automatic Metal Lathe For Increased Efficiency And Productivity?When upgrading an automatic metal lathe, consider its speed. A faster lathe can make pieces quicker. Look for better tools that last longer and cut better. Adding automatic sensors can help catch mistakes early. Finally, we should think about how easy it is to use and control the lathe.

How Can Integrating Advanced Cnc Technology Enhance The Capabilities Of An Automatic Metal Lathe?Advanced CNC technology helps people make metal parts more easily and accurately. With CNC, or Computer Numerical Control, we can program machines to do complex tasks. This means we can create new shapes quickly and use less material. It also helps reduce mistakes, so the parts fit together better. Overall, we can produce better products in less time!

What Are The Cost Implications Of Upgrading An Existing Automatic Metal Lathe Versus Purchasing A New Model?Upgrading an old automatic metal lathe can be cheaper than buying a new one. You save money on new parts instead of getting a whole new machine. However, an old lathe might need more repairs later. A new model often works better and lasts longer. We should think about how much we could save or spend now and in the future.

How Does The Choice Of Tooling And Accessories Impact The Performance Of An Upgraded Automatic Metal Lathe?The tools and accessories you choose for an automatic metal lathe can really change how well it works. Good tools help make clean cuts and shape metal better. Using the right accessories can make the lathe faster and easier to use. If you pick cheap or wrong tools, you might not get the best results. So, it’s important to choose wisely!

What Maintenance Practices Should Be Implemented Post-Upgrade To Ensure The Longevity And Reliability Of The Automatic Metal Lathe?After upgrading your automatic metal lathe, you should follow some simple maintenance steps. First, clean the lathe regularly to remove dust and chips. Next, check the oil levels and add more if needed to keep everything moving smoothly. You should also inspect the belts and parts for any wear or damage. Finally, keep the lathe in a dry place to prevent rust. This will help your lathe work well for a long time!