Have you ever wondered how metal parts are made? The magic often happens on a benchtop metal lathe. This handy tool helps create round objects like knobs or spacers, but it’s the carriage that makes everything run smoothly.

Imagine you want to make a small metal part for your project. You’ll need a device that controls the tool’s movements. That’s where the carriage comes in! It holds the cutting tool and helps it move back and forth. Without it, the lathe wouldn’t work properly.

Fun fact: Did you know that the first lathes were used thousands of years ago? Craftspeople relied on them to shape wood and metal. Today, benchtop metal lathe carriages make it easier to create precise parts in your workshop!

Are you ready to dive into the world of metalworking? Let’s explore how a benchtop metal lathe carriage can turn your ideas into reality!

Benchtop Metal Lathe Carriage: Essential Features & Benefits

Understanding the Benchtop Metal Lathe Carriage

The benchtop metal lathe carriage is an essential part of a lathe machine. It holds the cutting tool and moves it across the metal. Imagine trying to carve a perfect sculpture from a block of wood. You’d need the right tools and movements, right? The carriage allows for precise cuts and adjustments. With careful use, hobbyists and professionals can create parts for machines or artistic pieces. Curious about how it works? Learning about this part can make metalworking easier and more fun!Understanding the Benchtop Metal Lathe Carriage

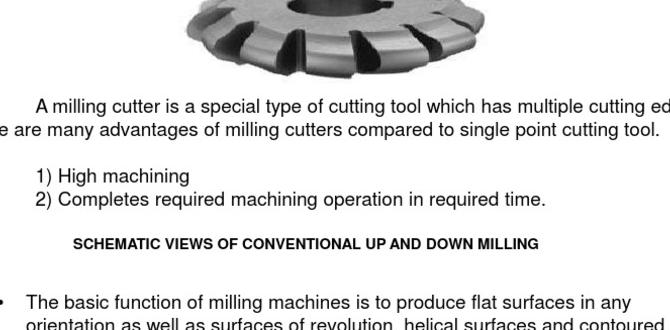

Definition and function of the carriage in metal lathes. Importance of the carriage in precision machining.The carriage on a metal lathe is like a little train that carries tools and helps them move across the workpiece. It holds the cutting tool in place and allows it to make accurate cuts as it travels. This means precision machining can happen smoothly! Without the carriage, your lathe work would be more like a game of dodgeball—chaotic and messy. So, keep your carriage well-groomed to ensure your projects turn out just right! Fun fact: a well-functioning carriage can improve your work by up to 50%. Now imagine that—it’s like getting an extra scoop of ice cream!

| Carriage Function | Importance |

|---|---|

| Holds cutting tools | Ensures precise cuts |

| Moves tool across material | Enhances smooth operation |

| Adjustable for various tasks | Makes diverse projects easier |

Key Features of a Quality Carriage

Essential components and materials used. Impact of features on machining performance.A quality carriage plays a big role in the performance of a benchtop metal lathe. It should be made of strong materials like steel or cast iron. These materials provide durability and stability during machining. Key features include:

- Precision movement: It allows smooth and accurate operation.

- Easy adjustments: This helps users set the tool height quickly.

- Safety mechanisms: These ensure safe operation, reducing accidents.

What makes a carriage essential for metal lathes?

The carriage is crucial because it supports the cutting tool, ensuring precision. Quality features boost performance, leading to better results. Strong materials and smart designs help users create accurate parts efficiently.

How to Maintain Your Benchtop Metal Lathe Carriage

Best practices for cleaning and lubrication. Signs of wear and when to replace parts.Keeping your benchtop metal lathe carriage in great shape is not rocket science. Start by cleaning it regularly. Use a soft cloth to wipe off dust, and don’t let chips pile up like they are throwing a party in your workshop. Lubricate moving parts with oil to keep everything sliding smoothly—like butter on toast!

Watch out for signs of wear, like unusual noises or shaking. If parts look worn out, replace them before they throw a tantrum and stop working. Remember, a happy lathe makes for a happy maker!

| Signs of Wear | Action Needed |

|---|---|

| Unusual noises | Lubricate or replace parts |

| Shaking during operation | Check alignment and replace worn parts |

| Visible damage | Replace immediately! |

Common Issues with Metal Lathe Carriages

Identification of usual problems encountered. Solutions and troubleshooting tips.Metal lathe carriages can face some common problems. Users might notice issues like wobbling or sticking. These problems can make it hard to get accurate cuts. Here are some solutions:

- Check Alignment: Make sure everything is straight and evenly placed.

- Clean Regularly: Remove dust and debris that can cause sticking.

- Lubricate: Use oil on moving parts to reduce friction.

With these tips, fixing your metal lathe carriage may be easier. Regular care helps keep it running smoothly!

What are the most common issues with metal lathe carriages?

Common issues include misalignment, wear and tear, and lubrication problems.

How can I troubleshoot my metal lathe carriage?

Check for dirt, ensure proper lubrication, and align the carriage. These steps can help resolve many issues.

Upgrading Your Lathe Carriage: When and Why

Factors to consider for upgrading. Benefits of modern carriages over older models.Upgrading your lathe carriage can seem tricky, but it doesn’t have to be. First, consider how often you use your lathe. If it’s gathering dust, maybe keep the old one. If it’s a workhorse, it’s time for a shiny upgrade! Modern carriages often provide better precision, less friction, and smoother movement. This means faster projects and fewer headaches—less time fixing, more time creating! Let’s break it down:

| Factor | Old Carriage | Modern Carriage |

|---|---|---|

| Precision | Limited | High |

| Wear and Tear | Frequent | Minimal |

| Ease of Use | Complicated | User-friendly |

Think of it this way: upgrading your carriage is like trading in a bicycle for a speedy motorcycle! Who wouldn’t want to zoom around the workshop with ease?

Buying Guide for Benchtop Metal Lathe Carriages

Key specifications and considerations when purchasing. Tips for evaluating and selecting the right carriage.Looking for the perfect benchtop metal lathe carriage? Start by checking key specifications. Focus on size, material, and weight capacity. Ensure it matches your needs. A sturdy carriage keeps your projects steady. To make the best choice, think about how you plan to use it. Are you a hobbyist or a pro? If you’re unsure, don’t be afraid to ask an expert or even your neighbor, who knows his way around tools like a pro!

| Specification | Importance |

|---|---|

| Size | Fits your space and projects |

| Material | Durability matters! |

| Weight Capacity | Supports your projects safely |

Also, read reviews from other users. Their experiences can guide you. A wise shopper once said, “Read before you leap!” It’s true! Give yourself time to pick the right carriage, and soon you’ll be crafting like a metalworking wizard!

Conclusion

In summary, a benchtop metal lathe carriage is essential for precise metalworking. It helps you move and control the cutting tool. Understanding its parts can improve your projects. We encourage you to explore videos or guides on using a lathe. This knowledge will help you create better tools and parts, making your metalworking experience more enjoyable and rewarding.FAQs

What Are The Key Components Of A Benchtop Metal Lathe Carriage, And How Do They Function Together To Facilitate Machining?A benchtop metal lathe carriage has important parts. The saddle moves side to side, and the cross slide goes forward and backward. The tool post holds the cutting tool in place. Together, these parts help you shape metal by moving the tool while the metal spins. This way, you make things smoothly and accurately!

How Do You Properly Maintain And Lubricate The Carriage Of A Benchtop Metal Lathe To Ensure Optimal Performance?To keep the carriage of your benchtop metal lathe running well, you should clean it regularly. Use a soft cloth to wipe off dust and old grease. Then, apply a special oil or grease made for metal machines. Make sure to get into all the moving parts. Finally, check it often to keep everything smooth and working right.

What Common Issues Might Arise With A Benchtop Metal Lathe Carriage, And How Can They Be Diagnosed And Resolved?A benchtop metal lathe carriage can have some problems, like sticking or not moving smoothly. You can check if there is dirt or rust on it. Cleaning the carriage with a soft cloth helps a lot. Sometimes, parts may get loose, so you should tighten any screws you see. If it still doesn’t work, you may need to ask an adult for help.

How Does The Design Of A Benchtop Metal Lathe Carriage Compare To That Of Larger Industrial Lathes In Terms Of Precision And Functionality?A benchtop metal lathe carriage is smaller and simpler than those on bigger industrial lathes. Because it’s smaller, it can be less precise. However, it still works well for small projects. Larger lathes are built for tougher jobs and can make really exact parts. You can think of the benchtop lathe as a handy tool for smaller, everyday tasks.

What Accessories Or Upgrades Can Enhance The Capabilities Of A Benchtop Metal Lathe Carriage For More Advanced Machining Projects?To make your benchtop metal lathe better, you can add a few upgrades. A quick change tool post helps you change tools easily. You can also get a DRO, or digital readout, to measure more accurately. Adding a larger chuck gives you more options for the pieces you can work on. Finally, a steady rest helps keep your work steady for cleaner cuts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components Of A Benchtop Metal Lathe Carriage, And How Do They Function Together To Facilitate Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A benchtop metal lathe carriage has important parts. The saddle moves side to side, and the cross slide goes forward and backward. The tool post holds the cutting tool in place. Together, these parts help you shape metal by moving the tool while the metal spins. This way, you make things smoothly and accurately!”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain And Lubricate The Carriage Of A Benchtop Metal Lathe To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the carriage of your benchtop metal lathe running well, you should clean it regularly. Use a soft cloth to wipe off dust and old grease. Then, apply a special oil or grease made for metal machines. Make sure to get into all the moving parts. Finally, check it often to keep everything smooth and working right.”}},{“@type”: “Question”,”name”: “What Common Issues Might Arise With A Benchtop Metal Lathe Carriage, And How Can They Be Diagnosed And Resolved? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A benchtop metal lathe carriage can have some problems, like sticking or not moving smoothly. You can check if there is dirt or rust on it. Cleaning the carriage with a soft cloth helps a lot. Sometimes, parts may get loose, so you should tighten any screws you see. If it still doesn’t work, you may need to ask an adult for help.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Benchtop Metal Lathe Carriage Compare To That Of Larger Industrial Lathes In Terms Of Precision And Functionality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A benchtop metal lathe carriage is smaller and simpler than those on bigger industrial lathes. Because it’s smaller, it can be less precise. However, it still works well for small projects. Larger lathes are built for tougher jobs and can make really exact parts. You can think of the benchtop lathe as a handy tool for smaller, everyday tasks.”}},{“@type”: “Question”,”name”: “What Accessories Or Upgrades Can Enhance The Capabilities Of A Benchtop Metal Lathe Carriage For More Advanced Machining Projects? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your benchtop metal lathe better, you can add a few upgrades. A quick change tool post helps you change tools easily. You can also get a DRO, or digital readout, to measure more accurately. Adding a larger chuck gives you more options for the pieces you can work on. Finally, a steady rest helps keep your work steady for cleaner cuts.”}}]}