Have you ever wondered how small metal pieces are made? It’s pretty fascinating! One big part of that process involves a benchtop metal lathe chuck. You might ask, what exactly is a chuck? Think of it as a clamp for holding metal. It keeps the metal steady while the lathe spins it around.

Using a benchtop metal lathe chuck can be exciting, especially for hobbyists or makers. Have you ever tried turning a piece of metal into something cool? With the right chuck, you can create beautiful shapes and designs.

Here’s a fun fact: some lathes are so precise that they can cut metal to nearly the thickness of a human hair! Imagine what you could create with that kind of tool.

This article will explore how to choose the right benchtop metal lathe chuck for your projects. Are you ready to discover the magic of metalworking?

Benchtop Metal Lathe Chuck: Essential Tools For Precision

Discovering the Benchtop Metal Lathe Chuck

A benchtop metal lathe chuck is key for holding tools while you work. This tool helps you create precise parts for projects. Have you ever built something and needed perfect accuracy? A lathe chuck helps with that! You can find different types, like 3-jaw and 4-jaw chucks. Each has unique benefits. Did you know that choosing the right chuck can make shaping metal easier? Users love how versatile they are for various tasks. Explore how a metal lathe chuck can elevate your craftsmanship!Types of Chucks for Metal Lathes

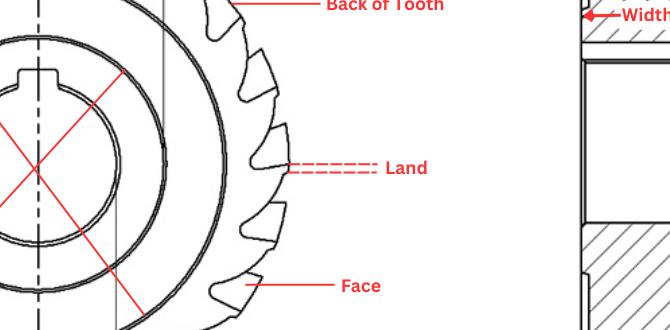

Threejaw vs. fourjaw chucks. Specialty chucks and their applications.Metal lathes use different types of chucks to hold materials tightly. The three-jaw chuck is popular because it grips round items evenly. It’s like a friendly octopus that hugs your workpiece! A four-jaw chuck offers more control. You can hold square or odd-shaped objects with ease. Then, there are specialty chucks, which serve unique tasks, such as gripping soft metals or even wood. They are like the Swiss Army knives of chucks!

| Chuck Type | Best For |

|---|---|

| Three-Jaw Chuck | Round shapes |

| Four-Jaw Chuck | Square/odd shapes |

| Specialty Chucks | Unique materials/tasks |

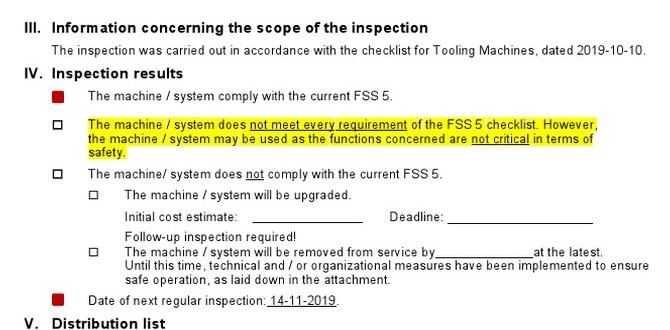

Key Features to Consider When Choosing a Chuck

Size and compatibility. Grip strength and precision.Choosing the right chuck can be tricky. First, think about size and compatibility. Make sure the chuck fits your lathe model. A mismatched chuck won’t work well. Next, consider grip strength and precision. A strong grip holds materials tightly, and precise movement helps create better products. Look for chucks with sturdy designs for great results.

What should I check before buying a chuck?

You should check the size compatibility with your lathe and the grip strength for holding materials securely. This will help achieve better accuracy in your work.

Key Features to Check:

- Size: Must fit the lathe.

- Grip: Should hold pieces firmly.

- Precision: Allows for accurate shaping.

Installation and Setup of Benchtop Metal Lathe Chucks

Stepbystep installation guide. Best practices for setup and alignment.Setting up your benchtop metal lathe chuck doesn’t have to be a puzzle! Start by securely bolting the chuck to the lathe. Make sure it’s tight—no one likes a wobbly chuck, right? Next, check your alignment by spinning it gently. If it wobbles like a penguin on ice, adjust it! The key is to ensure everything is level. Use a dial indicator if you can. It’s like having a tiny helper. So, let’s make it neat and precise!

| Step | Description |

|---|---|

| 1 | Securely fasten the chuck to the lathe. |

| 2 | Check alignment by spinning the chuck. |

| 3 | Adjust if necessary for a level setup. |

| 4 | Use a dial indicator for precision. |

Remember, a well-installed chuck can help you make smooth cuts. Or at the very least, it’ll save you from a wild ride in your workshop!

Maintenance Tips for Metal Lathe Chucks

Regular cleaning and lubrication. Troubleshooting common issues.Keeping your chuck clean and well lubricated is key to happy machining! Dust and shavings can jam it up faster than a cat on a hot tin roof. Give it a quick wipe after each use. For lubrication, a little oil goes a long way—think of it as a spa day for your metal lathe chuck! If things start to feel rough, it’s time to troubleshoot. Check for dirt or wear, because nobody wants a chuck that acts like it’s been wrestling with an octopus!

| Common Issues | Quick Fixes |

|---|---|

| Chuck not gripping | Clean and tighten the jaws. |

| Rust spots | Use rust remover and reapply lubricant. |

| Uneven spinning | Check alignment and adjust accordingly. |

Comparative Analysis of Popular Brands and Models

Features of top brands. Pros and cons of different models.Many brands offer exciting features in their benchtop metal lathe chucks. Some are known for their easy setup and solid grip. Other models shine with their precision and durability. But wait! Each model has its ups and downs. For example, a top brand might be expensive but work like a charm. Meanwhile, a budget option may save you cash but fall short on quality. Let’s look at some popular choices:

| Brand | Features | Pros | Cons |

|---|---|---|---|

| Brand A | Precision grip | High-quality | Pricey |

| Brand B | Easy to use | Affordable | Less durable |

| Brand C | Lightweight | Great for beginners | Weak hold |

In the world of lathes, not every shiny model is gold. Choose wisely, and your projects will shine like a knight in armor!

Applications of Benchtop Metal Lathe Chucks

Use cases in various industries. DIY projects and hobbyist applications.Benchtop metal lathe chucks are great tools for many jobs. They help make parts in different industries. For example, manufacturing uses them to shape metal for machines. In the automotive industry, they create precise components for cars. Hobbyists love them too! They use benchtop chucks for their DIY projects.

Here are some popular applications:

- Making custom parts for machines.

- Creating jewelry or art projects.

- Repairing or building model engines.

What are common uses for benchtop metal lathe chucks?

Benchtop metal lathe chucks are used mostly in crafts, repairs, and small manufacturing tasks. They make shaping metal easy and fun.

Conclusion

In summary, a benchtop metal lathe chuck holds your workpieces securely. It helps you shape metal parts efficiently. Choosing the right chuck enhances your projects and saves time. We should explore different types and sizes to find the best fit. Now, check out some tutorials or guides to learn how to use your lathe chuck effectively!FAQs

What Are The Different Types Of Chucks Available For Benchtop Metal Lathes, And How Do They Differ In Functionality?There are different types of chucks for metal lathes. The most common are three-jaw, four-jaw, and collet chucks. Three-jaw chucks hold round pieces tightly and are easy to use. Four-jaw chucks can grab both round and square things, but they take longer to set up. Collet chucks are great for smaller parts and hold them more precisely. Each type has its own special job!

How Do You Properly Install And Align A Chuck On A Benchtop Metal Lathe To Ensure Precision Machining?To install a chuck on a benchtop metal lathe, first, clean both the chuck and the spindle. Then, line up the chuck’s holes with the holes on the spindle. Use screws to attach the chuck tightly. Once it’s on, check that it spins straight. You can do this by using a dial indicator or measuring tool to see if it wobbles.

What Factors Should Be Considered When Selecting A Chuck For Specific Metal Lathe Applications?When picking a chuck for a metal lathe, think about the size of your workpiece. You should also consider the shape of what you’re holding. Different materials may need different types of chucks. Finally, remember how much force you will use. This helps keep everything safe while you work!

How Can You Troubleshoot Common Issues With Chucks On Benchtop Metal Lathes, Such As Jaw Misalignment Or Vibration During Operation?To fix problems with chucks on your metal lathe, start by checking the jaws. Make sure they are clean and not damaged. If the jaws don’t line up right, loosen them and adjust. For vibration, check that everything is tight and balanced. You can also run the lathe at slower speeds to see if it helps.

What Maintenance Practices Should Be Followed To Prolong The Lifespan And Performance Of A Benchtop Metal Lathe Chuck?To keep your lathe chuck working well, you should clean it often. Use a soft cloth to wipe off dirt and oil. Check for any loose parts and tighten them if needed. Apply a little grease on the moving parts to help them slide easily. Finally, always store it in a safe, dry place when you’re not using it.