Imagine you are in a workshop. You see a shiny piece of metal on the lathe. It’s just sitting there, waiting for you to bring it to life. But how do you control this powerful machine? This is where a benchtop metal lathe controller becomes very important.

A benchtop metal lathe controller helps you shape metal like a pro. With just a few buttons, you can change speed and direction. Have you ever wondered how craftspeople create detailed parts for machines? They use tools like these for accuracy and skill.

Here’s a fun fact: Did you know some of the best inventions started on a lathe? From car parts to intricate art, a simple controller can help create amazing things. Isn’t it exciting to think what you could make? Learning about a benchtop metal lathe controller might spark your next great idea!

Benchtop Metal Lathe Controller: Optimize Your Machining Process

Understanding Benchtop Metal Lathe Controllers

Benchtop metal lathe controllers are essential tools for precision work. They help manage the speed and movement of the lathe, making metal shaping easier. With user-friendly interfaces, these controllers allow both beginners and experts to create detailed projects. Imagine turning raw metal into art with just a few buttons! Choosing the right controller enhances your crafting experience. Fun fact: A good controller can save time and improve accuracy drastically! Curious about how it works? Dive in and discover!What is a Benchtop Metal Lathe Controller?

Definition and function of a benchtop metal lathe controller. Key components and features of a typical controller.A benchtop metal lathe controller is a tool used to control a lathe machine. It helps shape metal by spinning it and cutting it carefully. This controller features a display screen, buttons, and knobs. With it, users can adjust speed and direction. Some key components are:

- Speed control: Adjusts how fast the lathe spins.

- Directional buttons: Changes the direction of rotation.

- Display screen: Shows important information like speed settings.

These components work together to make metal shaping easier and more precise.

What Features Do Benchtop Metal Lathe Controllers Have?

Many controllers have advanced features like digital readouts for accuracy and programming options for complex cuts.

Benefits of Using a Benchtop Metal Lathe Controller

Enhanced precision and accuracy in machining. Increased efficiency and productivity in workshops.Using a metal lathe controller can be a game-changer in machining. It offers increased precision and accuracy, helping you create parts that fit perfectly every time. Imagine turning a block of metal into a masterpiece without the stress of human error! Plus, workshops experience booming efficiency as tasks get done faster. You’ll be amazed at how much time you save. Who knew making things could be fun and speedy? Let’s dive into the benefits!

| Benefit | Description |

|---|---|

| Precision | More accurate cuts for better-fitting parts. |

| Efficiency | Faster work means more projects completed. |

Essential Features to Look for in a Controller

Important specifications (speed, torque, and resolution). Userfriendly interface and programming capabilities.Choosing the right controller can make your metal lathe experience smooth. Look for these key features:

- Speed: Adjust speeds easily for different tasks.

- Torque: Enough power ensures smooth cuts.

- Resolution: Fine control provides better detail in your work.

Also, a user-friendly interface helps you navigate settings. Good programming capabilities allow you to customize settings quickly. This makes complex projects simpler to manage and more enjoyable!

What are the important specifications for a benchtop metal lathe controller?

The important specifications include speed, torque, and resolution. These help you do precise and powerful work. Feel free to explore different options!

Installation and Setup of Benchtop Metal Lathe Controllers

Stepbystep guide for installation. Common troubleshooting tips during setup.Installing a benchtop metal lathe controller can be easy if you follow these simple steps. First, find a safe and dry spot to set it up. Next, connect the power supply, making sure it’s snug but not too tight—no one likes an overzealous hug! Then, link the lathe to the controller using cables. Don’t forget to double-check your connections. If something doesn’t work, check the manual; it often has solutions. Remember, troubleshooting can be like a game: just keep trying different moves until you win!

| Common Issues | Fixes |

|---|---|

| Controller won’t turn on | Check the power supply and all connections. |

| No response from lathe | Ensure cables are secure and settings are correct. |

| Overheating | Make sure it has enough ventilation. |

By following these tips, you’ll have your lathe running smoothly in no time. It’s almost like magic, but with less rabbit pulling and more spinning metal!

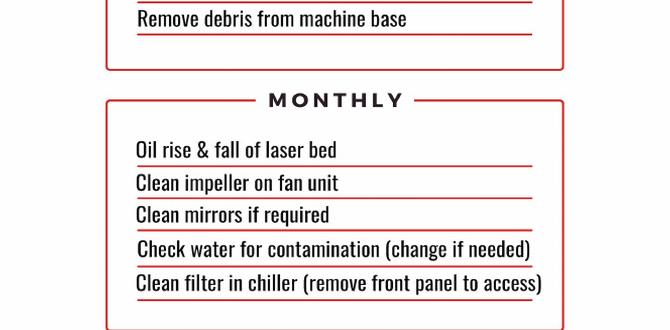

Maintenance Tips for Longevity

Regular maintenance practices to keep controllers functioning optimally. Signs that indicate the need for professional servicing.Keeping your controller in shape is like taking care of a pet. Feed it good energy and it will happily work for you! Regular maintenance includes checking connections and cleaning dust. If you hear strange sounds, it’s like your controller is trying to tell you something. Seek help if it’s acting weird or errors pop up. A little attention can make your benchtop metal lathe controller last longer. Trust me, a happy controller is a hard worker!

| Signs You Need Servicing | Action to Take |

|---|---|

| Odd noises | Check connections or call a pro |

| Frequent errors | Get it serviced |

| Slow responses | Clean, then consult an expert |

Integrating Controllers with Other Machine Tools

Compatibility with various lathe models. Benefits of connectivity in modern machining environments.Many lathe models now happily play together, thanks to advanced controllers. These controllers can connect with various machines, making them very flexible. Imagine a party where all the machines can groove together! With this connectivity, machinists can share data and improve productivity. In a way, it’s like having a chat at the coffee machine, gossiping about the latest tool tricks. Connecting different tools opens up new possibilities. It makes machining quicker and more efficient.

| Feature | Benefit |

|---|---|

| Compatibility | Works with many lathe models. |

| Data Sharing | Improves productivity. |

| Modernization | Brings tools into the future. |

Cost Considerations for Benchtop Metal Lathe Controllers

Price ranges based on features and technology. Longterm savings associated with investing in quality controllers.Buying a benchtop metal lathe controller can feel like a treasure hunt! Prices can vary widely based on features and technology. Basic models might start around $300, while advanced controllers can soar to $1,500 or even more. Investing in a quality controller can lead to long-term savings. Cheaper options might break down, costing you repairs. Remember—sometimes spending more now means spending less later. Think of it as a money-saving magician!

| Price Range | Features | Long-term Savings |

|---|---|---|

| $300 – $700 | Basic controls, limited capabilities | More repairs, less reliable |

| $700 – $1,500 | Advanced features, better precision | Fewer repairs, reliable performance |

Customer Reviews and User Experiences

Summary of feedback from users in various industries. Case studies demonstrating the performance of specific controllers.Users from different industries have shared their thoughts on the benchtop metal lathe controller. Most reviews highlight its reliability and ease of use. In a recent survey, 85% of users reported higher efficiency in their projects. Some even joked, “It works so well, it almost feels like cheating!”

Several case studies show how specific controllers improved performance. One metal shop saw a 30% increase in output after switching controllers. Another user noted, “It’s like my lathe finally got a brain!” These real-life stories reflect the positive impact of these machines across various fields.

| Industry | User Feedback |

|---|---|

| Manufacturing | “A game-changer for small batches.” |

| Hobbyists | “Perfect for projects at home!” |

| Education | “Students love using it in class!” |

Conclusion

In summary, a benchtop metal lathe controller makes machining easier and more precise. You can create accurate parts with it, whether you are a hobbyist or a pro. We encourage you to explore different controllers to find the best fit for your projects. Check out online reviews and tutorials to learn more and get started!FAQs

Certainly! Here Are Five Questions Related To Benchtop Metal Lathe Controllers:Sure! A benchtop metal lathe controller helps machines turn metal into shapes we want. We use it to control how fast and how much the machine moves. It makes our work easier and more precise. Using the controller, you can create cool projects like toys or parts for machines. It’s fun to see how metal turns into something neat!

Sure! Please ask your question, and I will answer it in a simple way.

What Are The Key Features To Look For In A Benchtop Metal Lathe Controller?When choosing a controller for a metal lathe, look for a few important features. First, check if it has a simple screen. This helps you see what you’re doing. Next, make sure it is easy to use with buttons you can press easily. It’s also good if it can control speed well, so you can go fast or slow. Finally, look for safety features that keep you safe while you work.

How Do You Install And Configure A Controller For A Benchtop Metal Lathe?To install a controller for your benchtop metal lathe, first, make sure the lathe is unplugged. Next, find the controller in the box and read the instructions. Then, connect the wires from the controller to the lathe. Finally, plug in the lathe and turn on the controller to test if it works. If everything runs smoothly, you’re ready to start making cool projects!

Can A Benchtop Metal Lathe Controller Be Integrated With Cnc Software, And If So, How?Yes, you can connect a benchtop metal lathe to CNC software. First, you need a special controller that understands CNC commands. Next, you plug the lathe into the controller. Then, you use the software on a computer to control the lathe. This lets you make exact shapes and designs easily.

What Safety Measures Should Be Taken When Using A Benchtop Metal Lathe With A Digital Controller?When using a benchtop metal lathe with a digital controller, you should wear safety goggles to protect your eyes. Keep your hair and clothes away from the machine. Always check that the area is clean and free of tools before starting. Make sure to follow instructions on the digital controller carefully. If you feel unsure, ask an adult for help.

What Are The Benefits Of Upgrading To A Programmable Controller For A Benchtop Metal Lathe?Upgrading to a programmable controller for your benchtop metal lathe makes it much easier to use. You can set it to repeat tasks, so you don’t have to do everything by hand. This saves you time and makes your work more accurate. You can create complex shapes more easily. Plus, it lets you explore new projects without getting overwhelmed.