Have you ever wondered how a small metal part is made? It all begins with a benchtop metal lathe drive system. This trusty tool spins metal and shapes it with precision. It’s like magic when a simple piece of metal transforms into something useful.

Picture this: you’re in a workshop filled with buzzing machines. You see the metal lathe in action. Sparks fly as the metal is cut into perfect shapes. It’s fascinating, isn’t it? Every maker uses these machines to build tools, parts, and even art!

But how does the drive system work? This system is the heart of the lathe. It controls the speed and movement. Without a good drive system, making precise parts would be nearly impossible. Let’s dive into the world of benchtop metal lathe drive systems and discover their secrets!

Benchtop Metal Lathe Drive System: A Comprehensive Guide

Benchtop Metal Lathe Drive System

The benchtop metal lathe drive system is vital for precision machining. It transforms motor power into smooth, steady rotation, allowing users to shape metal accurately. Many lathes use gears or pulleys for this conversion, impacting performance and durability. A good drive system ensures consistent speed and torque, making it easier to create detailed projects. Have you ever wondered how small adjustments can lead to big changes in your crafts? This system makes that possible!What is a Benchtop Metal Lathe?

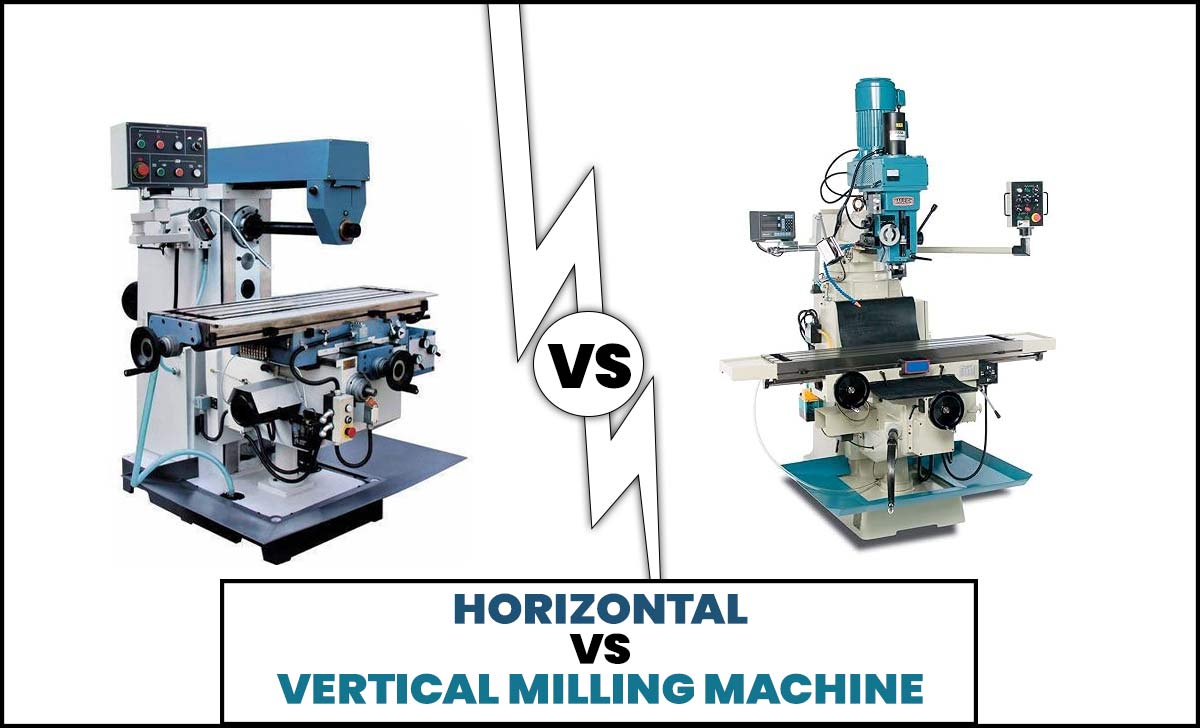

Definition and purpose of benchtop metal lathes. Comparison with larger lathes and their advantages.A benchtop metal lathe is a tool used for shaping metal. It spins metal pieces while cutting tools shape them. This is perfect for small projects and detailed work. Compared to larger lathes, benchtop models are compact, making them easy to use in small spaces. They are less expensive and great for hobbyists.

- Space-saving design

- Lower cost

- Good for small details

What is the purpose of a benchtop metal lathe?

The purpose is to allow users to create precise metal parts and designs with ease.

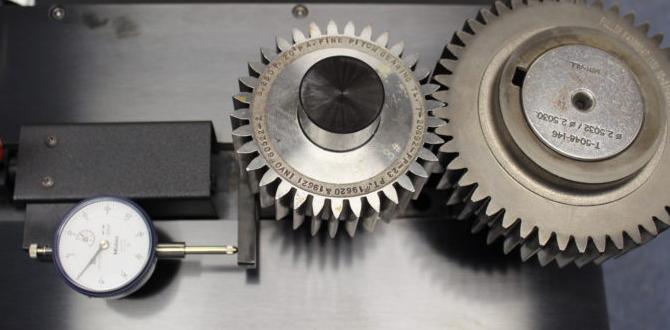

Key Components of a Drive System

Explanation of the main components: motor, belts, gears. Importance of each component in the overall functionality.A drive system is made up of key parts that work together. The main components are:

- Motor: This powers the lathe. It turns energy into motion.

- Belts: These connect the motor to other parts. They transfer the motion smoothly.

- Gears: These adjust the speed and torque. They help control the machine’s strength.

Each part is important. Without a motor, nothing moves. Belts keep everything connected. Gears make sure the lathe works properly. Together, they make the drive system effective!

What are the key parts of a drive system?

The motor, belts, and gears are the key parts. Each plays a vital role in making the lathe work smoothly.

Selecting the Right Drive System for Your Needs

Factors to consider: usage frequency, material type, and desired precision. Recommendations for hobbyists vs. professional users.Choosing the right drive system is key for success. Think about how often you will use the lathe. If you work a lot, you need a strong and stable system. Material type matters too. Softer materials require less power, while harder materials need more strength. Desired precision changes based on your projects. Hobbyists may not need high precision, but professionals usually do. Here are some tips:

- Hobbyists: Look for basic, affordable options.

- Professionals: Invest in advanced, precise systems.

- Use our guide to fit your needs.

What should I consider for a drive system?

Consider usage frequency, material type, and desired precision before choosing your drive system. This makes sure you get the best fit for your needs.

Maintenance Tips for Longevity of Drive Systems

Routine maintenance practices to enhance performance. Common issues and troubleshooting techniques.Taking care of your metal lathe drive system can make it last longer and work better. Regularly oiling parts keeps them running smoothly and prevents rust, like putting butter on toast! Check for loose screws or worn belts—tightening them can save you from future headaches. If something sounds funny, like a cat meowing, it’s time to investigate. Here’s a helpful guide:

| Maintenance Task | Frequency | Issues to Watch For |

|---|---|---|

| Lubricate moving parts | Every month | Rust, noise |

| Check belts | Every three months | Wear, slippage |

| Tighten screws | Every six months | Vibration, rattling |

So, keep up with these tasks, and your lathe can run like a well-oiled machine—or at least like a happy robot dancing to music!

Upgrading Your Benchtop Lathes Drive System

When and why to consider upgrades. Suggestions for aftermarket drive system components.Upgrading your lathe’s drive system can transform your crafting experience. If you notice your machine struggles or makes weird noises, it’s time for a change. Better components help with performance and can even save you time. From motors to pulleys, there are many aftermarket options available. Don’t worry, upgrading doesn’t mean your lathe will grow arms and start doing your work for you!

| Component | Benefits |

|---|---|

| DC Motor | Provides smoother operation and better speed control. |

| Belt System | Reduces vibration and enhances durability. |

Consider these upgrades to maximize your lathe’s abilities and make your projects more enjoyable.

Comparing Popular Brands and Models

Review of top manufacturers and their offerings. Features and specifications to look for in highquality systems.Many brands offer great benchtop metal lathes. Brand A stands out for strong motors and precision. Brand B excels with user-friendly controls. Brand C is known for its value and sturdy build. Here are features to consider:

- Motor Power: Higher power means better performance.

- Speed Range: More speeds allow for versatile projects.

- Build Quality: A solid lathe lasts longer.

- Ease of Use: Look for simple controls for beginners.

Choosing the right model can make a big difference in your work.

What are the best brands for benchtop metal lathes?

Top brands include Grizzly, Jet, and Sherline. They all offer reliable performance and a range of features that suit different needs.

Cost Analysis of Benchtop Lathe Drive Systems

Breakdown of costs associated with different types of drive systems. Budgeting tips for beginners and experienced users alike.Understanding the costs of different drive systems helps you make smart choices. Drive systems can range from budget-friendly options to pricey ones with extra features. For beginners, plan your budget like it’s a fun treasure hunt. Think about getting a great deal without sacrificing quality. Experienced users? Look for special discounts to save cash. Here’s a simple breakdown of costs:

| Type of Drive System | Average Cost |

|---|---|

| DC Motor | $150 |

| AC Motor | $300 |

| Stepper Motor | $200 |

| Servo Motor | $400 |

Remember, a fantastic lathe drive system doesn’t always mean spending a fortune. Keep your eyes open, and you might just score the best one at a surprising price!

Real User Experiences and Testimonials

Insights from hobbyists and professionals on their choices. Success stories and improvements after upgrading systems.Many users share great stories about their benchtop metal lathe drive system experiences. Hobbyists often improve their skills after upgrading their machines. Professionals report increased efficiency and better results. Here are some insights:

- Upgrades lead to smoother operation.

- Hobbyists create more impressive projects.

- Time savings are reported by many users.

One user said, “I never knew my projects could look this good!” Many feel that investing in a better drive system is worthwhile.

What are common benefits after upgrading your drive system?

Upgrading a drive system often results in improved accuracy, reduced noise, and enhanced speed.

Conclusion

In summary, a benchtop metal lathe drive system is essential for metalworking. It allows you to create accurate shapes and designs. Understanding its parts can help you use it better. We encourage you to explore more about different drive systems and their features. This knowledge will enhance your skills and projects. Start experimenting and enjoy your metalworking journey!FAQs

Sure! Here Are Five Related Questions On The Topic Of Benchtop Metal Lathe Drive Systems:A benchtop metal lathe uses a drive system to spin and shape metal. You can think of it like a giant pencil sharpener for metal. The drive system makes the machine go faster or slower, just like how you can twist a knob to change the volume on a radio. This helps you get the right shape for your project. It’s important to keep the drive system clean and well-oiled for best results.

Sure! Please provide the question you would like me to answer.

What Are The Key Components Of A Benchtop Metal Lathe Drive System, And How Do They Work Together To Facilitate Turning Operations?A benchtop metal lathe drive system has a few key parts. First, there is a motor. It gives power to the lathe. Second, we have belts and pulleys. These help the motor turn the lathe’s spindle. Finally, the spindle holds the metal piece and spins it. Together, these parts help us shape metal into different forms.

How Do Different Types Of Drive Systems (E.G., Belt-Driven, Direct Drive, And Gear-Driven) Affect The Performance And Versatility Of A Benchtop Metal Lathe?Different drive systems change how a benchtop metal lathe works. A belt-driven system uses a rubber belt. This system is flexible and can change speeds easily. A direct drive system connects the motor straight to the machine. This makes it powerful and quick, but it can be less flexible. A gear-driven system uses gears to control speed and torque. This means you can use it for tough jobs, but it may be slower to change speeds. Each system has its own strengths, so choose one that fits your needs!

What Factors Should Be Considered When Selecting A Motor For A Benchtop Metal Lathe Drive System To Ensure Optimal Performance For Various Machining Tasks?When picking a motor for a metal lathe, think about power first. More power helps for tough jobs. Next, consider speed. Different tasks need different speeds to work well. Don’t forget about size; the motor should fit in the lathe. Finally, check if the motor is easy to control. This way, you can adjust it for the best performance.

How Can One Troubleshoot Common Issues That May Arise In The Drive System Of A Benchtop Metal Lathe, Such As Vibrations, Inconsistent Speeds, Or Motor Overheating?To fix problems with a benchtop metal lathe, start by checking for loose parts. You can tighten bolts and screws. If the lathe shakes or vibrates, make sure it is level on the table. To fix speed issues, look at the belt that connects the motor to the lathe; it might need adjusting. If the motor gets too hot, let it cool down before using it again, and check if the motor is working properly.

What Are The Advantages And Disadvantages Of Using Variable Speed Drive Systems In Benchtop Metal Lathes Compared To Fixed Speed Systems?Using variable speed drive systems in benchtop metal lathes has some good and bad sides. The good part is you can change the speed easily, which helps you work better on different projects. This makes it easier to cut metal smoothly. But, a downside is that these systems can be more complicated and sometimes cost more. Fixed speed systems are simpler, but they can’t adjust as well for different tasks.