Have you ever thought about how things are made? It’s fascinating, right? A benchtop metal lathe handwheel is a key part of many machines.

This handy device helps you shape and cut metal with ease. Imagine creating perfect cylinders or intricate pieces in your garage. It’s like being a magician with metal!

Many people don’t know that a simple handwheel can change the way you work. Did you know that using a lathe can make your projects faster and more precise? It’s true!

Let’s dive into the world of benchtop metal lathes. You’ll discover how this simple tool can make metalworking fun and rewarding.

Benchtop Metal Lathe Handwheel: Enhance Precision And Control

Benchtop Metal Lathe Handwheel

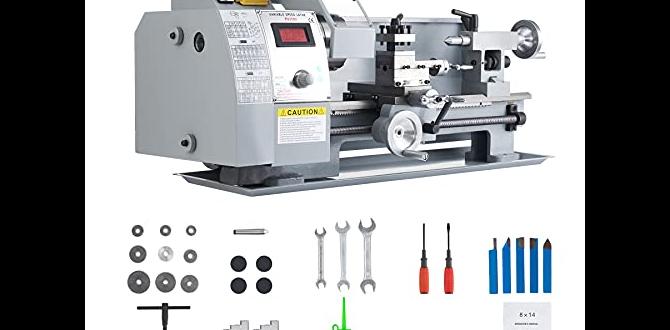

The benchtop metal lathe handwheel is a crucial tool for smooth metalworking. It allows precise control over the lathe’s movements. Do you wonder how artisans create such fine designs? With the handwheel, users can turn and adjust materials effortlessly, bringing their ideas to life. This tool is especially useful for beginners and experts alike. Fun fact: many start their metalworking journey using a simple benchtop lathe, learning skills that last a lifetime!What is a Benchtop Metal Lathe Handwheel?

Definition and purpose of the handwheel in metal lathes. Types of handwheels used in benchtop lathes.A handwheel is a round knob on a benchtop metal lathe that helps you control movement easily. It’s like using a steering wheel for your metalwork adventure! The purpose of the handwheel is to adjust the position of the tool or workpiece with precision. Now, there are two main types of handwheels found on benchtop lathes: the **manual handwheel** and the **power handwheel**. The manual version gives you full control, while the power one adds a little magic with powered movements.

| Type of Handwheel | Description |

|---|---|

| Manual Handwheel | Requires your hands to turn, giving precise movement. |

| Power Handwheel | Powered by the machine, making it easier to adjust. |

Key Features of Benchtop Metal Lathe Handwheels

Materials used in manufacturing handwheels. Size and ergonomic considerations for optimal use.Handwheels for benchtop metal lathes are made from strong materials like cast iron and aluminum. These materials make the handwheel durable and lightweight. The size of the handwheel matters, too. An ergonomic design fits comfortably in your hand. This allows for easier control, especially during long use. A good handwheel can improve your work quality. Always choose a size that feels right for you.

What are the advantages of ergonomic handwheels?

Ergonomic handwheels reduce strain on your hands and wrists. This makes it easier to work for longer periods. Plus, they help improve precision while you work.

Benefits of Using a High-Quality Handwheel

Enhancing precision and control in machining. Impact on overall lathe performance and productivity.Using a high-quality handwheel on a benchtop metal lathe improves machining precision. This leads to better shapes and sizes for your projects. When you have control over your tool, you can make changes easily. This makes your work faster and smoother.

Better handwheels also enhance the lathe’s overall performance. As a result, productivity can increase significantly. Here are some key benefits:

- Improved Accuracy: Cuts are more precise.

- Quicker Adjustments: You can make fast changes.

- Less Fatigue: Easier to use means less tiredness.

What makes a high-quality handwheel important?

A high-quality handwheel gives you better control and efficiency when using a lathe. It can reduce errors, leading to a smoother workflow and quicker project completion.

Choosing the Right Benchtop Metal Lathe Handwheel

Factors to consider when selecting a handwheel. Brand comparisons and recommendations.Picking a handwheel can feel like choosing between chocolate or vanilla ice cream—both delicious! First, think about size and grip; a comfy handwheel makes a big difference. Check out brands like Grizzly and Jet for reliable options. Look for one with good reviews, so you don’t end up with a wobbly disaster. Did you know that the right handwheel can improve your lathe’s accuracy by up to 20%? Here’s a quick comparison table to help:

| Brand | Grip Comfort | Durability | Price |

|---|---|---|---|

| Grizzly | High | Excellent | $$ |

| Jet | Medium | Good | $$$ |

| WEN | High | Fair | $ |

Installation and Maintenance of Handwheels

Stepbystep guide to properly install a handwheel. Maintenance tips for longevity and reliability.Installing a handwheel is important for your benchtop metal lathe. Follow these simple steps:

- Gather your tools: a wrench, screwdriver, and the handwheel.

- Remove the old handwheel if needed. Check for any dirt or debris.

- Align the new handwheel on the spindle. Ensure it sits straight.

- Tighten it with the wrench until secure but not too tight.

- Test the movement. It should turn smoothly.

For maintenance, keep it clean. Wipe it down after use. Check for loose screws regularly. Lubricate the handwheel with oil every few months for longevity. This helps keep it reliable and efficient.

How can I ensure my handwheel lasts longer?

Regular cleaning and lubrication are key. Inspect it for wear and tighten screws as needed.

Common Problems and Solutions with Handwheels

Identification of common issues faced by users. Troubleshooting tips and best practices.Handwheels on benchtop metal lathes can be tricky sometimes. You might notice the wheel feels stuck or doesn’t move as smoothly as a greased penguin. Common issues include slipping, wobbling, or grinding noises. To fix these, check for dirt buildup or loose screws. Keep it clean and tightened! Here’s a quick table for troubleshooting:

| Problem | Solution |

|---|---|

| Slipping | Adjust tension and check for wear. |

| Wobbling | Tighten the mounting screws. |

| Grinding Noises | Lubricate moving parts well! |

Using these tips, your handwheel can spin like a ballerina!

Upgrading Your Benchtop Metal Lathe Handwheel

Signs it’s time to upgrade your current handwheel. Market options for upgrades and enhancements.Knowing when to upgrade your handwheel is important. First, if you feel resistance while turning, it might be time for a change. Second, check for wear or damage. This can make working harder than needed. Lastly, if you want better precision while using your benchtop metal lathe, an upgrade can help.

There are many upgrade options on the market:

- Lightweight materials for easier movement.

- Large grips for better control.

- Digital readouts for precise measurements.

Upgrading can improve your work. Better tools mean better results!

Why Upgrade Your Handwheel?

Upgrading enhances precision and ease of use. A new handwheel can make your projects smoother and more enjoyable.

Real-World Applications of Handwheels in Metalworking

Case studies of projects utilizing benchtop lathes with handwheels. Insights from experienced metalworkers on effective usage.Handwheels play an essential role in metalworking projects. They offer precise control and make tasks easier. Here are some insights from metalworkers about using benchtop lathes with handwheels:

- For shaping metal parts, smooth movement is crucial. Handwheels allow for this.

- One project involved making custom knobs, where a handwheel provided perfect adjustments.

- Another case was a bicycle frame repair. A steady handwheel helped achieve the right fit.

Experts prefer handwheels for their accuracy. They suggest practicing on scrap metal first. This helps gain control before starting real projects.

What are practical uses for handwheels in metalworking?

Handwheels are used to adjust cutting depth and feed rate. They are ideal for creating parts that need exact measurements.

Frequently Asked Questions (FAQs) about Benchtop Metal Lathe Handwheels

Common queries and detailed answers regarding usage and features. Myths vs. facts surrounding handwheel benefits.People often have questions about the benchtop metal lathe handwheel. Understanding its use and features is important. Here are some common asks with easy answers:

What is the purpose of the handwheel?

The handwheel helps you move the lathe easily. It controls the cutting tools. Using it improves precision and makes work smoother.

Are they hard to use?

No, they are simple! Most people can learn quickly. Practice makes perfect. Use the handwheel gently for the best results.

What are some common myths about handwheels?

- Myth: Handwheels are only for experts.

- Fact: Beginners find them helpful too!

Do handwheels really improve efficiency?

Yes! They can save time and make tasks easier. Many users report quicker workdays with a handwheel.

Conclusion

In summary, the benchtop metal lathe handwheel is an important tool for precision work. It helps you easily control the movement of materials. With practice, you can create amazing projects. Remember to explore more about its features and techniques to improve your skills. Dive deeper into the world of lathes and start creating today!FAQs

Sure! Here Are Five Related Questions About Benchtop Metal Lathe Handwheels:Sure! A benchtop metal lathe is a machine that helps us shape metal. Handwheels are the round knobs we turn to control the lathe. They make it easier to move the metal piece closer to the cutting tool. By turning the handwheels, you can create different shapes and sizes. It’s like steering a vehicle, but with metal!

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help.

What Is The Primary Function Of The Handwheel On A Benchtop Metal Lathe?The handwheel on a benchtop metal lathe helps you move the tool closer to the metal piece. By turning the handwheel, you control how much the tool moves. This lets you shape the metal just right. It makes the job easier and more precise.

How Can You Adjust The Handwheel For Precise Control During Machining Operations?To adjust the handwheel for precise control, first, make sure it is clean and free of dirt. You can turn the handwheel slowly to see how it moves the machine part. If it feels too loose, tighten any screws. If it’s too tight, loosen them a bit. Practice turning it gently to get a feel for how it works!

What Are The Common Materials Used In The Construction Of Lathe Handwheels, And How Do They Affect Durability?Lathe handwheels are often made from metal or plastic. Metal, like steel, is very strong and lasts a long time. Plastic is lighter but can wear out faster. Using metal handwheels helps machines work better for longer periods. We want our tools to be tough and last, so choosing the right material is important.

Are There Any Aftermarket Modifications Or Upgrades Available For Lathe Handwheels To Enhance User Experience?Yes, there are aftermarket parts you can buy for lathe handwheels. These upgrades can make them easier to use. Some handwheels have better grips or smoother turning. You can also find bigger handwheels for more control. These changes can help you enjoy using your lathe more!

How Do Different Handwheel Designs Influence The Ease Of Use And Ergonomics For Operators Of Benchtop Metal Lathes?Different handwheel designs can make it easier or harder for you to use a benchtop metal lathe. A bigger handwheel is easier to grip and turn, which helps you make smooth movements. If the handwheel has a comfortable shape, it can lessen fatigue in your hands and arms. Some handwheels have special grips that make them easier to hold, which is better for long projects. Overall, good designs help you feel more comfortable while working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Benchtop Metal Lathe Handwheels:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A benchtop metal lathe is a machine that helps us shape metal. Handwheels are the round knobs we turn to control the lathe. They make it easier to move the metal piece closer to the cutting tool. By turning the handwheels, you can create different shapes and sizes. It’s like steering a vehicle, but with metal!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of The Handwheel On A Benchtop Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The handwheel on a benchtop metal lathe helps you move the tool closer to the metal piece. By turning the handwheel, you control how much the tool moves. This lets you shape the metal just right. It makes the job easier and more precise.”}},{“@type”: “Question”,”name”: “How Can You Adjust The Handwheel For Precise Control During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the handwheel for precise control, first, make sure it is clean and free of dirt. You can turn the handwheel slowly to see how it moves the machine part. If it feels too loose, tighten any screws. If it’s too tight, loosen them a bit. Practice turning it gently to get a feel for how it works!”}},{“@type”: “Question”,”name”: “What Are The Common Materials Used In The Construction Of Lathe Handwheels, And How Do They Affect Durability?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe handwheels are often made from metal or plastic. Metal, like steel, is very strong and lasts a long time. Plastic is lighter but can wear out faster. Using metal handwheels helps machines work better for longer periods. We want our tools to be tough and last, so choosing the right material is important.”}},{“@type”: “Question”,”name”: “Are There Any Aftermarket Modifications Or Upgrades Available For Lathe Handwheels To Enhance User Experience?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are aftermarket parts you can buy for lathe handwheels. These upgrades can make them easier to use. Some handwheels have better grips or smoother turning. You can also find bigger handwheels for more control. These changes can help you enjoy using your lathe more!”}},{“@type”: “Question”,”name”: “How Do Different Handwheel Designs Influence The Ease Of Use And Ergonomics For Operators Of Benchtop Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different handwheel designs can make it easier or harder for you to use a benchtop metal lathe. A bigger handwheel is easier to grip and turn, which helps you make smooth movements. If the handwheel has a comfortable shape, it can lessen fatigue in your hands and arms. Some handwheels have special grips that make them easier to hold, which is better for long projects. Overall, good designs help you feel more comfortable while working.”}}]}