Have you ever wondered how small metal pieces are shaped into precise parts? The answer often lies in the fascinating world of machine tools. Among them, a benchtop metal lathe is a powerful device that stands out. But what exactly makes it so special?

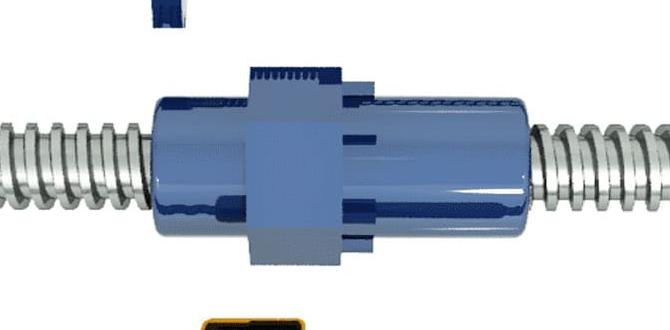

A benchtop metal lathe is compact and easy to use. It lets you create amazing things from metal with just a few simple steps. One important part of this machine is the lead screw. This tiny component plays a big role in moving the lathe accurately. Imagine you want to carve a beautiful design on a metal rod. The lead screw helps guide your tool perfectly, ensuring you get it right every time.

Did you know that lead screws have been around for a long time? They date back to ancient Greece! These clever devices have improved over the years, making machining easier and more precise. Using a benchtop metal lathe with a good lead screw can turn your metalworking dreams into reality.

So, are you ready to explore how this amazing tool works? Get ready to dive into the noisy yet exciting world of metal lathes!

Benchtop Metal Lathe Lead Screw: Essential Guide And Tips

Understanding the Benchtop Metal Lathe Lead Screw

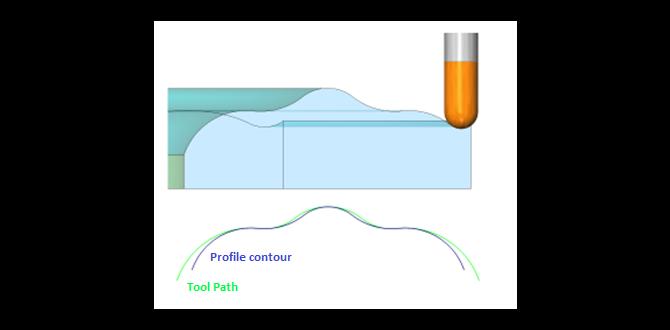

The lead screw of a benchtop metal lathe is crucial for precision machining. It controls the movement of the cutting tool along the workpiece. This mechanism helps ensure accurate cuts and smooth finishes. Imagine trying to carve a perfect sculpture without a steady hand—it’s nearly impossible! Choosing the right lead screw can elevate your projects and make metalworking more enjoyable. Did you know that even small adjustments can greatly improve your results? Exploring lead screw options might surprise you!What is a Lead Screw?

Definition and function in machining.. Importance in lathe operation and precision..A lead screw is a special type of screw that helps machines move parts smoothly. Think of it as a superpowered slider that can go back and forth! In machining, it plays a big role in moving the tool across the workpiece. The accuracy of the lead screw is vital for making precise cuts. If it isn’t accurate, your project might look like it went through a funhouse mirror!

| Function | Importance |

|---|---|

| Guides the tool movement | Ensures precise machining |

| Creates smooth motion | Helps maintain quality |

So, next time you see a lead screw, remember, it’s like the backbone of a lathe! Without it, making those fine cuts would be like trying to dance in clown shoes.

How Lead Screws Impact Lathe Performance

Influence on accuracy and repeatability in machining.. Effects on load capacity and material compatibility..Lead screws are key parts of a lathe. They help make sure your cuts are accurate. This means you get a smoother finish on your projects. If the lead screw is strong, it can hold heavier materials without bending. Here’s how lead screws impact performance:

- Accuracy: A tight lead screw means better precision in cutting.

- Repeatability: Consistent cuts every time build confidence in your work.

- Load Capacity: Stronger screws can handle more weight.

- Material Compatibility: Choose screws made from materials that fit your projects.

How does the lead screw affect machining quality?

The lead screw is crucial for achieving high-quality machining results. It ensures that each part is made just right, helping both new and experienced makers. Without a good lead screw, projects can turn out uneven.

Maintenance Tips for Lead Screws

Best practices for cleaning and lubrication.. Common issues and how to troubleshoot them..Keeping your lead screw in top shape is important. Regular cleaning helps it work better. Use a soft cloth to wipe away dirt. Lubrication is key too. Apply the right oil to keep it smooth. Avoid using too much oil, as this can attract dust. Here are some common issues:

- Grinding noise while moving

- Stiff movement

- Inconsistent threading

For troubleshooting, check for dirt buildup. Make sure it’s properly lubricated. Tightening loose parts can also help.

What are the best practices for maintaining a lead screw?

Regular cleaning and proper lubrication are the best practices for maintaining a lead screw. Check for wear often to catch issues early.

Choosing the Right Lead Screw for Your Benchtop Lathe

Factors to consider (e.g., material, length, thread pitch).. Recommendations for different lathe applications..Choosing the best lead screw for your benchtop lathe is important. Think about key factors like material, length, and thread pitch. These will affect how well your lathe performs. For precision work, go for a screw made of high-quality metal. If you need longer reach, choose a longer lead screw. A fine thread pitch helps with detailed cuts. Here are some tips:

- Use steel for strength.

- Choose aluminum for lighter tasks.

- A longer lead screw suits bigger projects.

- For fine work, pick a higher thread pitch.

What is the best material for lead screws?

The best material for lead screws is steel. It is strong and durable. However, aluminum is lighter and easier to handle for small jobs.

Upgrading Lead Screws: When and Why

Signs that your lead screw needs an upgrade.. Benefits of upgrading to a higher quality lead screw..Your lead screw might need an upgrade if you notice signs like uneven cuts or wobbly movements. A worn out lead screw can make your work harder. Upgrading can offer many benefits. Here are a few:

- Improved accuracy: Higher quality lead screws give you precise cuts.

- Better durability: Stronger materials last longer.

- Smoother operation: Upgraded screws reduce vibrations.

Overall, investing in a new lead screw can make your projects easier and more enjoyable.

How do I know if my lead screw needs replacement?

You can tell by checking for wear or poor accuracy in your cuts. If your machine makes noise or has difficulty moving, it may need a new lead screw.

Comparative Analysis of Popular Benchtop Lathes with Lead Screws

Highlighting top models and their lead screw specifications.. User reviews and performance ratings..Several popular benchtop lathes come with impressive lead screw features. Here are some top models worth knowing:

- Model A: 1/2 HP motor, 0.039-inch pitch lead screw

- Model B: 3/4 HP motor, 0.025-inch pitch lead screw

- Model C: 1 HP motor, 0.05-inch pitch lead screw

User reviews highlight their performance and ease of use. Many users rate Model A highly for precision. Model B shines with smooth operation. Model C receives praise for power. Overall, customers value reliability in these machines.

What are the benefits of using a benchtop lathe with a lead screw?

The lead screw helps create accurate movements and cuts, improving overall work quality.

Frequently Asked Questions (FAQs) about Lead Screws

Address common queries regarding lead screws in metal lathes.. Provide expert insights and solutions..Many people have questions about lead screws used in metal lathes. Let’s clear things up! A lead screw helps move the lathe tool smoothly, and it’s super important for precise work. You might wonder, “What should I do if my lead screw gets stuck?” The answer is easy: **clean it carefully, and make sure it’s lubricated!** Another common question is about replacing it. Don’t worry! **Usually, you just unscrew and swap it out.** Check the table below for more FAQs!

| Question | Answer |

|---|---|

| How often should I check my lead screw? | At least once a month! |

| Can I use any oil for lubrication? | No, use specific machine oil! |

| What if my lead screw is too loose? | It might need adjusting or replacing. |

Conclusion

In summary, a benchtop metal lathe lead screw is essential for precise machining. It helps move the tool smoothly along the metal. Understanding its function can improve your projects and skills. We encourage you to explore more about lathes and practice using one. This can make you a better maker and boost your creativity. Happy crafting!FAQs

What Is The Purpose Of The Lead Screw In A Benchtop Metal Lathe?The lead screw in a benchtop metal lathe helps the machine move the cutting tool smoothly. It turns as you work, which lets you make precise cuts. This keeps everything lined up so your pieces are shaped correctly. Without the lead screw, it would be hard to create the parts you want. It makes your job easier and more accurate!

How Can I Determine The Appropriate Lead Screw Pitch For My Metal Lathe Projects?To choose the right lead screw pitch for your metal lathe, start by deciding how precise you want to be. A smaller pitch means finer control. Check the projects you want to make. If they need tiny details, use a smaller pitch. For bigger cuts, a larger pitch works better.

What Are The Common Issues Associated With Lead Screws On Benchtop Metal Lathes, And How Can They Be Addressed?Lead screws on benchtop lathes can have some common problems. They might get worn out or dirty, which can cause them to move poorly. You can fix this by cleaning them and applying some oil. Sometimes, they can also bend, leading to more issues. If that happens, you may need to replace the lead screw.

What Materials Are Typically Used For Manufacturing Lead Screws In Benchtop Metal Lathes, And How Do They Affect Performance?Lead screws in benchtop metal lathes are usually made from steel, brass, or plastic. Steel is very strong and helps the lathe work smoothly. Brass is nice because it resists rust and wears down slowly. Plastic is lighter and cheaper but may not be as strong. The material you choose can change how well the lathe performs.

How Can I Maintain And Lubricate The Lead Screw On My Benchtop Metal Lathe For Optimal Operation?To keep your lead screw working well, first, clean it with a cloth to remove dirt and old oil. Next, apply a thin layer of machine oil or grease along the screw. Make sure to turn the screw while you do this so the oil spreads evenly. Check it regularly and clean it again if it gets dirty. This will help your lathe work smoothly!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of The Lead Screw In A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lead screw in a benchtop metal lathe helps the machine move the cutting tool smoothly. It turns as you work, which lets you make precise cuts. This keeps everything lined up so your pieces are shaped correctly. Without the lead screw, it would be hard to create the parts you want. It makes your job easier and more accurate!”}},{“@type”: “Question”,”name”: “How Can I Determine The Appropriate Lead Screw Pitch For My Metal Lathe Projects? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right lead screw pitch for your metal lathe, start by deciding how precise you want to be. A smaller pitch means finer control. Check the projects you want to make. If they need tiny details, use a smaller pitch. For bigger cuts, a larger pitch works better. “}},{“@type”: “Question”,”name”: “What Are The Common Issues Associated With Lead Screws On Benchtop Metal Lathes, And How Can They Be Addressed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lead screws on benchtop lathes can have some common problems. They might get worn out or dirty, which can cause them to move poorly. You can fix this by cleaning them and applying some oil. Sometimes, they can also bend, leading to more issues. If that happens, you may need to replace the lead screw.”}},{“@type”: “Question”,”name”: “What Materials Are Typically Used For Manufacturing Lead Screws In Benchtop Metal Lathes, And How Do They Affect Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lead screws in benchtop metal lathes are usually made from steel, brass, or plastic. Steel is very strong and helps the lathe work smoothly. Brass is nice because it resists rust and wears down slowly. Plastic is lighter and cheaper but may not be as strong. The material you choose can change how well the lathe performs.”}},{“@type”: “Question”,”name”: “How Can I Maintain And Lubricate The Lead Screw On My Benchtop Metal Lathe For Optimal Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your lead screw working well, first, clean it with a cloth to remove dirt and old oil. Next, apply a thin layer of machine oil or grease along the screw. Make sure to turn the screw while you do this so the oil spreads evenly. Check it regularly and clean it again if it gets dirty. This will help your lathe work smoothly!”}}]}