Do you have a benchtop metal lathe? If so, you know how handy it can be for your projects. But did you know that proper maintenance can keep it running smoothly for years? Just like a bicycle needs air in its tires, your lathe needs care too.

Imagine being in your workshop, ready to create something amazing. Suddenly, your lathe isn’t working right. Frustrating, isn’t it? Regular maintenance can prevent those moments. It’s not just about fixing problems; it’s about making sure your tools stay ready for action.

Here’s a fun fact: a well-maintained lathe can last much longer than one that’s neglected. Just shining it up and checking the parts often can make a big difference. So, let’s dive into the world of benchtop metal lathe maintenance. You’ll discover helpful tips that can keep your machine in top shape. Are you ready to learn how to care for your lathe like a pro?

Essential Benchtop Metal Lathe Maintenance Tips For Longevity

Benchtop Metal Lathe Maintenance

Keeping your benchtop metal lathe in top shape is easier than you think! Regular cleaning helps remove dust and chips. Lubricating moving parts prevents wear and ensures smooth operation. Do you check the alignment often? Proper alignment is key for accuracy in your work. A fascinating fact: even small adjustments can lead to big improvements! Following these simple maintenance steps will extend the life of your lathe and improve your projects’ quality.Understanding Your Benchtop Metal Lathe

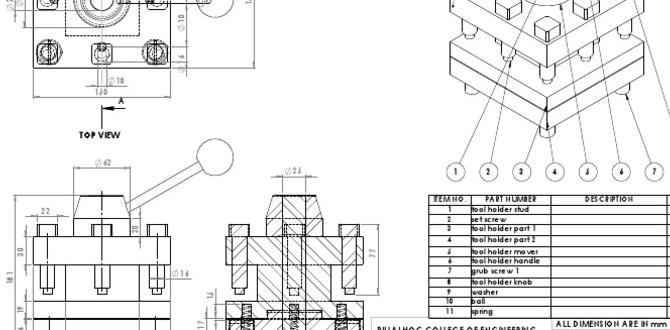

Components of a benchtop metal lathe. Importance of maintenance for longevity and performance.A benchtop metal lathe has many important parts. Each component helps the lathe work well. Key parts include the headstock, tailstock, bed, and carriage. Taking care of these parts is vital. Proper maintenance ensures the lathe lasts longer and runs better. Clean and oil them regularly. A well-maintained lathe gives smoother cuts and can save you money.

Why is maintenance important?

Regular maintenance helps keep your lathe in top shape. It reduces wear and tear. This means better performance and fewer repairs. Follow a routine to check for loose parts or rust.

- Check oil levels

- Clean chips and dust

- Tighten bolts and screws

Remember, a little care goes a long way!

Regular Maintenance Schedule

Daily, weekly, and monthly maintenance tasks. Recommended tools and supplies for maintenance.Keeping your benchtop metal lathe in shape is like brushing your teeth—do it often or face the consequences! Daily checks are simple; just clean off the dust and check for any odd sounds. Weekly, inspect the belts and lubricate moving parts. Monthly maintenance? It’s like a spa day for your lathe—tighten bolts and replace old lubricant. Remember, you’ll need some handy tools like wrenches, oil cans, and cleaning brushes. Here’s a quick look:

| Schedule | Tasks | Tools |

|---|---|---|

| Daily | Clean dust, check noises | Brush, cloth |

| Weekly | Inspect belts, lubricate | Oil can, wrench |

| Monthly | Tighten bolts, check lubricant | Wrenches, new oil |

So, keep your lathe happy, and it will help you create amazing things—no one likes a grumpy lathe!

Cleaning Your Metal Lathe

Proper cleaning techniques and materials. Removing chips and debris effectively.Keeping your metal lathe clean is key to its long life. Use a soft brush or cloth for regular dust removal. Brush off chips from the bed and around parts. For tougher spots, use a mild cleaner. Avoid harsh chemicals, as they can damage surfaces. Wipe down all areas after use. This prevents rust and maintains accuracy.

What are the best cleaning materials for a metal lathe?

The best materials are:

- Soft brushes

- Microfiber cloths

- Mild soap and water

- Machine oil for lubrication

Regular cleaning makes a big difference. It improves performance and safety. A clean machine is always ready for the next project!

Lubrication Techniques

Types of lubricants suitable for metal lathes. Stepbystep guide on lubricating critical parts.Keeping your benchtop metal lathe running smoothly is like giving it a spa day! First, choose the right lubricants. You can use light machine oil, heavy oil, or grease, depending on the job. Here’s a quick guide:

| Lubricant Type | Best For |

|---|---|

| Light Machine Oil | Spindles and gears |

| Heavy Oil | Slow-moving parts |

| Grease | Bearings and slides |

Now, let’s go through the lubrication steps:

- Wipe down the lathe’s surfaces to remove dust.

- Apply your chosen lubricant to the moving parts.

- Spindle? Don’t forget to be generous!

Keeping your lathe happy gives you smoother cuts. Remember, a well-lubricated lathe is a happy lathe!

Checking and Adjusting Precision

How to ensure accuracy in operations. Calibrating components for optimal performance.To keep your lathe running like a dream, checking for accuracy is a must! Start by looking at the components. Regularly calibrating parts ensures everything aligns perfectly. It’s like tuning a guitar – a tiny tweak can make a big difference. Here’s a quick checklist:

| Components | Adjustment Steps |

|---|---|

| Tailstock | Align it with the spindle for straight cuts. |

| Cross Slide | Adjust the gibs for smooth movement. |

| Chuck | Ensure it holds the workpiece firmly. |

Remember, a happy lathe is a precise lathe! So, tweak those knobs and keep your projects on point.

Troubleshooting Common Issues

Identifying signs of wear and tear. Tips for resolving common lathe problems.Every metal lathe can show signs of wear, like strange noises or odd vibrations. If your lathe starts making the sounds typically reserved for a monster movie, it’s time to check it out. Look closely for rust, loose parts, or worn bearings. Simple fixes, like tightening screws, can bring it back to life. If you notice uneven cuts, it might be time for some adjustments. Often, a good cleaning works wonders. Remember, keeping it clean is almost like giving your lathe a spa day!

| Issue | Solution |

|---|---|

| Noisy operation | Check for loose parts and tighten |

| Uneven cuts | Adjust the tool or clean the chuck |

| Rust buildup | Use rust remover and lubricate |

Replacing Wear Parts

Understanding when to replace parts. Common wear parts and how to replace them.Parts of your lathe will wear out over time. Knowing when to replace them is key. Check for signs like noise, poor performance, or visible damage. Common parts that need replacing include:

- Chuck: The part that holds the workpiece.

- Bearings: They help parts move smoothly.

- Belt: This drives the machine.

To replace these, always follow instructions from your manual. Take your time and ensure everything is secure. Regular checks keep your lathe working well.

How do you know when to replace parts?

Look for signs like strange noises or poor cuts. If the machine feels rough while using, it may be time for a change.

What are common wear parts?

Important parts that often wear out include:

- Chuck – holds the material

- Bearings – allow movement

- Belt – connects and powers

Safety Considerations

Essential safety practices during maintenance. Personal protective equipment (PPE) recommendations.Keeping safe while working on your metal lathe is very important. Always wear personal protective equipment (PPE) to protect yourself. This includes:

- Safety goggles to protect your eyes

- Earplugs to reduce loud noises

- Gloves to keep your hands safe

- Steel-toed boots to protect your feet

Remember to keep your workspace tidy and never wear loose clothing. Being careful helps prevent accidents!

Why is PPE important during maintenance?

PPE is important because it helps keep you safe from injuries and accidents. It protects your body from flying metal pieces and loud noises that can hurt you.

Conclusion

In summary, keeping your benchtop metal lathe in good shape is essential. Regularly clean it, lubricate moving parts, and check for wear. This helps extend its life and improve performance. Remember to follow the manufacturer’s guidelines. For more tips, explore repair guides or maintenance videos online. Taking care of your lathe ensures it works well for your projects!FAQs

What Are The Essential Daily Maintenance Tasks For A Benchtop Metal Lathe To Ensure Optimal Performance?To keep a benchtop metal lathe working well, you should do a few simple tasks each day. First, clean off any chips or dirt from the machine. Next, check the oil levels and add more if needed. You should also look for loose parts and tighten them. Finally, make sure the cutting tools are sharp and ready to use. These steps help your lathe work better and last longer!

How Often Should The Lubrication System Of A Benchtop Metal Lathe Be Checked And What Type Of Lubricant Is Recommended?You should check the lubrication system of a benchtop metal lathe regularly, at least once a week. This helps keep the machine running well. Use a light oil or grease, which is best for machines. Always follow the machine’s manual for specific instructions. Keeping it lubricated helps it last longer and work better!

What Steps Should Be Taken To Clean The Bed And Ways Of A Benchtop Metal Lathe To Prevent Wear And Corrosion?To clean the bed and ways of a benchtop metal lathe, start by removing dirt and dust with a soft cloth. Next, use a mild cleaner and a brush to scrub away any grime. After that, dry it completely to prevent rust. You can also apply a light oil to protect the metal from wear and corrosion. Regularly checking and cleaning will keep your lathe in good shape!

How Can One Troubleshoot Common Issues Such As Vibration Or Noise In A Benchtop Metal Lathe During Operation?To troubleshoot vibration or noise in a benchtop metal lathe, you can start by checking the tightness of all screws and bolts. Loose parts can cause extra noise and shaking. Next, look at the tool you are using. If it’s dull or damaged, it can make strange sounds. Also, make sure the lathe is on a stable surface. If everything looks good, but the problem continues, it might help to ask someone more experienced for advice.

What Are The Best Practices For Storing Accessories And Tools Used With A Benchtop Metal Lathe To Prolong Their Lifespan?To keep your tools and accessories safe, store them in a dry place. Use a toolbox or drawer that closes tight. Always clean tools after use to remove dirt and oil. Label boxes or spots where you keep things so you can find them easily. Finally, keep tools away from moisture and direct sunlight to prevent rust and damage.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Daily Maintenance Tasks For A Benchtop Metal Lathe To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a benchtop metal lathe working well, you should do a few simple tasks each day. First, clean off any chips or dirt from the machine. Next, check the oil levels and add more if needed. You should also look for loose parts and tighten them. Finally, make sure the cutting tools are sharp and ready to use. These steps help your lathe work better and last longer!”}},{“@type”: “Question”,”name”: “How Often Should The Lubrication System Of A Benchtop Metal Lathe Be Checked And What Type Of Lubricant Is Recommended? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the lubrication system of a benchtop metal lathe regularly, at least once a week. This helps keep the machine running well. Use a light oil or grease, which is best for machines. Always follow the machine’s manual for specific instructions. Keeping it lubricated helps it last longer and work better!”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Clean The Bed And Ways Of A Benchtop Metal Lathe To Prevent Wear And Corrosion? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean the bed and ways of a benchtop metal lathe, start by removing dirt and dust with a soft cloth. Next, use a mild cleaner and a brush to scrub away any grime. After that, dry it completely to prevent rust. You can also apply a light oil to protect the metal from wear and corrosion. Regularly checking and cleaning will keep your lathe in good shape!”}},{“@type”: “Question”,”name”: “How Can One Troubleshoot Common Issues Such As Vibration Or Noise In A Benchtop Metal Lathe During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot vibration or noise in a benchtop metal lathe, you can start by checking the tightness of all screws and bolts. Loose parts can cause extra noise and shaking. Next, look at the tool you are using. If it’s dull or damaged, it can make strange sounds. Also, make sure the lathe is on a stable surface. If everything looks good, but the problem continues, it might help to ask someone more experienced for advice.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Storing Accessories And Tools Used With A Benchtop Metal Lathe To Prolong Their Lifespan? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your tools and accessories safe, store them in a dry place. Use a toolbox or drawer that closes tight. Always clean tools after use to remove dirt and oil. Label boxes or spots where you keep things so you can find them easily. Finally, keep tools away from moisture and direct sunlight to prevent rust and damage.”}}]}