Have you ever wondered how metal pieces get their precise shapes? Benchtop metal lathes are the secret tools behind this magic. They make it easy for anyone to turn raw metal into useful objects. Just imagine crafting your own toy car or a custom tool!

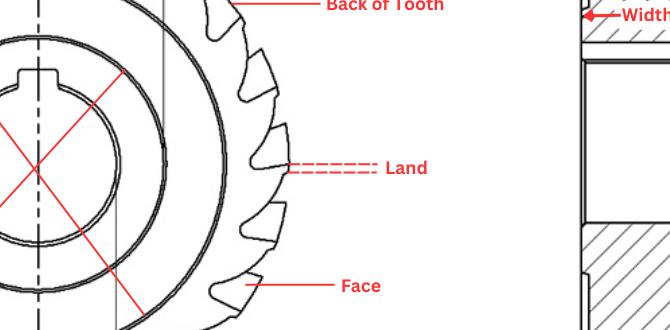

Using a benchtop metal lathe involves some fascinating operations. These machines spin metal while cutting it down to size. You can create anything from simple rods to complex gears. Each part you make tells a story of creativity and skill.

Did you know that lathes have been used for thousands of years? They started with simple designs and evolved into today’s powerful machines. Now, with a benchtop version, you can start making amazing things right in your garage!

So, are you ready to explore the world of metal lathe operations? This article will guide you through the basics and show you how fun and rewarding it can be.

Benchtop Metal Lathe Operations: A Comprehensive Guide

Benchtop Metal Lathe Operations

A benchtop metal lathe is a powerful tool for shaping metal. It enables you to create precise parts with ease. By understanding basic lathe operations, like turning, facing, and threading, you can produce high-quality results. Did you know that the first lathes date back to ancient Egypt? With practice, you become better at this craft. Whether you are a hobbyist or a professional, mastering these operations can open up a world of possibilities.Understanding Benchtop Metal Lathes

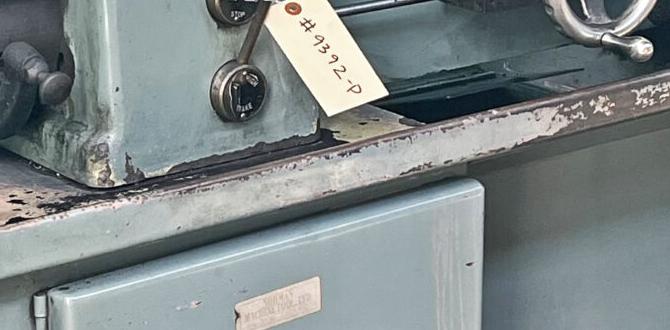

Definition and purpose of benchtop metal lathes. Key features and specifications to consider.A benchtop metal lathe is a machine used for shaping metal. Think of it as a sculptor for metal! It spins the material while tools carve it into precise shapes. The main purpose is to help makers create parts for machines or other projects.

Key features to look for include size, power, and speed settings. It’s also important to consider the type of materials you can use. Some lathes can handle brass, steel, or aluminum, while others may prefer softer materials. Choosing the right lathe can keep your projects spinning smoothly!

| Feature | Importance |

|---|---|

| Size | Fits your workspace |

| Power | Determines cutting efficiency |

| Speed Settings | Allows flexibility for different materials |

Safety Precautions for Lathe Operation

Importance of safety gear and equipment. Best practices to prevent accidents.Using a lathe can be fun, but safety comes first! Always wear safety glasses to protect your eyes from flying bits. A good pair of gloves is also a must; just not the fluffy ones, please! They don’t mix well with sharp tools. Keep your workspace clean to avoid accidents. It’s like keeping your room tidy, only with less homework involved. Remember, moving parts can be sneaky, so stay focused! Here’s a quick look at some important safety gear:

| Safety Gear | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris |

| Gloves | Protects hands from cuts |

| Ear Protection | Reduces noisy machine sounds |

Following these rules can help you avoid the “oops” moments that make great stories but aren’t as fun in real life. Let’s keep it safe and sound!

Setting Up Your Benchtop Lathe

Stepbystep guide to installation. Tips for leveling and securing the lathe.Before starting your projects, you must set up your benchtop lathe correctly. Follow these simple steps for a safe and effective setup:

- Find a sturdy, flat surface for the lathe.

- Level the lathe using a bubble level. Adjust the feet to ensure it sits evenly.

- Secure the lathe with bolts to prevent movement during use.

- Check all connections and settings before powering it on.

With everything in place, you are ready to begin your metalworking journey!

How do you level a benchtop lathe?

To level a benchtop lathe, use a bubble level and adjust the feet until it is even on all sides. Make sure it does not rock or move easily.

Routine Maintenance and Care

Importance of regular maintenance. Best practices for cleaning and lubrication.Taking care of your metal lathe is vital for great performance. Regular maintenance keeps it running smoothly and extends its life. Here are some best practices for cleaning and lubrication:

- Clean the lathe each time after use to prevent dust buildup.

- Wipe down all surfaces with a soft cloth.

- Oil moving parts lightly to keep them operating well.

- Check for loose screws or parts regularly.

Following these steps helps ensure safe and effective benchtop metal lathe operations.

How often should you clean a metal lathe?

You should clean your metal lathe after each use. This simple action prevents rust and keeps it in good shape. Regular upkeep is key!

Common Problems and Troubleshooting

Identification of frequent issues faced during operations. Effective solutions to common problems.Lathe enthusiasts often encounter a few hiccups during their creative adventures. Common problems like poor surface finish or strange noises can turn a fun day into a challenge. Don’t worry, it’s usually fixable! A well-aligned tool can enhance precision, while a worn-out chuck might just need some TLC or a quick replacement. Check out the table below for solutions to frequent issues:

| Problem | Solution |

|---|---|

| Poor surface finish | Check the tool sharpness and alignment. |

| Vibration/noise | Tighten all fixtures and check for wear. |

| Inaccurate dimensions | Calibrate the machine and use quality tools. |

With a little patience and the right approach, you can give those pesky problems the ol’ one-two! Keep your lathe healthy, and it will repay you with smooth operation and great fun.

Tips for Improving Lathe Skills

Recommended resources for further learning. Practice projects to enhance your skills.Becoming skilled at using a lathe takes time and practice. To improve, consider these resources: books, online courses, and videos. They will show you great techniques. Try simple projects such as making small parts or tool handles. These projects help you learn by doing.

- Check out local workshops or maker spaces for hands-on learning.

- Join online forums to ask questions and share tips.

- Practice with scrap materials to avoid wasting good stock.

What projects can help improve lathe skills?

Engaging in various projects boosts your skills. Start with small wooden toys or basic metal parts. These activities are fun and greatly enhance your experience!

Conclusion

In conclusion, benchtop metal lathe operations are essential for shaping and crafting metal. You can create precise parts for various projects. Remember to prioritize safety by using protective gear. Start with simple projects to build your skills. We encourage you to explore additional resources or tutorials to deepen your understanding and boost your confidence in working with lathes. Happy machining!FAQs

Certainly! Here Are Five Related Questions On Benchtop Metal Lathe Operations:Sure! A benchtop metal lathe is a tool that helps us shape metal pieces. With it, we can cut, drill, and polish metal. We must follow safety rules to avoid getting hurt. It’s important to keep our hands away from moving parts. Always wear safety goggles to protect your eyes!

Of course! Please provide the question you would like me to answer.

What Are The Key Components Of A Benchtop Metal Lathe, And How Do They Contribute To Its Functionality?A benchtop metal lathe has several key parts. The bed holds everything steady while you work. The motor powers the lathe and makes it spin. The chuck grabs the metal piece tightly so it doesn’t move. The carriage helps you move cutting tools up and down to shape the metal. These parts work together to help you cut and create metal shapes easily.

How Do You Properly Set Up A Workpiece On A Benchtop Metal Lathe For Precise Turning Operations?To set up a workpiece on a benchtop metal lathe, start by securely clamping it in the chuck. Check that the workpiece is straight and centered. Next, adjust the tailstock if needed to support the end of the piece. Finally, tighten all the clamps and make sure everything is locked in place before you start turning.

What Safety Precautions Should Be Taken When Operating A Benchtop Metal Lathe To Prevent Accidents And Injuries?When using a benchtop metal lathe, always wear safety goggles to protect your eyes. Keep long hair tied back and wear tight clothing to prevent getting caught in the machine. Make sure your hands are clear of moving parts, and never touch the cutting tool while it’s running. Always check that the lathe is working properly before starting. Finally, keep your work area clean and organized to avoid tripping or accidents.

How Do You Select The Appropriate Cutting Tool And Speeds For Different Materials When Using A Benchtop Metal Lathe?To choose the right cutting tool for a metal lathe, start by knowing your material. Soft metals like aluminum need different tools than hard metals like steel. Next, check the speed; softer materials work well with faster speeds. For harder materials, slow down the speed to prevent damage. Always follow instructions or guides to help you make the best choices.

What Techniques Can Be Employed For Finishing A Workpiece On A Benchtop Lathe To Achieve A Smooth Surface And Accurate Dimensions?To finish a workpiece on a benchtop lathe, you can use a few simple techniques. First, you can sand the surface to make it smooth. Use finer sandpaper for a nicer finish. Next, you might use a cutting tool to trim the edges for precise shapes. Finally, make sure to check the size often to keep everything accurate.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On Benchtop Metal Lathe Operations:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A benchtop metal lathe is a tool that helps us shape metal pieces. With it, we can cut, drill, and polish metal. We must follow safety rules to avoid getting hurt. It’s important to keep our hands away from moving parts. Always wear safety goggles to protect your eyes!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Benchtop Metal Lathe, And How Do They Contribute To Its Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A benchtop metal lathe has several key parts. The bed holds everything steady while you work. The motor powers the lathe and makes it spin. The chuck grabs the metal piece tightly so it doesn’t move. The carriage helps you move cutting tools up and down to shape the metal. These parts work together to help you cut and create metal shapes easily.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Workpiece On A Benchtop Metal Lathe For Precise Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a workpiece on a benchtop metal lathe, start by securely clamping it in the chuck. Check that the workpiece is straight and centered. Next, adjust the tailstock if needed to support the end of the piece. Finally, tighten all the clamps and make sure everything is locked in place before you start turning.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Benchtop Metal Lathe To Prevent Accidents And Injuries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a benchtop metal lathe, always wear safety goggles to protect your eyes. Keep long hair tied back and wear tight clothing to prevent getting caught in the machine. Make sure your hands are clear of moving parts, and never touch the cutting tool while it’s running. Always check that the lathe is working properly before starting. Finally, keep your work area clean and organized to avoid tripping or accidents.”}},{“@type”: “Question”,”name”: “How Do You Select The Appropriate Cutting Tool And Speeds For Different Materials When Using A Benchtop Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right cutting tool for a metal lathe, start by knowing your material. Soft metals like aluminum need different tools than hard metals like steel. Next, check the speed; softer materials work well with faster speeds. For harder materials, slow down the speed to prevent damage. Always follow instructions or guides to help you make the best choices.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed For Finishing A Workpiece On A Benchtop Lathe To Achieve A Smooth Surface And Accurate Dimensions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To finish a workpiece on a benchtop lathe, you can use a few simple techniques. First, you can sand the surface to make it smooth. Use finer sandpaper for a nicer finish. Next, you might use a cutting tool to trim the edges for precise shapes. Finally, make sure to check the size often to keep everything accurate.”}}]}