Have you ever wondered how metal parts get those perfect threads? If you have a benchtop metal lathe, you can create them yourself! Thread cutting is an essential skill for anyone who wants to make metal pieces fit together nicely.

Imagine being able to turn a plain metal rod into a threaded masterpiece. With a little practice on your lathe, you can achieve that. It’s like magic when you see a plain piece of metal transform right before your eyes. Have you thought about what projects you might start?

Did you know that many people use thread cutting in their metal-working hobbies? From making tools to crafting unique gifts, the possibilities are endless. A benchtop metal lathe is a great tool to help you explore this exciting world.

In this article, we will guide you through the basics of thread cutting. You’ll learn what tools you need and how to get started. Let’s dive into the fascinating world of metal lathes!

Benchtop Metal Lathe Thread Cutting: A Complete Guide

Benchtop Metal Lathe Thread Cutting

Using a benchtop metal lathe for thread cutting opens up a world of possibilities. This tool helps create precise threads for screws and bolts. Imagine easily making parts for your next project! You can craft custom designs right from your workspace. Proper setup and safety measures make this process smooth and enjoyable. Did you know that mastering this skill can save on costly parts? Thread cutting teaches problem-solving and enhances creativity. The rewards are worth every moment spent learning!Understanding Benchtop Metal Lathes

Definition and purpose of benchtop metal lathes. Key components and features that influence thread cutting performance.A benchtop metal lathe is a small machine that shapes metal parts. It spins the metal while cutting tools remove material to create different shapes and threads. This tool is essential for hobbyists and craftsmen working on projects. Key features that help with thread cutting include:

- Spindle speed: Controls how fast the metal rotates.

- Cutting tool: This part shapes the metal accurately.

- Tailstock: Supports long pieces of metal and helps with threading.

What is the purpose of a benchtop metal lathe?

The purpose is to create precise metal shapes and threads for various projects.Essential Tools and Accessories for Thread Cutting

List of necessary tools, including cutting tools and inserts. Importance of tailstock and tool holders in achieving accurate threads.To cut threads like a pro, you need some key tools. First up, cutting tools and inserts are essential. They make precise cuts. Next, don’t forget the tailstock. This handy part helps hold your work steady while you spin away. Tool holders? They keep your tools snug and in line. If your tools feel like they’re on a vacation instead of doing work, that might cause wonky threads!

| Essential Tools | Function |

|---|---|

| Cutter Tool | Creates the thread profile. |

| Inserts | Replaceable edges for sharp cuts. |

| Tailstock | Stabilizes the workpiece for accuracy. |

| Tool Holders | Secure the cutting tools. |

Setting Up Your Lathe for Thread Cutting

Stepbystep instructions for proper lathe setup. Tips for aligning and calibrating your lathe effectively.Before cutting threads, it’s key to set up your lathe properly. Start by checking the machine’s level. A stable lathe ensures accuracy. Then, install the right tools for cutting threads. Ensure they are sharp and in good condition. Next, align the tailstock with the spindle. This step avoids misalignment during cutting.

- Secure the workpiece tightly.

- Adjust the feed rate for smooth cuts.

- Double-check measurements before starting.

Finally, calibrate the lathe. Use a thread gauge to ensure the threads are correct. A small adjustment can make a big difference!

How do I ensure my lathe is set up correctly for thread cutting?

Check levels, align parts, and use the right tools to get a perfect setup.

Proper setup leads to better results in thread cutting.Measuring and Selecting Thread Parameters

Explanation of thread standards and types (UNC, UNF, metric). How to choose appropriate pitch and diameter for your project.Thread standards can feel like a puzzle, but they’re not too tricky! We have UNC (Unified National Coarse), UNF (Unified National Fine), and metric threads. Each one has a specific use, like how a cat prefers the comfy chair over the floor. Choosing the right pitch and diameter is like picking the right size pizza—too small won’t feed you, and too big is just messy!

| Thread Type | Description |

|---|---|

| UNC | Coarse threads that are easier to cut and use. |

| UNF | Fine threads suitable for precision and less space. |

| Metric | Common in many countries, using millimeters instead of inches. |

Always remember which thread fits your project best. It makes all the difference between a strong hold and a sticky situation! Choose wisely, and your work will shine like a new penny.

Thread Cutting Techniques: A Step-by-Step Guide

Detailed processes for cutting internal and external threads. Insights on feed rate, depth of cut, and speed settings.Thread cutting on a benchtop metal lathe is fun and precise. First, set the tool for external or internal threads. Use the right feed rate and speed settings. A slower speed helps with better control. The depth of cut affects how deep the thread is. For best results, follow these steps:

- Choose the correct thread pitch.

- Set the tool against the workpiece.

- Adjust the feed rate to match the material.

- Carefully monitor the depth with each pass.

Practice makes perfect, so keep trying!

What should I consider when thread cutting?

The important factors are feed rate, depth of cut, and speed settings. Adjusting these helps create better threads.

Troubleshooting Common Issues in Thread Cutting

Identification of frequent problems such as chip buildup and misalignment. Solutions and preventative measures to enhance threading results.Thread cutting can sometimes feel like a puzzle with missing pieces. Common issues like chip buildup or misalignment often cause headaches. These pesky chips can clog your work and lead to poor cuts. Misalignment? That’s like trying to play a game with your eyes closed! Both can be fixed with a few quick checks. Keep your lathe clean and ensure everything is lined up. With these tips, your threading will be smooth as butter!

| Issue | Identification | Solution |

|---|---|---|

| Chip Buildup | Watch for clogs or uneven cuts. | Regularly clean the lathe. |

| Misalignment | Check for strange noises or uneven threads. | Realign your workpiece carefully. |

Maintaining Your Benchtop Metal Lathe for Thread Cutting

Best practices for routine maintenance and cleaning. Importance of lubrication and parts inspection for longevity.Keeping your benchtop metal lathe in top shape is key for thread cutting success. Regular cleaning is super important. Use a soft cloth to wipe away dust and shavings. Lubrication is like giving your lathe a spa day— it helps parts move smoothly. Check parts often for wear and tear; you want your lathe to last as long as your favorite pair of socks. A happy lathe means happy threads!

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Clean the lathe | After each use | Use a soft cloth for dust |

| Lubricate moving parts | Weekly | A little oil goes a long way! |

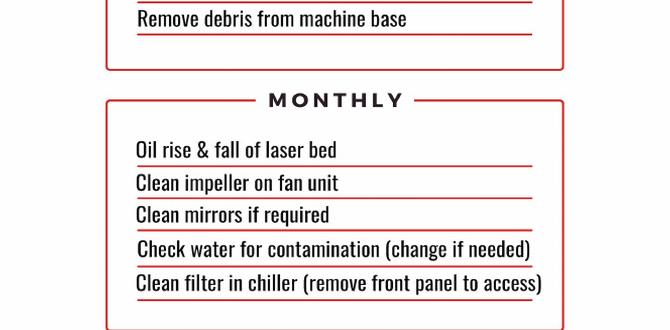

| Inspect parts | Monthly | Look for cracks or wear |

By following these best practices, you’ll keep your lathe running smoothly, just like a well-oiled machine—or a well-oiled dad joke!

Advanced Techniques and Tips for Precision Thread Cutting

Strategies for achieving tighter tolerances and finishes. Exploring CNC options for automated thread cutting processes.Achieving tight tolerances in thread cutting is like trying to thread a needle while wearing boxing gloves. Start by using the right cutting tools and maintaining sharpness for better finishes. Don’t forget about tool speed and feed rate—finding the sweet spot can drastically improve results. For those who dream of automation, CNC machines are the superheroes of the lathe world. They can consistently produce perfect threads, saving time and reducing human error. Want to see how it all stacks up?

| Technique | Benefits |

|---|---|

| Sharp Cutting Tools | Improves finish quality |

| Proper Tool Speed | Reduces chatter |

| CNC Automation | Increases consistency |

Safety Precautions When Using a Benchtop Metal Lathe

List of essential safety gear and practices. Importance of workplace safety and risk management during operation.Before using a benchtop metal lathe, safety is key. Wear essential gear to protect yourself. This includes safety goggles, ear protection, and gloves. Always follow good practices, like keeping tools organized and hands away from moving parts. Proper workplace safety reduces risks. Make sure the area is clean and well-lit. Remember, safety comes first!

What safety gear should you use?

Use the following safety gear:

- Safety goggles to protect your eyes

- Earmuffs or earplugs to shield your ears

- Gloves to keep your hands safe

- Dust mask for breathing protection

Conclusion

In summary, benchtop metal lathes are great tools for thread cutting. They help you make precise, strong threads quickly. Practice using your lathe to improve your skills. Be sure to read more about safe operations and techniques. With time, you’ll create amazing projects. So, let’s get started and explore this exciting world of metalworking!FAQs

What Are The Main Factors To Consider When Setting Up A Benchtop Metal Lathe For Thread Cutting?When setting up a benchtop metal lathe for thread cutting, you need to think about a few important things. First, make sure the lathe is stable and well-secured on the bench. Next, check that the cutting tool is sharp and set to the right height. You also need to choose the correct speed for the metal you’re working with. Finally, keep the area clean and safe to work without any distractions.

How Do You Determine The Appropriate Feed Rate And Spindle Speed For Cutting Threads On A Benchtop Lathe?To find the right feed rate and spindle speed for cutting threads on a lathe, you check the size of the thread you want to make. You can look in a chart that shows speeds for different thread sizes. Then, you set the lathe to those numbers. Make sure to go slow at first to see if it works well. Always be careful and keep an eye on what you’re doing!

What Are The Differences Between Cutting Internal And External Threads On A Benchtop Lathe?Cutting internal threads means making grooves inside a hole. You need a tool that fits into the hole to do this. On the other hand, cutting external threads happens on the outside of a piece, like a screw. For this, you use a tool that wraps around the outside. Both ways help create threads but in different places!

What Tools And Accessories Are Essential For Achieving Accurate Thread Profiles On A Benchtop Metal Lathe?To make accurate threads on a benchtop metal lathe, you need some important tools. First, you should have a threading tool, which shapes the metal. A caliper helps you measure the thickness of the threads. You also need a taper gauge to check the angles. Finally, some lubricant keeps everything running smoothly and prevents sticking.

How Can You Troubleshoot Common Issues That Arise During The Thread Cutting Process On A Benchtop Lathe?To fix problems when cutting threads on a benchtop lathe, start by checking the tool’s sharpness. A dull tool can make bad threads. Then, make sure the lathe is set to the right speed for cutting. If the threads look rough, you might need to adjust how deep you cut. Lastly, watch how the workpiece is held; it should stay tight and not move.