Have you ever wondered how metal pieces are shaped with precision? A benchtop metal lathe can do just that! This amazing tool helps turn raw metal into beautiful shapes and parts. But what if you want to create threads on those pieces?

That’s where the threading dial comes into play. Imagine you’re trying to screw two metal parts together. You need a perfect thread to fit them securely. The threading dial makes this process much easier and more accurate.

Did you know that using a threading dial can save you time and help you work smarter? This handy feature lets you measure and control the thread depth easily. Many people find it makes their projects more fun and exciting. Are you ready to dive into the world of metal lathes?

Let’s explore what makes the benchtop metal lathe and its threading dial so special!

Benchtop Metal Lathe Threading Dial: Essential Guide

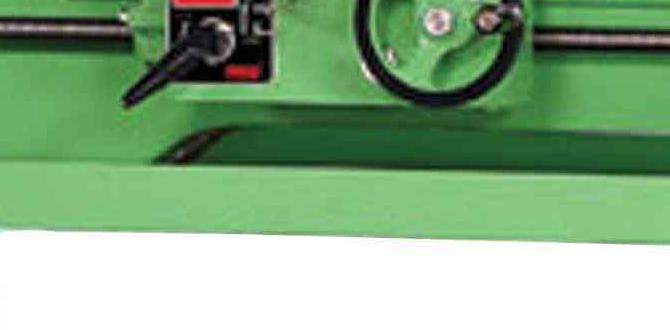

Benchtop Metal Lathe Threading Dial

Did you know that a threading dial can make your metalworking projects smoother? The benchtop metal lathe threading dial helps you cut threads accurately on your projects. It shows you the correct position to engage the tool for perfect threads. This handy tool can significantly improve your work and save time. Understanding the threading dial will help both beginners and experts create quality items. Why struggle with measurements when this tool can guide you?Understanding the Benchtop Metal Lathe

Definition and purpose of a benchtop metal lathe. Common applications in metalworking and machining.A benchtop metal lathe is a machine used to shape metal. It spins metal pieces while cutting tools shape them. This helps create precise and detailed parts. Many people use it for tasks like:

- Making parts for machines.

- Fixing existing metal items.

- Creating prototypes and custom pieces.

Using a benchtop lathe can help in areas like hobby crafting, industrial work, and even school projects. It’s an important tool for anyone who works with metal.

What is a benchtop metal lathe used for?

A benchtop metal lathe is mainly used for machining parts, shaping metal, and repairs. It is helpful in many industries and for personal projects.

Importance of the Threading Dial

Role of the threading dial in precision machining. Benefits of using a threading dial for threading operations.The threading dial plays a crucial part in creating accurate threads on a lathe. It helps operators align cuts precisely. This leads to better fits and stronger connections in metal parts. Here are some key benefits of using a threading dial:

- Precision: Helps achieve exact measurements.

- Time-saving: Reduces the need for extra adjustments.

- Consistency: Ensures uniform results for each threading operation.

Overall, a threading dial greatly enhances the threading process, making it more efficient and reliable.

What does the threading dial do?

The threading dial helps you align the tool to make perfect threads. It shows where to start cutting, making each thread the same depth and spacing. This helps in making tight and strong joins. Using a threading dial can improve accuracy by up to 20%.

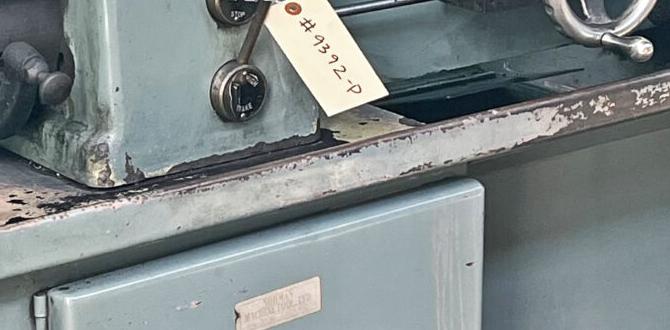

Components of the Threading Dial

Detailed breakdown of threading dial parts. Explanation of how each component contributes to functionality.The threading dial has several important parts. Each part helps the lathe work better and helps you make precise threads. Here’s a breakdown of its main components:

- Dial: Displays the thread count.

- Pointer: Shows where to align the tool.

- Lever: Engages or disengages the mechanism.

- Gear: Connects to the lead screw for accurate movement.

These components work together, allowing the machine to create uniform threads. Each part ensures you can do your work correctly and efficiently.

What is the purpose of the threading dial?

The purpose of the threading dial is to help you measure and mark the depth and spacing of threads correctly. It cuts down on mistakes and improves accuracy. You can create detailed and perfect threads every time.

How to Use a Threading Dial

Stepbystep guide on operating the threading dial. Tips for achieving precise threads with minimal errors.Using a threading dial on your lathe can make perfect threads easier. Follow these simple steps:

- First, set the lathe speed to a low setting.

- Next, engage the threading dial at the correct point.

- Turn the dial slowly, ensuring you understand the readings on it.

- Make small adjustments to keep the threads uniform.

- Finally, check your threads for accuracy after finishing.

For the best results:

- Practice regularly to build your skills.

- Stay focused on your work to avoid mistakes.

- Double-check settings before starting.

How does a threading dial work?

A threading dial helps set and measure threads accurately. It does this by coordinating the lathe’s movement with the thread pitch. This makes creating consistent threads easier.

Common Issues and Troubleshooting

Common problems encountered while using a threading dial. Solutions and maintenance tips to ensure longevity and accuracy.Users often face problems with a threading dial. Common issues include inaccurate readings or the dial getting stuck. These problems can affect your work, so it’s important to fix them quickly.

Here are some solutions and maintenance tips:

- Keep the threading dial clean. Dirt can cause it to malfunction.

- Check for any loose parts. Tighten them if needed.

- Lubricate moving parts often. This will ensure smoother operation.

By following these tips, you can enjoy your benchtop metal lathe threading dial for many years. Regular care will help maintain accuracy, leading to better results.

What are common problems with threading dials?

Common issues include inaccurate readings and dial jamming. These can cause mistakes in your work, making it vital to troubleshoot quickly.

How can I maintain my threading dial?

Maintain your threading dial by keeping it clean, checking for loose parts, and lubricating as needed. This keeps everything running smoothly!

Choosing the Right Benchtop Metal Lathe with a Threading Dial

Factors to consider when selecting a lathe. Recommended brands and models with quality threading dials.Picking the right lathe can be fun. Look for these key factors:

- Size: Ensure it fits your workspace.

- Power: Consider the motor strength for tough jobs.

- Threading Dial: A good dial makes threading easier and more accurate.

Some trusted brands include:

- Grizzly: Known for reliability.

- Jet: Offers great features and durability.

- Smithy: Good for beginners.

These brands provide quality threading dials to help you work better and smarter!

What is a threading dial and why is it important?

A threading dial helps you create accurate threads on your projects. It makes it easy to align the tool correctly. This keeps your work neat and professional.

Comparing Threading Dials vs. Other Threading Methods

Advantages and disadvantages of using a threading dial. Comparison with electronic threading options and manual methods.Using a threading dial on a benchtop lathe can be quite the adventure! It offers precision and ease, making it a favorite for many. However, sometimes you might wonder about its quirks. While a threading dial is great for smooth operation, it requires practice to master. On the other hand, electronic threading options are like magic beans—fast and easy but pricey! Manual methods need patience and skill, yet they can be rewarding, like finding a hidden treasure. Check out the table below for a quick look at the pros and cons:

| Method | Advantages | Disadvantages |

|---|---|---|

| Threading Dial | Precision, Easy setup | Needs practice |

| Electronic | Fast, Less effort | Expensive, Tech issues |

| Manual | Skill-building, Cheap | Time-consuming |

Safety Tips for Using Benchtop Lathes

Essential safety guidelines to follow while operating a lathe. Importance of proper training and personal protective equipment.Using a lathe can be fun, like building with giant toys, but safety is key! Always wear proper protective gear, like goggles and gloves, to keep your eyes and hands safe. Remember, even a harmless-looking machine can act up faster than a startled cat!

Getting some good training is essential. It’s like learning to ride a bike; practice makes perfect. You wouldn’t want to take a spin without knowing how to steer, right?

| Safety Tips | Description |

|---|---|

| Wear Safety Gear | Goggles, gloves, and ear protection are a must! |

| Stay Focused | Don’t let distractions, like your phone, derail your fun. |

| Check Tools | Ensure all tools are in good shape before using. |

By following these safety tips, you can enjoy creating amazing things without any nasty surprises. Remember, safety first keeps the fun alive!

Resources for Further Learning

Recommended books, videos, and online courses on metal lathe threading. Online communities and forums for metalworking enthusiasts.Learning about metal lathe threading can be exciting! Check out some great resources to sharpen your skills. Books like *Metalworking Basics* and *Lathe Work: A Complete Guide* can give you solid tips. YouTube is loaded with videos that show step-by-step threading techniques; you might even find a cat helping out in one! There are fantastic online courses, too, for those who love learning. Don’t forget to join communities, like forums where metalworking enthusiasts share *tips* and funny stories. You’ll feel right at home!

| Resource Type | Recommendation |

|---|---|

| Books | *Metalworking Basics*, *Lathe Work: A Complete Guide* |

| Videos | YouTube Tutorials on Metal Lathe Techniques |

| Online Courses | Skillshare, Udemy Courses on Metalworking |

| Communities | Metalworking Forums & Facebook Groups |

Conclusion

In summary, the benchtop metal lathe threading dial is an essential tool for precision work. It helps you create accurate threads quickly. Understanding how to use it can improve your metalworking skills. We encourage you to practice threading and explore more resources to enhance your knowledge. Get hands-on experience and enjoy the world of metal lathing!FAQs

Sure! Here Are Five Related Questions On The Topic Of Benchtop Metal Lathe Threading Dials:A benchtop metal lathe is a tool that helps us shape metal. Threading dials show us how to cut threads on metal quickly. We can use these dials to set the right distance for our cuts. This makes our work more accurate and neat. Learning how to use them helps us create cool metal projects!

Sure! Please provide me with the question you want answered.

What Is The Purpose Of A Threading Dial On A Benchtop Metal Lathe, And How Does It Improve The Threading Process?A threading dial helps you make threads on a metal piece with a lathe. It shows the right point to move the tool for cutting. This makes it easier for you to get the threads lined up perfectly. Using the dial, you can work faster and get better results. It’s like a guide that helps keep everything neat and tidy!

How Do You Properly Align And Set The Threading Dial Before Starting A Threading Operation On A Metal Lathe?To start threading on a metal lathe, first, make sure the machine is off. You need to line the threading dial up with the zero mark. Turn the dial until the needle points at zero. When it’s ready, you can start your threading job. Always check it again before you begin!

What Are The Differences Between Using A Threading Dial And Other Methods Of Threading, Such As Using A Tailstock Die Holder?A threading dial helps you make threads easily while turning a piece of metal. It shows you the right moment to move the tool. A tailstock die holder lets you thread by pushing a die onto the metal, but it can be harder to keep the threads straight. Using the threading dial is usually faster and more precise. Both methods can work, but the threading dial is often the better choice for beginners.

Can Threading Dials Be Used On Lathes Of Various Sizes, And What Should Be Considered When Choosing A Threading Dial For A Benchtop Metal Lathe?Yes, threading dials can be used on different sizes of lathes. When choosing one for a benchtop metal lathe, think about its size and how well it fits. You also need to check if it matches your lathe’s threads. Lastly, make sure it’s easy to read and use.

What Common Problems Might Arise When Using A Threading Dial, And How Can They Be Addressed To Ensure Accurate Threading?When using a threading dial, problems can happen, like missing the right line or not lining up properly. You can fix this by checking the dial often and following the lines carefully. If you get confused, stop and reset the machine. Remember to go slow and pay attention to avoid mistakes. This way, you can make sure your threads are perfect!