Have you ever tried to fix a tricky tool? Imagine your benchtop metal lathe suddenly stops working. It can be frustrating! You might wonder what went wrong. Troubleshooting a benchtop metal lathe doesn’t have to be scary. In fact, it can be a fun puzzle to solve.

Many users face similar challenges. Picture this: you’re halfway through an important project, and the lathe just won’t cooperate. What do you do next? Knowing some basic tips can make all the difference.

Let’s explore common issues and easy fixes. Did you know that simple problems often have simple answers? Learning how to troubleshoot your benchtop metal lathe can save you time and money. Plus, it can boost your confidence as a maker. So, are you ready to dive in and discover the secrets of smooth lathe operation?

Benchtop Metal Lathe Troubleshooting: Common Issues & Solutions

Benchtop Metal Lathe Troubleshooting

Are you facing issues with your benchtop metal lathe? You’ll discover common problems, like unusual noises or poor cut quality. Learning simple fixes can save you time and money. Did you know that regular maintenance can enhance your lathe’s performance? You’ll also find helpful tips on checking alignment and adjusting speed settings. Troubleshooting doesn’t have to be overwhelming. With a little knowledge, you can keep your lathe running smoothly and efficiently.Common Issues with Benchtop Metal Lathes

Identification of frequent problems encountered by users. Explanation of potential causes for each issue.Users often face a few common problems with benchtop metal lathes. One issue is excessive vibration. This might happen due to an unbalanced workpiece or loose parts. Another pesky problem is inconsistent speed. This can result from a faulty motor or worn belts. Finally, there’s the pesky issue of poor surface finish, often caused by dull tools or incorrect settings. Remember, a lathe is like a cranky pet – treat it well, and it’ll perform beautifully!

| Issue | Potential Cause |

|---|---|

| Excessive Vibration | Unbalanced workpiece or loose parts |

| Inconsistent Speed | Faulty motor or worn belts |

| Poor Surface Finish | Dull tools or incorrect settings |

Safety Precautions During Troubleshooting

Necessary safety gear and equipment. Guidelines to ensure a safe working environment while troubleshooting.Using the right gear and keeping your space safe is key in troubleshooting. Always wear safety glasses, gloves, and a mask to protect yourself. A clean workspace prevents accidents. Keep tools organized and within reach. Make sure the area has good lighting. Remember, being cautious helps everyone stay safe!

- Wear safety glasses to protect your eyes.

- Use gloves to keep your hands safe.

- Have a mask for dust and particles.

- Keep the area clean and organized.

- Ensure good lighting to see clearly.

What should you wear while troubleshooting a benchtop metal lathe?

While troubleshooting, you should wear safety glasses, gloves, and a mask. These items protect you from dust and injury.

Step-by-Step Troubleshooting Process

Systematic approach to diagnose and fix issues. Flowchart or checklist to follow during the troubleshooting process.To troubleshoot your benchtop metal lathe, follow a systematic path! Start by checking the basics like power supply and settings. A simple checklist can help you remember important steps. If you’re stumped, a flowchart might save the day. Flip through the flowchart for guidance, like a treasure map for lost tools! Keep calm, breathe, and a cup of coffee can turn ‘uh-oh’ into ‘aha!’ Here’s a handy checklist:

| Step | Action |

|---|---|

| 1 | Check if the machine is plugged in |

| 2 | Inspect for loose components |

| 3 | Verify the tool settings |

| 4 | Look for signs of wear |

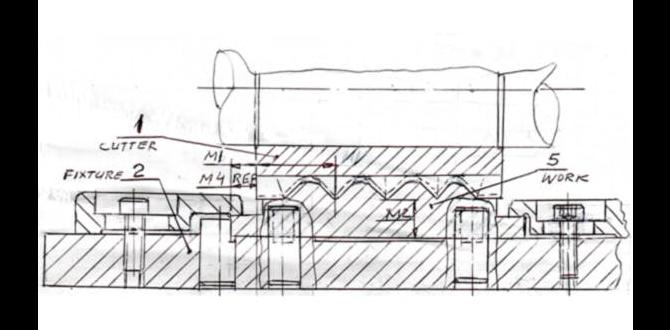

Identifying Mechanical Problems

Signs of wear and tear in components. Solutions for common mechanical failures.Worn-out lathe parts can cause big issues. Look for cracks, rust, or chips in metal pieces. You might notice strange noises or vibrations when running the machine. These signs mean it’s time to act. To fix problems:

- Check bearings for wear.

- Tighten loose screws on the machine.

- Clean the lathe to remove debris.

- Replace damaged parts immediately.

Regular checks can keep your lathe running smoothly. Prevent accidents and extend its life with simple repairs.

What are common lathe mechanical issues?

Common lathe issues include worn bearings, loose parts, and rust. Regular maintenance helps keep the machine in good shape.

Electrical and Motor Troubleshooting

Common electrical failures in benchtop lathes. Testing and repairing motor issues.Electrical issues can really throw a wrench into your metal lathe fun. Common problems include faulty wires, blown fuses, and bad switches. If your machine takes a break mid-project, it’s time to investigate! Start by checking the power cords for damage. If the motor isn’t turning on, test the switch with a multimeter. The table below outlines some common electrical failures.

| Issue | What to Check |

|---|---|

| Power Failure | Check power cords and fuses |

| Motor Not Running | Inspect the switch and connections |

| Strange Noises | Look for loose parts or bad bearings |

Meanwhile, don’t forget to give your motor a little love. If it’s acting up, check if it’s overheating or making strange noises. Remember, a happy motor is a quiet motor! Sometimes, it just needs a good cleaning or a new capacitor. So, roll up your sleeves and get to troubleshooting!

Tuning and Calibration Techniques

Importance of proper tuning for optimal performance. Tips for calibrating your benchtop metal lathe.Tuning your benchtop lathe is like tuning a guitar. If it’s off, the music (or in this case, the metalwork) just doesn’t sound right. Proper tuning ensures your machine runs smoothly and gives accurate results. Here are some tips to help you calibrate:

| Tip | Description |

|---|---|

| Check Alignment | Make sure the lathe’s parts line up nicely. Misalignment can turn your projects into funky shapes! |

| Tighten Components | Loose screws can make for a wobbly adventure. Keep things snug! |

| Test Cuts | Make a few test cuts. If they look like potato chips, something is off! |

Follow these steps to keep your lathe in top shape. Happy machining!

Maintenance Tips to Prevent Issues

Routine maintenance schedules and best practices. Recommended tools and products for maintenance.To keep your lathe spinning smoothly, stick to a routine maintenance schedule. Take time each week to clean and oil the moving parts. It’s like giving your machine a spa day! Use quality tools like a brush, some oil, and a level to check everything. Here’s a handy table for your maintenance toolkit:

| Tool/Product | Purpose |

|---|---|

| Brush | Removes debris |

| Oil | Keeps parts lubricated |

| Level | Ensures accuracy |

Remember, a well-maintained lathe is a happy lathe! Keep it clean, and it will work wonders for you.

Resources for Further Support

Where to find manuals and guides. Online forums and communities for expert advice.Finding help for your benchtop metal lathe is easier than you think! Start by checking out manuals and guides. Many lathe manufacturers have PDFs available on their websites. These can help you understand your machine better.

Online forums are also great for advice. You can ask questions and learn from people who have faced similar problems. Here are some helpful places to look:

- Manufacturer’s website: Find manuals and troubleshooting tips.

- Facebook Groups: Join communities to share experiences and ask questions.

- Reddit: Check out lathe-related subs for support.

- YouTube: Find videos showing common repairs and solutions.

Where can I find manuals and guides?

Check the manufacturer’s website or forums. These sources often have helpful documents to guide you.

What online communities can I join for advice?

Look for groups on Facebook or Reddit. These platforms have many experts willing to share their tips.

Conclusion

In conclusion, troubleshooting a benchtop metal lathe helps ensure smooth operation. Check for common issues like noise, vibration, or speed problems. Regular maintenance can prevent many troubles. If you encounter issues, refer to your manual or online guides for help. Remember, practice makes perfect! Keep learning about your lathe to improve your skills and confidence.FAQs

What Are The Common Signs That Indicate A Problem With The Alignment Of The Headstock On A Benchtop Metal Lathe?If the headstock of your metal lathe is not aligned properly, you might see a few signs. First, the parts you make might not be straight or smooth. You could also notice extra noise when the lathe is running. If the tool chatters or shakes, that’s another clue. Finally, if the cutting tool wears out too quickly, it could mean there’s an alignment problem.

How Do You Troubleshoot Uneven Cutting Or Chatter During Machining Operations On A Benchtop Lathe?If your lathe is cutting unevenly or making a chatter sound, let’s check a few things. First, make sure the cutting tool is sharp and clean. A dull tool can cause problems. Next, check if the tool is set at the right angle. If it’s too high or low, it can cause chatter. Lastly, make sure the piece you’re working on is tightly held in place. A loose piece can shake and make noise.

What Steps Should Be Taken To Diagnose And Fix Issues With The Drive Belt Or Motor Of A Benchtop Metal Lathe?First, make sure the lathe is turned off and unplugged. Next, check the drive belt for any tears or wear. If the belt looks damaged, it should be replaced. Then, look at the motor. You should listen for any strange sounds when it runs. Tighten any loose screws and connections. If the motor still has problems, you might need help from an adult or a repair expert.

How Can You Determine If The Tool Post Is Secure And Properly Adjusted, And What Are The Signs Of A Loose Or Faulty Tool Post?To check if the tool post is secure, you can try to move it by hand. If it wiggles or moves easily, it may be loose. A secure tool post holds the tool tightly and doesn’t let it move. Watch for uneven cuts or strange sounds when using the machine; these could mean the tool post is not adjusted well. If you see or hear anything unusual, it might need to be checked again.

What Maintenance Practices Can Help Prevent Common Problems Encountered With A Benchtop Metal Lathe?To keep your benchtop metal lathe working well, you should clean it regularly. Dust and chips can build up and cause issues. Check the oil level and add more if it’s low. You should also tighten loose parts so everything stays in place. Lastly, keep the tools sharp and replace them when they become dull.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Problem With The Alignment Of The Headstock On A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the headstock of your metal lathe is not aligned properly, you might see a few signs. First, the parts you make might not be straight or smooth. You could also notice extra noise when the lathe is running. If the tool chatters or shakes, that’s another clue. Finally, if the cutting tool wears out too quickly, it could mean there’s an alignment problem.”}},{“@type”: “Question”,”name”: “How Do You Troubleshoot Uneven Cutting Or Chatter During Machining Operations On A Benchtop Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your lathe is cutting unevenly or making a chatter sound, let’s check a few things. First, make sure the cutting tool is sharp and clean. A dull tool can cause problems. Next, check if the tool is set at the right angle. If it’s too high or low, it can cause chatter. Lastly, make sure the piece you’re working on is tightly held in place. A loose piece can shake and make noise.”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Diagnose And Fix Issues With The Drive Belt Or Motor Of A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, make sure the lathe is turned off and unplugged. Next, check the drive belt for any tears or wear. If the belt looks damaged, it should be replaced. Then, look at the motor. You should listen for any strange sounds when it runs. Tighten any loose screws and connections. If the motor still has problems, you might need help from an adult or a repair expert.”}},{“@type”: “Question”,”name”: “How Can You Determine If The Tool Post Is Secure And Properly Adjusted, And What Are The Signs Of A Loose Or Faulty Tool Post? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if the tool post is secure, you can try to move it by hand. If it wiggles or moves easily, it may be loose. A secure tool post holds the tool tightly and doesn’t let it move. Watch for uneven cuts or strange sounds when using the machine; these could mean the tool post is not adjusted well. If you see or hear anything unusual, it might need to be checked again.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Help Prevent Common Problems Encountered With A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your benchtop metal lathe working well, you should clean it regularly. Dust and chips can build up and cause issues. Check the oil level and add more if it’s low. You should also tighten loose parts so everything stays in place. Lastly, keep the tools sharp and replace them when they become dull.”}}]}