If you’ve ever thought about working with metal, you might have wondered which tools to use. A metal lathe can be your best friend in metalwork. But how do you choose the right one?

Imagine you want to create a beautiful metal sculpture or fix up an old machine. A great metal lathe can help you do both. It shapes metal into amazing designs. But with so many options available, picking the best metal lathe can feel overwhelming.

Did you know that the right lathe can last for many years? This means it’s a big investment. You want to make sure you pick one that meets your needs. In this buying guide, we will explore key features. You will learn how to find the best metal lathe for your projects.

Let’s dive into the details together. By the end, you’ll feel ready to make a smart choice. Are you excited to learn? Let’s get started!

Buying Guide: Best Metal Lathe For Your Workshop Needs

Buying Guide for the Best Metal Lathe

Choosing the right metal lathe can be exciting yet challenging. This buying guide highlights key features to consider, like size, power, and precision. Did you know some lathes can shape metal as easily as a pencil sharpener? Understanding your project needs helps you find a machine that’s perfect for you. Price matters, but investing in quality often pays off. With the right information, your metalworking journey can be fun and rewarding!Understanding Metal Lathes

Definition and purpose of a metal lathe. Types of metal lathes: manual vs CNC.A metal lathe is a tool that shapes metal into useful parts. It spins the metal while a cutting tool shapes it. Think of it as a giant pencil sharpener—only for steel instead of wood! There are two main types: manual and CNC. Manual lathes are great for hands-on work, like crafting a wooden toy. CNC lathes use computers to be super precise. Imagine a robot doing the hard work while you relax with some snacks!

| Type | Description |

|---|---|

| Manual Lathe | Operated by hand. Great for beginners and small projects. |

| CNC Lathe | Computer-controlled. Ideal for advanced projects and high precision. |

Key Features to Consider

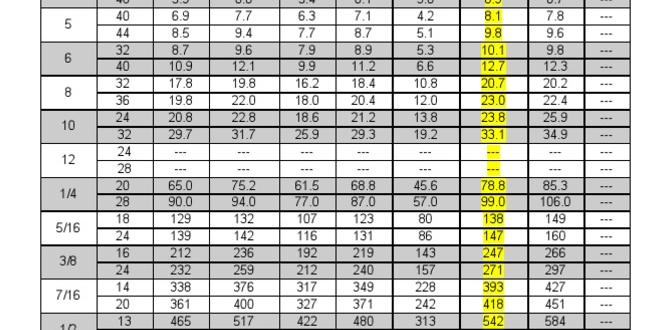

Bed length and swing over bed. Spindle speed and torque ratings.When choosing a metal lathe, the first thing to check is the bed length and swing over bed. These measurements tell you how long and big the projects can be. Longer beds mean more options for big projects, like making a pencil or a sword! Spindle speed also matters. Higher speeds help work on smaller details, while torque ratings ensure you still have power for tougher tasks. Think of it like the difference between a race car and a monster truck—they each excel in their own way!

| Feature | Importance |

|---|---|

| Bed Length | Allows for bigger projects |

| Swing Over Bed | Determines the diameter of workpieces |

| Spindle Speed | Helps with fine detailing |

| Torque Ratings | Ensures power for difficult materials |

Types of Metal Lathes

Bench lathes vs. industrial lathes. Specialty lathes for specific tasks.Metal lathes come in various types, suited for different tasks. First, you have bench lathes, which are small and perfect for hobbyists. They don’t take up much space and can handle lightweight jobs. Then, there’s the big league—industrial lathes. These machines are like the giants of the lathe world, built for heavy-duty tasks. Lastly, specialty lathes are designed for specific tasks, like threading or shaping. They’re like the superheroes of lathes, ready to tackle unique challenges!

| Type | Size | Best For |

|---|---|---|

| Bench Lathes | Small | Hobbyists |

| Industrial Lathes | Large | Heavy-Duty Tasks |

| Specialty Lathes | Varies | Specific Tasks |

Material Quality and Build

Importance of construction materials. Impact of weight and stability on performance.Choosing the right materials for a metal lathe is crucial. Quality materials ensure better performance and longevity. Heavy, stable lathes provide more accuracy while working. They resist vibrations and ensure smooth operation. A sturdy base can prevent accidents, making your work safer.

- Steel: Strong and durable

- Cast Iron: Reduces vibrations

- Aluminum: Lightweight and easy to move

In fact, lathes made from quality materials can perform better over time. This means less wear and tear and fewer repairs. Investing in good materials really pays off!

Why is weight important for a metal lathe?

The weight of a lathe impacts its stability. A heavier lathe stays in place during use, providing focused cuts. This makes it easier to create accurate projects.

What factors affect the performance of a metal lathe?

Several factors play a role in a lathe’s performance:

- Material Quality: Better materials lead to better results.

- Weight: Heavier lathes offer more stability.

- Design: A thoughtful design can influence usability.

Essential Accessories and Tools

Commonly used tools for metal lathes. Optional accessories for enhanced functionality.Many tools help you use a metal lathe well. Here are some commonly used tools:

- Cutting tools

- Chucks

- Tool holders

- Tailstock

- Faceplates

Optional accessories can make your metal lathe even better. These include:

- Digital readouts

- Tool organizers

- Chip trays

Using the right tools and accessories helps create quality pieces. Remember, the right setup is key to success.

What tools should you have for a metal lathe?

You need cutting tools, chucks, and a tailstock for basic projects.Budget Considerations

Pricing range of metal lathes. Cost vs. features analysis.Metal lathes can fit many budgets. Prices usually range from $200 for smaller models to $3,000 for more advanced ones. You might wonder, is a fancy metal lathe really worth it? More features often mean more fun, but also a bigger bill! If you’re new, a simpler model might be best. Here’s a quick table to help:

| Price Range | Features |

|---|---|

| $200 – $700 | Basic controls, small size |

| $700 – $1,500 | Medium size, more options |

| $1,500 – $3,000 | Large workspaces, advanced features |

Remember to balance your budget with your needs. After all, a fancy lathe won’t turn you into a master overnight—unless it has a magic wand!

Safety Features and Maintenance

Important safety features to look for. Maintenance tips for longevity.Using a metal lathe can be fun, but safety always comes first! Look for features like automatic shutoff sensors and sturdy guards. These help keep fingers where they should be—safely away from moving parts. Regular maintenance is key, too. Clean your lathe often and check for rust. It’s like giving your tool a spa day! Treat it well, and it’ll be spinning metal for years.

| Safety Feature | Why It’s Important |

|---|---|

| Emergency Stop Button | Stops the machine immediately in case of danger. |

| Protective Guards | Prevents accidental contact with moving parts. |

| Metal Shields | Reduces flying debris and accidents. |

Remember, if your lathe could talk, it would say, “Keep me clean and I’ll keep you safe!”

User Reviews and Recommendations

Importance of customer feedback. How to evaluate user reviews.Customer feedback is very important. It helps buyers know what to expect. Reviews show real experiences with the product. This feedback can guide decisions. To evaluate user reviews:

- Look for detailed comments.

- Check for common issues mentioned.

- See how the company responds to complaints.

Reading reviews can save time and money. It can help you pick the best metal lathe for your needs.

What should you look for in user reviews?

Focus on the quality, durability, and ease of use. Check for any patterns in feedback about these features. This will help you understand which products work well for others.

Where to Buy

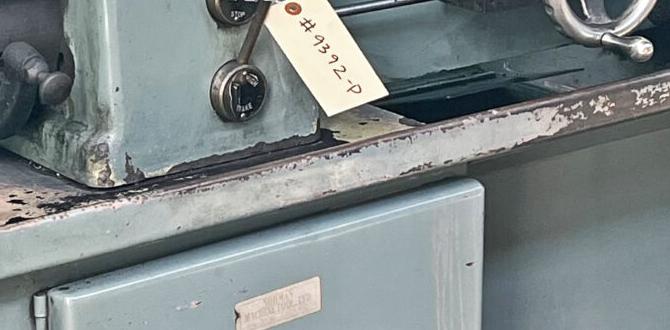

Recommended online retailers. Considerations for buying used lathes.Shopping for a metal lathe? You’re in luck! There are many great places online. Retailers like Amazon and eBay often have the best deals. They even sell used lathes if you’re feeling brave. A used lathe can save money, but be sure to check its condition. After all, no one wants to invest in a machine that sounds like it’s on its last leg!

| Retailer | Highlights |

|---|---|

| Amazon | Wide selection, user reviews |

| eBay | Used options, potential bargains |

| Grizzly | Specializes in tools and lathes |

Always read the reviews and check the seller’s ratings. Remember, a good lathe can make your projects smoother than butter on toast!

Conclusion

In conclusion, a buying guide for the best metal lathe helps you choose wisely. Look for size, power, and features that match your needs. Read reviews and compare brands to find the perfect fit. Remember to consider your budget and skills. Now, dive into more resources and start your metalworking journey with confidence! Happy lathe shopping!FAQs

Sure! Here Are Five Related Questions You Might Consider When Looking For The Best Metal Lathe:When choosing the best metal lathe, think about how big it should be for your projects. Consider what materials you will be working with, like steel or aluminum. You should also check how easy it is to use and set up. Look for extra features that help you work better. Lastly, see if it fits your budget, so you can afford it!

Of course! Just let me know what question you would like me to answer.

What Features Should I Look For In A Metal Lathe For Both Beginners And Advanced Users?When choosing a metal lathe, look for these important features. First, find one with a sturdy frame. This helps it stay steady while you work. Next, check for easy controls. You want to handle it without getting confused. Also, a good range of speeds is helpful for different types of work. Finally, good safety features keep you safe while you create!

How Do I Determine The Right Size And Capacity Of A Metal Lathe For My Specific Projects?To find the right size and capacity of a metal lathe, think about your projects. First, consider the biggest piece you want to work on. Measure its length and diameter. Then, check the lathe’s specifications to see if it can handle those sizes. Finally, choose a lathe that can do a bit more than your biggest project, just in case!

What Are The Key Differences Between Cnc Lathes And Manual Lathes, And Which One Is Better For My Needs?CNC lathes use computers to help make things. They can work faster and create precise shapes. Manual lathes need you to control everything by hand, which can take more time. If you want to make lots of the same thing, a CNC lathe is better. If you like simple projects and hands-on work, then a manual lathe might be right for you.

What Is The Average Price Range For Quality Metal Lathes, And How Do I Find The Best Value For My Budget?The average price for quality metal lathes is between $1,000 to $5,000. You can find good lathes at different prices. To get the best value, start by making a budget. Then, compare different models online or at stores. Look for reviews that tell you about their performance and quality.

Are There Any Specific Brands Or Models Of Metal Lathes That Are Highly Recommended By Professionals In The Industry?Yes, many professionals like brands such as Haas, Grizzly, and Jet. Haas machines are known for their quality and strong performance. Grizzly offers good options for beginners and hobbyists. Jet lathes are also recommended for their reliability and ease of use.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions You Might Consider When Looking For The Best Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing the best metal lathe, think about how big it should be for your projects. Consider what materials you will be working with, like steel or aluminum. You should also check how easy it is to use and set up. Look for extra features that help you work better. Lastly, see if it fits your budget, so you can afford it!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Just let me know what question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Features Should I Look For In A Metal Lathe For Both Beginners And Advanced Users?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe, look for these important features. First, find one with a sturdy frame. This helps it stay steady while you work. Next, check for easy controls. You want to handle it without getting confused. Also, a good range of speeds is helpful for different types of work. Finally, good safety features keep you safe while you create!”}},{“@type”: “Question”,”name”: “How Do I Determine The Right Size And Capacity Of A Metal Lathe For My Specific Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right size and capacity of a metal lathe, think about your projects. First, consider the biggest piece you want to work on. Measure its length and diameter. Then, check the lathe’s specifications to see if it can handle those sizes. Finally, choose a lathe that can do a bit more than your biggest project, just in case!”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between Cnc Lathes And Manual Lathes, And Which One Is Better For My Needs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC lathes use computers to help make things. They can work faster and create precise shapes. Manual lathes need you to control everything by hand, which can take more time. If you want to make lots of the same thing, a CNC lathe is better. If you like simple projects and hands-on work, then a manual lathe might be right for you.”}},{“@type”: “Question”,”name”: “What Is The Average Price Range For Quality Metal Lathes, And How Do I Find The Best Value For My Budget?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The average price for quality metal lathes is between $1,000 to $5,000. You can find good lathes at different prices. To get the best value, start by making a budget. Then, compare different models online or at stores. Look for reviews that tell you about their performance and quality.”}},{“@type”: “Question”,”name”: “Are There Any Specific Brands Or Models Of Metal Lathes That Are Highly Recommended By Professionals In The Industry?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, many professionals like brands such as Haas, Grizzly, and Jet. Haas machines are known for their quality and strong performance. Grizzly offers good options for beginners and hobbyists. Jet lathes are also recommended for their reliability and ease of use.”}}]}