Have you ever wondered how a metal lathe works? It’s a fascinating tool that shapes metal into just about anything! But if you want to use one properly, alignment is key. Imagine trying to draw a straight line while holding the paper crooked. It just doesn’t work, right? That’s why knowing how to align a metal lathe is so important.

Buying a metal lathe can feel confusing. There are so many options available! Each lathe has unique features that meet different needs. But if your lathe isn’t aligned well, you won’t get the best results.

Here’s a fun fact: Did you know that even a tiny misalignment can cause big problems in your project? It can lead to uneven cuts or even damage to the lathe. In this buying guide, we will explore alignment tips and tricks. You’ll learn how to spot the right lathe for your needs. Get ready to dive into the world of metal lathes!

Essential Buying Guide For Metal Lathe Alignment Techniques

Buying Guide Metal Lathe Alignment

Discover essential tips for ensuring your metal lathe is perfectly aligned. Proper alignment improves accuracy and prolongs tool life. A well-aligned lathe can save you time and money. Did you know that even a slight misalignment can cause poor finishes on your work? Learn how to check alignment using simple tools and techniques. Understanding these key points will help you enhance your projects and achieve professional results. Ready to elevate your metalworking skills?Understanding Metal Lathe Alignment

Definition and importance of metal lathe alignment. Common alignment issues and their impact on machining.Metal lathe alignment is the process of ensuring all parts of the lathe are straight and level. It is crucial for producing precise and accurate workpieces. Poor alignment can cause problems, such as:

- Inaccurate cuts

- Uneven wear on tools

- Poor surface finish

What are common alignment issues?

Common alignment issues include bent axes, misaligned tailstock, and warped beds. These can create errors in your finished products and require frequent recalibrations.

Key Features to Consider When Buying a Metal Lathe

Essential specifications that influence alignment accuracy. Importance of build quality and material in maintaining alignment.Choosing a metal lathe can be as tricky as finding a needle in a haystack! It’s crucial to check certain features. First, consider the alignment accuracy. This is determined by specifications like the tailstock and headstock alignment. Next, pay attention to build quality and material. A strong, sturdy lathe will hold its position better, just like a dog on a leash. Cheaper materials can lead to misalignment faster than you can say “lathe”!

| Feature | Importance |

|---|---|

| Alignment Accuracy | Ensures precise cuts and smooth operation. |

| Build Quality | Maintains stability and longevity. |

| Material Strength | Prevents wear and keeps alignment. |

Tools for Metal Lathe Alignment

List and description of essential alignment tools (e.g., dial indicators, laser alignment tools). Tips for choosing the right tools for your lathe setup.To align your metal lathe properly, you need some important tools. Here are two essential tools:

- Dial Indicators: These help measure tiny movements. They make it easy to see if everything is straight.

- Laser Alignment Tools: These project a laser beam to show the correct alignment. They are accurate and can save time.

Choosing the right tools is key. Make sure they fit your lathe’s size and type. Look for tools that are easy to read and use. Quality matters too. Well-made tools last longer and give better results.

Why do I need alignment tools for a metal lathe?

Alignment tools ensure your lathe works smoothly and accurately. Proper alignment helps create better projects and reduces wear on the machine.

Step-by-Step Guide to Aligning Your Metal Lathe

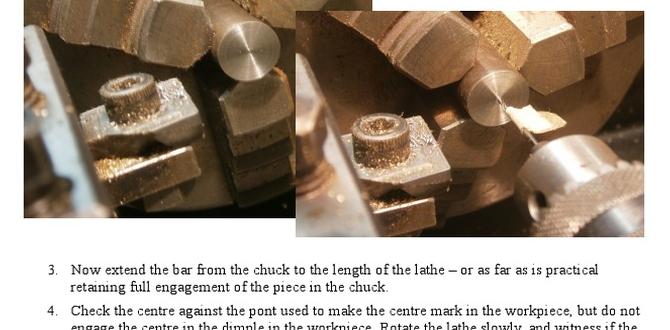

Detailed procedures for aligning different components of a metal lathe. Common pitfalls to avoid during the alignment process.Aligning your metal lathe is like tuning a guitar; it can make a huge difference! Start with the bed. Use a level and adjust the feet until it’s perfectly flat. Next, check the tailstock. It should line up with the spindle. If not, simply adjust the tailstock’s position. Now, look at the carriage. A quick check with a dial indicator will help to spot any misalignment.

Watch out for common tricks that can trip you up! Don’t forget to tighten screws after adjustments. Loose screws are like a band without rhythm—nothing works right! Also, avoid rushing. Patience is key in this process. Take your time, and your lathe will be ready to rock and roll!

| Component | Adjustment Method |

|---|---|

| Bed | Level it with feet adjustments |

| Tailstock | Align with the spindle |

| Carriage | Check using a dial indicator |

Maintenance Tips for Sustaining Metal Lathe Alignment

Routine maintenance practices to ensure longterm alignment. How environmental factors can affect alignment and ways to mitigate them.To keep your metal lathe in tip-top shape, regular check-ups are key. Routine cleaning can prevent dust from causing havoc. Also, make friends with oil; a little lube goes a long way! Remember to check the levels of humidity and temperature in your workspace. Too much moisture can lead to misalignment. If it’s getting steamy, use a dehumidifier to keep things dry.

| Factor | Impact | Solution |

|---|---|---|

| Temperature Fluctuation | Can cause expansion or contraction | Keep in a controlled environment |

| Humidity | Increases rust risk | Use a dehumidifier |

| Dust & Debris | Can affect precision | Regular cleaning |

Finally, a little TLC will keep your lathe running smoothly. After all, a happy lathe makes for happy projects!

Frequently Asked Questions About Metal Lathe Alignment

Answers to common queries related to metal lathe alignment. Resources for further learning and troubleshooting alignment issues.When it comes to metal lathe alignment, many folks have questions. One common query is, “How often should I check my lathe’s alignment?” The answer is simple: you should do it regularly—like checking for snacks in the pantry! Another question is, “What tools do I need?” You can use a dial indicator or a simple ruler; both work well. For those looking deeper into the topic, there are useful resources available.

| Resource | Description |

|---|---|

| Manufacturer’s Manual | Best place for guidelines and tips. |

| Online Forums | A treasure chest of advice from experienced users. |

And remember, nothing beats practice. The more you align, the better you get—just like riding a bike, minus the scraped knees!

Conclusion

In conclusion, a buying guide for metal lathe alignment helps you choose the right tools for precision. Remember, check specifications, read reviews, and prioritize quality. Observing alignment is essential for better projects. We encourage you to research more about lathe maintenance and alignment techniques. With the right knowledge, you’ll improve your metalworking skills and achieve great results.FAQs

Sure! Here Are Five Related Questions On The Topic Of Buying A Metal Lathe And Its Alignment:Buying a metal lathe can be fun! First, you want to find one that fits your needs. You should check if it comes with good instructions to help you. After you buy it, make sure to align it properly so it works well. You can ask for help or watch videos to learn how to do this.

Sure! Please ask your question, and I’ll be happy to answer it simply and clearly.

What Key Features Should I Look For In A Metal Lathe To Ensure Proper Alignment Capabilities?When choosing a metal lathe, look for a sturdy base. A heavy base keeps the lathe steady and helps with alignment. Check for adjustable tailstocks and tool posts. These will help you make precise adjustments easily. Also, look for clear markings on the dials to measure changes accurately.

How Can I Accurately Check The Alignment Of A Metal Lathe Before Making A Purchase?To check a metal lathe’s alignment, first, look for a level surface. You can use a carpenter’s level to see if the lathe is flat. Next, measure the distance from the center to both ends of the lathe. If the measurements are the same, it’s aligned. Finally, spin the lathe by hand and listen for any strange sounds that might mean something is wrong.

What Are Some Common Alignment Issues To Be Aware Of When Buying A Used Metal Lathe?When buying a used metal lathe, you should check for a few alignment problems. First, look if the bed is straight. If it’s bent, the lathe won’t work well. Next, check the tailstock and chuck to see if they line up correctly. Misalignment here can cause wobbly cuts. Lastly, make sure the spindle spins straight; if it doesn’t, your projects might go wrong.

How Important Is The Quality Of The Bed And Saddle In Maintaining Alignment On A Metal Lathe?The bed and saddle of a metal lathe need to be really good for proper alignment. If they’re not straight and strong, your work might not come out right. A good bed holds everything steady, while a good saddle keeps the cutting tool in the right place. This helps us make better pieces and work safely. So, we should care about the quality of these parts!

What Tools Or Accessories Are Recommended For Aligning A Metal Lathe After Purchase?To align a metal lathe, you might need a few helpful tools. A good level helps check if the lathe is even. A dial indicator is great for measuring tiny movements accurately. A straight edge can show if surfaces are flat and straight. Lastly, some shims can help adjust the height if needed.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Buying A Metal Lathe And Its Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Buying a metal lathe can be fun! First, you want to find one that fits your needs. You should check if it comes with good instructions to help you. After you buy it, make sure to align it properly so it works well. You can ask for help or watch videos to learn how to do this.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to answer it simply and clearly.”}},{“@type”: “Question”,”name”: “What Key Features Should I Look For In A Metal Lathe To Ensure Proper Alignment Capabilities?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe, look for a sturdy base. A heavy base keeps the lathe steady and helps with alignment. Check for adjustable tailstocks and tool posts. These will help you make precise adjustments easily. Also, look for clear markings on the dials to measure changes accurately.”}},{“@type”: “Question”,”name”: “How Can I Accurately Check The Alignment Of A Metal Lathe Before Making A Purchase?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check a metal lathe’s alignment, first, look for a level surface. You can use a carpenter’s level to see if the lathe is flat. Next, measure the distance from the center to both ends of the lathe. If the measurements are the same, it’s aligned. Finally, spin the lathe by hand and listen for any strange sounds that might mean something is wrong.”}},{“@type”: “Question”,”name”: “What Are Some Common Alignment Issues To Be Aware Of When Buying A Used Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When buying a used metal lathe, you should check for a few alignment problems. First, look if the bed is straight. If it’s bent, the lathe won’t work well. Next, check the tailstock and chuck to see if they line up correctly. Misalignment here can cause wobbly cuts. Lastly, make sure the spindle spins straight; if it doesn’t, your projects might go wrong.”}},{“@type”: “Question”,”name”: “How Important Is The Quality Of The Bed And Saddle In Maintaining Alignment On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The bed and saddle of a metal lathe need to be really good for proper alignment. If they’re not straight and strong, your work might not come out right. A good bed holds everything steady, while a good saddle keeps the cutting tool in the right place. This helps us make better pieces and work safely. So, we should care about the quality of these parts!”}},{“@type”: “Question”,”name”: “What Tools Or Accessories Are Recommended For Aligning A Metal Lathe After Purchase?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align a metal lathe, you might need a few helpful tools. A good level helps check if the lathe is even. A dial indicator is great for measuring tiny movements accurately. A straight edge can show if surfaces are flat and straight. Lastly, some shims can help adjust the height if needed.”}}]}