Have you ever needed to fix something, but the right tool wasn’t available? Imagine working on a project and your metal lathe belt breaks. You might feel stuck, right?

Understanding how to choose the right metal lathe belt can save you lots of trouble. Many people don’t realize that the right belt can make your lathe run smoother and last longer. Did you know that a good belt can improve your machine’s performance? It’s true!

In this buying guide, we will explore the key factors to consider when selecting a metal lathe belt. You’ll learn what makes a belt the best fit for your needs. With the right knowledge, you can confidently make your purchase.

So, are you ready to dive in and discover more? Let’s find that perfect metal lathe belt together!

Essential Buying Guide For Metal Lathe Belt Selection

Buying Guide for Metal Lathe Belt

Looking for a metal lathe belt? Choosing the right one can make a big difference in your projects. Consider factors like size, material, and durability. Did you know that the right belt can improve your lathe’s performance? Measure your lathe carefully before purchasing. A good-fitting belt saves you time and boosts efficiency. There are many brands available, so it’s wise to read reviews. Remember, a quality belt leads to smoother operations and better results!Understanding Metal Lathe Belts

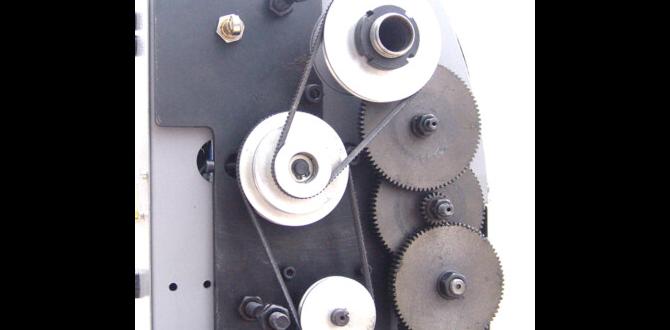

Definition and purpose of metal lathe belts. Types of belts commonly used in metal lathes.Metal lathe belts play an essential role in machinery. They transfer power from the motor to the lathe. This helps the lathe spin and work with metal smoothly. Different types of belts are used in metal lathes, including:

- V-belts: Common and widely used for their efficiency.

- Flat belts: Flexible and suitable for light loads.

- Timing belts: Precise and great for synchronized movements.

Understanding these belts helps you choose the right one for your lathe.

Why do metal lathe belts matter?

Metal lathe belts are crucial for effective machinery operation. Without them, your lathe won’t function properly. Choosing the right belt leads to better performance and longer tool life.

Factors to Consider When Buying a Metal Lathe Belt

Material composition and its impact on performance. Size and compatibility with different metal lathe models. Durability and wear resistance.Choosing a metal lathe belt is not as silly as picking a favorite ice cream flavor! First, check the material. Strong belts made of rubber or polyurethane work best for long-lasting performance. Next, size matters! Make sure the belt fits your metal lathe model perfectly. A loose belt is like a clown in a small car—awkward and ineffective. Lastly, think about durability. A high-quality belt should resist wear and tear, making it a true workhorse in your workshop.

| Factor | Tip |

|---|---|

| Material | Look for strong rubber or polyurethane. |

| Size | Ensure compatibility with your lathe. |

| Durability | Choose belts that resist wear. |

Make these factors your trusty sidekicks, and your metal lathe will be happy to spin things up! Remember, a good belt is key to smooth operations, much like a solid friendship – always dependable!

Types of Metal Lathe Belts

Vbelts: Features and benefits. Flat belts: Pros and cons. Timing belts: Usage specificities.Metal lathe belts come in different types, each with its own quirks. Let’s dive in! First up, V-belts. These are shaped like a “V,” which helps them grip well. Great for power transfer, they last long and can handle heavy loads. Next, we have flat belts. They are wide and smooth but can slip easily. Still, they are easy to replace and work well on simple machines. Timing belts are a bit of a show-off. They help keep things in sync, perfect for machines needing precise movement. Just remember, each type has pros and cons, so choose wisely!

| Type | Features | Pros | Cons |

|---|---|---|---|

| V-Belts | V-shaped for grip | Durable, great for power | Can wear over time |

| Flat Belts | Wide and smooth | Easy to replace | Can slip under high load |

| Timing Belts | Teeth for grip | Precise movement | Specific usage only |

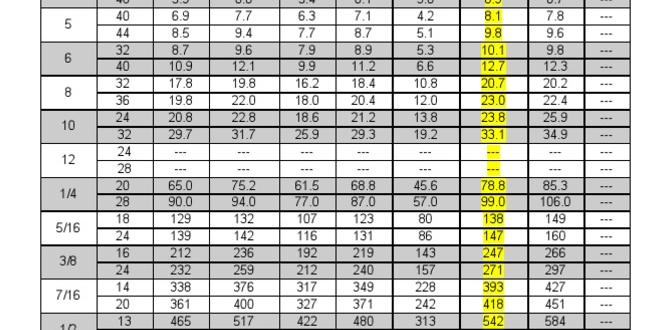

Cost Analysis

Price ranges for different types of belts. Cost versus performance: Is higher always better?.Metal lathe belts come in various price ranges. Basic belts start around $20, while high-performance options can reach $100 or more. So, does paying more mean better quality? Not always! Sometimes, a mid-range belt can perform just as well as a pricey one. Remember, you want quality without breaking the bank for a belt that won’t even win a race with your favorite sloth!

| Type of Belt | Price Range | Performance |

|---|---|---|

| Basic | $20 – $40 | Good for starters |

| Mid-range | $40 – $80 | Great balance |

| High-performance | $80+ | Best for pros |

Buying wisely means considering both price and quality. A high price tag doesn’t guarantee long-lasting performance. So, keep an eye on the details that really matter!

Installation and Maintenance Tips

Stepbystep installation guidelines. Best practices for prolonging belt life.Installing and maintaining your metal lathe belt is vital for smooth operation. Follow these steps for installation:

- Start by turning off the lathe and unplugging it.

- Remove the old belt carefully.

- Align the new belt with the pulleys.

- Tighten the belt without overdoing it.

- Plug the lathe back in and double-check everything.

To prolong your belt’s life, follow these best practices:

- Keep the lathe clean and free of debris.

- Adjust the tension regularly.

- Lubricate the pulleys to reduce wear.

How can I ensure my belt lasts longer?

To ensure your belt lasts longer, keep it clean and adjust the tension regularly. This will help prevent friction and wear over time. Regular checks can make a big difference!

Common Problems and Solutions

Troubleshooting belt issues: Slippage, wear, and tear. When to replace your metal lathe belt.Metal lathe belts can sometimes act like a mischievous cat—always slipping away! This often happens due to wear and tear. If your belt looks frayed or thin, it’s time for a change. You should replace it if you notice frequent slippage or unusual noises. Let’s take a look at some common problems and quick fixes in the table below:

| Problem | Solution |

|---|---|

| Slippage | Tighten the belt or check the alignment. |

| Wear and Tear | Look for cracks; replace if necessary! |

| Noisy Operation | Inspect for loose parts or old belts. |

Stay ahead of the game! Remember, a happy belt means a happy lathe, and who doesn’t want that?

Where to Purchase Metal Lathe Belts

Recommendations for online retailers. Benefits of buying from local suppliers.Finding the right metal lathe belt is easy with online retailers. Websites like Amazon and eBay have many choices. You can compare different brands and read reviews before buying. Local suppliers also have great benefits. They provide friendly advice and you can see the product before purchasing. Here are some reasons to consider local shops:

- Quick access to helpful staff.

- No shipping costs or delays.

- Support your community!

Where can I find affordable metal lathe belts?

You can find affordable options online. Websites like Amazon often have discounts. Local shops may have sales too, especially during the holidays.

Conclusion

In conclusion, a metal lathe belt buying guide helps you choose the right belt for your machine. Look for quality materials, proper size, and compatibility. Always check reviews to ensure you’re making a smart purchase. Now that you know the basics, explore more about lathe maintenance or accessories to enhance your workshop. Happy crafting!FAQs

Here Are Five Questions Related To Buying A Metal Lathe Belt:Sure! When you buy a metal lathe belt, think about the size and width you need. You should also check the price to see if it fits your budget. Look at the brand, too, because some brands are more reliable than others. Finally, read reviews from other buyers to know if they like it. This way, you can make a good choice!

Sure! Please provide the question you would like me to answer.

What Factors Should I Consider When Selecting The Right Metal Lathe Belt For My Machine?When picking a metal lathe belt, you should think about a few things. First, check the size of the belt. It must fit your lathe well. Next, look at the material. Some materials last longer than others. Also, consider how much weight the belt needs to carry. A strong belt is better for heavy work. Lastly, check the design. Some belts are meant for specific tasks.

How Do I Determine The Correct Size And Type Of Belt For My Specific Metal Lathe Model?To find the right belt for your metal lathe, first check the manual it came with. The manual usually tells you the size and type. You can also measure the old belt. Use a ruler for length and check the width too. If you’re unsure, ask at a hardware store or look online for help.

What Materials Are Commonly Used For Metal Lathe Belts, And How Do They Affect Performance And Durability?Metal lathe belts are often made from rubber, leather, or synthetic materials. Rubber belts are stretchy and grip well, helping machines run smoothly. Leather belts are strong but can wear out faster. Synthetic materials are very durable and can handle heavy use. The right belt makes a lathe last longer and work better.

Are There Any Recommended Brands Or Manufacturers Known For High-Quality Metal Lathe Belts?Some good brands for metal lathe belts include Gates and Fenner. These companies make strong and reliable belts. You can trust them to last a long time. Always check reviews to see what others think. This will help you pick the best one!

How Can I Troubleshoot Common Issues With A Metal Lathe Belt, Such As Slippage Or Wear?To troubleshoot a metal lathe belt, first, check for slippage. Make sure the belt is tight enough. You can adjust the tension if it’s loose. Next, look for wear on the belt. If you see cracks or frays, it’s time to replace it. Regular checks help keep your lathe running smoothly!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Questions Related To Buying A Metal Lathe Belt:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you buy a metal lathe belt, think about the size and width you need. You should also check the price to see if it fits your budget. Look at the brand, too, because some brands are more reliable than others. Finally, read reviews from other buyers to know if they like it. This way, you can make a good choice!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Factors Should I Consider When Selecting The Right Metal Lathe Belt For My Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a metal lathe belt, you should think about a few things. First, check the size of the belt. It must fit your lathe well. Next, look at the material. Some materials last longer than others. Also, consider how much weight the belt needs to carry. A strong belt is better for heavy work. Lastly, check the design. Some belts are meant for specific tasks.”}},{“@type”: “Question”,”name”: “How Do I Determine The Correct Size And Type Of Belt For My Specific Metal Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right belt for your metal lathe, first check the manual it came with. The manual usually tells you the size and type. You can also measure the old belt. Use a ruler for length and check the width too. If you’re unsure, ask at a hardware store or look online for help.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Metal Lathe Belts, And How Do They Affect Performance And Durability?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathe belts are often made from rubber, leather, or synthetic materials. Rubber belts are stretchy and grip well, helping machines run smoothly. Leather belts are strong but can wear out faster. Synthetic materials are very durable and can handle heavy use. The right belt makes a lathe last longer and work better.”}},{“@type”: “Question”,”name”: “Are There Any Recommended Brands Or Manufacturers Known For High-Quality Metal Lathe Belts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some good brands for metal lathe belts include Gates and Fenner. These companies make strong and reliable belts. You can trust them to last a long time. Always check reviews to see what others think. This will help you pick the best one!”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot Common Issues With A Metal Lathe Belt, Such As Slippage Or Wear?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot a metal lathe belt, first, check for slippage. Make sure the belt is tight enough. You can adjust the tension if it’s loose. Next, look for wear on the belt. If you see cracks or frays, it’s time to replace it. Regular checks help keep your lathe running smoothly!”}}]}