Have you ever thought about making your own tools? Imagine shaping metal into beautiful objects or useful parts. A metal lathe can help you do just that! But how do you choose the right one? That’s where our buying guide comes in.

In this article, we’ll explore the world of metal lathes and CAD design. Many people wonder how to get started with metalworking. A metal lathe lets you create precise and creative designs. Do you like the idea of crafting pieces from scratch?

Now, here’s a fun fact: Did you know that metal lathes have been around for centuries? They have evolved from simple machines to advanced tools used in modern workshops. Choosing the right metal lathe will make all the difference in your projects.

This guide will help you navigate the options. We want to make sure you find the perfect metal lathe for your needs. Whether you are a beginner or an expert, you’ll discover tips and tricks for using CAD design efficiently. Let’s dive in and find the best metal lathe for you!

Buying Guide For Metal Lathe Cad Design Essentials

Buying Guide: Metal Lathe CAD Design

Are you ready to conquer the world of CAD design with a metal lathe? This buying guide reveals what to consider before making a purchase. Learn about essential features like precision, power, and user-friendliness. Did you know a great metal lathe can transform your ideas into reality with ease? Discover tips on choosing the right design software, ensuring compatibility, and maximizing your machine’s potential. Get ready to craft impressive projects!Understanding Metal Lathes

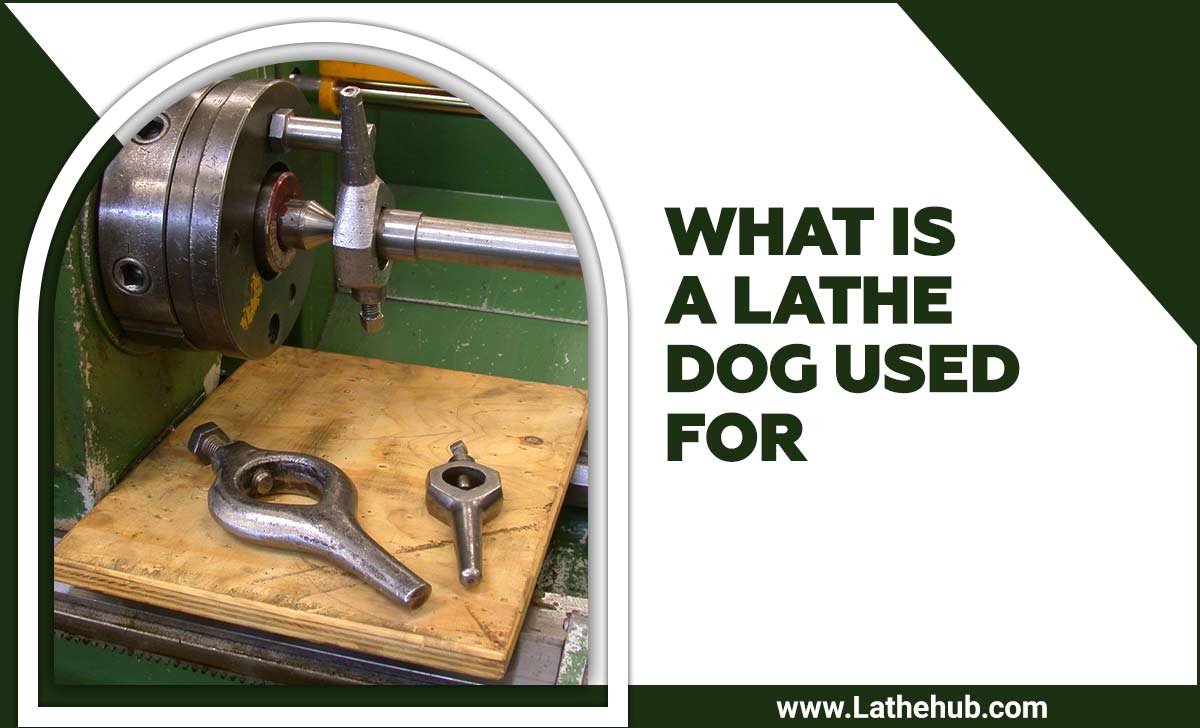

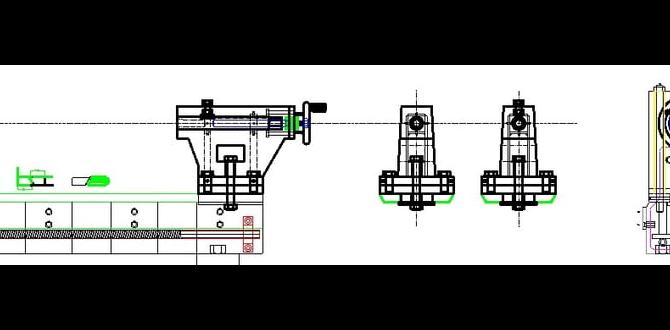

Definition and function of metal lathes. Types of lathes and their applications in CAD design.A metal lathe is a machine that shapes materials like metal and wood. It spins the material while cutting tools shape it. This lets users create parts like gears and shafts. Different types of lathes include:

- Engine Lathes: Great for general tasks.

- CNC Lathes: Controlled by computers for precise work.

- Turret Lathes: Ideal for mass production.

In CAD design, these lathes help make models. They turn digital ideas into real objects. Using the right lathe can change how designs come to life!

What are the uses of metal lathes?

Metal lathes are used to produce parts for cars, machines, and tools. They are essential in factories and workshops to create items from blueprints or CAD designs.

Key Features to Look for in a Metal Lathe

Precision and accuracy specifications. Size and swing capacity considerations. Motor power and speed variability.Choosing the right metal lathe can change your projects. Pay attention to these key features:

- Precision and Accuracy: Look for lathes that offer high precision, usually measured in microns. Better precision means better results.

- Size and Swing Capacity: Consider the size of your projects. The swing capacity tells you how large a piece you can work on. A larger swing means more options.

- Motor Power and Speed Variability: A powerful motor gives you more strength for tougher materials. Speed variability helps with different tasks, making it easier to switch between jobs.

What is the best size for a metal lathe?

The best size depends on your needs. For small projects, a lathe with a 12-inch swing is good. For bigger projects, choose one with a 16-inch swing or more.

Popular Metal Lathe Brands and Models

Top recommended brands in the market. Comparison of popular models and their features.Some well-known brands stand out in the metal lathe world. They offer different models to fit various needs. Here are a few top brands:

- Grizzly Industrial: Known for quality and variety.

- Jet Tools: Offers reliable options for beginners and pros.

- Shop Fox: Combines performance with affordable prices.

Each model has its own features. For example, Grizzly’s G0602 has a solid build and excellent precision. Jet’s JWL-1442 is portable and easy to use. Shop Fox’s W1704 is great for hobbyists. Always compare models to find the best fit for your projects.

What are the most recommended metal lathe models?

The top recommended models include the Grizzly G0602 and Jet JWL-1442. They are praised for their quality and user-friendly features.

Essential Accessories for Metal Lathes

Musthave tools and attachments for enhanced functionality. Safety equipment and maintenance supplies.Metal lathes need some cool tools and safety gear to work their best. Having the right attachments can really help you create amazing projects. Here are some must-have items:

- Cutting tools

- Tool holders

- Chucks

- Tailstocks

Also, remember to keep safe with:

- Safety glasses

- Gloves

- Dust masks

Lastly, don’t forget maintenance supplies like oil and cleaning cloths. They keep your lathe running smoothly.

What tools are essential for metal lathes?

Essential tools include cutting tools, tool holders, and safety gear. These items help you create safe and effective projects.

Cost Analysis: Budgeting for Your Metal Lathe

Price ranges for different types of lathes. Understanding the costbenefit ratio for CAD design projects.When shopping for a metal lathe, it’s essential to know your budget. Prices can vary widely, from $200 for small, basic models to over $5,000 for high-end ones. Have you ever seen a lathe that costs more than a used car? It happens! Understanding the cost-benefit ratio is crucial, especially if you plan to use CAD design. Investing wisely now might save you money later! Here’s a simple table for quick comparison:

| Type of Lathe | Price Range |

|---|---|

| Mini Lathe | $200 – $500 |

| Mid-Range Lathe | $500 – $2,000 |

| High-End Lathe | $2,000+ |

Choose wisely, and you might just create some amazing projects without breaking the bank!

Common Mistakes to Avoid When Buying a Metal Lathe

Overlooking the importance of specifications. Ignoring manufacturer reviews and ratings.When buying a metal lathe, it’s easy to make mistakes. Many people forget to check important specifications like size and power. These details matter for your projects. Also, looking at manufacturer reviews can save you time and money. Many buyers share their experiences, helping you choose wisely.

- Always check size and power ratings.

- Read multiple reviews before buying.

- Look for trusted brands with good ratings.

Why are specifications and reviews important?

Specifications help you find the right tool for your needs. Reviews guide you toward reliable options. Ignoring these can lead to costly mistakes.

Maintenance Tips for Longevity of Your Metal Lathe

Routine maintenance practices. Troubleshooting common issues.To keep your metal lathe working well, follow some easy maintenance tips. Regular checks help catch problems early. Clean your lathe often to avoid dust build-up. Lubricate parts to reduce wear. Check the alignment of tools too. If you notice strange noises, stop and check the machine.

- Inspect belts for wear.

- Look for loose screws and tighten them.

- Keep the cutting tools sharp.

Staying proactive will help your lathe last longer and work better!

What are common issues with metal lathes?

Common issues include noisy operation, poor surface finish, and alignment problems. Regular maintenance can help prevent these troubles and keep your lathe running smooth.

Integrating Metal Lathes into Your CAD Workflow

Software recommendations for effective CAD design. Best practices for designing lathe projects in CAD programs.Using metal lathes with your CAD software can be exciting and helpful. First, choose the right software. Good ones include Fusion 360 and SolidWorks. They make it easy to design parts for lathes. Second, keep a few tips in mind:

- Start with simple shapes.

- Check all dimensions carefully.

- Use layers for different parts.

Following these practices helps make great designs that work well on a metal lathe.

What software is best for CAD design with metal lathes?

Fusion 360 and SolidWorks are popular choices for beginners and pros.

Customer Testimonials and Case Studies

Realworld experiences from satisfied users. Examples of successful projects involving metal lathes in CAD design.Many users share their success stories after using metal lathes for CAD design. Take Mike, for example. He turned a stack of scrap metal into a stunning clock. “I never thought I could create something so cool!” he laughed. Similarly, Lucy crafted intricate jewelry, proving that metal lathes can suit any project. Their testimonials highlight how these tools help unleash creativity. People love making things that look impressive. It’s like magic, but with metal!

| User Name | Project | Experience |

|---|---|---|

| Mike | Metal Clock | “It was easier than I thought!” |

| Lucy | Jewelry | “I feel like a master designer!” |

Conclusion

In summary, a buying guide for metal lathes with CAD design helps you make smart choices. Remember to consider size, features, and your project needs. We recommend comparing different models and reading reviews. For a better understanding, explore resources on metal lathes and CAD design. Happy crafting, and let your creativity shine!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Buying A Metal Lathe For Cad Design:When buying a metal lathe for CAD design, think about what you need it for. You should check its size and features. Make sure it fits your projects. Look for a machine that is easy to use. Lastly, ask for help if you’re not sure what to choose!

Sure! Please provide me with the question you’d like me to answer.

What Key Specifications Should I Look For In A Metal Lathe For Design Purposes?When choosing a metal lathe for design, look for its size and weight. A bigger and heavier lathe is usually more stable. Check the speed settings, too. You want a lathe that can go slow and fast for different projects. Lastly, make sure it has good tools and parts support, so you can fix it easily if needed.

How Do I Determine The Appropriate Size And Capacity Of A Metal Lathe For My Cad Projects?To choose the right size of a metal lathe, think about what you will make. Look at the biggest pieces you want to create. If you need to work with large items, you should pick a bigger lathe. Also, check how heavy the items can be, as lathes have weight limits. Make sure the lathe can handle the materials in your projects.

What Are The Advantages Of Cnc (Computer Numerical Control) Lathes Compared To Manual Lathes In A Cad Design Environment?CNC lathes are better than manual lathes for several reasons. They use a computer to control movement, which makes them very precise. This means you get exact shapes every time you use them. CNC lathes also work faster, helping us finish projects sooner. Plus, they can be programmed to do the same job repeatedly without mistakes.

What Essential Accessories And Tools Should I Consider Purchasing Alongside A Metal Lathe For Optimal Performance?To use your metal lathe well, you’ll need some important tools. First, buy cutting tools to shape the metal. Next, get a good measuring tool, like calipers, to check sizes. A chuck can help hold your metal pieces securely. Finally, don’t forget safety gear like goggles to protect your eyes!

How Can I Evaluate The Quality And Reliability Of Different Metal Lathe Brands For Cad Design Applications?To check the quality of metal lathe brands, you can read reviews online. Look for feedback from other people who use them. You can also ask friends or teachers who know about machines for their opinions. Finally, try to find out if the brand has good customer service, like helping if something breaks. This way, you can make a smart choice!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Buying A Metal Lathe For Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When buying a metal lathe for CAD design, think about what you need it for. You should check its size and features. Make sure it fits your projects. Look for a machine that is easy to use. Lastly, ask for help if you’re not sure what to choose!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Key Specifications Should I Look For In A Metal Lathe For Design Purposes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe for design, look for its size and weight. A bigger and heavier lathe is usually more stable. Check the speed settings, too. You want a lathe that can go slow and fast for different projects. Lastly, make sure it has good tools and parts support, so you can fix it easily if needed.”}},{“@type”: “Question”,”name”: “How Do I Determine The Appropriate Size And Capacity Of A Metal Lathe For My Cad Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right size of a metal lathe, think about what you will make. Look at the biggest pieces you want to create. If you need to work with large items, you should pick a bigger lathe. Also, check how heavy the items can be, as lathes have weight limits. Make sure the lathe can handle the materials in your projects.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Cnc (Computer Numerical Control) Lathes Compared To Manual Lathes In A Cad Design Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC lathes are better than manual lathes for several reasons. They use a computer to control movement, which makes them very precise. This means you get exact shapes every time you use them. CNC lathes also work faster, helping us finish projects sooner. Plus, they can be programmed to do the same job repeatedly without mistakes.”}},{“@type”: “Question”,”name”: “What Essential Accessories And Tools Should I Consider Purchasing Alongside A Metal Lathe For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use your metal lathe well, you’ll need some important tools. First, buy cutting tools to shape the metal. Next, get a good measuring tool, like calipers, to check sizes. A chuck can help hold your metal pieces securely. Finally, don’t forget safety gear like goggles to protect your eyes!”}},{“@type”: “Question”,”name”: “How Can I Evaluate The Quality And Reliability Of Different Metal Lathe Brands For Cad Design Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check the quality of metal lathe brands, you can read reviews online. Look for feedback from other people who use them. You can also ask friends or teachers who know about machines for their opinions. Finally, try to find out if the brand has good customer service, like helping if something breaks. This way, you can make a smart choice!”}}]}