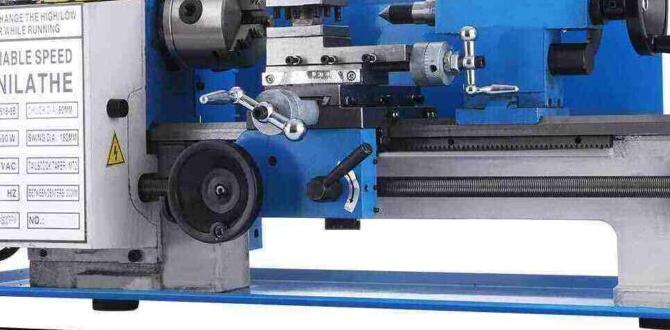

Have you ever watched a metal lathe spin? It’s like magic! The way metal transforms into different shapes is fascinating. If you want to dive into the world of metal lathes, a good controller is key. But how do you choose the right one?

A buying guide for a metal lathe controller can help you make smart choices. Whether you’re a beginner or a seasoned pro, the options can feel overwhelming. What features do you really need? How can you tell which controller is best for your projects?

Did you know that the right controller can improve your work quality? It can make your tasks easier and your projects more fun! In this article, we will explore everything you need to know about buying a metal lathe controller. Get ready to power up your creativity and skills!

Your Essential Buying Guide For Metal Lathe Controllers

Buying Guide for Metal Lathe Controller

Looking for the perfect metal lathe controller? This buying guide offers essential tips to help you choose wisely. First, consider the compatibility with your lathe. Next, think about features like speed control and ease of use. Did you know a good controller can improve precision in your work? Additionally, check user reviews to ensure reliability. By keeping these factors in mind, you can make a smart purchase that enhances your metalworking projects.Understanding Metal Lathe Controllers

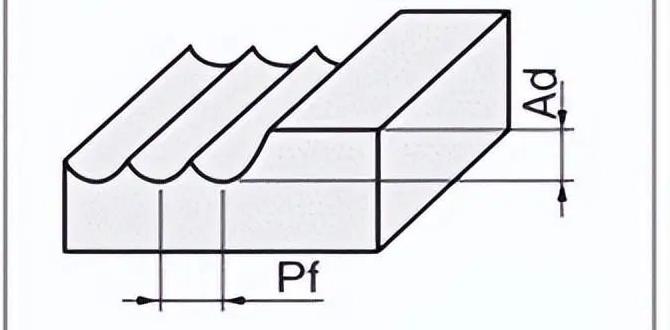

Definition and purpose of metal lathe controllers. Different types of metal lathe controllers available.Metal lathe controllers are devices that help control how a metal lathe machine works. They guide the movements of the lathe, letting it cut, shape, or polish metal precisely. Different types of controllers are available, each with unique features. Here are some common types:

- Manual Controllers: Operated by hand for basic tasks.

- Digital Controllers: Use screens for easy adjustments.

- CNC Controllers: Computer-operated for complex designs.

Choosing the right controller can greatly improve your metalworking projects. Knowing the options helps you make better decisions.

What are the benefits of using metal lathe controllers?

Using these controllers increases precision and efficiency. They make it easier to achieve intricate designs and save time during projects. This leads to higher-quality results.

Key Features to Look for in a Metal Lathe Controller

Precision and accuracy specifications. Compatibility with various lathe models. User interface design and ease of use. Programmable functions and adaptability.Choosing the right metal lathe controller can feel like searching for a needle in a haystack. First, look for precision and accuracy specifications. These will help you make smooth and exact cuts. Next, check if the controller is compatible with various lathe models. Nobody wants a controller that doesn’t fit! The user interface should be friendly. A confusing screen is like a maze without an exit. Lastly, programmable functions mean you can adapt to different tasks without breaking a sweat!

| Feature | Importance |

|---|---|

| Precision | Ensures clean, accurate cuts |

| Compatibility | Works with your lathe model |

| User Interface | Easy navigation and use |

| Programmable Functions | Customizable for various tasks |

Types of Metal Lathe Controllers

CNC (Computer Numerical Control) vs. standalone controllers. Advantages and disadvantages of each type. Ideal applications for different types.Metal lathe controllers come mainly in two types: CNC (Computer Numerical Control) and standalone controllers. Each has its own strengths and weaknesses.

- CNC Controllers: These are more advanced. They run on computer software. They allow precise cuts and can handle complex designs. Great for detailed work but can be pricey and need training.

- Standalone Controllers: These are simpler and easier to use. They are less expensive and good for basic tasks. However, they might not offer the same precision as CNC controllers. Best for beginners and simple projects.

Choosing the right type depends on your needs. If you want detailed designs, go for CNC. If you need something simple and affordable, choose standalone controllers.

What are the best applications for each type?

CNC controllers work well in professional settings, while standalone controllers suit hobbies or small projects.

Budget Considerations

Price ranges for metal lathe controllers. Cost vs. features analysis. How to determine the best value for your needs.Finding the right metal lathe controller for your budget is important. Prices can vary widely. Basic models start around $100, while advanced ones may reach $1,000 or more. Compare features to get the best value. Ask yourself: Do you need special functions? More features can mean higher costs. Keep your needs in mind to make a smart choice.

What should I consider when budgeting for a metal lathe controller?

Features matter most. Look for items like speed control and accuracy. Make a list of must-haves. Then, compare prices. This way, you can find a controller that fits your needs and your wallet.

Installation and Setup Process

Stepbystep guide to installing a metal lathe controller. Common challenges and troubleshooting tips. Safety precautions during installation.Setting up a metal lathe controller sounds tough, but it can be easy if you follow these steps. Start by reading the manual carefully. Make sure you have all the parts ready. Next, amake sure the machine is off and unplugged. Connect the wires according to the instructions. Check for loose connections.

If something goes wrong, don’t panic. Common issues include wrong wiring or loose parts. Double check each step if you face trouble. Always wear safety goggles and keep hands away from moving parts. It helps to have a friend during installation, too!

What are some common issues during installation?

Some common issues are incorrect wiring, loose connections, and software glitches. Always refer to the manual for troubleshooting tips.

- Check all connections

- Reset the controller if needed

- Make sure the power supply is working

Maintenance and Support

Routine maintenance tips for longevity. How to find technical support and resources. Warranty considerations and customer service ratings.Keeping your metal lathe controller in top shape is vital for its longevity. Regularly clean dust and debris. Check belts and wires for wear. Oil moving parts to prevent rust. This helps everything run smoothly. If problems arise, seek technical support online or from the manufacturer. Always read manual instructions for troubleshooting.

Consider warranty options before buying. A good warranty protects your investment, covering repairs. Check customer service ratings to find reliable support. Friendly service makes fixing issues easier.

How can I find help if my lathe controller breaks?

To find help, visit the manufacturer’s website or user forums. They often have guides and tips. You can also reach out to customer service. They can provide quick answers. Fast support saves time!

Real-World Applications and Use Cases

Industries that benefit from metal lathe controllers. Examples of projects and tasks accomplished with different controllers. Testimonials from professional users.Metal lathe controllers are like the magic wands of several industries. They help make everything from car parts to fun sculptures. For example, a small team of mechanics used a controller to build custom engine blocks. It saved them time and effort. In the jewelry business, experts create intricate designs quickly and accurately.

| Industry | Project Example | Feedback |

|---|---|---|

| Automotive | Custom engine components | “It changed our game!” |

| Jewelry | Artistic pendants | “I can make my dreams real!” |

| Manufacturing | Precision mechanical parts | “Efficiency at its best!” |

Users rave about the power of these controllers. They say things like, “I never knew lathes could be this smart!” With a little creativity and a sturdy controller, anyone can create masterpieces without too much hassle!

Future Trends in Metal Lathe Controls

Innovations in technology for metal lathe controllers. Predictions for industry advancements. How to stay ahead with the latest developments.Technology is changing fast. In metal lathe controls, new tools make us more precise and efficient. Innovations include smart sensors and user-friendly interfaces. These tools help workers make better parts quickly. Predicting advancements means watching for features like automation and improved software. Keeping up is key. You can:

- Attend workshops or trade shows.

- Join online forums or groups.

- Follow industry news and trends.

What is the future of metal lathe controls?

Future metal lathe controls will focus on greater efficiency, automation, and advanced materials. This means faster production and better quality work. The right tools today can help you stay ahead tomorrow.

Conclusion

In conclusion, when buying a metal lathe controller, remember to check compatibility, features, and ease of use. Quality matters, so look for reliable brands. Compare prices to find the best deal. By following this guide, you’ll make an informed choice for your projects. For more tips, explore our other articles or ask questions in forums. Happy crafting!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Buying A Metal Lathe Controller:Buying a metal lathe controller can be exciting! First, think about what you need it for. If you’re making small parts, a simple controller will work. For bigger projects, you might want a more advanced one. Always check reviews to see what others think before you buy.

Sure! Please provide the question you’d like me to answer, and I’ll help you with it.

What Are The Key Features To Look For In A Metal Lathe Controller To Ensure Compatibility With My Lathe Model?When choosing a metal lathe controller, check the power requirements first. You need to match the voltage and current to your lathe. Look for a controller that fits the size of your lathe. Make sure it can control the speeds you need, too. Finally, check if it connects easily to your lathe’s parts.

How Does The Type Of Control System (Manual Vs. Cnc) Affect The Performance And Capabilities Of A Metal Lathe Controller?A metal lathe is a machine that shapes metal. A manual lathe needs you to turn the knobs and levers to control it. This can take a lot of time and practice. A CNC lathe, which stands for Computer Numerical Control, uses a computer to move parts of the machine. This makes it faster and more accurate, so you can make better shapes with less effort.

What Is The Typical Price Range For A Reliable Metal Lathe Controller, And How Can I Determine If I’M Getting Good Value For My Investment?A reliable metal lathe controller usually costs between $300 to $1,500. To check if you’re getting good value, look for user reviews and ratings. You can also compare features with other controllers. Ask if it comes with a warranty, too. This way, you’ll feel more confident about your choice!

Are There Specific Brands Or Manufacturers Known For High-Quality Metal Lathe Controllers, And What Do Customers Say About Their Performance?Yes, some brands are known for making great metal lathe controllers. Brands like Tormach and Haas are popular among users. Customers say these controllers are easy to use and very reliable. Many love how well they control their lathes and help them create cool projects. Overall, people are happy with their performance!

What Additional Accessories Or Software Should I Consider Purchasing Alongside My Metal Lathe Controller To Enhance Its Functionality?To make your metal lathe controller even better, you might want some cool accessories. Laser measuring tools help you check sizes easily. A nice set of cutting tools makes your work smoother. You could also get a software program to plan your projects better. These additions will help you create awesome things!