Have you ever watched a metal lathe in action? It’s like watching a magician at work! A metal lathe turns metal into beautiful shapes, but the magic doesn’t just happen. The secret lies in the gear train. If you’re thinking about buying a metal lathe, you must understand its gear train.

What is a gear train? Imagine it as a team of gears working together. Each gear helps the lathe spin at the right speed. Without a good gear train, your projects might not turn out well. But how do you choose the best one?

In this buying guide, we’ll explore what to look for when buying a metal lathe gear train. We’ll share tips, fun facts, and things to watch out for. Whether you’re a hobbyist or just curious, this guide will help you make a great choice.

So, are you ready to discover the world of metal lathe gear trains? Let’s get started!

A Comprehensive Buying Guide For Metal Lathe Gear Train

Buying Guide: Metal Lathe Gear Train

When exploring a metal lathe gear train, understanding its importance is key. A gear train helps control speed and torque, making tasks smoother. Did you know that having the right gears can improve project accuracy? Look for features like gear ratios and materials. Consider your needs—are you a beginner or an expert? This buying guide helps you make informed choices. With the right metal lathe, your projects can shine with precision and ease!Types of Gear Trains in Metal Lathes

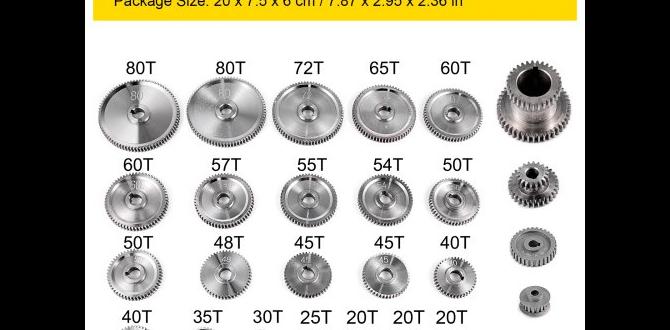

Explanation of different types (e.g., spur, helical, bevel gears). Benefits and drawbacks of each type.There are three common types of gear trains used in metal lathes: spur gears, helical gears, and bevel gears. Each type has its own benefits and drawbacks.

- Spur Gears: Simple and easy to produce. However, they can be noisy and generate vibrations.

- Helical Gears: Quieter and smoother in operation. They can be more complex and expensive to manufacture.

- Bevel Gears: Great for changing the direction of motion. They may have lower efficiency and can be tricky to align.

Choosing the right gear train depends on your needs. Think about cost, noise, and how you want your lathe to work.

What is a spur gear?

A spur gear is a type of gear with straight teeth that can mesh easily with other gears. They help in transmitting motion efficiently in machines.

What makes helical gears special?

Helical gears have angled teeth. This provides smoother and quieter operation. They are often used in heavy machinery for better performance.

Why use bevel gears?

Bevel gears allow for changes in direction. This is useful in machines that need to turn at different angles.

Key Factors to Consider When Buying a Gear Train

Compatibility with your lathe model. Gear ratio implications on performance.Before you leap into buying a gear train, check if it matches your lathe model. Compatibility is key; otherwise, you might end up with a fancy paperweight! Gear ratios are equally important. A higher ratio means faster spinning but can reduce power. Think of it like a bicycle: low gears are great for climbing hills, while high gears zoom on flat roads. Balance performance and power for the best results.

| Key Factor | Description |

|---|---|

| Compatibility | Must match your lathe model to function properly. |

| Gear Ratio | Higher ratios mean speed; lower ratios mean power. |

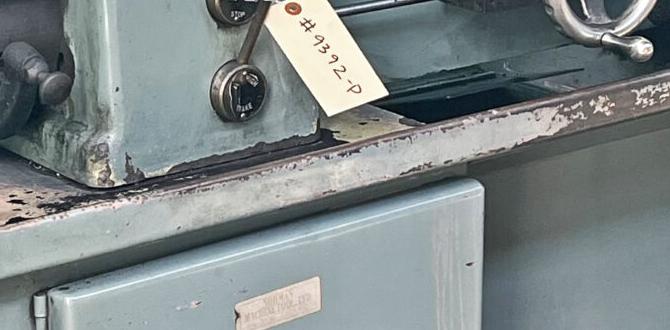

Common Brands and Models of Gear Trains

Comparison of popular brands in the market. Pros and cons of specific models.In the world of gear trains, certain brands stand out. For instance, Grizzly is known for its reliable models. However, some users say their customer service could be better. On the other hand, South Bend lathes are famous for their precision, but they can be pricey. Here’s a simple table comparing some brands:

| Brand | Pros | Cons |

|---|---|---|

| Grizzly | Great performance | Customer service issues |

| South Bend | High precision | Expensive |

| Jet | Good features | Heavier machines |

Choosing the right metal lathe gear train can be tricky. Each brand has its own strengths. Always weigh the pros and cons before making a final decision.

Installation and Maintenance Tips

Stepbystep installation procedure. Regular maintenance practices to ensure longevity.Installing your metal lathe gear train? It’s easier than baking a cake! First, gather your tools. Next, follow these steps: secure the lathe to a sturdy surface, install the motor, and connect the gears according to the manual. Then, check for tightness—no one wants a wobbly lathe! For maintenance, remember to oil the gears regularly and clean off dust. Think of it as giving your lathe a spa day!

| Task | Frequency |

|---|---|

| Oil Gears | Every Month |

| Clean Dust | Weekly |

| Check Belt Tension | Every Three Months |

With these tips, your metal lathe will keep running like a well-oiled machine. Literally!

Cost Considerations and Budgeting

Average costs associated with different gear trains. Tips for budgeting effectively.Buying a metal lathe with the right gear train can be expensive. The average cost ranges from $200 to $5,000. More complex gear trains typically cost more. To budget wisely, consider these tips:

- Set a clear budget before shopping.

- Research various models and their prices.

- Compare features to find the best value.

- Look for used options to save money.

Planning ahead helps you avoid overspending and make the right choice.

What should I look for in a metal lathe gear train?

Look for durability, ease of use, and versatility. A good gear train can make your work easier and more precise.

Conclusion

In summary, a buying guide for metal lathe gear trains helps you make smarter choices. Look for quality, compatibility, and feedback from other users. Understand the gear ratios for better performance. Don’t forget to check for warranty options. We encourage you to explore more guides and reviews to find the perfect gear train for your needs!FAQs

Sure! Here Are Five Related Questions On The Topic Of Buying A Metal Lathe Gear Train:Sure! When buying a metal lathe gear train, think about what you need. You should check how strong it is. Look at its size and make sure it fits your lathe. It’s also important to see if parts are easy to get if you need to fix it. Finally, compare prices to find a good deal!

Sure! Just ask your question, and I’ll be happy to help.

What Are The Key Features To Look For In A Metal Lathe Gear Train When Purchasing For A Specific Project?When buying a metal lathe gear train, look for a few important features. First, check the size. It should fit your lathe well. Next, think about the speed settings. You want options for different projects. Also, ensure it is made from strong materials. This helps it last longer. Lastly, consider how easy it is to change gears. You want to switch them quickly.

How Do Different Gear Ratios In A Metal Lathe Gear Train Affect Machining Speed And Torque?Different gear ratios in a metal lathe change how fast it spins and how strong it is. A high gear ratio makes it spin faster, which is good for lighter work. A low gear ratio gives you more power, perfect for tough jobs. By changing the gears, you can control the speed and strength for what you’re making. This helps us do our work better!

What Materials Are Commonly Used In Constructing Metal Lathe Gear Trains, And How Do They Impact Durability?Metal lathe gear trains are often made from steel and bronze. Steel is strong and lasts a long time. Bronze is good because it doesn’t wear down easily. Using these materials makes the gear trains durable, so they work better and longer.

Are There Specific Brands Or Models Of Metal Lathe Gear Trains That Are Recommended For Beginners Versus More Advanced Users?For beginners, brands like Grizzly and Harbor Freight offer good metal lathes. These are easy to use and not too expensive. Advanced users might prefer brands like Taig or Sherline because they have more features. They are great for tricky projects. Choose your lathe based on your skill level and what you want to make!

How Do I Determine Whether To Buy A Complete Metal Lathe With An Integrated Gear Train Or To Purchase A Separate Gear Train For An Existing Lathe?To decide, think about what you need. A complete metal lathe with an integrated gear train is all together. It might be easier to use. If your existing lathe works well, adding a separate gear train could save money. Choose what fits your projects and budget best.