Have you ever watched a craftsman shape metal into something useful? It’s like magic! If you are curious about how to bring that magic into your own workshop, you are in the right place. This buying guide for a metal lathe machine will help you make the best choice.

Buying a metal lathe is exciting, but it can also feel overwhelming. There are so many types, sizes, and features to choose from. How do you know what really fits your needs? Think about what projects you want to create. Would you like to turn wood or metal? Do you want to make simple tools or complex parts?

Here’s an interesting fact: The first metal lathes appeared over 200 years ago! They helped inventors and engineers create amazing things. Today, you can have this powerful tool in your home. Let’s dive into some key points to consider when buying a metal lathe machine that suits you best.

Essential Buying Guide For Metal Lathe Machines

Buying Guide for Metal Lathe Machines

Choosing a metal lathe machine can be tricky. Understanding different types and their uses helps you make the right choice. Consider your project needs and skill level first. Will you create tiny parts or large components? A fun fact: metal lathes can date back to ancient times, used for making tools and weapons. Prioritize features like precision, durability, and safety. By doing careful research, you’ll find the perfect machine to match your crafting dreams.Understanding Metal Lathes

Definition and function of a metal lathe machine. Types of metal lathes available in the market.A metal lathe is a special tool that spins metal to shape it into different designs. Imagine it as a giant pencil sharpener, but for metal! The machine carves away material to create precise parts. There are several types of lathes, each with its unique features. Here’s a handy table to make it clear:

| Type of Metal Lathe | Description |

|---|---|

| Manual Lathe | Operated by hand, great for learning! |

| CNC Lathe | Computer-controlled for advanced work, like magic! |

| Bench Lathe | Small and easy to use, perfect for hobbyists. |

The right lathe can make your projects fly! So, choose wisely, or you might end up with the wrong tool and a funny-shaped paperweight!

Key Features to Consider

Spindle speed and torque options. Size and bed length specifications.Choosing a metal lathe machine is like picking a good pizza; toppings matter! First off, remember spindle speed and torque options. The right speeds and torque let you shape metal with ease. You want it zippy and strong! Next, think about the size and bed length. A longer bed gives you more space to spin big pieces. Check out the table below for some quick comparisons:

| Feature | Importance |

|---|---|

| Spindle Speed | Determines how fast you can work. |

| Torque Options | Helps with tougher materials. |

| Bed Length | More length = more freedom! |

Remember, these features can make your projects easier and more fun, like a cat in a box!

Types of Metal Lathes

CNC lathes vs. manual lathes: pros and cons. Specialty lathes for specific projects.There are two main types of metal lathes: CNC lathes and manual lathes. CNC lathes are like robots; they follow instructions and can create precise cuts without much help. They save time but can be pricey. Manual lathes, on the other hand, need a human touch. They are cheaper and great for learning but require more skill. Then, there are specialty lathes for specific projects. These lathes are perfect for unique tasks, like making shiny knobs or fancy shapes. Remember, whether you’re a seasoned pro or a newbie, choosing the right lathe can make your project a breeze—or a wobbly mess!

| Type | Pros | Cons |

|---|---|---|

| CNC Lathes | High precision, Less manual effort | More expensive, Requires training |

| Manual Lathes | Cost-effective, Hands-on experience | Time-consuming, Needs skill |

| Specialty Lathes | Tailored for specific tasks, Unique designs | Limited use, Can be expensive |

Determining Your Needs

Assessing your project requirements. Understanding the skill level and operational ease.Before buying a metal lathe machine, think about what you need. Ask yourself these questions:

- What projects will you work on?

- What size materials will you use?

- Do you have experience using machines?

Your skill level matters too. If you’re new, choose a machine that’s easy to use. A good lathe should help you learn without being too complicated.

Finding the right lathe makes all the difference in your projects!

What should I consider for my project?

Think about your project size, type, and your skills.

Budgeting for Your Metal Lathe

Price ranges and what to expect. Longterm investment vs. upfront cost considerations.Choosing the right metal lathe requires smart budgeting. Prices can range widely. Entry-level models may cost around $300, while high-end machines can be over $5,000. Consider how often you’ll use it. Will you create projects for fun or run a business? Think of it as a long-term investment. Spending more now may save money later. Quality tools last longer and work better!

What should I consider when budgeting for a metal lathe?

Keep these points in mind:

- Price Range: Entry-level lathes start at $300; advanced models can exceed $5,000.

- Long-term Costs: Consider maintenance and extra tools needed over time.

- Usage Frequency: More frequent use may justify a higher initial cost.

Top Brands to Consider

Features and reputation of leading manufacturers. Customer reviews and feedback analysis.Some popular brands shine brightly in the metal lathe market. Notably, brands like Grizzly and Jet have earned strong reputations for their durable tools. Customers rave about Grizzly’s *sturdy build* and *precision*, often calling their lathe “a workhorse.” Jet tools, known for their *smooth operation*, receive thumbs up for being user-friendly. It’s amusing how many reviews involve customers teaming up with their lathes to create masterpieces. Check the table below for a quick snap of features from top brands:

| Brand | Notable Features | Customer Feedback |

|---|---|---|

| Grizzly | Sturdy build, precision | “A real workhorse!” |

| Jet | Smooth operation, user-friendly | “Perfect for beginners!” |

| Shop Fox | Affordable, versatile | “Great value for money!” |

Safety Tips and Maintenance

Essential safety practices while using a lathe. Routine maintenance tips for longevity.Using a metal lathe can be safe and fun if you follow important tips. Always wear safety glasses to protect your eyes. Keep fingers away from moving parts. Never wear loose clothing, as it can get caught. Here are some routine maintenance tips:

- Always clean the lathe after use.

- Check oil levels regularly.

- Lubricate moving parts to prevent wear.

These practices can help your lathe last longer and work better.

What are the essential safety practices while using a lathe?

Essential practices include wearing safety glasses, keeping a safe distance from moving parts, and ensuring clothing fits snugly.

How can I maintain my lathe effectively?

To maintain your lathe, clean it after each use and check the oil levels regularly for the best performance.

Where to Buy

Online vs. physical stores: advantages and disadvantages. Recommended platforms and dealers for purchasing.Buying a metal lathe? You’re in luck; both online and physical stores have their perks! Online shops are like a magic portal, offering choices from the comfort of your couch. However, you can’t touch the tools or haggle for a discount. Physical stores let you see what you are getting, but they might have a smaller selection.

| Buying Method | Advantages | Disadvantages |

|---|---|---|

| Online | More choices, better prices | No hands-on experience |

| Physical Stores | See before you buy | Less variety, price tag shock |

For great deals, check out sites like Amazon and eBay. They can sometimes have discounts that make you feel like you just found a treasure! Local dealers often offer support, which is like having a wise friend guide you to the perfect lathe.

FAQs About Metal Lathes

Common questions and expert answers for potential buyers. Troubleshooting tips for new users.Buying a metal lathe can raise many questions. Here are some common ones with answers to help you out. For example, “What size lathe should I choose?” The answer is it depends on your projects! Next, if you face issues like strange noises, remember, it’s often just a loose bolt. Check your machine regularly. If you encounter a jammed piece, don’t panic! Run a quick cool-off and recheck your settings. Here’s a handy table to summarize:

| Question | Answer |

|---|---|

| What size lathe do I need? | It depends on your projects! |

| What if it makes strange noises? | Check for loose bolts! |

| How do I fix a jammed piece? | Cool down and recheck settings. |

This little guide should help you handle the common bumps along the way to metal lathe mastery!

Conclusion

In conclusion, a buying guide for metal lathe machines helps you choose the right one. Focus on your needs, budget, and space. Consider features like size, power, and durability. Read reviews to compare options. Make informed decisions for your projects. Start exploring different machines now to find the perfect fit for you! Happy turning!FAQs

Sure! Here Are Five Related Questions About Buying A Metal Lathe Machine:Sure! When buying a metal lathe machine, first, think about what you want to make. Next, check how big the lathe is to fit in your space. Compare prices from different stores to find a good deal. You should also read reviews from other people who bought the same machine. Finally, make sure you have the tools and safety gear you need to use it safely.

Sure! I can help with that. Just give me the question you’d like me to answer, and I’ll make sure to keep it clear and simple for you!

What Factors Should I Consider When Selecting The Right Size Of Metal Lathe For My Workshop?When picking a metal lathe, think about the space in your workshop. You need enough room to operate it safely. Consider what projects you will do. A bigger lathe is good for bigger tasks, while a smaller one works for lighter jobs. Also, check how much money you want to spend.

How Do I Determine The Appropriate Spindle Speed And Torque Capacity For My Metal Lathe Needs?To find the right spindle speed for your metal lathe, check the material you’re using. Soft metals, like aluminum, need a higher speed, while hard metals need a slower speed. For torque, think about how much force you need to turn the material. If you’re working with bigger pieces or harder materials, you’ll need more torque. Always read your machine’s manual for the best settings!

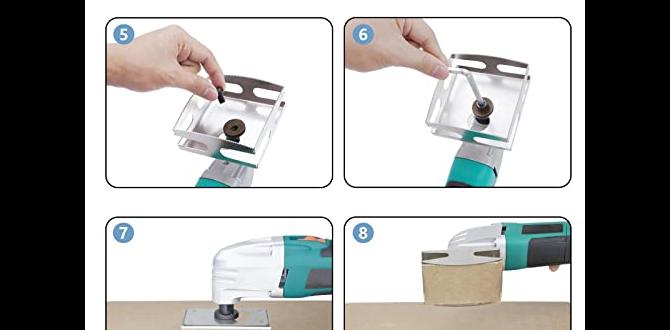

What Additional Features And Accessories Should I Look For In A Metal Lathe To Enhance My Machining Capabilities?To make your metal lathe better, look for a few cool features. A quick-change tool post helps you switch tools fast. A dro, or digital readout, shows exact measurements. You might also want a bigger chuck to hold larger pieces. Finally, extra tooling like different cutting bits can help you make more things!

How Can I Evaluate The Build Quality And Durability Of Different Metal Lathe Brands And Models?You can check if a metal lathe is sturdy by looking at its materials. Good lathes use strong metals like cast iron. You should read reviews from other people. They can tell you how long the lathe lasts. Also, you might want to ask a friend or a teacher who knows about tools.

What Is The Typical Price Range For Metal Lathe Machines, And How Can I Identify A Good Value For My Budget?Metal lathe machines usually cost between $1,000 and $10,000. Smaller ones are cheaper, and bigger ones cost more. To find a good deal, set a budget first. Look for machines that have good reviews and meet your needs. Make sure the machine is from a trusted brand and check if it has a warranty.