Have you ever wondered how to keep your metal lathe running smoothly? Maintenance might not sound exciting, but it’s key to any project. Picture this: you’re working on a great piece, and suddenly, your lathe stops. Frustrating, right?

With proper care, you can avoid these mishaps. This buying guide on metal lathe maintenance will help you learn easy tips. You’ll discover how simple steps can greatly extend your lathe’s life. Did you know that regular cleaning can improve performance? It’s true!

Join us as we explore the essentials of metal lathe care. From cleaning to lubrication, we’ve got you covered. Let’s make your metal lathe work better for you!

Essential Buying Guide For Metal Lathe Maintenance Tools

Buying Guide: Metal Lathe Maintenance

When you buy a metal lathe, keeping it running well is crucial. Regular cleaning and lubrication can extend its life. Did you know that dust and debris can stop a lathe from working properly? Always check belts and gears for wear. This simple act can save you time and money. Plus, knowing how to tackle small repairs can boost your confidence. Following these maintenance tips ensures your lathe remains a reliable tool in your workshop.Understanding Metal Lathes

Definition and purpose of a metal lathe. Types of metal lathes available in the market.Metal lathes are amazing machines that help shape and cut metal into useful parts. Think of them as big spinning toys for grown-ups! They come in different types, perfect for different jobs. Some are small for hobbyists, while others are gigantic and used in factories. Here’s a quick look at the types you can find:

| Type | Description |

|---|---|

| Benchtop Lathe | Small, perfect for home use and beginner projects. |

| Engine Lathe | Versatile and commonly used in machine shops. |

| CNC Lathe | Computer-controlled for precision and automation. |

Choosing the right lathe can make your metalworking dreams come true. So don’t go spinning your wheels—find the right metal lathe for you!

Importance of Regular Maintenance

Benefits of maintaining a metal lathe. Common issues arising from neglect.Taking care of your metal lathe is like giving it a Spa Day. Regular maintenance keeps it happy and running well. A well-maintained lathe produces smoother cuts and lasts longer. Plus, who likes dealing with unexpected breakdowns? Neglect can lead to wear and tear, which means more repairs and less time for fun projects. Trust me, you’ll appreciate the difference!

| Benefits of Maintenance | Common Issues from Neglect |

|---|---|

| Longer Lifespan | Rust Formation |

| Smoother Operations | Increased Breakdowns |

| Better Results | Safety Hazards |

Key Maintenance Tasks for Metal Lathes

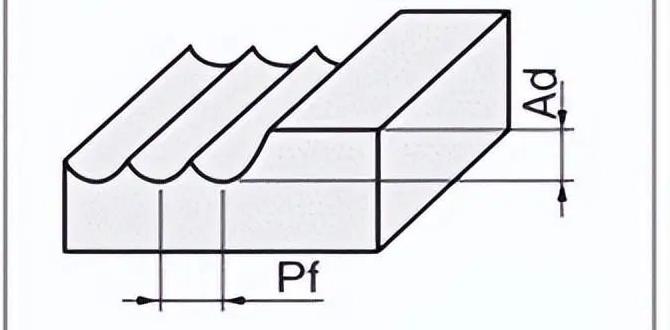

Lubrication: types and techniques. Cleaning: recommended products and methods.Taking care of your metal lathe is like feeding a pet; it keeps everything running smoothly! First off, let’s talk about lubrication. You can use grease, oil, or even a fancy synthetic lube to keep the moving parts happy. A simple squirt goes a long way! Next up is cleaning. A good brush and some mild cleaner will work wonders, so you don’t have to turn your lathe into a dust bunny habitat. Here’s a handy table to help you remember:

| Task | Tip |

|---|---|

| Lubrication | Use grease or synthetic oil. |

| Cleaning | Avoid harsh chemicals; stick to mild cleaners. |

Keeping your lathe clean and oiled will make it last longer. Remember, a happy lathe makes for happy projects!

Essential Tools for Metal Lathe Maintenance

Musthave tools for effective maintenance. Safety equipment considerations.To keep your metal lathe in shape, you need some essential tools. These tools help you maintain the lathe effectively. Here are some must-have items:

- Wrenches: For tightening and loosening parts.

- Oil: Keeps the lathe running smoothly.

- Brushes: Clean dust and chips from the machine.

- Calipers: Measure parts accurately.

- Safety Gloves: Protect your hands while working.

- Safety Glasses: Shield your eyes from flying debris.

Using these tools makes maintenance easier. Safety equipment is just as important. It ensures you stay safe while keeping your lathe in good condition.

What tools do I need for metal lathe maintenance?

You need wrenches, oil, brushes, calipers, gloves, and safety glasses for effective maintenance. These tools help you keep your lathe running well and safe to use.

Tips for Selecting the Right Metal Lathe

Factors to consider: size, power, and features. Comparing brands and models.Selecting the right metal lathe can be exciting. Consider a few important factors to make your choice easier.

- Size: Choose one that fits your workspace.

- Power: Look for enough horsepower for your projects.

- Features: Check if it has automatic feeds and speed settings.

Also, compare different brands and models. Some well-known brands may offer good customer support. Read reviews to see how satisfied users are with their lathes. This helps you make a smart decision and find the best fit for your needs.

What should I look for in a metal lathe?

Look for size, power, and features that suit your projects. Read reviews and compare brands.Common Problems and Their Solutions

Identifying signs of wear and tear. Troubleshooting tips for common issues.Lathe troubles? Don’t worry! Every machine shows signs of age, like an old car with squeaky brakes. Look for things like unusual noises or difficulty in movement. These often signal wear and tear. If you spot something funky, grab your toolbox! Common fixes include lubricating parts or tightening screws. Remember, even machines need some pampering. Check this handy table for quick fixes:

| Problem | Solution |

|---|---|

| Unusual noises | Lubricate moving parts |

| Poor cutting | Sharpen or replace tools |

| Vibration | Tighten loose screws |

Address these issues quickly to keep your lathe running smoothly. A happy lathe makes happy projects!

Advanced Maintenance Techniques

Upgrading components for better performance. When to seek professional help.Want to get your metal lathe running like a finely tuned sports car? Start by upgrading its components. New parts can boost performance and extend its life. Think of it like swapping out old sneakers for a shiny new pair—your lathe will thank you! However, if you’re faced with mysterious noises or alarming vibrations, it might be time to call in the pros. After all, even superheroes need sidekicks sometimes!

| Signs You Need Help | What to Do |

|---|---|

| Strange noises | Consult a technician |

| Inconsistent cuts | Upgrade your tool |

| Excess vibration | Get professional assistance |

Costs Involved in Metal Lathe Maintenance

Breakdown of regular maintenance costs. Longterm savings from proper upkeep.Keeping your metal lathe in shape costs a bit each year, but think of it like buying ice cream. It feels good to splurge sometimes, right? Regular maintenance can cost a few hundred dollars yearly, mostly for lubricants, belts, and maybe some new tools. But guess what? Proper upkeep means fewer breakdowns. It’s like a magic trick that saves money in the long run! Here’s a quick breakdown:

| Maintenance Item | Estimated Cost |

|---|---|

| Lubricants | $50 |

| Belts Replacement | $100 |

| Tool Sharpening | $200 |

| Total Annually | $350 |

With proper care, you avoid those big surprise repair bills. It’s like checking your fridge for old food; it saves you from an unexpected smell!

Conclusion

In summary, a metal lathe needs regular maintenance to stay in great shape. You should clean it, check for wear, and lubricate moving parts. Following a buying guide helps you choose the right tools for upkeep. Remember, taking care of your lathe will improve its performance. For more tips, explore further resources and keep your lathe running smoothly!FAQs

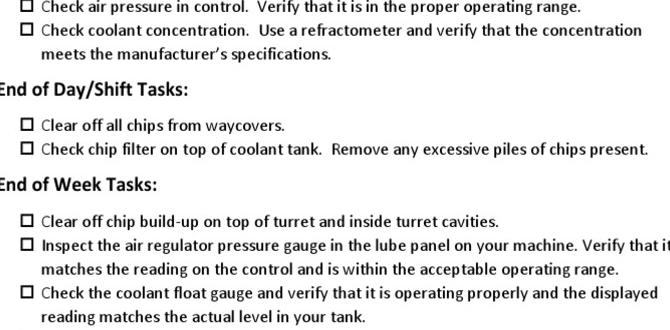

What Are The Essential Maintenance Tasks Required To Keep A Metal Lathe In Optimal Working Condition?To keep a metal lathe working well, you should clean it regularly. Dust and metal shavings can cause problems. You also need to oil the moving parts, so they don’t get stuck. Checking for loose screws or parts is important too. Finally, cover it when you’re not using it to keep it safe from dust.

How Often Should I Perform Routine Inspections And Lubrication On My Metal Lathe?You should check your metal lathe every week. Look for any wear or damage. Lubricate moving parts once a month. This keeps your lathe working well and helps it last longer. Remember to always follow the user manual for best results!

What Type Of Cleaning Products And Tools Are Recommended For Maintaining A Metal Lathe?To keep a metal lathe clean, you should use mild soap and water. A soft cloth works well for wiping it down. You can use a small brush to get dust from hard-to-reach places. For tough spots, a gentle cleaner made for metal is good. Make sure to always dry the lathe afterward to prevent rust.

How Can I Identify Signs Of Wear And Damage On My Metal Lathe, And What Steps Should I Take To Address Them?You can spot wear and damage on your metal lathe by looking for rust, deep scratches, or cracks. Check the parts that move, like the spindle and carriage, for any strange noises or wobbling. If you see any problems, clean the lathe and oil the parts to help them move smoothly. If it still doesn’t work right, ask a tool expert to help fix it. Taking care of your lathe helps it last longer!

Are There Specific Maintenance Procedures That Differ Between Manual And Cnc Metal Lathes?Yes, there are differences in how we take care of manual and CNC (Computer Numerical Control) metal lathes. For manual lathes, you need to check the belts and oil the parts by hand. With CNC lathes, you often check the software and do more computer updates. Both types need cleaning and checking, but the tools and ways to do it can vary. Always remember to follow the instructions for each type!