Have you ever wondered how metalworkers create those smooth, sloping surfaces on metal pieces? It’s often done with a process called taper turning. This technique shapes metal into perfect cones or tapers, and it’s a skill every metalworker should master.

When looking to start taper turning, buying the right metal lathe is key. But with so many options, how do you find the best one? A good metal lathe will make taper turning easier and more fun.

Imagine you’re in a shop filled with shiny machines. You see an old lathe that looks cool but doesn’t work well. Or a brand-new lathe that can do amazing things! Selecting the right lathe affects your project’s success.

This buying guide for metal lathe taper turning will help you choose the perfect machine. You’ll learn what features to look for and how they can benefit your work. Ready to dive in? Let’s find the best metal lathe for your taper turning adventures!

Buying Guide: Metal Lathe Taper Turning Essentials

Looking to make precise parts with a metal lathe? Understanding taper turning is key. This guide helps you choose the right lathe by exploring essential features. Learn about the importance of bed length and spindle speed. Discover why a reliable taper attachment can improve your accuracy. Did you know that taper turning can enhance the strength of your projects? With the right tools, you can create perfect angles effortlessly. Happy turning!

Understanding Metal Lathes

Definition and function of metal lathes. Importance of taper turning in metalworking.

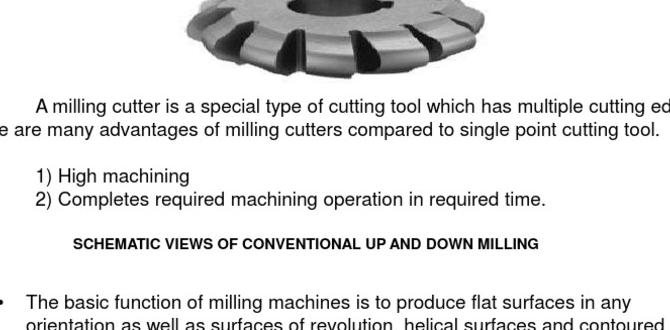

Metal lathes are machines that shape metal into useful parts. They spin the metal while a cutting tool removes pieces to create precise shapes. This process is essential in many industries. One key technique is taper turning. It helps make tapered shapes, like cones, which fit together perfectly. This is important for things like fitting parts in a car engine.

What is the role of taper turning in metalworking?

Taper turning is used to create angled shapes on metal parts. It improves the fitting of parts and ensures they work smoothly together. This technique is vital in making items like tools and machinery.

- Creates smooth, accurate angles

- Improves part compatibility

- Reduces wear and tear on machinery

Key Features to Look for in a Metal Lathe

Swing over bed and length of the bed. Spindle speed and motor power considerations.

Choosing the right metal lathe involves knowing key features. First, consider the swing over bed. This tells you the largest diameter of the workpiece you can use. The length of the bed is vital too. A longer bed helps in handling bigger projects.

Next, look at the spindle speed. A higher speed means faster work. Pay attention to motor power. A powerful motor makes tougher jobs easier.

- Swing over Bed: Larger diameter means more options.

- Length of Bed: Longer beds are better for large projects.

- Spindle Speed: Faster speeds save time.

- Motor Power: More power tackles tougher tasks.

What should I consider in a metal lathe?

Key features are swing over bed, length of bed, spindle speed, and motor power. These elements help you choose the best metal lathe for your needs.

Essential Accessories for Taper Turning

Required tooling for taper turning (centers, chucks, jaws). Recommended attachments (taper turning attachment, tailstock).

For successful taper turning, you need special tools and attachments. Some key accessories include:

- Centers: These help hold your workpiece securely.

- Chucks: They grip materials tightly for turning.

- Jaws: They ensure your work stays in place during operations.

Additionally, consider these recommended attachments:

- Taper Turning Attachment: This accessory simplifies creating tapered shapes.

- Tailstock: Use this for added support while turning.

Having the right tools makes taper turning easier and more accurate!

What tools are essential for taper turning?

The essential tools are centers, chucks, jaws, taper turning attachments, and tailstocks. These tools help hold materials securely and ensure clean, precise cuts.

Factors Affecting Lathe Performance

Material compatibility and workpiece size. Stability and vibration control.

Several factors can affect how well a lathe performs. First, material compatibility matters. Your lathe should handle different materials smoothly. Using the wrong material can lead to frustration and bad results. Second, consider the workpiece size. Bigger pieces need more power and careful handling. Third, stability is key. A wobbly lathe can turn your project into a dance party! Lastly, vibration control helps keep things steady, making your work look professional.

| Factor | Importance |

|---|---|

| Material Compatibility | Ensures smooth operations |

| Workpiece Size | Affects power and handling |

| Stability | Prevents wobbling |

| Vibration Control | Keeps work steady |

Budget Considerations

Price ranges for hobbyist vs. professional lathes. Longterm investment: quality vs. cost.

Choosing a metal lathe depends on your budget. Hobbyist lathes can cost between $300 and $1,000. Professionals may spend $1,000 to $10,000 or more. Remember, investing in quality is wise. A good lathe lasts longer and works better, saving money in the long run.

- Hobbyist Lathes: $300 – $1,000

- Professional Lathes: $1,000 – $10,000+

Quality makes a difference. A cheaper lathe may seem nice, but repairs and issues can add up. Think about what you need and what you can afford.

What is the best metal lathe for beginners?

The best metal lathe for beginners is often a smaller model, like the Grizzly G8688, which is easy to use and affordable.

How much should I spend on a lathe?

If you’re a hobbyist, spending $300 to $1,000 is good. If you’re serious about your work, consider investing more for quality.

Maintenance and Care for Longevity

Routine maintenance tips to enhance performance. Common issues and troubleshooting techniques.

Keeping your metal lathe in top shape is easier than you think! Regularly check and clean the machine to avoid buildup. A quick wipe with a soft cloth can do wonders. If a part starts to rattle, it might be loose. Tighten it up! If your lathe won’t start, inspect the power switch. Sometimes it’s just a matter of being unplugged, like finding out your pet was hiding under the couch!

| Routine Maintenance Tips | Common Issues |

|---|---|

| Check the oil levels | Machine won’t turn on |

| Clean chips from the bed | Rattling noise |

| Inspect belts for wear | Unusual vibrations |

Follow these simple tips, and your lathe will thank you with smooth operations! Remember, a happy lathe makes happy projects. So, give your machine some love, and it’ll return the favor.

Brands and Models to Consider

Toprated brands with reputations in the market. Comparison of popular models with a focus on taper features.

Choosing a metal lathe can feel like picking a favorite ice cream flavor—so many great choices! Popular brands like Grizzly, Jet, and PM offer solid reputations. Grizzly lathes are known for their strength. Jet models shine with their easy taper adjustments. PM combines great features with user-friendliness. Check out the comparison table below for a quick look at taper features.

| Brand | Model | Taper Features |

|---|---|---|

| Grizzly | G0766 | Adjustable, easy to use |

| Jet | JWL-1442 | Quick-change, precise settings |

| PM | 1440GT | Versatile, user-friendly |

Remember, the right lathe helps you turn projects into masterpieces, and maybe even a few funny table legs along the way!

Expert Tips for Successful Taper Turning

Techniques to achieve precision in taper turning. Common mistakes to avoid when using a metal lathe.

Taper turning can be tricky, but following expert tips can help you succeed. First, use a steady hand and take your time. Measure often to ensure accuracy. Here are some common mistakes to avoid:

- Rushing through the process can lead to errors.

- Not securing materials properly can cause shifting.

- Ignoring the lathe’s instructions may lead to mishaps.

Remember, practice makes perfect. The more you work, the better you will become at taper turning.

What is taper turning?

Taper turning is shaping a piece of material so it gradually becomes narrower at one end. This technique is often used in woodworking and metalworking.

Tips for precision in taper turning

- Always check measurements frequently.

- Set your tool correctly to avoid mistakes.

- Practice on scrap material before starting your final piece.

Conclusion

In conclusion, a metal lathe taper turning buying guide helps you choose the right tools for your projects. Understand the features, types, and sizes before making a purchase. Always consider your needs and budget. We encourage you to explore more guides and reviews to gain confidence. Happy turning, and may your projects be a success!

FAQs

What Are The Key Features To Consider When Selecting A Metal Lathe For Taper Turning?

When choosing a metal lathe for taper turning, you should look for a few important features. First, make sure it has good power to cut the metal. Second, check if it can easily adjust the angles for different tapers. Third, look for a sturdy base that keeps the lathe steady while you work. Finally, find one with clear dials and controls so you can use it easily.

How Do Different Types Of Metal Lathes (Manual Vs. Cnc) Affect The Process Of Taper Turning?

Manual lathes need you to turn the handle yourself to make a taper. It takes practice to get it just right. CNC lathes, on the other hand, are computer-controlled. You just set it up, and the machine does all the work for you! This makes taper turning faster and easier with CNC lathes.

What Tooling And Attachments Are Needed For Effective Taper Turning On A Metal Lathe?

To taper turn on a metal lathe, you need special tools. First, grab a tool holder for the cutting tool. You’ll also need a taper attachment, which helps you make the shape. A measuring tool, like a caliper, is useful to check your work. Lastly, use cutting oil to make turning smoother and cooler.

How Can I Accurately Set Up A Metal Lathe For Taper Turning To Ensure Precision?

To set up a metal lathe for taper turning, first measure the angle you want. You can do this using a protractor. Then, adjust the tailstock or the tool position to match that angle. Tighten everything so it doesn’t move. Finally, test it on a scrap piece before working on your actual project.

What Common Mistakes Should I Avoid When Using A Metal Lathe For Taper Turning?

When using a metal lathe for taper turning, avoid rushing your work. Take your time to measure carefully. If you set the angles wrong, your taper will not look right. Always keep your tools sharp and check them often. Finally, make sure everything is tight and secure before starting the lathe.