Lathe speed plays a crucial role in the machining process, determining the efficiency and accuracy of the final product. It refers to the rotation speed of the lathe machine, which is responsible for shaping and cutting materials such as wood, metal, and plastic.

The correct lathe speed is essential for achieving precise cuts, preventing tool damage, and ensuring a smooth finishing touch on the workpiece. As such, understanding how to calculate lathe speed is fundamental for anyone working with a lathe machine.

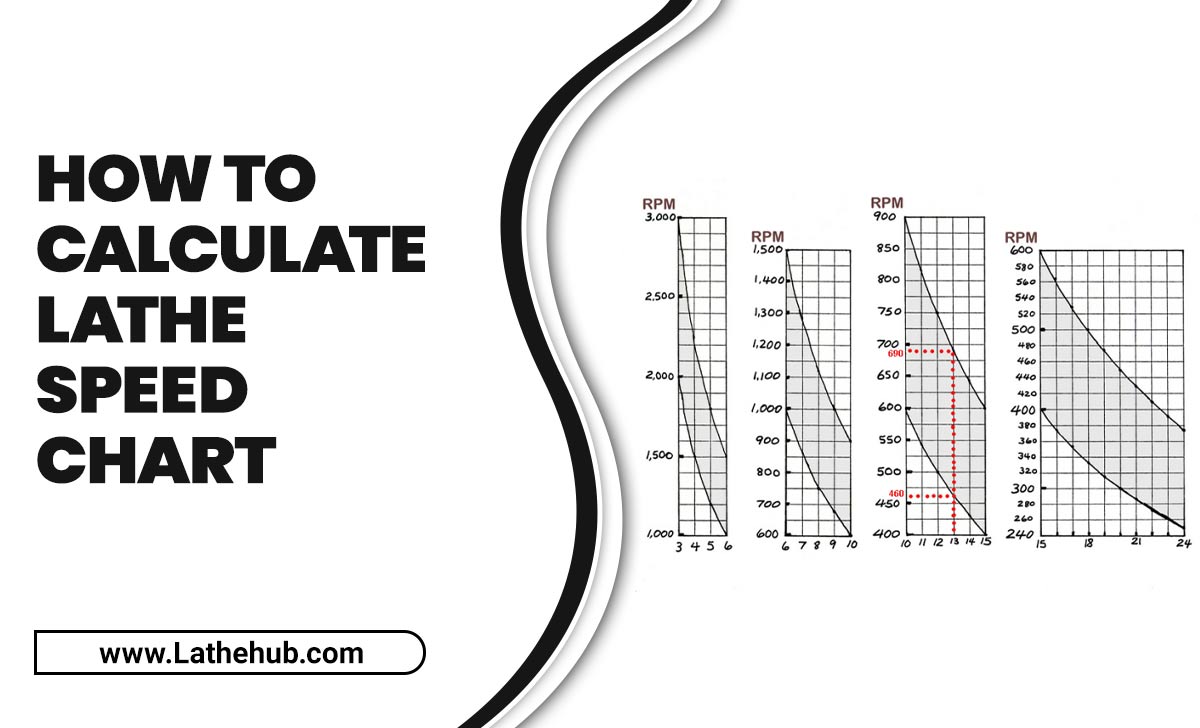

Here, we will explore the importance of understanding how to calculate lathe speed using a lathe speed chart. We will discuss the factors that affect lathe speed, step-by-step guidelines on calculating lathe speed chart, examples of lathe speed calculations, safety precautions, common mistakes, and resources for proper guidance. So, let’s dive deeper into lathe speed calculation and discover its significance in the machining industry.

What Is Lathe Speed?

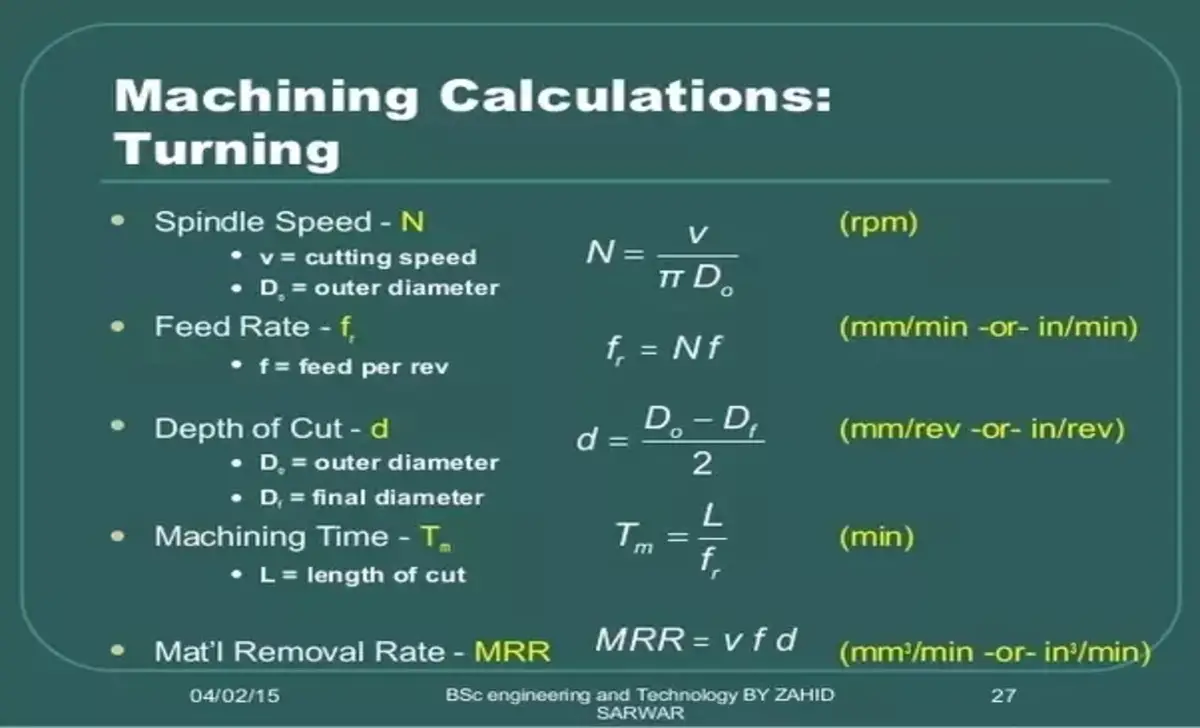

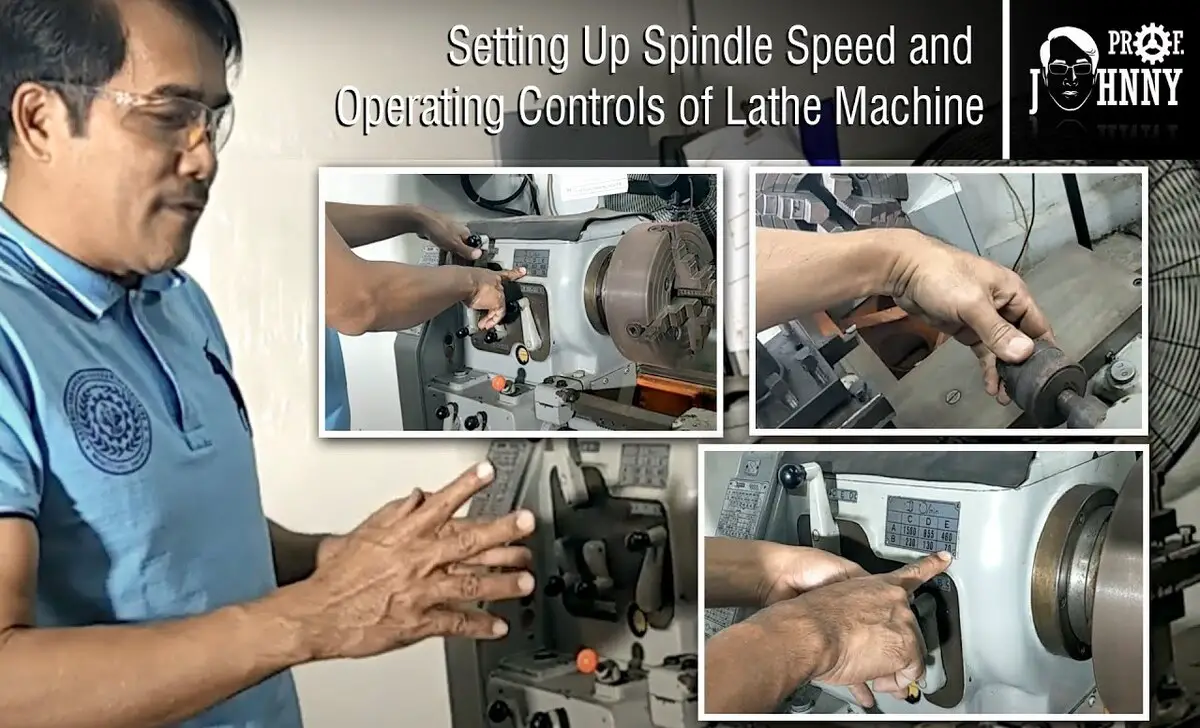

Lathe speed, also known as spindle speed, is crucial for turning operations. It affects the cutting tool’s performance and workpiece surface speed. Understanding lathe speed is essential for achieving the desired results. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute.

These factors determine the cutting tool’s longevity, accuracy, and workpiece quality. In simple terms, lathe speed determines how fast the workpiece rotates and affects the material removal rate. Different turning applications, materials, and cutting tools require specific lathe speeds for optimal results. For example, spindle turning, bowl turning, and wood lathe speed have specific requirements based on bowl diameter, maximum speed, and material being turned.

Different Factors Affecting Lathe Speed

Understanding these factors is crucial for accurately calculating lathe speed and achieving desired results in turning operations. Lathe speed can significantly impact the quality and efficiency of turning operations. The speed at which the lathe rotates determines the workpiece’s cutting speed and surface finish. To calculate the appropriate lathe speed for a turning operation, several factors must be considered:

- Material Type: Different materials have unique properties that require varying lathe speeds. Consult machining guidelines or manufacturer recommendations for specific speed ranges.

- Cutting Tool: The material, geometry, and coating of the cutting tool influence the spindle speed, feed rate, and surface speed required.

- Workpiece Diameter: Larger workpieces require slower lathe speeds to adjust for cutting speed. Consider the engagement with the cutting tool and centrifugal force.

- Feed Rate: The amount of material advanced per revolution affects the spindle speed calculation. Synchronize feed rate, spindle speed, and cutting tool material for optimal results.

- Surface Speed: The speed at which the workpiece moves past the cutting tool influences material removal rate, surface finish, and tool life.

How To Calculate Lathe Speed Chart: A Step-By-Step Guide

Calculating lathe speed can be a crucial step in ensuring the success of your machining project. By determining the correct speed for your lathe, you can achieve optimal cutting performance and avoid any potential issues, such as tool wear or workpiece damage. You are additionally, finding the recommended cutting speed and following the rule of thumb for Diameter play crucial roles in setting the spindle speed.

The lathe speed chart is helpful, especially regarding high rpms and wood lathe machinery’s handbook recommendations. By following these steps and ensuring that you use appropriate cutting speeds for your specific material and workpiece diameter, you can optimize your lathe’s performance and achieve high-quality machining results. Here is a step-by-step guide on how to calculate the lathe speed chart:

Step 1: Determine The Material Type

Determining the material type being turned is the first step in calculating lathe speed. Different materials require specific lathe speeds, cutting speeds, and feed rates to achieve optimal results. Consult the machinery’s handbook or manufacturer recommendations to identify the appropriate speed range for your working material. Proper material identification ensures the correct rpm setting, wood lathe speed, and diameter considerations for the turning operation.

Step 2: Identify The Cutting Tool

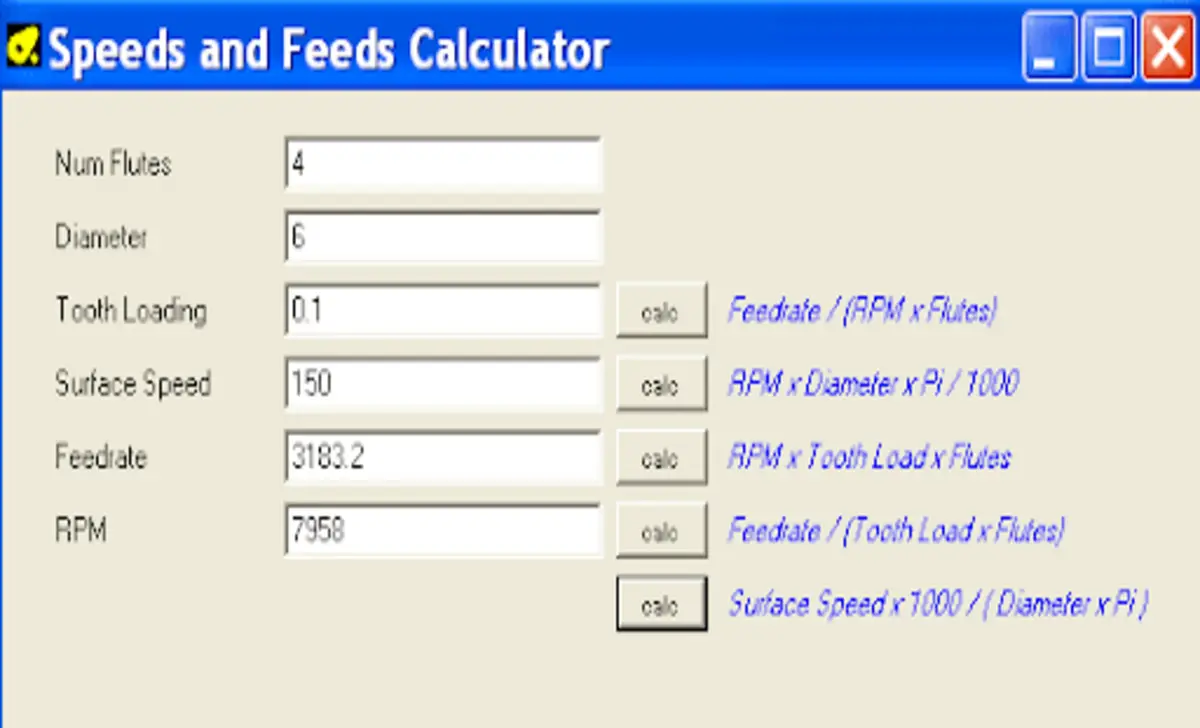

Once the material type is determined, the next step is to identify the cutting tool used. The cutting tool material, geometry, and coating can impact the recommended cutting speed, feed rate, and surface speed. Consider the cutting tool’s characteristics, such as high-speed steel or carbide, to adjust the lathe speed accurately. Proper cutting tool identification influences the turning operation’s spindle speed, feed rate, and calculated rpm.

Step 3: Find The Recommended Cutting Speed

When determining the recommended cutting speed, it’s essential to factor in surface speed, feed rate, and spindle speed calculations. The recommended cutting speed plays a crucial role in the turning operation, calculated rpm, and wood lathe speed setting. Understanding the recommended cutting speed significantly impacts new turners, bowl turning, and the proper lathe speed. Adhering to the rule of thumb for the recommended cutting speed influences the Diameter, high rpm, and spindle turning speed, ensuring the safety of the turning operation, cutting tool, and feed rate.

Step 4: Calculate The Spindle Speed

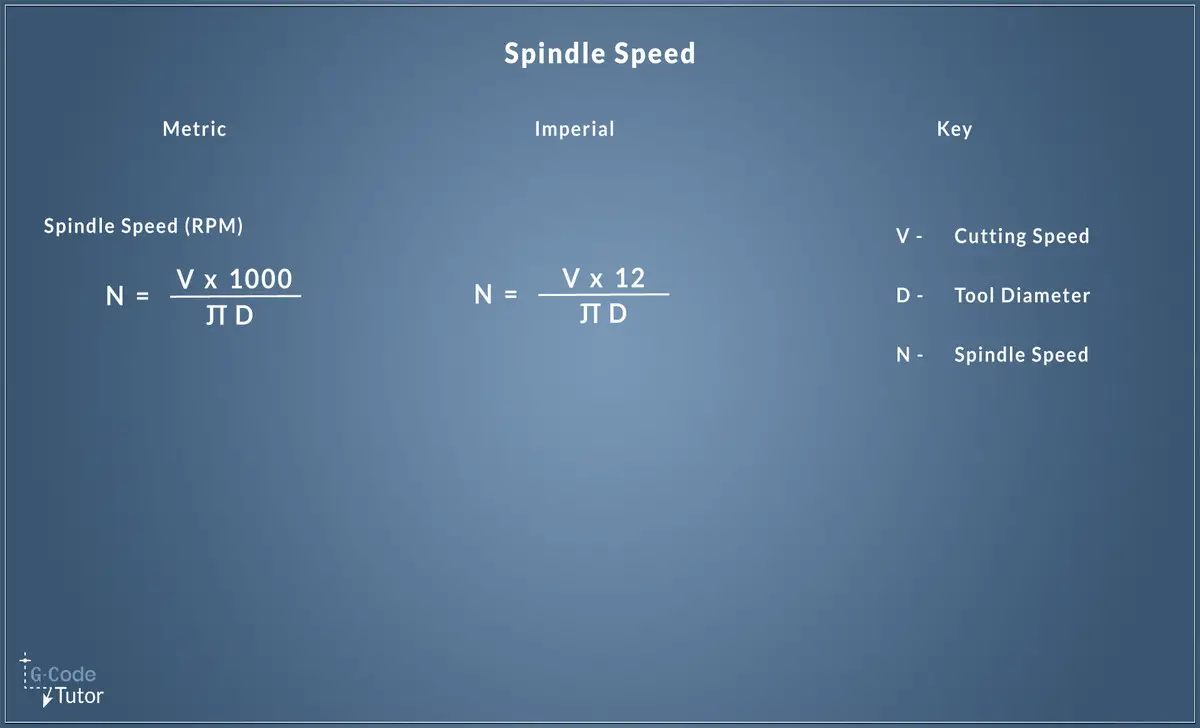

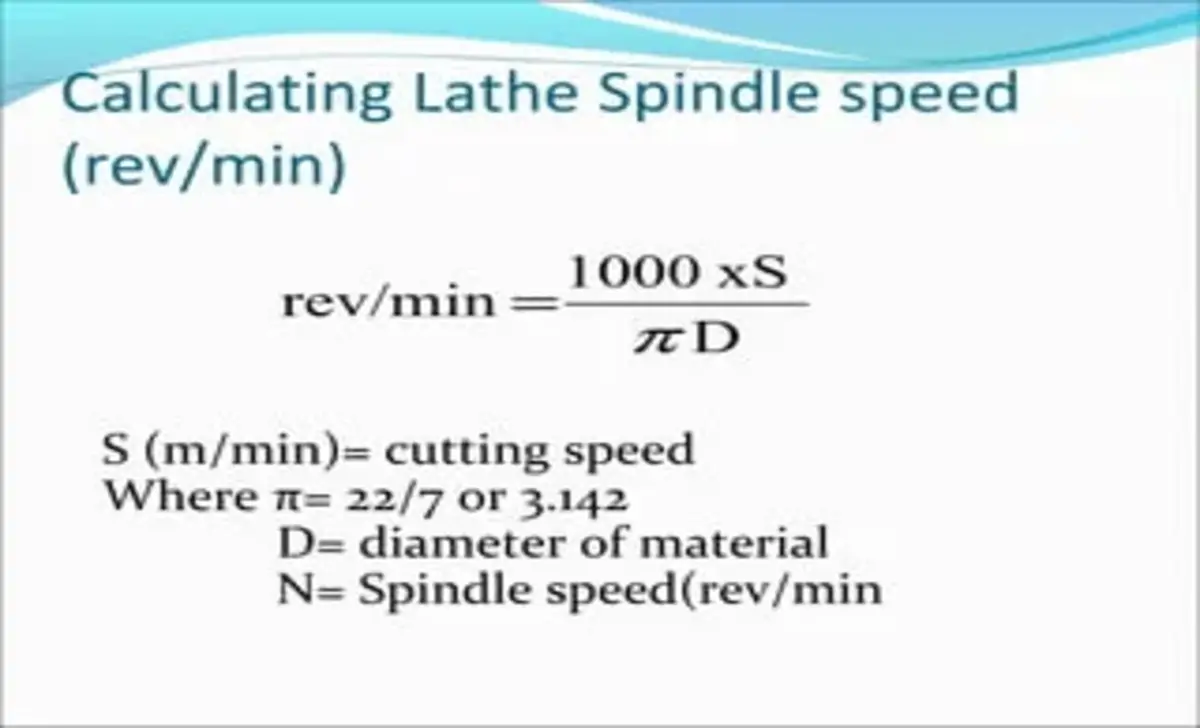

Once the recommended cutting speed is determined, the next step is to calculate the spindle speed. Spindle speed, measured in revolutions per minute (RPM), directly affects the material removal rate, surface finish, and tool life. To calculate the spindle speed, use the following formula:

RPM = (Cutting Speed x 4) / Diameter of the workpiece

By plugging in the cutting speed and the workpiece diameter, lathe operators can compute the appropriate spindle speed for the turning operation. A thorough understanding of the spindle speed calculation ensures the lathe operation’s accuracy, efficiency, and safety.

Step 5: Adjust For The Number Of Teeth On The Cutting Tool

In addition to material type, cutting tool, and spindle speed considerations, lathe operators must adjust for the number of teeth on the tool. The number of teeth impacts the feed rate, surface feet per minute, and cutting speed. By considering the number of teeth, lathe operators can optimize the cutting operation’s efficiency and accuracy. Adjusting the feed rate accordingly is crucial, considering the surface feet per minute and the cutting tool’s engagement with the workpiece.

Step 6: Check For Safety Precautions

When operating machinery, prioritizing safety precautions is crucial. Mitigating the risk of accidents during lathe operations can be achieved by thoroughly checking for safety precautions. This ensures a secure and controlled lathe environment, minimizing the potential for workplace injuries. Verifying safety precautions is essential to guarantee a safe working environment for lathe operators. Adhering to safety precautions upholds workplace safety and instils confidence in the operators, promoting a culture of responsibility and awareness.

Step 7: Practice And Refine Your Calculation Skills

Lathe speed calculation is a skill that improves with practice and experience. After going through the steps of calculating lathe speed, practising and refining your skills is important. Spent time practising lathe speed calculations and adjusting spindle speeds. And analyzing the results will help you become more proficient in the field. As with any skill, repetition and learning from mistakes are crucial in mastering lathe speed control. You will become a more confident and effective lathe operator by continually practising and refining your calculation skills.

Examples Of Lathe Speed Calculation

Calculating the correct speed for a lathe is crucial for achieving optimal results in your machining projects. To calculate the lathe speed, you must consider two main factors. To further illustrate the importance of correct lathe speed calculation, let’s examine a few examples:

Example 1: Spindle Turning

Let’s say you are turning a piece of wood with a diameter of 6 inches. Consult the machinery’s handbook or manufacturer guidelines and determine that the ideal surface speed for the wood is 800 feet per minute (SFM). Using the formula mentioned earlier, the spindle speed can be calculated as follows:

RPM = (800 SFM x 4) / 6 inches = 533.33 RPM

In this example, the calculated rpm is approximately 533.33, the recommended spindle speed for turning the wood piece.

Example 2: Bowl Turning

Suppose you are turning a bowl made of a specific wood material. Consult the wood lathe speed recommendations for the material and determine that the optimal lathe speed range is between 500 and 700 RPM. Based on the Diameter of the bowl, you can adjust the spindle speed within this range to achieve the desired turning results.

These examples highlight the importance of proper lathe speed calculation and its impact on achieving the desired cutting operation results. By following the recommended lathe speed guidelines and adjusting the spindle speed accordingly, lathe operators can optimize the turning operation for various workpiece types, sizes, and materials.

Safety Measures While Adjusting Lathe Speed

Adjusting lathe speed requires careful consideration of safety measures to ensure the lathe operator’s well-being and the equipment’s proper functioning. Here are some essential safety tips to keep in mind when adjusting lathe speed:

- Follow The Maximum Speed Limits: Always adhere to the maximum speed limits specified for the lathe and the cutting tool. Exceeding the recommended speed limit can lead to tool failure, workpiece damage, or even personal injury.

- Use Common Sense: When adjusting lathe speed, use common sense and sound judgment. Consider the material, workpiece diameter, and cutting tool requirements to determine the appropriate lathe speed. When in doubt, consult the machinery’s handbook or seek expert advice.

- Be Aware Of Centrifugal Force: As the lathe speed increases, centrifugal force comes into play, which can affect the stability of the workpiece, workholding, and tool performance. Ensure the workpiece is securely clamped and the cutting tool properly installed and balanced.

- Regularly Inspect The Lathe: Inspect the lathe, cutting tools, and work holding setup. Check for any signs of wear, damage, or tool runout, as these factors can compromise the safety of the turning operation.

- Implementing these safety measures when adjusting lathe speed ensures a safe and controlled lathe environment, minimizing the risk of accidents and promoting a secure work atmosphere.

Common Mistakes In Calculating Lathe Speed

While lathe speed calculation is a straightforward process, there are common mistakes that lathe operators should be aware of to avoid errors and produce high-quality workpieces. Awareness of these common mistakes helps lathe operators avoid errors in lathe speed calculation, ultimately improving efficiency, workpiece quality, and tool life. Here are a few common mistakes in calculating lathe speed:

- Incorrect Rpm Setting: Failing to accurately calculate the spindle speed based on the material type, cutting tool, and workpiece diameter can lead to poor cutting performance, tool breakage, or workpiece damage. Always double-check the lathe speed calculation to ensure the correct rpm setting.

- Ignoring Cutting Speed, Feed Rate, And Surface Speed: Neglecting the cutting speed, feed rate, and surface speed guidelines can result in inefficiency, poor surface finish, or tool wear. It is crucial to factor in these parameters when calculating lathe speed for turning operations.

- Relying Solely On Maximum Speed: While maximum speed limits are essential for safety, relying solely on this information without proper calculation can lead to lathe speed settings that are too high or too low for the workpiece material or cutting tool. Consider the material and cutting tool requirements to determine the appropriate lathe speed rather than relying solely on maximum speed limits.

- Lack Of Attention To Diameter Considerations: The workpiece’s Diameter directly impacts the lathe spindle’s rotational speed. Neglecting to account for the workpiece diameter during lathe speed calculation can result in inaccurate spindle speed settings, affecting the turning operation’s accuracy, surface finish, and tool life.

Still, Having Trouble Calculating Lathe Speed?

If you are still having trouble calculating lathe speed, resources are available to assist you in understanding and mastering the process. By leveraging these troubleshooting tips and support resources, you can overcome challenges, refine your lathe speed calculation skills, and ensure the accuracy and efficiency of your turning operations. Here are a few troubleshooting tips and support resources:

- Consult The Machinery’s Handbook: The handbook is an invaluable resource for lathe operators, providing comprehensive information on lathe speed, cutting speeds, feed rates, and other machining parameters.

- Seek Proper Guidance: If you are new to lathe operation or facing specific challenges in lathe speed calculation, consider seeking guidance from experienced lathe operators or industry experts.

- Explore Online Forums And Communities: Online forums and communities dedicated to machining, lathe operation, or turning processes can be excellent sources of information and support.

Conclusion

Understanding how to calculate a lathe speed chart is crucial for achieving optimal results in your machining operations. You can determine the spindle speed that will yield the best performance and safety by considering factors such as material type, cutting tool, and recommended cutting speed.

It is important always to prioritize safety precautions and regularly practice and refine your calculation skills to ensure accurate results. However, if you still struggle with lathe speed calculations, don’t hesitate to seek assistance from an expert or consult additional resources. Remember, mastering lathe speed calculation will not only enhance the efficiency of your machining processes but also contribute to the longevity of your lathe and the quality of your finished products.

Frequently Asked Questions

1.What Is The Formula For Lathe Speed?

The formula for calculating lathe speed is RPM = (Cutting Speed x 4) / Diameter of the workpiece. Using the correct lathe speed to achieve desired results and prevent equipment damage is essential.

2.How Do You Measure Lathe Speed?

Ans: Lathe speed can be measured using a tachometer or a digital RPM meter. Adjusting the speed based on the material being turned and always following safety guidelines is important.

3.How Do I Choose A Lathe Speed?

Ans: Consider the material type and consult the manufacturer’s recommended speed chart for your lathe. Aim for a balance between efficiency and safety, adjusting the speed based on the size and shape of your workpiece.

4.How Do You Find The RPM Of A Lathe?

Ans: To find the RPM of a lathe, use this formula: RPM = (cutting speed x 4) / (workpiece diameter). Check the lathe speed chart or consult the manufacturer for cutting speed recommendations. Measure the workpiece diameter with a calliper or ruler.

5.What Is A Wood Lathe Speed?

Ans: A wood lathe speed refers to the rotation speed at which the wood turns on a lathe. The speed is measured in revolutions per minute (RPM) and can vary depending on the type of wood being turned, the size and shape of the workpiece, and the desired outcome.