Carbide end mills deliver exceptional performance on aluminum, offering superior cutting speeds and tool life. For 1/4-inch shank stub-length mills, choosing the right one optimizes material removal and minimizes deflection, making them ideal for achieving smooth finishes and precise cuts in aluminum 6061.

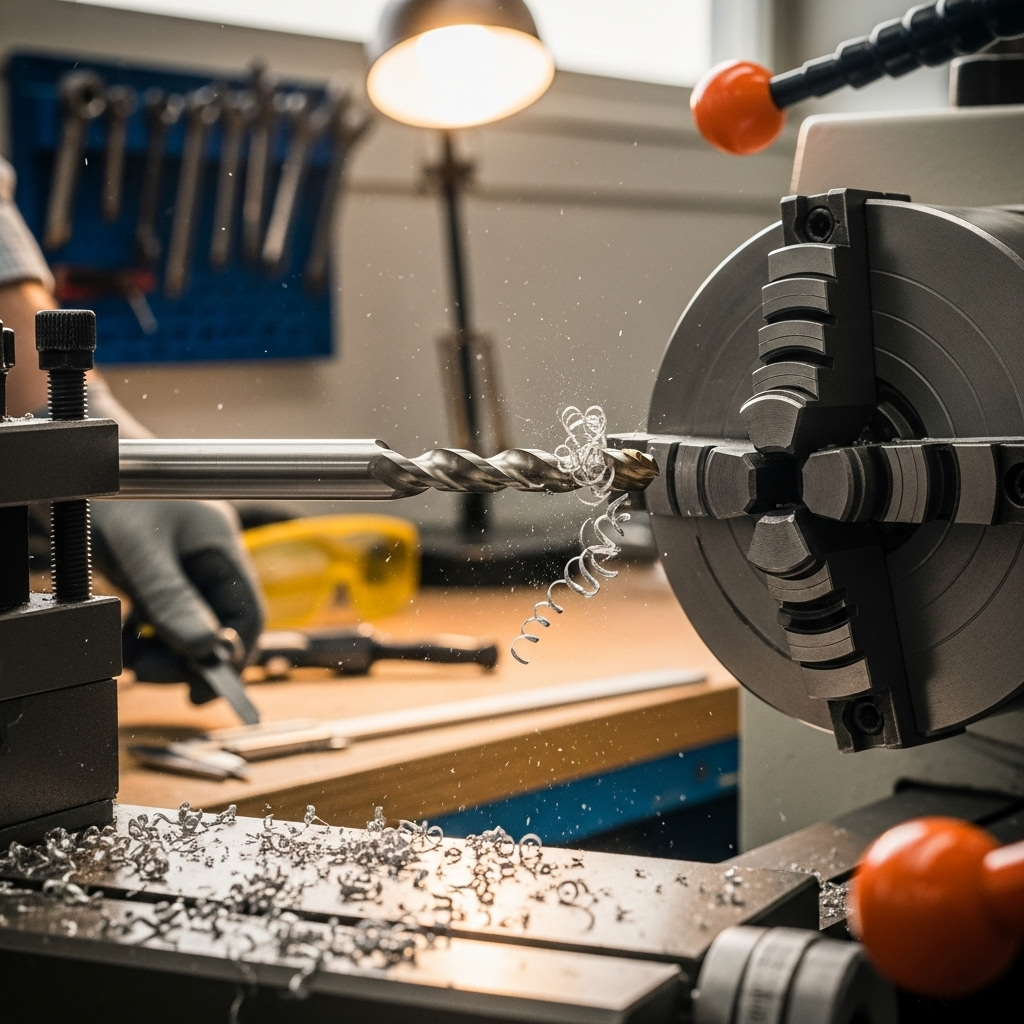

Working with aluminum, especially a common alloy like 6061, can sometimes feel like wrestling with a sticky sponge. It’s soft, yes, but it also has a tendency to gunk up your tools and leave a fuzzy finish if you’re not careful. If you’ve ever struggled with aluminum pushing instead of cutting, leaving ugly burrs, or just chewing up your end mill far too quickly, you’re not alone. Many beginners face this challenge. Setting up your milling operations incorrectly can lead to frustrating results and a lot of wasted material and tool wear. But the good news is, with the right tool and a few simple techniques, you can achieve clean, precise cuts in aluminum that will make your projects shine. This guide is all about harnessing the power of a specific type of cutting tool – the carbide end mill – to unlock its impressive performance on aluminum. We’ll walk through exactly why carbide reigns supreme for this material and how to pick the perfect one, especially a 1/4-inch shank stub-length variety, to really make your aluminum machining a breeze. Get ready to say goodbye to sticky messes and hello to beautiful, crisp cuts!

Why Carbide End Mills Rule for Aluminum

Aluminum, in its various alloys like the popular 6061, presents a unique machining challenge. It’s relatively soft and ductile, which means it can be prone to “gumming up” on cutting edges. This can lead to poor surface finishes, increased tool wear, and even tool breakage. Traditional high-speed steel (HSS) end mills can struggle with aluminum because they don’t dissipate heat effectively, and their softer nature means they can embed aluminum chips into their flutes, leading to rapid dulling.

Enter carbide. Carbide, or cemented carbide, is a composite material made from a hard carbide compound (like tungsten carbide) mixed with a binder metal, often cobalt. This combination creates an incredibly hard and wear-resistant material that can handle significantly higher cutting speeds and temperatures than HSS. For aluminum, this translates to:

- Faster Machining: You can push carbide end mills harder and faster, meaning you get parts done quicker.

- Superior Finish: The hardness of carbide allows for sharper cutting edges that slice through aluminum cleanly, reducing burrs and leaving a smoother surface.

- Longer Tool Life: Carbide’s resistance to heat and wear means your end mill will stay sharp for many more parts compared to HSS.

- Reduced Chip Buildup: The materials and coatings used on carbide end mills are often designed to prevent aluminum chips from sticking, keeping the flutes clear.

When we talk about optimizing performance for aluminum, especially with a common size like a 1/4-inch shank, a stub-length carbide end mill is often the sweet spot. Let’s break down why.

Understanding the 1/4-Inch Shank Stub-Length Carbide End Mill for Aluminum

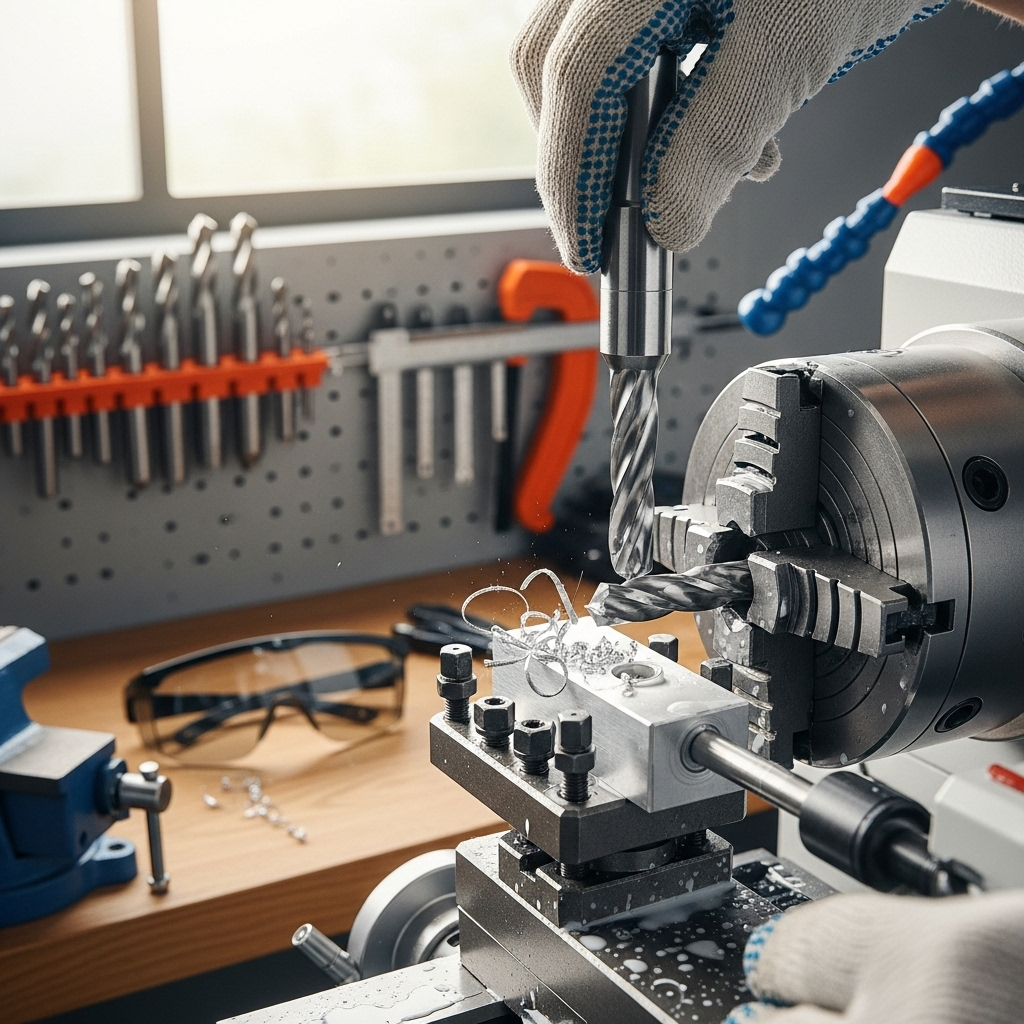

You’ve decided carbide is the way to go for aluminum. Great! Now, let’s narrow it down to a specific type that’s incredibly versatile and effective for many common aluminum machining tasks: the 1/4-inch shank stub-length carbide end mill.

What Does “1/4-Inch Shank” Mean?

This is quite literal. The shank is the part of the end mill that goes into your milling machine’s collet or tool holder. A 1/4-inch shank means the diameter of this holding portion is one-quarter of an inch (0.25 inches or approximately 6.35 mm). This size is very common in smaller milling machines, CNC routers, and even some larger drill presses adapted for milling, making it a popular choice for hobbyists and those with more compact workshops.

What is “Stub Length”?

End mills come in different lengths. “Stub length” refers to an end mill that has a shorter flute length and overall length compared to a standard or “longer reach” end mill. For aluminum, this shorter design offers several advantages:

- Increased Rigidity: Because there’s less of the tool sticking out, stub-length end mills are much more rigid. This means less deflection (bending) under cutting forces. Deflection is a major enemy when trying to achieve precise dimensions, and it’s particularly problematic with softer materials like aluminum that can easily push away from the cutting tool.

- Reduced Vibration: The increased rigidity also helps to dampen vibrations, leading to a smoother cut and less chatter marks on your workpiece.

- Better Chip Evacuation (in some designs): While shorter, many stub-length mills are designed with optimized flute geometry to help clear chips effectively, especially in aluminum.

Carbide for Aluminum 6061: Specfic Considerations

Even within carbide end mills, there are variations. When targeting aluminum 6061 and aiming to minimize deflection, consider these features:

- Number of Flutes: For aluminum, 2-flute or 3-flute end mills are generally preferred.

- 2-Flute: These often offer the best chip clearance, which is crucial for gummy materials like aluminum. The larger gullets (the space between the flutes) can accommodate more aluminum chips, preventing them from packing up and causing issues. This is often the go-to for general aluminum machining.

- 3-Flute: While typically used for harder materials or when a smoother finish is paramount (as they engage the material more times per revolution), 3-flute mills can also work well on aluminum. They can sometimes be run at higher feed rates than 2-flute mills, but chip evacuation needs careful management.

- Avoid 4-Flute on Aluminum: Generally, 4-flute end mills are designed for finishing harder metals where chip evacuation is less of a concern and multiple teeth are needed for a smooth surface. The tight flutes on a 4-flute can quickly get clogged with aluminum.

- Helix Angle: The helix angle is the angle of the flutes around the tool.

- High Helix (e.g., 45-60 degrees): These tools have a steeper spiral. They tend to “slice” into the material with less chip thickness. This results in a smoother cut, reduced cutting forces, and excellent chip evacuation, making them ideal for soft, gummy materials like aluminum. They also help minimize vibration.

- Standard Helix (e.g., 30 degrees): These are good all-around performers but might not be as specialized for aluminum as high-helix designs.

- Coatings: While many end mills designed for aluminum are uncoated to allow for better chip flow and heat dissipation through the carbide itself, some specialized coatings can offer benefits.

- ZrN (Zirconium Nitride): This gold-colored coating is very effective on aluminum. It provides a slick surface that reduces friction and prevents chips from welding to the cutting edge. This significantly improves tool life and surface finish.

- AlTiN (Aluminum Titanium Nitride) or TiCN (Titanium Carbon Nitride): These are generally more suited for harder materials and can sometimes be counterproductive on aluminum as they can increase friction and heat buildup if not managed carefully. For aluminum, uncoated or ZrN are usually preferred.

So, for proven aluminum performance with a 1/4-inch shank stub-length carbide end mill, you’re looking for a 2-flute or 3-flute tool, ideally with a high helix angle (45-60 degrees) and possibly a ZrN coating. This combination will provide the best balance of cutting efficiency, chip evacuation, rigidity, and tool life for aluminum 6061.

Setting Up for Success: Feeds, Speeds, and Technique

Even with the perfect tool, improper setup can lead to frustration. Getting the feeds and speeds right is key to unlocking that proven aluminum performance. Don’t worry, we’ll break it down simply.

The Magic Numbers: Feeds and Speeds Explained

In simple terms:

- Spindle Speed (RPM): How fast your milling machine’s spindle is rotating.

- Feed Rate (IPM – Inches Per Minute): How fast the cutting tool is moving through the material.

Aluminum 6061 can be machined at relatively high speeds compared to steel. The goal is often to get the chips to fly off cleanly rather than melting and sticking to the tool.

General Guidelines for 1/4-inch Carbide End Mill on Aluminum 6061:

These are starting points. Your actual machine, rigidity, coolant, and specific alloy can influence the ideal settings. Always prioritize listening to the cut and watching for chip formation.

For a 1/4-inch 2-Flute High-Helix Carbide End Mill:

- Spindle Speed (RPM): 10,000 – 20,000 RPM (higher if your spindle can handle it and you have good cooling)

- Feed Rate (IPM): 30 – 60 IPM

- Depth of Cut (DOC): For roughing, try 0.050″ – 0.100″. For finishing passes, use 0.010″ – 0.020″.

- Width of Cut (WOC): Aim for a radial depth of cut (how wide the cut is across the endmill’s diameter) of around 25-50% of the tool diameter for slots, and 50-100% for profiling (cutting around the outside of a part).

For a 1/4-inch 3-Flute High-Helix Carbide End Mill:

- Spindle Speed (RPM): 8,000 – 18,000 RPM

- Feed Rate (IPM): 40 – 80 IPM

- Depth of Cut (DOC): Similar to 2-flute, roughing 0.050″ – 0.100″, finishing 0.010″ – 0.020″.

- Width of Cut (WOC): Similar to 2-flute.

Why are these numbers important?

- Too Slow RPM / Too Fast Feed: Results in large, thick chips that overwork the tool and can pack up your flutes. This is called “rubbing” and generates a lot of heat, leading to poor finish and tool damage.

- Too Fast RPM / Too Slow Feed: Generates excessive heat at the cutting edge without effectively clearing chips. This can lead to aluminum welding onto the end mill and premature wear.

- Depth of Cut: Taking too deep a cut will overload the tool, leading to deflection, chatter, and potential breakage. For soft aluminum, you can usually take fairly aggressive depths, but it’s wise to start shallower.

Minimizing Deflection: The Stub Length Advantage in Action

We’ve already touched on this, but it’s worth reiterating. Deflection is when the cutting force pushes the end mill away from its intended path. For a 1/4-inch end mill, especially a longer one, this bending can be quite noticeable. The stub-length design inherently reduces this problem because there’s much less tool length sticking out of the collet. This increased rigidity means:

- More Accurate Dimensions: Your part will be closer to the size you programmed or intended.

- Fresher Cutting Edge: Less deflection means the tool is cutting cleanly rather than rubbing, preserving the sharp edge.

- Better Surface Finish: Chatter marks caused by vibration are reduced or eliminated.

To further minimize deflection when cutting aluminum 6061:

- Use Climb Milling: Whenever possible, use climb milling. In climb milling, the cutter rotates in the same direction as the feed direction, causing the cutter to “climb” up and over the material. This results in a thinner chip at the start of the cut and a thicker one at the end, which is generally better for aluminum and reduces the tendency for the tool to be pushed away from the workpiece. On manual machines, be sure the backlash is taken up to avoid the tool jumping.

- Reduce Radial Depth of Cut: If you’re slotting (making a full-width cut), try to do it in multiple passes, taking shallower side cuts (e.g., 25-50% of diameter per pass) rather than trying to cut the full width in one go.

- Use a Toroidal (Ball-Nose) End Mill for Finishing: For very smooth surface finishes, a ball-nose end mill with a small stepover (the distance the tool offsets between passes) can create a golf-ball-like texture that is very smooth. With a ball end mill, the radius means that even at a small stepover, the cutting forces are spread out.

- Ensure Your Workpiece is Secure: A wiggly workpiece is just as bad as a wiggly tool. Make sure your aluminum is firmly clamped to the machine table.

Coolant and Lubrication Are Your Friends

Aluminum machining generates heat. While carbide is good at handling heat, keeping the cutting zone cool and lubricated is crucial for optimal performance and tool life. For aluminum:

- Mist Coolant/Lubricant: A fine mist of air and coolant is often ideal. It blows chips away and provides cooling without overloading the work area with liquid, which can be messy.

- Cutting Fluid: Specialized aluminum cutting fluids are available. A good fluid will help prevent chip welding and improve surface finish. A dab of cutting paste or WD-40 can work in a pinch for very light tasks, but a dedicated fluid is better for serious work.

- Air Blast: A strong blast of compressed air can help clear chips and cool the workpiece. This is especially useful if full coolant systems are unavailable.

For precise cuts, consider a high-quality lubricant designed for aluminum. Resources like those from the National Institute of Standards and Technology (NIST) offer insights into material properties and machining which can indirectly inform best practices for lubricants and coolants.

Practical Applications: What Can You Make?

With your 1/4-inch stub-length carbide end mill ready for aluminum 6061, the possibilities are vast, especially for home workshop projects. Here are a few ideas:

- Custom Fixtures and Jigs: Need a special clamp, a bracket to hold something in place, or a jig for drilling accurate holes? Aluminum 6061 is perfect for this, and a CNC or manual mill with the right end mill can create them precisely.

- Intricate Model Parts: For RC car enthusiasts, drone builders, or model builders, creating custom-machined aluminum parts can elevate their projects. Think custom chassis components, mounts, or decorative elements.

- Tooling Components: Make custom handles for your tools, specialized adapters, or even parts for other machines.

- Enclosures for Electronics: Design and mill custom project enclosures for your Arduino, Raspberry Pi, or other electronics projects. This not only provides protection but also gives a professional, finished look.

- Artistic Pieces: Explore creating geometric patterns, engraved plates, or decorative components for furniture or art installations.

Example Project: Machining a Small Aluminum Bracket

Let’s say you want to make a simple L-shaped bracket from 1/4-inch thick aluminum 6061 plate.

Tools Needed:

- 1/4-inch, 2-flute, high-helix carbide end mill (ZrN coated is a plus)

- Milling machine (CNC or manual)

- Collet or tool holder

- Clamp or vise

- Aluminum 6061 plate

- Measuring tools (calipers, ruler)

- Safety glasses and hearing protection

- Coolant/lubricant

Steps:

- Secure the Workpiece: Clamp your 1/4-inch aluminum plate firmly to the milling machine bed using a sturdy vise or clamps. Ensure it won’t move during machining.

- Set Up the Tool: Install your 1/4-inch carbide end mill into the collet/tool holder. Ensure it’s seated properly.

- Set Zero/Origin: Using your machine’s DRO (Digital Readout) or programming your CNC origin point, set your X, Y, and Z zero relative to your workpiece. For Z-zero, it’s often best to touch off on the top surface of the aluminum.

- Program or Manually Cut the Profile:

- For a Slot: If you need to cut out the L-shape exactly, you’ll likely need to make a slot slightly larger than

- For a Slot: If you need to cut out the L-shape exactly, you’ll likely need to make a slot slightly larger than