Quick Summary: For G10 dry cutting, a 1/4 inch carbide end mill with a 1/4 inch shank and stub length is ideal. It offers precision and durability for this challenging material, ensuring clean cuts with minimal chipping and excellent tool life when used correctly.

Mastering G10 Machining: Your Guide to Carbide End Mills

Ever found yourself staring at a piece of G10 fiberglass laminate, wondering how to get a clean, precise cut without turning your material into a confetti party? You’re not alone! G10 is a fantastic material for many project builds, but it can be a real bear to machine cleanly. The dust, the potential for chipping, and the unforgiving nature of the material can make even experienced makers hesitate. But don’t worry, with the right tools and techniques, you can achieve impressive results. This guide is all about demystifying the process, focusing on a crucial tool: the 1/4 inch carbide end mill, specifically a stub length version perfect for dry cutting G10.

We’ll break down why this particular end mill is so effective, what to look for when you’re buying one, and how to use it safely and efficiently. By the end of this article, you’ll have the confidence to tackle G10 projects with precision and ease. Let’s get those machines running cleaner and your projects looking sharper!

Why G10 Machining Needs Special Attention

G10, or Garolite, is a high-pressure epoxy resin and woven fiberglass composite. It’s incredibly strong, rigid, and has excellent electrical insulating properties. These characteristics make it popular for knife handles, custom firearm components, circuit boards, and even aerospace applications. However, these same qualities also make it difficult to machine.

- Abrasiveness: The fiberglass component is highly abrasive, meaning it can quickly wear down softer cutting tools.

- Brittleness: While strong, G10 can also be brittle. Aggressive cutting or improper tool paths can lead to chipping or delamination.

- Friction and Heat: Machining G10 generates significant friction and heat, which can melt the epoxy binder if not managed, leading to gummed-up tools and poor cut quality.

- Dust: The dust produced is fine and can be irritating, making good dust collection and personal protection essential.

Because of these challenges, using the right cutting tool is paramount. A general-purpose bit simply won’t cut it – literally. This is where specialized tooling like a carbide end mill comes into play.

The Champion Tool: Carbide End Mills for G10

When it comes to cutting tough, abrasive materials like G10, carbide (specifically tungsten carbide) is king. Here’s why:

- Hardness: Carbide is significantly harder than High-Speed Steel (HSS), allowing it to retain its cutting edge much longer when encountering the abrasive fibers in G10.

- Heat Resistance: It can withstand higher temperatures generated during cutting, reducing the risk of melting and gumming.

- Rigidity: Carbide cutters are stiffer, which means less deflection and chatter, leading to cleaner, more precise cuts.

Now, let’s get even more specific. For G10, a particular type of carbide end mill often excels: the 1/4 inch shank, stub length end mill designed for dry cutting.

Why This Specific End Mill?

Let’s break down the specifications:

1/4 Inch Diameter

This is a common and versatile size. For many G10 projects, especially those involving pockets, slots, or profile cuts, a 1/4 inch diameter offers a good balance between material removal rate and precision. It’s small enough to get into tight areas but substantial enough for efficient work.

1/4 Inch Shank

This refers to the diameter of the part of the end mill that fits into your tool holder or collet. A 1/4 inch shank is standard for many milling machines and CNC routers. Ensure your machine’s collet system can accommodate this size.

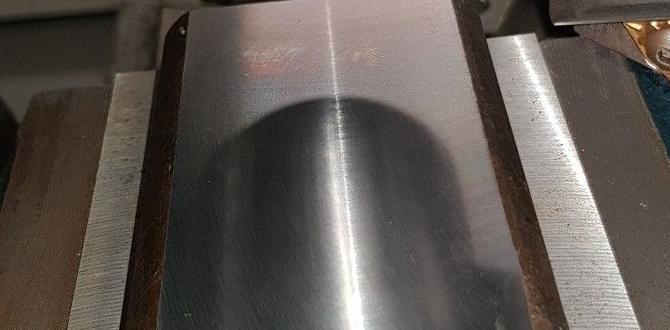

Stub Length

This is a critical feature for G10. Stub length end mills have a shorter flute length and overall length compared to standard end mills. This increased rigidity dramatically reduces deflection and vibration. When you’re cutting a tough material like G10, which can cause chatter, a stub length end mill provides the stiffness needed for a smooth, clean cut and helps prevent tool breakage.

Designed for Dry Cutting

While some operations benefit from coolant, G10 is often best machined dry or with a light mist of air. Some end mills are specifically manufactured with coatings and geometries optimized for dry machining, minimizing heat buildup and chip welding. These often have polished flutes to help eject chips effectively.

The Keyword Integration: “Carbide End Mill 1/4 Inch 1/4 Shank Stub Length for G10 Dry Cutting”

This specific combination targets the exact tool needed for efficient and clean G10 fabrication. It combines the material (carbide), size (1/4 inch diameter), shank size (1/4 inch), critical geometry (stub length), application material (G10), and machining method (dry cutting). Finding an end mill with all these attributes is key to unlocking the best performance for your G10 projects. You can often find these on reputable industrial supply websites or specialized tooling distributors.

Choosing the Right End Mill: What to Look For

Not all 1/4 inch stub length carbide end mills are created equal. Here are some factors to consider:

Material and Coating

- Grade of Carbide: Look for fine-grain or micro-grain carbide for better edge strength and wear resistance.

- Coatings: While not always necessary for G10, coatings like ZrN (Zirconium Nitride) or TiAlN (Titanium Aluminum Nitride) can offer additional heat resistance and lubricity, further extending tool life, especially in high-volume production. For simpler G10 work, an uncoated, polished carbide bit is often sufficient and more cost-effective.

Number of Flutes

This is important for G10. Common options are 2-flute and 4-flute end mills.

- 2-Flute: Generally better for chip evacuation, especially in softer materials or when taking deeper cuts. They create larger chip gullets.

- 4-Flute: Offer a smoother finish and can handle harder materials and higher feed rates due to more cutting edges. However, they can struggle to clear chips effectively in softer, gummy materials or when cutting deep slots.

For G10, a 2-flute end mill is often the preferred choice for dry cutting. The increased chip clearance helps prevent the G10 dust and debris from packing into the flutes, which can lead to tool breakage or overheating. Some specialized end mills designed for composites even feature a higher helix angle or specific flute geometry to aid chip ejection.

Helix Angle

The helix angle is the slant of the cutting edges. Common angles are 30°, 45°, and sometimes 60° for specialized tasks.

- Lower Helix (e.g., 30°): Provides more support to the cutting edge, making it stronger for harder materials.

- Higher Helix (e.g., 45° and above): Offers a sharper cutting action and better chip evacuation, which can be beneficial for preventing chip recutting and improving surface finish in materials like G10.

A moderate to high helix angle (like 45°) often works well for composite materials like G10, helping to shear the material cleanly and push chips away efficiently.

Corner Radius (Optional but Recommended)

Some end mills have a slight radius on the corner instead of a sharp 90-degree edge. This can strengthen the corner, making it less prone to chipping and providing a slightly rounded edge on the machined profile. For G10, this can be a good option to prevent sharp corners from becoming weak points.

Essential Machine Setup and Parameters

Even the best tool needs to be set up correctly. For G10, specific speeds and feeds are crucial. These are starting points, and you may need to adjust based on your specific machine, rigidity, and the exact type of G10.

Spindle Speed (RPM)

This is how fast the spindle rotates. For a 1/4 inch carbide end mill, typical ranges are:

- CNC Routers: Often higher RPMs, starting around 18,000-24,000 RPM.

- Metal Milling Machines: Typically lower RPMs, starting around 3,000-10,000 RPM, depending on the machine’s capability.

Always consult the end mill manufacturer’s recommendations if available. A good rule of thumb for carbide in composites is to start on the higher end of RPMs to take advantage of carbide’s heat resistance and achieve a good surface speed.

Feed Rate (IPM or mm/min)

This is how fast the tool moves through the material. This is highly dependent on the spindle speed, diameter of the end mill, number of flutes, and depth of cut.

- General Recommendation: Start conservative. For a 1/4 inch, 2-flute carbide end mill in G10, a starting point might be between 20-40 inches per minute (IPM) on a CNC router, or 5-15 IPM on a metal mill.

- Chip Load: A more technical approach is to consider ‘chip load’ – the thickness of material removed by each cutting edge per revolution. A common chip load for a 1/4 inch carbide end mill in G10 might be in the range of 0.002″ – 0.005″. Chip Load = Feed Rate / (RPM * Number of Flutes).

The goal is to create a reasonable chip, not dust. Too slow a feed rate will rub and create excessive heat, while too fast can overload the tool. Listen to your machine and observe the chips.

Depth of Cut (DOC)

This is how deep the end mill cuts into the material in a single pass.

- Stepover: This is how much the end mill moves sideways between passes when profiling or pocketing, typically set at 40-60% of the tool diameter for good balance between efficiency and surface finish.

- Depth of Cut: For G10, it’s often best to use a shallow depth of cut – typically no more than 1/8″ (3mm) or even less, especially when starting. This reduces the load on the tool and helps maintain cut quality. You can always take multiple shallow passes rather than one deep, aggressive pass.

Example Machining Parameters Table (Starting Points)

Here’s a general guideline to get you started. Always adjust based on your machine, end mill specifics, and observations.

| Parameter | CNC Router (High Speed) | Metal Milling Machine (Lower Speed) | Notes |

|---|---|---|---|

| End Mill Type | 1/4″ Carbide 2-Flute Stub Length for Composites | 1/4″ Carbide 2-Flute Stub Length for Composites | Primary recommendation for G10 |

| Spindle Speed (RPM) | 18,000 – 24,000 RPM | 3,000 – 8,000 RPM | Start conservatively. Higher RPMs help with better surface finish and chip formation in G10. |

| Feed Rate (IPM) | 20 – 40 IPM | 5 – 15 IPM | Adjust to get audible, crisp cutting sound, not rubbing. |

| Depth of Cut (DOC) | 0.06″ – 0.125″ (1.5mm – 3mm) | 0.06″ – 0.125″ (1.5mm – 3mm) | Take multiple passes for deeper cuts. |

| Stepover (Radial – for pockets/profiles) | 40% – 60% of tool diameter | 40% – 60% of tool diameter | Affects surface finish and machining time. |

| Cooling/Lubrication | Compressed Air Blast | Compressed Air Blast or Dry | Avoid liquid coolants that can mix with G10 dust and create a mess. |

Disclaimer: These are general guidelines. Always refer to the end mill manufacturer’s specifications and perform test cuts on scrap material before machining your final part. Tooling behavior can vary significantly between brands and specific carbide grades.

Step-by-Step Guide to Machining G10

Let’s get hands-on. Follow these steps for successful G10 machining:

- Secure Your Material:G10 needs to be held down firmly and without flexing. Use clamps, vacuum hold-down, or double-sided tape suitable for CNC work. Ensure your workholding doesn’t interfere with the cutting path.

- Prepare Your CNC Project File:Design your part or select pocket/profile paths in your CAD/CAM software. Ensure you’ve selected the correct tool (1/4 inch, 2-flute, stub length carbide end mill) and entered appropriate cutting parameters. Roughing and finishing passes can be beneficial for complex shapes.

- Set Up Your Machine:Insert the 1/4 inch carbide end mill securely into your collet. Make sure the collet is clean and properly seated in the spindle. Always zero your X, Y, and Z axes accurately.

- Dust Collection is Crucial:G10 dust is fine and abrasive. Ensure your dust collection system is running at full capacity. If using compressed air, set it to a strong blast focused at the cutting point to clear chips and also help cool the bit.

- Safety First! Personal Protective Equipment (PPE):Always wear safety glasses or a face shield. G10 dust is an irritant. Wear a dust mask or respirator rated for fine particulates (N95 or higher). Hearing protection is also recommended as machining can be loud.

- Perform a Test Cut:Before cutting your actual part, run your toolpath on a scrap piece of G10 or a similar material. Watch and listen. Are the chips forming correctly? Is there excessive chatter or rubbing? Adjust feed rates or spindle speeds as needed. A crisp “shiiiing” sound is good; a high-pitched squeal or grinding is bad.

- Begin Machining:Once you’re confident with your test cut, start the program on your actual workpiece. Monitor the process, especially for the first few minutes, to ensure everything is running smoothly. Don’t leave your machine unattended while it’s running.

- Clearing the Workspace:After the cut is complete, allow the dust to settle before removing the part or clearing the machine. Use a brush and your dust collection to clean up any residual dust.

- Inspect Your Work:Examine the cut edges for any signs of chipping or delamination. The 1/4 inch stub length end mill should have provided clean, sharp edges.

Alternative Tooling Considerations

While the 1/4 inch stub length carbide end mill is ideal, there might be situations where an alternative is useful:

- Different Diameter End Mills: For very fine details, you might need a 1/8″ or 3/16″ end mill. For larger pockets, a 1/2″ end mill could be more efficient, but remember to adjust parameters. Stub length is still recommended for these sizes if available.

- Specialized Composite Bits: Some manufacturers offer end mills specifically designed for composites, featuring unique flute geometries (e.g., up-cut, down-cut, or compression spirals) or higher helix angles to optimize chip evacuation and finish. These can be excellent for G10. For example, an “O-flute” or “single-flute” end mill can also be very effective for plastics and compsotes, providing excellent chip clearing.

- Down-Cut End Mills: While often used for creating a smooth top surface finish in plastics and composites by pushing chips down, they can exacerbate heat buildup if not used with excellent chip evacuation. They are less common for G10 dry cutting compared to up-cut, but can be part of a strategy.

The key takeaway is that carbide is essential, a good chip evacuation strategy is critical, and rigidity (which stub length provides