Unlock amazing MDF cutting with a carbide end mill! Learn how to choose the right one for a clean finish, extended tool life, and effortless routing. Get started today!

Working with Medium Density Fiberboard (MDF) can be a bit tricky for hobbyists and beginners. It’s a fantastic material for many projects, but it can also be tough on your tools, leading to frustrating tear-outs, rough edges, and short tool life. You might have found that your standard bits just aren’t cutting it, literally. This is where a specialized tool, the carbide end mill, truly shines. In this guide, we’ll explore why a carbide end mill is your secret weapon for achieving a perfect, splinter-free finish on MDF, while also making your tool last much longer. Let’s dive into how to make MDF work for you, the easy way!

Why MDF is a Challenge and How Carbide Saves the Day

MDF is made from wood fibers, resin, and wax, all pressed together under high heat and pressure. This composition gives it a smooth, uniform surface, excellent for painting or veneering. However, this dense, abrasive structure is also its downfall when paired with the wrong cutting tools. The fine wood particles and the glue used in its manufacturing act like a constant sandpaper, quickly dulling conventional bits, especially those made of High-Speed Steel (HSS).

This is where the genius of carbide comes in. Tungsten carbide is incredibly hard and wear-resistant, outperforming HSS by a significant margin. For MDF, this means:

- Longer Tool Life: A carbide end mill can handle the abrasive nature of MDF for many more cuts before needing replacement or sharpening.

- Cleaner Cuts: Its hardness allows it to maintain a sharp edge, leading to less chipping and tear-out, resulting in smoother edges and surfaces.

- Faster Cutting: Because it stays sharp longer and can handle more aggressive feed rates, you can often cut MDF faster and more efficiently.

When we talk about “carbide end mill performance” for MDF, we’re talking about a tool that is specifically suited to overcome the material’s inherent challenges, giving you professional-looking results without the usual headaches.

Choosing the Right Carbide End Mill for MDF

Not all carbide end mills are created equal, especially when it comes to MDF. For optimal results, consider these key features:

1. Material: Tungsten Carbide

This is the non-negotiable core of your tool. Tungsten carbide offers superior hardness and wear resistance, making it ideal for abrasive materials like MDF. Look for solid carbide end mills.

2. Flute Design: The Key to Chip Evacuation

End mills have “flutes,” which are the helical grooves that run along the cutting edge. For MDF, you want to think about how well these flutes can clear out the material they cut. Dust and chips can quickly clog up the flutes, leading to overheating and a rough cut.

- 2-Flute Designs: Generally considered the best for routing softer materials like MDF and plastics. The two flutes provide good chip clearance, preventing material from getting packed and causing overheating or a poor finish.

- 3 or 4-Flute Designs: These are often better for harder metals or when a smoother surface finish is paramount in wood. However, they can sometimes struggle with chip evacuation in MDF, leading to excessive dust buildup.

For MDF, starting with a 2-flute design is usually your best bet. If you find you need an even smoother finish and your machine can handle it, a high-quality 3-flute might be worth exploring, but always prioritize chip evacuation.

3. Flute Count and Helix Angle

While we often recommend 2-flute for MDF, understanding flute count is important. The helix angle (how much the flutes are twisted) also plays a role. A steeper helix angle can lead to a smoother cut but may require a more rigid machine. A shallower helix angle can provide more aggressive cutting action but might chatter. For MDF, a standard helix angle (around 30 degrees) is usually a good starting point.

4. Coatings: Adding an Extra Layer of Performance

End mills can come with various coatings that enhance their performance. For MDF, coatings aren’t always strictly necessary, but they can further improve tool life and cutting efficiency.

- Uncoated: Perfectly adequate for many MDF tasks, especially with good feed rates.

- ZrN (Zirconium Nitride): Offers good lubricity and heat resistance, helping to reduce friction and wear.

- AlTiN (Aluminum Titanium Nitride): Excellent for high-temperature applications and provides superior wear resistance. This is a more premium option and might be overkill for typical hobbyist MDF routing but can extend life significantly.

For most beginner hobbyists, an uncoated or ZrN-coated 2-flute end mill will provide excellent performance on MDF.

5. Shank Diameter and Length: Finding the Sweet Spot

This is where the keyword “carbide end mill 1/8 inch 1/4 shank stub length for mdf long tool life” comes into play. Let’s break it down:

- Shank Diameter: This is the part of the end mill that grips into your machine’s collet or chuck. Common sizes are 1/8 inch (3.175mm), 1/4 inch (6.35mm), and 1/2 inch (12.7mm). A 1/4 inch shank is a very common and versatile size for hobbyist CNC routers and milling machines. It’s robust enough for most tasks.

- Bit Diameter (Cutting Diameter): This is the actual diameter of the cutting portion of the end mill. For MDF, common sizes range from 1/8 inch up to 1/2 inch, depending on the detail required. Smaller bits are good for fine details, while larger bits are good for clearing material quickly.

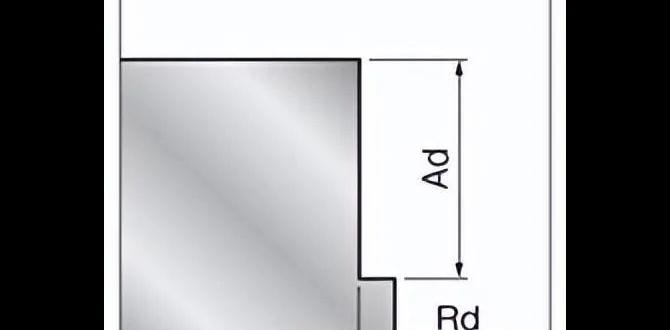

- Stub Length: A “stub length” end mill has a shorter flute length and overall length compared to a standard end mill of the same diameter. Why is this beneficial for MDF?

- Increased Rigidity: Shorter tools are inherently more rigid. This means less deflection (wobble) during cutting, leading to more accurate dimensions and a cleaner finish.

- Reduced Vibration: Rigidity also means less vibration, further reducing the chance of tear-out and improving surface quality.

- Reduced Tool Breakage: Less deflection means a lower risk of snapping the tool, especially beneficial when you’re learning or pushing the boundaries.

So, a “carbide end mill 1/8 inch 1/4 shank stub length for mdf long tool life” points to a very specific and highly effective tool for your MDF projects. The 1/8 inch cutting diameter is great for detail, the 1/4 inch shank provides good grip, and the stub length maximizes rigidity to ensure a long tool life and a superior finish on MDF.

| End Mill Feature | Why it’s Good for MDF | Considerations |

|---|---|---|

| Material | Tungsten Carbide: Superior hardness & wear resistance for abrasive MDF. | Solid carbide is best. |

| Flute Count | 2-Flute: Excellent chip evacuation, prevents clogging & overheating. | 3-Flute can be smoother but may clog. |

| Helix Angle | Standard (~30°) works well. | Steeper for smoother, shallower for aggressive. |

| Coating | Uncoated or ZrN: Good performance. AlTiN is premium. | Not always necessary, but can extend life. |

| Shank Diameter | 1/4 inch: Common, provides solid grip. | Depends on your machine’s collet size. |

| Cutting Diameter | 1/8 inch to 1/4 inch: Good for detail and general work. | Smaller for fine details, larger for bulk removal. |

| Length (Stub) | Stub Length: Great rigidity, less deflection, reduced breakage, cleaner cuts. | Ideal for maximizing tool life and accuracy. |

Setting Up for Success: Feed Rates and Spindle Speed

Even with the perfect end mill, incorrect machine settings will lead to poor results. Getting your feed rate and spindle speed right is crucial for optimal MDF cutting with a carbide end mill.

- Spindle Speed (RPM): This is how fast the end mill rotates. For MDF with a carbide end mill, a good starting point is typically between 10,000 and 20,000 RPM. The exact speed depends on the diameter of your end mill and your machine’s capabilities. Smaller diameter bits generally run faster than larger ones.

- Feed Rate (IPM or mm/min): This is how fast the cutting tool moves through the material. This is arguably more important than spindle speed for preventing tear-out and ensuring a good finish on MDF. You want to feed fast enough to allow the cutting edges to actually cut, rather than rub or scrape.

A common mistake beginners make is feeding too slowly. This causes the bit to essentially melt rather than cut, leading to premature dulling and a burnt, rough finish. Conversely, feeding too fast can overstress the tool and machine, leading to tool breakage or a very rough cut.

Calculating Your “Chucks” (Chip Load)

A more advanced, but very useful, concept is chip load (or chip thickness). This refers to the thickness of the material each cutting edge removes with each revolution. The ideal chip load depends on the end mill diameter, number of flutes, material, and spindle speed.

A helpful rule of thumb for MDF with a 2-flute carbide end mill:

- For a 1/8 inch (3.175mm) end mill: Aim for a chip load of around 0.001 to 0.003 inches (0.025 to 0.076 mm).

- For a 1/4 inch (6.35mm) end mill: Aim for a chip load of around 0.002 to 0.005 inches (0.05 to 0.127 mm).

You can calculate your feed rate using this formula:

Feed Rate = Spindle Speed (RPM) × Number of Flutes × Chip Load (inches) × 60 (minutes/hour)

Example: For a 1/8 inch end mill at 18,000 RPM, with 2 flutes, and a desired chip load of 0.002 inches:

Feed Rate = 18,000 × 2 × 0.002 × 60 = 4,320 inches per minute (IPM).

This might seem fast, but it’s often necessary for a clean cut in MDF. Always start on the conservative side of your calculated range and make test cuts if possible.

Depth of Cut

For MDF, it’s generally best to perform a full depth cut in one pass if your machine is rigid enough and your end mill is suitable. However, if you’re experiencing chatter, vibration, or poor surface finish, you can reduce the depth of cut. Taking shallow passes (e.g., 1/8″ or 3mm) can sometimes lead to more heat buildup and slower cutting, so it’s usually better to go deeper in one pass if possible.

Consulting resources like the excellent tool recommendations from the Sandvik Coromant website can provide more detailed cutting data for various materials and tools, though their calculators are geared towards industrial use. For beginners, focusing on achieving a good chip load and listening to the sound of the cut is a great way to learn.

Step-by-Step Guide: Cutting MDF with Your Carbide End Mill

Let’s get cutting! Follow these steps for smooth, clean results:

Step 1: Secure Your MDF and Machine

Ensure your MDF sheet is firmly secured to your workbench or CNC machine bed. Use clamps, double-sided tape, or your machine’s vacuum hold-down system. A well-secured workpiece is essential for safety and cut quality.

Step 2: Install the Correct End Mill

Carefully insert your chosen carbide end mill (e.g., a 1/8 inch shank, 1/4 inch cutting diameter, stub length, 2-flute end mill) into your router collet or milling machine chuck. Ensure it’s seated properly and tightened securely. Never overtighten or undertighten.

Step 3: Set Up Your Spindle Speed and Feed Rate

Based on the guidelines above, set your spindle speed (e.g., 18,000 RPM) and calculate a starting feed rate (e.g., 4,320 IPM for a 1/8″ bit). Listen to the machine – if it sounds like it’s struggling or burning, adjust your feed rate slightly faster. If it’s chattering or vibrating, you might need to adjust speed or feed, or potentially reduce depth of cut temporarily.

Step 4: Perform a Test Cut (Recommended)

If possible, make a test cut on a scrap piece of MDF. This allows you to dial in your settings without risking your main project. Check the edge quality, surface finish, and listen to the sound of the cut.

Step 5: Execute the Cut

If using on a manual machine like a milling machine, use steady, firm pressure. For CNC machines, ensure your program uses optimal feed rates and plunge speeds. For MDF, a plunge rate around half of your typical feed rate is often suitable.

Step 6: Chip and Dust Management

MDF produces a lot of fine dust. Ensure you have adequate dust collection. This keeps your work area cleaner, prevents dust buildup on your workpiece, and is crucial for your health. OSHA regulations highlight the importance of controlling wood dust exposure, and MDF dust is particularly fine.

Step 7: Inspect the Cut

Once the cut is complete, carefully remove the workpiece. Inspect the edges and surfaces for smoothness, tear-out, or burning. If you see any issues, go back to Steps 3 and 4 to adjust your settings.

Maintaining Your Carbide End Mill for Maximum Life

Even the best carbide end mill will eventually wear out, but proper care can significantly extend its useful life, especially when cutting abrasive MDF.

- Keep it Clean: After each use, clean your end mill thoroughly. Remove any MDF dust and residue. A wire brush or compressed air works well.

- Inspect for Damage: Regularly check the cutting edges for chipping or excessive wear. The sooner you identify wear, the sooner you can address it.

- Avoid Re-Milling Chips: Ensure your machine’s motion control doesn’t cause the end mill to re-cut chips already on the surface. This generates excessive heat.

- Proper Storage: Store your end mills in a protective case to prevent them from banging against each other and dulling the cutting edges.

- Sharpening: While sharpening carbide is possible, it usually requires specialized diamond grinding wheels and expertise. For most hobbyists cutting MDF, it’s often more cost-effective to replace a dull end mill rather than sharpen it, especially given the excellent tool life you can achieve with the right bit. However, if you have access to professional sharpening services, it’s an option.

The “long tool life” mentioned in our targeted keyword isn’t just about having a good tool; it’s also about how you treat it.

When To Replace Your End Mill

How do you know when it’s time for a new carbide end mill for your MDF projects?

- Rough Edges: If you start seeing fuzzy or chipped

edges where the cut was previously clean. - Burning: If the MDF begins to look scorched or smell burnt, even with correct feed rates.

- Increased Heat: The end mill feels excessively hot to the touch (be very careful if testing this!).

- Vibration or Chatter: If you start experiencing chatter that wasn’t there before, and you’ve ruled out workpiece insecurity or machine issues.

- Visible Wear: If you can visually see that the cutting edges are rounded or chipped under magnification.

Don’