Carbide end mills are essential for efficiently and cleanly machining carbon steel, offering superior hardness and heat resistance for longer tool life and better finish.

Working with carbon steel can present some challenges, especially when you’re starting out. It’s a tough material, and using the wrong cutting tool can lead to frustration, poor results, and even damaged workpieces. If you’ve ever seen chips clog up, dull edges, or just a generally rough surface finish, you might be wondering if there’s a better way. The good news is, there is! The right tool makes all the difference, and for carbon steel, that tool is often a carbide end mill. In this guide, we’ll dive into why carbide is so great for steel and how to choose and use the right kind for your projects.

Why Carbide End Mills Rule for Carbon Steel

Carbon steel is a workhorse material, strong and versatile. But its strength and hardness also mean it’s tougher to cut. Traditional high-speed steel (HSS) end mills can do the job, but they wear out much faster and struggle with the heat generated. This is where carbide end mills shine.

The Magic of Carbide

Carbide, specifically tungsten carbide, is an incredibly hard and dense material. Its composition (often a powder of tungsten carbide particles sintered with binders like cobalt) gives it some amazing properties:

Hardness: Carbide is significantly harder than HSS. This means it can cut through tough materials like carbon steel with less wear and tear.

Heat Resistance: Machining creates friction, and friction creates heat. Carbide can withstand much higher temperatures than HSS before it softens or degrades. This is crucial for cutting steel, which tends to get hot quickly.

Rigidity: Due to its density, carbide is also more rigid. This means less “chatter” or vibration during cutting, leading to a smoother finish and more accurate parts.

Better Chip Evacuation (often): While not inherent to carbide itself, end mills made from carbide often feature advanced flute designs specifically engineered to help clear chips effectively from the cut.

What is Carbon Steel Anyway?

Carbon steel is a broad category of steel alloys where carbon content is the primary alloying element. It’s known for its strength, hardness, and wear resistance, making it ideal for everything from structural components and tools to machinery parts. However, these desirable properties also make it more challenging to machine than softer metals like aluminum. For more on the different types of carbon steel and their applications, check out resources from organizations like the National Small Industries Corporation (NSIC).

Choosing the Right Carbide End Mill

It’s not enough to just grab any carbide end mill. For carbon steel, you need to consider a few key features. Think of it like picking the right screwdriver for a specific screw – the right tool makes the job easier and better.

Key Features to Look For:

Flute Count: This refers to the number of cutting edges on the end mill.

2-Flute: Generally best for slotting and pocketing in softer materials or gummy metals. They provide excellent chip clearance. For carbon steel, they can work but might not be the most efficient for heavier cuts.

3-Flute: A good all-around choice for carbon steel. They offer a balance between cutting efficiency and chip evacuation.

4-Flute: Ideal for heavier cuts, peripheral milling, and finishing operations in steel. They provide good rigidity and a smoother finish. For carbon steel, 4-flutes are a very popular and effective choice.

More Flutes (5+): Typically used for finishing very hard materials or for high-speed machining where chip thinning is managed. For beginners working with carbon steel, 3 or 4 flutes are usually the sweet spot.

Helix Angle: The angle of the flutes.

Standard (30-45 degrees): A good default for general machining of steels. They offer a good balance of cutting action and strength.

High Helix (60+ degrees): Provide a shearing action that can reduce cutting forces and improve chip evacuation. These are excellent for slotting and can be very effective in carbon steel.

Variable Helix: Designed to break up harmonic vibrations, leading to smoother cuts and quieter operation, especially beneficial in materials prone to chatter like steel.

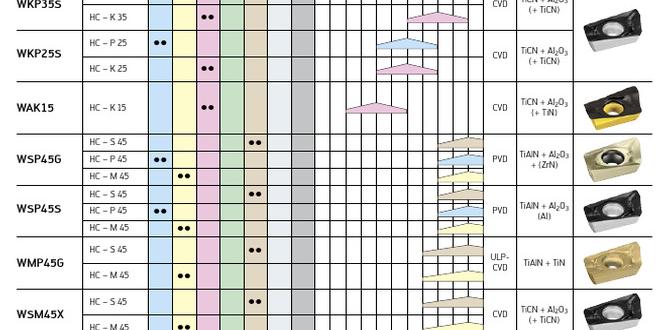

Coating: While uncoated carbide is good, coatings make it even better for steel.

TiN (Titanium Nitride): A common, all-purpose coating. It adds hardness and lubricity, reducing friction. It’s a good starting point for carbon steel.

TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications. It forms a protective oxide layer at high heat, making it superb for machining steels that generate significant heat. This is a top choice for carbon steel.

AlTiN (Aluminum Titanium Nitride): Similar to TiAlN, offering superior performance at higher temperatures and longer tool life in steels.

ZrN (Zirconium Nitride): A good general-purpose coating, offering slightly better performance than TiN.

End Type:

Square End: The most common type. Useful for general milling, facing, and contouring.

Ball End: Has a rounded tip. Ideal for creating contoured surfaces, rounding edges, and 3D milling.

Corner Radius: A square end with a small rounded corner. This adds strength to the cutting edge and can help produce a better surface finish than a sharp square corner. Highly recommended for steel.

Material: While we’re focusing on carbide, ensure it’s solid carbide. Some tools are carbide-tipped, which is different and less suitable for the fine details and precision needed for many steel milling operations.

Size Matters: Common Sizes for Carbon Steel

For beginner projects and general use with carbon steel, you’ll often find yourself reaching for 1/8 inch or 1/4 inch shank end mills. The size of the shank (the part that goes into your tool holder or collet) is important for rigidity and how much torque you can apply.

1/8 inch Shank: Good for smaller machines or when working on delicate parts or tight spaces. However, smaller shanks can be less rigid and more prone to breaking under heavy loads.

1/4 inch Shank: A very common and practical size for many hobbyist and entry-level milling machines. Offers a good balance of rigidity and versatility for carbon steel.

Extra Long Tool Holders: For reaching into deeper pockets or around features, “extra long” end mills are available. However, be very mindful of rigidity and potential deflection. For carbon steel, it’s usually best to use as short an effective reach as possible given your workpiece setup.

Here’s a quick look at how flute count and coatings can impact your milling:

| Feature | Best For Carbon Steel | Why It Helps |

|---|---|---|

| Flute Count | 3 or 4 Flutes | Good balance of cutting action, chip evacuation, and rigidity. 4 flutes offer a smoother finish. |

| Helix Angle | 30-45 degrees (standard) or High Helix (60+ degrees) | Standard is versatile. High helix improves chip clearance and reduces cutting forces for slotting. Variable helix reduces vibration. |

| Coating | TiAlN or AlTiN | Excellent heat resistance and wear life for demanding steel machining. |

| End Type | Corner Radius or Square End | Corner radius adds edge strength and improves finish over a sharp corner. Ball end for contours. |

Essential Setup for Milling Carbon Steel

Before you even think about hitting the “start” button, proper setup is critical. This isn’t just about safety; it’s about getting a good cut and making your tools last.

Workholding is King

Your workpiece needs to be held securely. Any movement or vibration will lead to poor cuts, tool breakage, and safety hazards.

Vise: A good quality milling vise is your best friend. Ensure it’s clean, the ways are lubricated, and it’s securely mounted to your milling machine table.

Clamps: For larger or irregularly shaped parts, clamping directly to the table with T-nuts and clamps is necessary. Always ensure clamps are positioned to provide strong support without impeding the cutting path.

Tooling: Use a clean, runout-tested collet or tool holder. Runout (wobble) in your tool holder is a major cause of poor finishes and premature tool wear. A dial indicator can help you check this.

Coolant or Lubricant is Your Friend

Carbon steel generates a lot of heat. Without adequate cooling and lubrication, your end mill will overheat, dull quickly, and can even weld chips to its flutes.

Soluble Oil Coolant: This is a mix of water and a soluble oil concentrate. It provides excellent cooling and lubrication. You’ll need a system to deliver it to the cutting zone, often a pump and nozzle setup.

Cutting Fluid/Paste: For smaller machines or manual milling where a full flood system is impractical, a specialized cutting fluid or paste applied directly to the cutting area can significantly help. Look for products specifically designed for steel.

Air Blast: While not as effective as liquid coolant, a steady stream of compressed air can help blow chips away and provide some cooling effect.

Speeds and Feeds: The Golden Ratio

This is where many beginners get stuck. Every end mill, material, and machine is different. However, there are starting points.

Surface Speed (SFM): This is the speed at which the cutting edge moves across the material. For carbide end mills in carbon steel, this typically ranges from 200 to 600 SFM, depending on the specific carbide grade, coating, and coolant.

Chipload: This is the thickness of the chip each flute removes. It’s crucial for tool life and finish. For a 1/4 inch end mill in carbon steel, a chipload might range from 0.001 to 0.004 inches per tooth.

Spindle Speed (RPM): You calculate RPM from SFM using the formula: `RPM = (SFM 3.25) / Diameter`.

Feed Rate (IPM): You calculate the table feed rate from chipload and RPM: `Feed Rate (IPM) = Chipload Number of Flutes RPM`.

Example Calculation (using typical values for a 1/4″ 4-flute carbide end mill in medium carbon steel):

Assume SFM = 300

Diameter = 0.25 inches

Chipload = 0.002 inches/tooth

1. Calculate RPM:

`RPM = (300 SFM 3.25) / 0.25 inches = 3900 RPM`

2. Calculate Feed Rate:

`Feed Rate = 0.002 inches/tooth 4 flutes 3900 RPM = 31.2 IPM`

Always start conservatively (lower SFM, chipload) and increase if the cut is clean and the tool isn’t overheating. Listen to your machine!

For more detailed information on calculating speeds and feeds, resources from manufacturers like Sandvik Coromant offer excellent calculators and guidance.

Step-by-Step: Machining Carbon Steel with a Carbide End Mill

Let’s walk through a common milling task: creating a simple slot.

Step 1: Prepare Your Machine and Workpiece

1. Cleanliness: Ensure your milling machine table, vise, and spindle area are clean and free of debris.

2. Mount the Workpiece: Securely clamp your carbon steel workpiece in the vise or with clamps. Double-check its stability.

3. Select the Right End Mill: Choose a carbide end mill with appropriate features (e.g., 1/4 inch, 4-flute, TiAlN coated, corner radius) for the job.

4. Install the End Mill: Insert the end mill into a clean collet or tool holder and tighten securely in the spindle. Ensure it’s seated correctly.

5. Set Up Coolant: If using a coolant system, ensure it’s ready to deliver fluid to the cutting zone.

Step 2: Set Cutting Parameters

1. Determine Speeds and Feeds: Use the guidelines above or a reliable calculator to determine a starting RPM and feed rate. For a 1/4 inch, 4-flute TiAlN coated end mill in 1018 steel, you might start around 300 SFM.

2. Set Machine Controls: Input your calculated RPM and feed rate into your milling machine’s controls.

Step 3: Perform the Cut

1. Touch Off: Carefully bring the end mill down to the surface of the workpiece to establish your Z-zero. Use a touch probe, a dial indicator, or a piece of paper for this.

2. Engage Spindle: Start the spindle at your programmed RPM.

3. Initiate Coolant: Turn on your coolant system.

4. Engage Feed: Slowly engage the feed rate, moving the cutting axis towards the workpiece.

Climb Milling vs. Conventional Milling: For most operations with end mills, especially on a CNC, climb milling is preferred. The cutter rotates in the same direction as the feed. This results in a thinner chip at the start of the cut, a smoother finish, and less force on the workpiece. Conventional milling is when the cutter rotates against the feed direction. It can be harder on the tool and workpiece.

5. Monitor the Cut: Watch and listen.

Listen: Are there any unusual noises, chattering, or grinding sounds?

Look: Are chips being evacuated effectively? Is the surface finish smooth? Is there excessive heat or smoke?

6. Complete the Slot: Allow the end mill to complete its programmed path.

7. Retract: Once the cut is finished, retract the end mill clear of the workpiece before stopping the spindle.

Step 4: Inspect and Repeat

1. Inspect: Carefully examine the machined slot for size, shape, and surface finish.

2. Adjust: If the finish isn’t satisfactory or the tool seems to be working too hard, you may need to adjust your speeds and feeds. Often, a slightly slower feed rate or a small reduction in RPM can improve results. If the cut is too light, you might be able to increase chipload or SFM slightly.

3. Repeat: For multiple passes or multiple slots, ensure you are precisely setting your depths and positions.

Advanced Considerations and Tips

As you gain experience, you’ll encounter more scenarios. Here are a few tips to keep in mind:

Depth of Cut (DOC): Don’t try to take too much material in a single pass. For a 1/4 inch end mill in steel, a radial depth of cut (how wide the cut is across the face of the end mill) is often less than half the diameter, and an axial depth of cut (how deep into the material) is often 1-2 times the diameter, but this varies greatly. It’s better to take multiple shallow passes than one deep, aggressive pass.

Work Hardening: Carbon steel can work-harden, meaning it becomes harder and more difficult to cut the more you abrade its surface. Taking lighter, cleaner cuts and ensuring proper chip evacuation helps prevent this.

Tool Breakage: This is a common issue for beginners. It’s usually caused by:

Insufficient rigidity in the setup (workpiece, tool holder, machine).

Incorrect speeds and feeds (too fast, incorrect chipload).

Poor chip evacuation (chips recutting, clogging).

Plunging the end mill too aggressively unless it’s designed for it.

Running into existing material unexpectedly.

* Material Variations: Not all carbon steels are the same! Higher carbon content generally means higher hardness and strength, requiring slower speeds and potentially lighter cuts. Always verify the exact steel grade if possible. The American Iron and Steel Institute (AISI) provides detailed information on steel designations.

Carbide End Mills vs. HSS for Carbon Steel

It’s worth reiterating why carbide is superior for this task.

| Feature | Carbide End Mill | High-Speed Steel (HSS) End Mill |

|---|---|---|

| Hardness | Very High (resists wear and deformation) | Good, but significantly less than carbide. Softens at lower temperatures. |

| Heat Resistance | Excellent (can operate at higher temperatures) | Limited (can lose hardness at high temperatures) |

| Rigidity | High (less deflection, better accuracy) | Lower (more prone to chatter and vibration) |

| Tool Life in Steel | Much Longer |