Cutting aluminum smoothly with a 1/8 inch carbide end mill is achievable for beginners. This guide details why the right end mill is crucial for aluminum, how to select one, and essential techniques for clean, precise cuts every time. You’ll be creating amazing parts in no time.

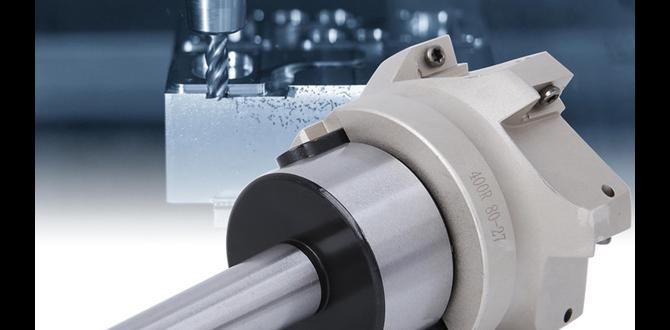

The Mighty 1/8 Inch Carbide End Mill: Your Aluminum Secret Weapon

Hey there, fellow makers! Daniel Bates here from Lathe Hub. Ever stare at an aluminum block on your mill and feel a bit intimidated, especially when thinking about the tiny, precise cuts needed? You’re not alone. Many of us start out wondering how to get those clean edges and intricate details. The answer often lies in a tool that’s small but mighty: the 1/8 inch carbide end mill. Why is this little guy so important, especially for aluminum? Because aluminum can be sticky and gummy, and the wrong tool can make for a frustrating, messy job. But with the right carbide end mill, you’ll find it becomes a joy to work with. Today, we’re diving deep into why a 1/8 inch carbide end mill is practically essential for tackling aluminum, and I’ll show you how to use it like a pro, even if you’re just starting out.

Why 1/8 Inch Carbide End Mills Rock for Aluminum

Aluminum is a fantastic material for hobbyists and professionals alike. It’s lightweight, strong, and relatively easy to machine. However, its softness can also be its challenge. When machined with the wrong tools or settings, aluminum tends to stick to the cutting edges, causing chatter, poor surface finish, and tool breakage. This is where carbide truly shines, and a 1/8 inch size offers a sweet spot for detail and control.

The Magic of Carbide

Carbide, specifically tungsten carbide, is an incredibly hard and wear-resistant material. Unlike High-Speed Steel (HSS) tools, carbide cutters can withstand higher temperatures and maintain their sharp cutting edges for much longer, especially when milling tougher materials or running at faster speeds. For aluminum, this hardness means the tool is less likely to “gum up” or build up material on its edges, leading to cleaner cuts.

The Versatility of the 1/8 Inch Size

A 1/8 inch end mill seems small, but in the world of CNC and manual milling, it’s a workhorse. This size is perfect for:

- Achieving fine details and sharp internal corners.

- Slotting and pocketing small features without removing excessive material.

- Creating intricate designs for jewelry, models, or decorative parts.

- Working with smaller aluminum stock where larger tools would be too aggressive.

- Balancing detail with efficient material removal for its size.

Aluminum’s Specific Needs

So, why is this combination so good for aluminum? Aluminum alloys, especially common ones like 6061, have a lower melting point and a tendency to deform rather than chip cleanly like steel. This can lead to:

- Galling: Aluminum sticking to the cutting edge.

- Heat Buildup: Friction generating excessive heat, exacerbating galling.

- Poor Surface Finish: Rough or smeared surfaces.

- Tool Breakage: When material builds up, it can overload and snap the end mill.

Carbide’s hardness and heat resistance battle these issues. Furthermore, a 1/8 inch end mill, when properly designed for aluminum, often features a higher number of flutes (like 3 or 4) and specific helix angles that help evacuate chips efficiently, keeping the cutting zone cooler and cleaner. We’ll get into specifics about these features soon.

Choosing the Right 1/8 Inch Carbide End Mill for Aluminum

Not all 1/8 inch carbide end mills are created equal, especially when your target is aluminum. Here’s what to look for:

Material: Solid Carbide is Key

For aluminum, you absolutely want a solid carbide end mill. This means the entire cutting tool is made of carbide, not just tipped. Solid carbide offers superior rigidity and edge retention compared to HSS or carbide-tipped tools, which is crucial for preventing galling and achieving a good finish on aluminum.

Number of Flutes: More is Often Better (for Aluminum)

The number of flutes (the helical cutting edges) on an end mill affects chip clearance and surface finish.

- 2 Flutes: Typically offers the best chip evacuation, which is excellent for softer, gummy materials like aluminum. The larger chip gullets can handle more material. Often the go-to for aluminum.

- 3 Flutes: A good compromise. Offers better rigidity than 2-flute and can still provide decent chip clearance. Can achieve a smoother finish than 2-flute in some applications.

- 4 Flutes: Provides the best surface finish and rigidity, but the smaller chip gullets can lead to chip packing in softer materials like aluminum. Best suited for finishing passes or harder aluminum alloys.

For general-purpose aluminum machining with a 1/8 inch end mill, a 2-flute or 3-flute end mill is usually your best bet. They balance chip evacuation with cutting edge engagement.

Coating: Uncoated or Specialized

For aluminum, coatings can be a double-edged sword. While coatings like TiN (Titanium Nitride) or TiCN (Titanium Carbonitride) add hardness, they can sometimes increase friction or adhesion with aluminum. Many machinists prefer uncoated carbide end mills for aluminum because the natural slickness of the carbide, combined with good chip evacuation, often performs best. If you do opt for a coating, look for specialized coatings designed for aluminum machining, which aim to reduce friction and prevent buildup. Examples include AlTiN (Aluminum Titanium Nitride), but even then, uncoated is often preferred by seasoned users.

Helix Angle: The Sweet Spot

The helix angle refers to the steepness of the flutes. For aluminum, a higher helix angle (e.g., 45 degrees or more) is generally preferred. A steeper helix:

- Provides a “shearing” action, cutting more cleanly.

- Helps to lift chips out of the cut more effectively, crucial for preventing buildup.

- Can result in a smoother surface finish.

A standard 30-degree helix is okay, but if you consistently machine aluminum, investing in end mills with 45-degree or even higher helix angles will pay dividends in performance.

End Type: Square vs. Corner Radius

The end of the end mill determines the shape of the internal corners it can create.

- Square End: Leaves a square corner. Essential for pockets where sharp 90-degree internal corners are required.

- Corner Radius: Has a small rounded profile at the tip. This adds strength to the cutting edge and avoids stress risers that can lead to chipping. It’s great for creating fillets (rounded internal corners) and can lead to a slightly better finish and longer tool life, but won’t produce true sharp 90-degree internal corners.

For general-purpose work, a square end is versatile. If you plan on making parts with fillets, a corner radius end mill is a good choice. For 1/8 inch, a common corner radius might be 0.010″ or 0.020″.

Shank: Straight vs. Weldon

The shank is the part of the end mill that goes into the tool holder. For most beginner setups, a straight shank is standard. This is what most collets and tool holders are designed for. Some larger tools might feature a Weldon flat on the shank for extra security, but it’s less common and usually not necessary for a 1/8 inch end mill unless you’re experiencing slippage.

Length: Standard, Extended, or Extra Long

For a 1/8 inch end mill, “extra long” is a key consideration. A standard length end mill might have a cutting length of only 1/4 inch or 3/8 inch. An “extra long” or “extended reach” version will have a much longer cutting flute, allowing you to:

- Reach deeper into workpieces.

- Machine features further down inside pockets.

- Combine machining passes with less need to reposition the workpiece or tool holder.

When the keyword mentions “1/8 inch shank extra long,” it’s pointing towards a tool designed for reaching into deeper features. Just be mindful that longer tools are more prone to vibration and deflection, so careful setup and slower speeds might be needed.

Heat Resistance

While carbide is inherently heat resistant, some manufacturers specify this for certain grades or coatings. For general aluminum machining, standard solid carbide is usually sufficient. If you’re working with high-temperature aluminum alloys or doing very aggressive cuts, exploring specialized heat-resistant carbide grades or coatings might be beneficial, but it’s often overkill for hobbyist applications of 6061 aluminum.

Key Specifications to Look for (Summary Table)

Here’s a quick rundown of what makes a 1/8 inch carbide end mill your ideal aluminum partner:

| Feature | Ideal for Aluminum | Why it Matters |

|---|---|---|

| Material | Solid Carbide | Hardness, wear resistance, heat resistance; prevents galling and maintains sharp edge. |

| Number of Flutes | 2 or 3 Flutes | Better chip evacuation, reduces heat and clogging, prevents tool breakage. |

| Coating | Uncoated (preferred) or specialized for aluminum | Natural slickness of carbide reduces adhesion. Specialized coatings can add benefits but aren’t always necessary. |

| Helix Angle | High Angle (45°+) | Shearing action cuts cleaner, lifts chips effectively, smoother finish. |

| End Type | Square End or Corner Radius | Square for sharp corners, radius for fillets and stronger edges. Choice depends on desired geometry. |

| Length | Standard to Extra Long (depending on reach needed) | Extra long allows machining deeper features. Longer tools require careful setup. |

Essential Accessories and Setup

Having the right end mill is only half the battle. To use your 1/8 inch carbide end mill effectively and safely on your milling machine (whether it’s a small desktop CNC or a manual Bridgeport-style mill), you’ll need a few key items:

- Collet Chuck or Collet Block: A high-quality collet chuck system is crucial. For a 1/8 inch end mill, you’ll need a 1/8 inch collet. Ensure your collet system is clean and provides true concentricity (meaning the end mill runs perfectly centered). Runout (wobble) is a major enemy of small end mills and can lead to breakage. A good set of R8 or ER collets for your machine is a worthwhile investment.

- Tool Holder: This is what holds the collet chuck in your machine’s spindle.

- Workholding: Securely clamping your aluminum workpiece is paramount. Use parallels to lift the work off the machine table and clamps or a vise. Ensure the clamps don’t interfere with the cutting path. For 6061 aluminum, a good vise with soft jaws can work well.

- Coolant/Lubricant: While some machinists run aluminum dry, using a cutting fluid or lubricant significantly improves performance. It helps with chip evacuation, reduces heat buildup, and prevents galling. For aluminum, a mist coolant system or a spray bottle with a suitable cutting fluid (like a high-quality synthetic or semi-synthetic coolant specifically designed for aluminum) is often ideal. Hairspray is a surprisingly effective, albeit temporary, lubricant for small aluminum hobbyist jobs.

- Safety Gear: Always wear safety glasses. Hearing protection is also recommended. Consider gloves when handling sharp tools and materials.

- Chipload Calculator: While we’ll discuss recommended settings, having a chipload calculator handy (many are available online or as apps) is useful. You input your tool diameter, material, spindle speed, and machine capabilities, and it suggests feed rates.

Step-by-Step: Milling Aluminum with Your 1/8 Inch Carbide End Mill

Let’s get down to the practical steps. These are general guidelines, and you’ll always fine-tune based on your specific machine, end mill, and aluminum alloy.

Step 1: Secure Your Workpiece

Place your aluminum stock (e.g., 6061 aluminum plate or block) on the milling machine table. Use parallels to ensure it’s elevated for clamp clearance and to provide a flat reference surface. Clamp it down securely using a vise or clamps. Ensure the clamps are positioned so they won’t be hit by the end mill. Double-check that the workpiece cannot move at all.

Step 2: Install the End Mill

Select the appropriate collet for your 1/8 inch end mill (often a 1/8″ ER collet or similar). Clean the collet and the end mill shank thoroughly. Insert the end mill into the collet, ensuring it’s seated properly. Tighten the collet within the tool holder. Install the tool holder into your machine’s spindle. Ensure it’s tightened securely.

Step 3: Set Up Coolant/Lubrication

If using a mist coolant system, turn it on. If using spray, have your lubricant ready. A light mist is usually sufficient for small end mills.

Step 4: Set Your Zero Point (Work Origin)

This is critical. You need to tell your machine where the workpiece is in relation to the tool. Bring the spinning end mill down carefully to touch the top surface of your aluminum block. This sets your Z-axis zero. Then, move the end mill to the desired starting X and Y coordinates on your workpiece and set those as your X and Y zeros. For manual machines, this involves using edge finders or dial indicators. For CNC, you’ll use probe routines or manual jogging.

Step 5: Determine Cutting Parameters (Speeds and Feeds)

This is where experience and good data come in. For a 1/8 inch solid carbide end mill in 6061 aluminum:

- Spindle Speed (RPM): A good starting point is often in the range of 6,000 to 12,000 RPM. Higher speeds are generally better for aluminum with carbide.

- Feed Rate (IPM – Inches Per Minute): This depends heavily on the chipload. A desirable chipload for a 1/8 inch end mill in 6061 aluminum might be around 0.001 to 0.003 inches per tooth.

- For a 2-flute end mill: Feed Rate = RPM × Number of Flutes × Chipload

- Example: 10,000 RPM × 2 flutes × 0.002 in/tooth = 40 IPM.

- Depth of Cut (DOC): For roughing, a common DOC might be around 0.060″ to 0.125″ (1.5mm to 3mm). For finishing, you’d use a much shallower DOC, perhaps 0.005″ to 0.010″ (0.125mm to 0.25mm).

- Stepover: This is how much the end mill moves sideways on each pass when milling a pocket or contour. For roughing, a stepover of 40-60% of the tool diameter (e.g., 0.050″ to 0.075″) is common. For finishing, a smaller stepover (e.g., 10-25% of the tool diameter, 0.012″ to 0.030″) will yield a smoother surface.

Important Note: Always start conservatively! If you hear chatter, see excessive heat, or if the chips are not clearing well, reduce your feed rate or increase spindle speed slightly, and ensure your coolant is adequate.

You can find excellent resources for recommended speeds and feeds. For example, companies like Sandvik Coromant provide extensive data, though sometimes their recommendations are for industrial machines and larger tools. Look also for guides from manufacturers of your specific milling machine or end mills.

Step 6: Initiate the Cut

Once your parameters are set and you’ve performed safety checks, start the spindle. Then, activate the feed. For manual machines, this means carefully advancing the X, Y, or Z axis handwheel. For CNC, it’s starting the program. Approach the material slowly and smoothly. Listen to the cut. A good cut will sound like a consistent, light “hiss