For machining tough Inconel 718, a specialized 1/8-inch carbide end mill with a 1/2-inch shank and long reach is key. By using the right tools and techniques, you can drastically minimize deflection, leading to cleaner cuts and extended tool life.

Working with Inconel 718 can feel like trying to machine a superalloy with ordinary tools. It’s tough, it springs back, and it loves to make your end mill dance around – a phenomenon we call deflection. When your tool deflects too much, you get poor surface finish, inaccurate dimensions, and a very unhappy machinist. But what if I told you there’s a simple, genius way to get much better Inconel deflection control, especially when using a small but mighty 1/8-inch carbide end mill with a 1/2-inch shank and a long reach? Stick around, because we’re about to unlock that secret.

You want those clean, precise cuts that Inconel 718 demands. You’ve probably seen your end mill bowing under pressure, leaving fuzzy edges and making you question your sanity. It’s a common frustration for anyone tackling this challenging material. But fear not! With the right approach to selecting and using your carbide end mill, particularly a long-reach 1/8-inch variant, you can achieve remarkable control. We’ll go through exactly what makes these tools so special and how to wield them effectively. Let’s dive into how we can tame Inconel and get those perfect cuts, every time.

Why Inconel 718 is a Machining Challenge

Inconel 718 is a nickel-based superalloy renowned for its exceptional strength, heat resistance, and corrosion properties. These are fantastic qualities for aerospace, automotive, and oil & gas applications, but they make it a real bear to machine. Unlike softer metals, Inconel 718 has a high work-hardening rate. This means the more you cut it, the harder the material becomes right in front of your tool. It also has low thermal conductivity, so heat generated during machining builds up rather than dissipating quickly.

This combination of properties leads to several machining headaches:

- High cutting forces: It simply takes more force to push a tool through Inconel than through steel or aluminum.

- Rapid tool wear: The abrasive nature and high temperatures can quickly dull even good cutting bits.

- Work hardening: As mentioned, the material gets harder as you machine it, making subsequent cuts even more difficult.

- Chip welding: Hot chips can weld themselves to the cutting edge, leading to poor surface finish and tool breakage.

- Deflection: This is where it really gets tricky. The material’s resistance, combined with the cutting forces, can easily make a smaller diameter tool flex or bend away from the desired cutting path.

The Hero of Our Story: The 1/8-Inch Carbide End Mill, Long Reach, 1/2-Inch Shank

When you hear “1/8-inch end mill,” you might think of delicate engraving or tiny detail work. But when it comes to Inconel 718, this specific configuration becomes a specialist tool for tackling tricky situations, especially when deflection is a major concern and you need to get into tight spots or make fine features. Let’s break down why this combination is so effective for controlling Inconel deflection:

Carbide: The Tough Material

Carbide, or more formally tungsten carbide, is an incredibly hard and rigid material. It far surpasses high-speed steel (HSS) in hardness and stiffness. This rigidity is crucial for Inconel because:

- Resists deformation: A solid carbide end mill is much less likely to bend or flex under cutting forces compared to HSS.

- Maintains sharpness: Carbide can be manufactured to extremely tight tolerances and can hold a sharp cutting edge for longer, even at high temperatures.

- Handles heat better: While it doesn’t conduct heat as well as steel, its ability to withstand very high temperatures without softening is paramount.

1/8-Inch Diameter: Precision and Access

This small diameter might seem counterintuitive for a material as demanding as Inconel. However, it’s precisely this size that opens up possibilities:

- Smaller cutting forces per tooth: While total cutting force might be high, the force applied by each small tooth is manageable.

- Access to tight areas: It allows you to machine intricate shapes, small slots, or pockets that larger end mills simply can’t reach.

- Reduced material removal per pass: Smaller tools naturally lend themselves to lighter, more controlled cuts, which is vital for managing Inconel’s work-hardening.

1/2-Inch Shank: Shank Rigidity Boost

The 1/2-inch shank is a significant advantage over a 1/4-inch or 1/8-inch shank for a tool of this diameter. Why? Shank diameter directly impacts the overall rigidity of the tool holder assembly. A larger shank:

- Increases stiffness: A thicker shank provides more resistance to bending.

- Better clamping: It securely grips in collets and tool holders, reducing the chance of runout or slippage.

- Reduced vibration: A more rigid shank helps to dampen vibrations, leading to a smoother cut.

Long Reach: The Enabling Feature

The “long reach” aspect of these end mills is where they truly shine for specific Inconel applications. It means the cutting flutes extend further up the tool body, allowing you to:

- Machine deeper features: Get into pockets or slots that are deeper than the tool holder’s reach.

- Clear fixturing or clamps: Avoid collisions with workholding devices by using a longer tool to reach the workpiece.

- Reduce setups: Sometimes, a long-reach end mill can perform operations that would otherwise require multiple setups with shorter tools.

However, with increased reach comes increased potential for deflection. This is where the genius design of these specific end mills, combined with careful machining practices, comes into play to control that deflection.

Genius Inconel Deflection Control: It’s All About the Design and Application

So, how does a small, long-reach end mill specifically help control deflection in Inconel 718? It’s a combination of specialized flute geometry, coating, and how we choose to use it. These aren’t your average end mills.

Specialized Flute Geometry for Tough Materials

End mills designed for Inconel and other superalloys often feature geometries optimized for rigidity and chip evacuation, even at a small diameter:

- High Helix Angle: A steeper helix angle (often 30-45 degrees or more) helps to:

- Smooth out the cutting action, reducing chatter and vibration.

- Provide better chip thinning and evacuation from the cutting zone, preventing chip recutting.

- Improve surface finish by slicing through the material rather than pushing it.

- Corner Radii: Many Inconel end mills feature a small corner radius rather than a sharp corner. This radius helps to:

- Strengthen the cutting edge against chipping.

- Reduce the tendency for the tool to “dig in,” which can exacerbate deflection.

- Provide a smoother transition into and out of the cut, reducing shock loads.

- Number of Flutes: For Inconel, 3-flute or 4-flute end mills are common.

- 3-flute: Offers a good balance between chip space for evacuation and rigidity. It’s often preferred for finishing and slotting.

- 4-flute: Provides higher rigidity and can handle heavier cuts if chip evacuation can be managed.

- For a 1/8-inch end mill, 3 flutes are very common and a good default for Inconel.

- Center Cutting: Ensure your end mill is center-cutting. This is essential for plunging operations and for pocketing where the tool needs to be able to cut downwards into the material.

Advanced Coatings: Battling Heat and Wear

A bare carbide end mill is good, but a coated one designed for Inconel is much better. Coatings add a sacrificial layer that:

- Reduces friction: Lower friction means less heat generated at the tool tip.

- Increases hardness: Provides an even harder surface for cutting.

- Improves chip flow: Some coatings help prevent chip welding.

- Common coatings for Inconel machining:

- TiAlN (Titanium Aluminum Nitride): A popular choice for high-temperature alloys. It forms a hard, heat-resistant aluminum oxide layer when run at high temperatures, providing excellent performance in dry machining or with minimal coolant.

- AlTiSiN (Aluminum Titanium Silicon Nitride): An even more advanced coating offering superior heat resistance and wear resistance compared to TiAlN, especially in very demanding applications.

For Inconel, an AlTiSiN coating is often a superior choice if available for your 1/8-inch long-reach tool.

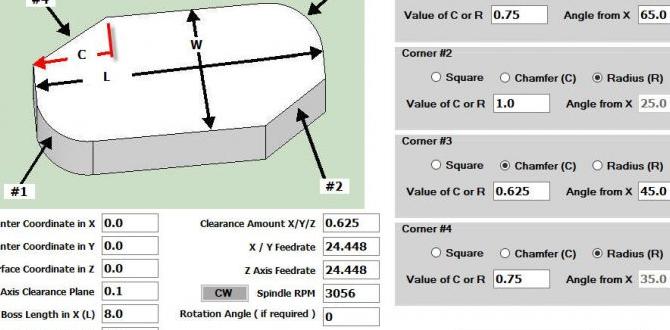

The “Genius” Application: How to Use It for Deflection Control

Even the best tool can be misused. The real genius comes from how you apply these specialized end mills:

- Conservative Depth of Cut (DOC): This is paramount. Because the tool is small and long, you cannot plunge into Inconel with deep cuts.

- Radial DOC: For slotting or profiling, keep the radial engagement (how much of the tool’s diameter is engaging the material sideways) relatively small, especially if full slotting. Consider using techniques like trochoidal milling (more on this later) to manage radial and axial forces.

- Axial DOC: This is the depth of the cut along the tool’s length. For Inconel with a long tool, this needs to be shallow. Start with very small values – perhaps 0.010″ to 0.020″ (0.25mm to 0.5mm) at a time, or even less, depending on your machine’s rigidity and the holder.

- Appropriate Feed Rate: While you need a good chip load to evacuate heat and prevent work hardening, it cannot be so high that it overloads the small tool. Workload calculators, like those from the Machinery’s Handbook (a foundational text for machinists), can help, but always start conservatively and listen to your machine.

- Optimized Spindle Speed (RPM): This works in conjunction with feed rate to achieve the correct chip load. For Inconel, higher speeds are often beneficial to help get the heat into the chips rather than the workpiece or tool, but the small diameter of your end mill will limit the absolute RPM you can run.

- Trochoidal Milling (High-Speed Machining – HSM): This is where the magic really happens for slotting and pocketing with long, slender tools. Instead of making a full-width slotting cut, trochoidal milling uses a series of overlapping circular or helical paths. This means:

- Constant Radial Engagement: The tool always engages only a small portion of its diameter radially (e.g., 10-30%).

- Reduced Cutting Forces: This significantly lowers the forces the tool experiences at any given moment.

- Improved Chip Evacuation: The path naturally clears chips better than a conventional slotting cut.

- Reduced Heat Buildup: With lighter, continuous cuts, heat is managed more effectively.

This technique is ideal for small diameter, long-reach end mills in Inconel, as it directly combats deflection by reducing the stress on the tool. Many modern CAM software packages have dedicated trochoidal milling strategies.

- Rigid Workholding: A flexible workpiece is just as bad as a flexible tool. Ensure your Inconel part is securely held to prevent any movement that could exacerbate deflection. Use appropriate vices, clamps, or fixtures.

- High-Quality Tool Holders: A runout-prone or worn tool holder will ruin the precision of even the best end mill. Use a high-quality collet chuck or shrink-fit holder for your 1/2-inch shank end mill to ensure minimal runout. This is critical for a 1/8-inch tool!

- Coolant/Lubrication: While some advanced coatings excel in dry machining, Inconel typically benefits greatly from a good coolant or lubricant. This helps flush chips, cool the cutting zone, and reduce friction. High-pressure coolant can be especially effective for flushing chips from deep pockets accessed by your long-reach end mill.

Selecting the Right 1/8-Inch Carbide End Mill for Inconel

When shopping for these specialized tools, here’s what to look for:

- Material: Solid Carbide (preferably sub-micron grain for best edge strength).

- Coating: AlTiSiN or a high-performance TiAlN variant.

- Geometry:

- High helix angle (30°+).

- Corner radius (e.g., 0.010″ or 0.020″ for a 1/8″ tool).

- 3 or 4 flutes (3 is often a safe bet for Inconel).

- Center cutting.

- Reach: Ensure it offers enough reach for your specific application, but be mindful that longer reach equals more potential deflection. Balance is key.

- Shank: 1/2-inch (often stated as 12.7mm).

- Manufacturer Reputation: Buy from reputable manufacturers known for their high-performance cutting tools. Brands like Sandvik Coromant, Iscar, Kennametal, and Walter are excellent places to start.

Example Tool Specifications

A typical Inconel-optimized 1/8-inch carbide end mill might look like this:

| Feature | Specification for Inconel Machining |

|---|---|

| Diameter | 1/8 inch (0.125″) |

| Shank Diameter | 1/2 inch (0.500″) |

| Material | Solid Carbide (Sub-micron grain) |

| Coating | AlTiSiN or High-Performance TiAlN |

| Number of Flutes | 3 or 4 |

| Helix Angle | 30° – 45° |

| Corner Radius | 0.010″ – 0.020″ |

| Reach (Effective Cutting Length) | Varies; e.g., 1 inch, 1.5 inches, 2 inches. Choose based on necessity. |

| Type | Center Cutting |

Machining Strategies and Parameters for Inconel 718

Here’s a very general starting point for parameters. Remember that your specific machine, setup rigidity, coolant, and the exact geometry of your tool will influence the optimal settings. Always start conservatively!

General Machining Parameters (Starting Point)

These are rough guidelines for a 3-flute, 1/8-inch carbide end mill with a long reach, optimized for Inconel 718. Always consult tool manufacturer recommendations first!

| Operation | Spindle Speed (RPM) | Feed Rate (IPM) | Axial Depth of Cut (DOC) | Radial Depth of Cut (DOC) | Notes |

|---|---|---|---|---|---|

|

Slotting (Trochoidal / HSM) |

10,000 – 20,000+ |

5 – 15 |

0.010″ – 0.025″ |

0.040″ – 0.100″ (approx. 30-80% of tool diameter) |

Use HSM/Trochoidal CAM strategy. Maintain light radial engagement. Ensure excellent chip evacuation. |

|

Profile / Contouring (Light Passes) |

12,000 – 24,000+</ |