A2 carbon steel demands precision, and a carbide end mill with the right specifications is key for achieving those essential tight tolerances in your machining projects.

Working with metal, especially tougher materials like A2 tool steel, can sometimes feel like a puzzle. You’ve got your project in mind, your machine is humming, but getting those perfectly precise cuts can be a real challenge. This is especially true when you need parts to fit together with very little room for error – what we call “tight tolerances.” The right tool makes all the difference, and today, we’re going to talk about a specific hero: the carbide end mill. Specifically, we’ll dive into how selecting the right carbide end mill, particularly in common sizes like 1/8 inch or 1/4 inch shank stub length, is absolutely vital for nailing those tight tolerances when machining A2 steel. Stick around, and we’ll break down why this tool is so important and how to choose the best one for your needs.

Understanding Tight Tolerances in Machining

Before we get into the nitty-gritty of end mills, let’s take a moment to understand what “tight tolerances” really means in the world of machining. Imagine you’re building something where parts need to slide together, connect securely, or function with extreme accuracy. Think of precision engine components, intricate molds for injection molding, or even custom robotics parts. In these cases, the difference between a perfect fit and a useless part can be as little as a few thousandths of an inch, or even less!

These tiny allowances are what we call tolerances. When we talk about “tight tolerances,” we mean very small acceptable variations from a specified dimension. Achieving these demands a high degree of accuracy and repeatability from our machining process. It’s not just about making a hole or a slot; it’s about making it exactly the size and shape required, every single time. This is where the choice of your cutting tool becomes incredibly important.

Why Carbide End Mills for A2 Tool Steel?

A2 tool steel is a popular choice for tooling because it’s hard, durable, and holds an edge well. However, these qualities also make it notoriously tough to machine. It’s significantly harder than common metals like aluminum or mild steel. Trying to cut A2 with inadequate tooling can lead to a host of problems, including:

Tool Chatter: The tool vibrates, leading to a poor surface finish and inaccurate dimensions.

Reduced Tool Life: Softer tool materials will wear out incredibly quickly.

Overheating: Friction generates heat, which can warp your workpiece or damage the tool.

Inaccurate Cuts: The tool might deflect, resulting in dimensions that are off spec.

This is where carbide comes into play. Carbide, specifically tungsten carbide, is a super-hard, wear-resistant material. It’s vastly superior to high-speed steel (HSS) for machining hard materials like A2. Here’s why carbide is your best friend for this job:

Extreme Hardness: Carbide’s hardness allows it to cut through tough materials like A2 without deforming or wearing down prematurely.

High Heat Resistance: Carbide can withstand higher temperatures generated during cutting, which is crucial for efficient machining of hard steels. This means less heat transfer to your workpiece, preserving its integrity.

Rigidity: Carbide tools are generally more rigid than HSS. This reduced flex contributes to more stable cutting, less chatter, and ultimately, more precise results and tighter tolerances.

Better Surface Finish: When used correctly, carbide end mills often produce a superior surface finish compared to HSS, which is vital for precision parts.

The “A2” in Carbide End Mill A2: What Does it Mean?

When you see “Carbide End Mill A2,” it’s a bit of a shorthand. “Carbide End Mill” tells you the material of the tool itself. The “A2” is referring to the material you are machining, the A2 tool steel. So, “Carbide End Mill A2” essentially means a carbide end mill suitable for machining A2 tool steel, designed to handle its hardness and demanding cutting conditions. It highlights the intended application and the critical pairing of tool material to workpiece.

Key Features of Carbide End Mills for Tight Tolerances

When you’re chasing those tight tolerances, especially in A2 steel, not just any carbide end mill will do. You need to look for specific features:

1. Material Quality & Grade

Grade: Carbide itself comes in different grades, which are determined by the size of the tungsten carbide grains and the cobalt binder content. Finer grain sizes generally offer better wear resistance and a smoother finish, which is excellent for tight tolerances. Look for grades like those designed for general machining or specifically for hardened steels.

Coating: For A2 steel, a coating can significantly improve performance.

TiN (Titanium Nitride): A common, general-purpose coating. It adds a layer of hardness and reduces friction, but it’s not the supreme choice for very high-temperature applications.

TiCN (Titanium Carbonitride): Offers better wear resistance than TiN, especially in abrasive materials.

AlTiN (Aluminum Titanium Nitride): This is often your go-to for cutting hardened steels like A2. It forms a protective aluminum oxide layer at high temperatures, greatly improving heat resistance and preventing premature tool failure. This is crucial for maintaining consistent cutting and tight tolerances.

DLC (Diamond-Like Carbon): Offers extremely low friction and high hardness, excellent for non-ferrous materials but also beneficial for certain difficult-to-machine alloys due to its lubricity.

2. Geometry and Design

The shape and design of the end mill’s cutting edges and flutes play a massive role in performance and precision.

Number of Flutes:

2 Flutes: These are excellent for slotting and pocketing. The larger chip gullets (the space between the flutes) allow for better chip evacuation, which is critical when machining tough materials like A2. Less chip recutting means less heat buildup and a cleaner cut.

3 or 4 Flutes: These offer more cutting edges, leading to a smoother finish and better rigidity. They are generally preferred for profiling and general milling where chip evacuation is less of a bottleneck. For A2 and tight tolerances, 4-flute designs often provide the best balance of rigidity and finish.

End Type:

Square End: The most common type. Creates a square corner.

Ball End: Creates a radiused corner, useful for contouring and creating fillets.

Corner Radius: A small radius (chamfer or radiused corner) on a square end mill can add strength to the cutting edge, preventing chipping, and can help guide the tool into the cut more smoothly for improved accuracy.

Helix Angle:

Standard (30° helix): A good all-rounder.

High Helix (45° or 60° helix): These provide a shearing action, which results in a smoother cut, reduced cutting forces, and better chip evacuation. This is highly beneficial for cutting hardened steels and achieving precise surface finishes. A higher helix angle effectively “lifts” chips away.

Center Cutting vs. Non-Center Cutting:

Center Cutting: Has cutting edges on the end face, allowing it to plunge vertically into the material. Essential for milling slots or pockets from solid material.

Non-Center Cutting: Lacks cutting edges on the end face and cannot plunge into the material. Used for surface milling or contouring. For most A2 milling tasks requiring tight tolerances, you’ll likely need a center-cutting end mill.

3. Length and Diameter (Stub Length Importance)

For A2 steel and tight tolerances, the length of the end mill relative to its diameter (its “stick-out”) is crucial for rigidity.

Stub Length: This is where the keyword “stub length” becomes very important. A stub length end mill has a shorter flute length and often a slightly larger diameter shank compared to a standard end mill of the same overall length.

Benefit: This significantly increases rigidity. Less tool overhang means less tendency for the tool to flex or vibrate under cutting forces. For maintaining tight tolerances and achieving precise dimensions, minimizing tool deflection is paramount. A stub length end mill is your best bet for this.

Common Sizes: When working with tight tolerances, smaller diameters are often necessary. Common sizes you’ll be looking for will include:

1/8 inch shank: These are very fine tools, often used for intricate engraving, detailed features, or very small parts where precision is everything.

1/4 inch shank: A very versatile size. You can find stub length 1/4 inch shank end mills that offer a great balance of cutting ability and rigidity.

Choosing the Right Carbide End Mill: Specifications to Look For

Let’s get specific. If you’re searching for a carbide end mill for machining A2 steel to tight tolerances, here are the key specifications that will appear on product listings and what they mean for you:

Material: Tungsten Carbide (often specified as solid carbide)

Coating: AlTiN or similar high-performance coating for hardened steels.

Diameter: The cutting diameter of the end mill (e.g., 1/8″, 1/4″).

Shank Diameter: The diameter of the shank that fits into your collet or holder. Often, for stub length, the shank diameter might be the same or slightly larger than the cutting diameter for added rigidity.

Flute Count: 2, 3, or 4 flutes. For A2 and precision, 4 flutes are often ideal for profiling, while 2 flutes are great for dedicated slotting.

Length of Cut: The length of the cutting flutes. A shorter length of cut relative to the diameter indicates a stub length.

Overall Length: The total length of the tool.

Helix Angle: 30°, 45°, or 60°. High helix (45° or 60°) is preferred for better finish and chip evacuation.

End Type: Square, ball, or corner radius. Square with a small corner radius is often a good choice for general work.

Center Cutting: Yes (usually required for milling from the solid).

Example Specification:

“1/4″ Carbide End Mill, AlTiN Coated, 4 Flutes, 1/4″ Shank, 1/2″ Length of Cut, 2″ Overall Length, Square End with 0.010″ Corner Radius, Center Cutting, High Helix (45°)”

This example describes a robust tool perfect for demanding applications like A2 steel. Notice the shorter “Length of Cut” (1/2″) compared to the shank diameter (1/4″), indicating a stubby, rigid design.

Carbide End Mills for A2 Steel: A Comparison Table

To help you visualize the differences and choose wisely, let’s look at some typical end mill characteristics relevant to machining A2 for tight tolerances.

| Feature | Ideal for Tight Tolerances (A2 Steel) | Good for General Machining | Less Suitable for Tight Tolerances (A2 Steel) |

| :——————- | :—————————————————————— | :————————————————————- | :—————————————————————- |

| Tool Material | Solid Carbide | Solid Carbide | High-Speed Steel (HSS) |

| Coating | AlTiN, TiCN, or other advanced coatings for heat and wear resistance | TiN (Titanium Nitride) | Uncoated |

| Flute Count | 4 Flutes (for profiling), 2 Flutes (for slotting) | 4 Flutes | High flute counts (e.g., 6+) can pack chips |

| Helix Angle | High Helix (45° or 60°) | Standard Helix (30°) | Low Helix (<30°) |

| Length | Stub Length (short flute L/D ratio) | Standard Length | Extended or Long Reach |

| Rigidity | High | Medium | Low |

| Chip Evacuation | Excellent | Good | Can be problematic |

| Surface Finish | Excellent | Good | Fair to Good |

| Tool Life | Excellent | Good | Lower |

Understanding Shank and Diameter Combinations

The “carbide end mill 1/8 inch 1/4 shank stub length” phrase is very specific and highlights common choices for precision work:

1/8 inch (cutting diameter): This refers to the diameter of the cutting portion of the end mill. A 1/8 inch diameter is quite small, allowing for fine details and intricate features. It also means achieving extremely tight tolerances becomes more visually apparent on the resulting part.

1/4 inch shank: This refers to the diameter of the tool’s shank, which is what you’ll insert into your collet or tool holder. A 1/4 inch shank is a common, robust size for many desktop and small-to-medium sized milling machines.

Stub Length: This is the crucial part for rigidity. A stub length end mill, even with a 1/8 inch cutting diameter, will often have a shank diameter that is proportionally larger or the flute length is kept very short. This minimizes the tool’s tendency to bend under pressure. For instance, a 1/8″ cutting diameter end mill with a 1/4″ shank and a very short flute length (e.g., 3/8″ or 1/2″ length of cut) is the epitome of a rigid tool for fine, precise work on A2 steel.

Why This Combination is Powerful for A2 Steel

When you combine these attributes:

1. Carbide: Handles the hardness of A2.

2. AlTiN Coating: Protects the tool from heat and wear, maintaining its sharp edge.

3. Stub Length: Maximizes rigidity, preventing deflection.

4. Smaller Diameter (e.g., 1/8″): Allows for intricate details and fits into smaller areas.

5. Favorable Geometry (High Helix, 4 Flutes): Provides shear, smooth cuts, and effective chip evacuation.

…you get a tool perfectly suited for achieving those hard-won tight tolerances in A2 steel. The smaller chip load associated with smaller diameters is easier for a higher number of flutes to manage, while the stub length fights any resultant flex and chatter.

Machining Best Practices for A2 Steel and Tight Tolerances

Even with the perfect tool, how you use it is just as important. Here are some tips for machining A2 steel to achieve those precise dimensions:

1. Machine Setup and Rigidity

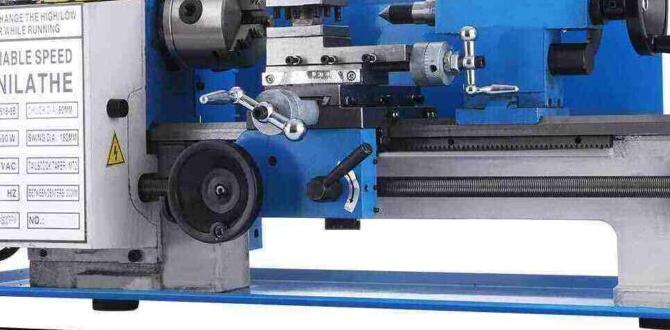

Rigid Machine: Ensure your milling machine is rigid. Check for any play in the ways, ball screws, or spindle. A wobbling machine will never produce precise parts.

Secure Workholding: Use a robust vise, clamps, or fixture. The workpiece must be absolutely rock-solid. Avoid long workholding set-ups that can flex.

Shortest Possible Tool Projection: Mount the end mill as close to the collet nut as possible. Always aim for the shortest possible “stick-out” or tool overhang. This is where stub length tools shine.

Clean Spindle and Collet: Ensure your spindle taper and collet are perfectly clean. Any debris can cause runout, ruining your precision.

2. Cutting Parameters: Speed, Feed, and Depth of Cut

This is where experience meets calculation. A good starting point is crucial, and then you’ll fine-tune based on what the machine and the cut are telling you. For A2 steel with carbide, you’ll generally be working at relatively lower speeds and feeds compared to softer materials.

Surface Speed (SFM or V_c): For A2 steel with carbide, surface speeds can range from 150-300 SFM (approx. 45-90 m/min), but this depends heavily on the coating, machine rigidity, and coolant. Always consult your tool manufacturer’s recommendations as a starting point.

Feed Per Tooth (F_z): This is critical for chip formation. For a 1/8″ or 1/4″ carbide end mill in A2, you might start with a feed per tooth of 0.0005″ to 0.002″ (0.013mm to 0.05mm). Stub length and rigidity allow you to push this a bit more.

Depth of Cut (a_p): For roughing, you can take a reasonable depth, but for finishing passes to achieve tight tolerances, you’ll want very shallow depths.

Stepover (a_e): How much the tool moves sideways in each pass. For finishing, a small stepover (e.g., 10-25% of the tool diameter) will give a better surface finish. For high-efficiency roughing (like trochoidal milling), you might use a larger stepover with a specialized tool rather than a general-purpose end mill.

A Note on Calculators: Many tool manufacturers offer online machining calculators. These are invaluable for getting starting parameters. For example, ISCAR’s machining calculator can provide excellent recommendations. Always look for calculators that specify hardened steel (like A2).

3. Coolant and Chip Evacuation

Flood Coolant or Mist: A2 steel generates significant heat. Using a good quality cutting fluid (flood or mist coolant) is essential. It lubricates the cut, cools the tool and workpiece, and helps wash away chips.